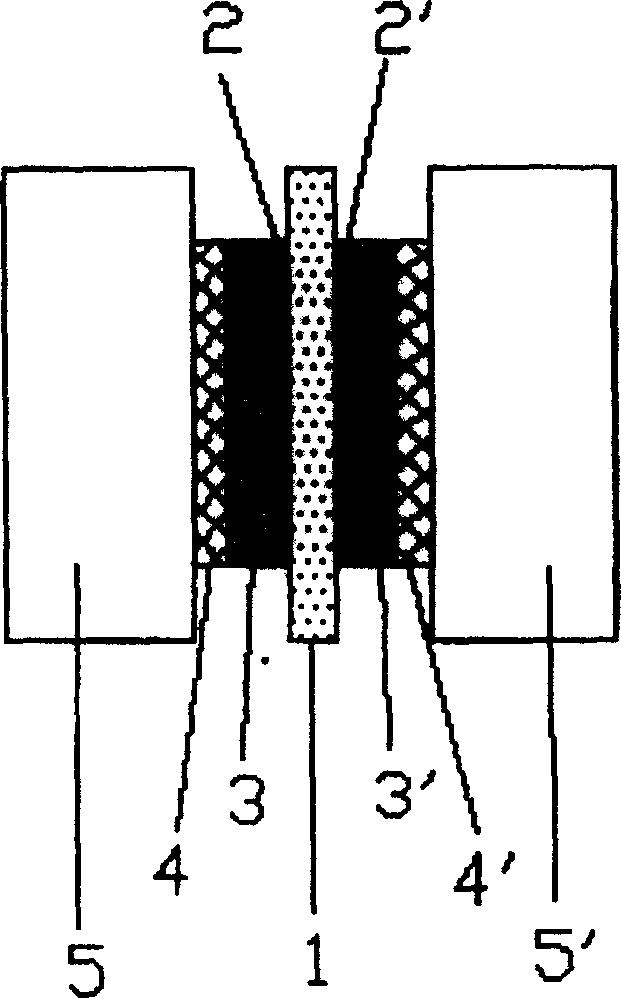

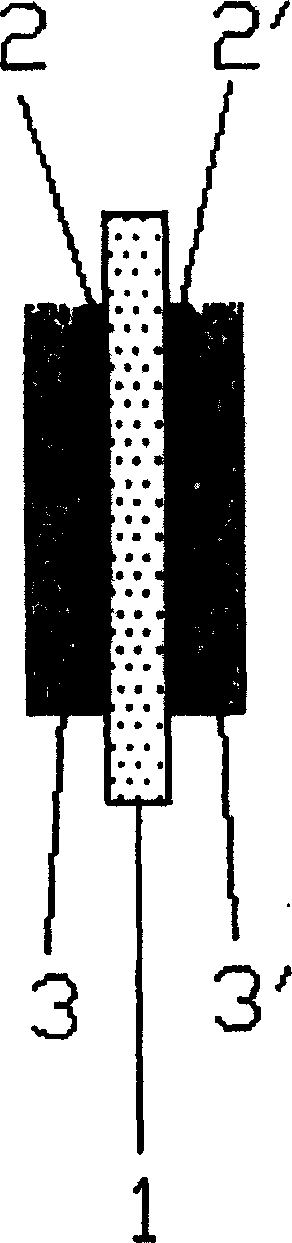

Direct alcohol fuel cell diaphragm electrode structure and preparing process

A fuel cell and membrane electrode technology, applied in battery electrodes, structural parts, circuits, etc., can solve the problems of low mechanical strength of carbon fiber, increase of contact resistance, and influence on current collection effect, etc., to achieve integration, reduce resistance, The effect of simplifying the preparation procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The sintered stainless steel fiber mat is used as the diffusion layer and the current collector. The porosity is 90%, the pore diameter is 400 mesh, and the thickness is 145 μm. The preparation process is as follows:

[0051] Anode diffusion layer: Prepare a slurry containing 80% XC-72R and 20% Nafion polymer, smear it on the stainless steel fiber felt after ultrasonic vibration, and dry it to obtain a slurry containing 6mg / cm 2 Diffusion layer of XC-72R and Nafion mixture, and then flatten the diffusion layer with a certain pressure, the pressure is determined according to the size of the area, so as to ensure that the diffusion layer has no cracks.

[0052] Cathode diffusion layer: Prepare a slurry containing 80% XC-72R and 20% PTFE, smear it on the stainless steel fiber felt after ultrasonic vibration, and obtain a solution containing 6mg / cm 2 Diffusion layer of XC-72R and PTFE mixture, and then flatten the diffusion layer with a certain pressure, the pressure is det...

Embodiment 2

[0061] The sintered stainless steel fiber mat was used as the diffusion layer and current collector, with a porosity of 85%, a pore diameter of 300 mesh, and a thickness of 160 μm. Other preparation processes were the same as in Example 1.

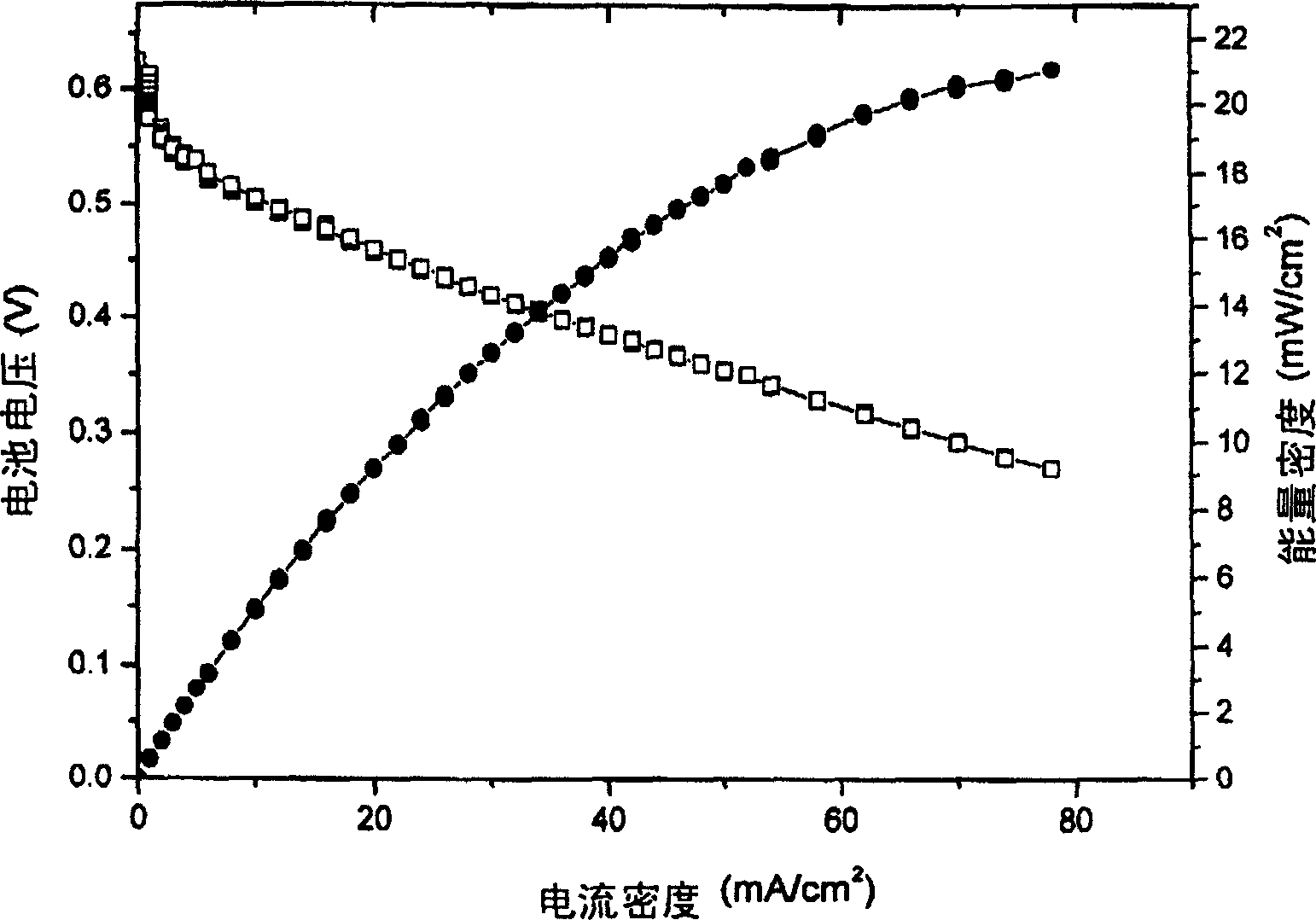

[0062] Figure 4 In the specific embodiment 2 of the present invention, the membrane electrode made of stainless steel braided mesh is under the condition of air self-breathing at room temperature, and the electrode area is 2 × 2 cm 2 single-cell discharge curve.

[0063] Put the membrane electrode obtained above into a battery testing device for testing, and its discharge curve is shown in image 3 and Figure 4 .

[0064] The working conditions of the battery are as follows:

[0065] Under normal temperature and pressure, the cathode is directly exposed to the air, and the anode is injected with 6.5ml of 1M methanol without any auxiliary equipment.

[0066] From image 3 It can be seen that the current density at 78mA / cm 2 , the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com