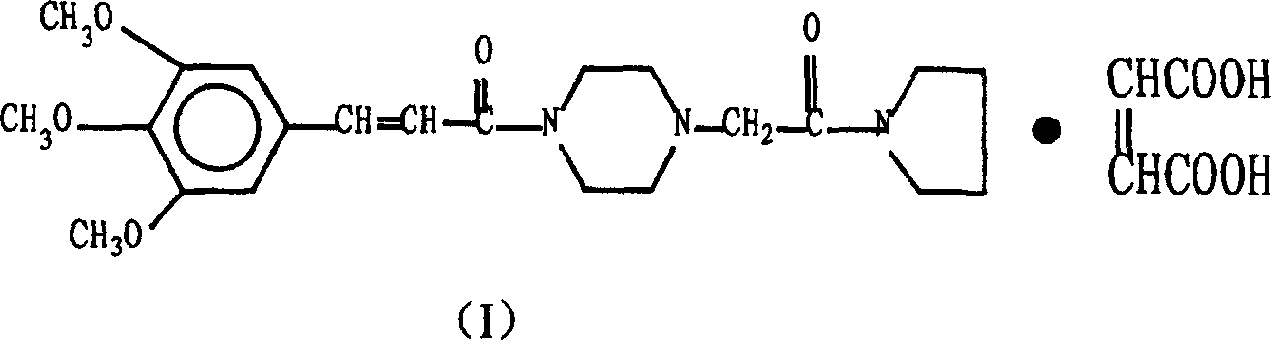

Synthesis method of cinepazide maleate

A technology of cinepazide maleate and a synthesis method, which is applied in a synthesis field of cinepazide maleate, can solve the problems of high production cost, low boiling point of diethyl ether, high requirements on production conditions and equipment, and achieves the Simplified production conditions and processes, high product yield and good safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

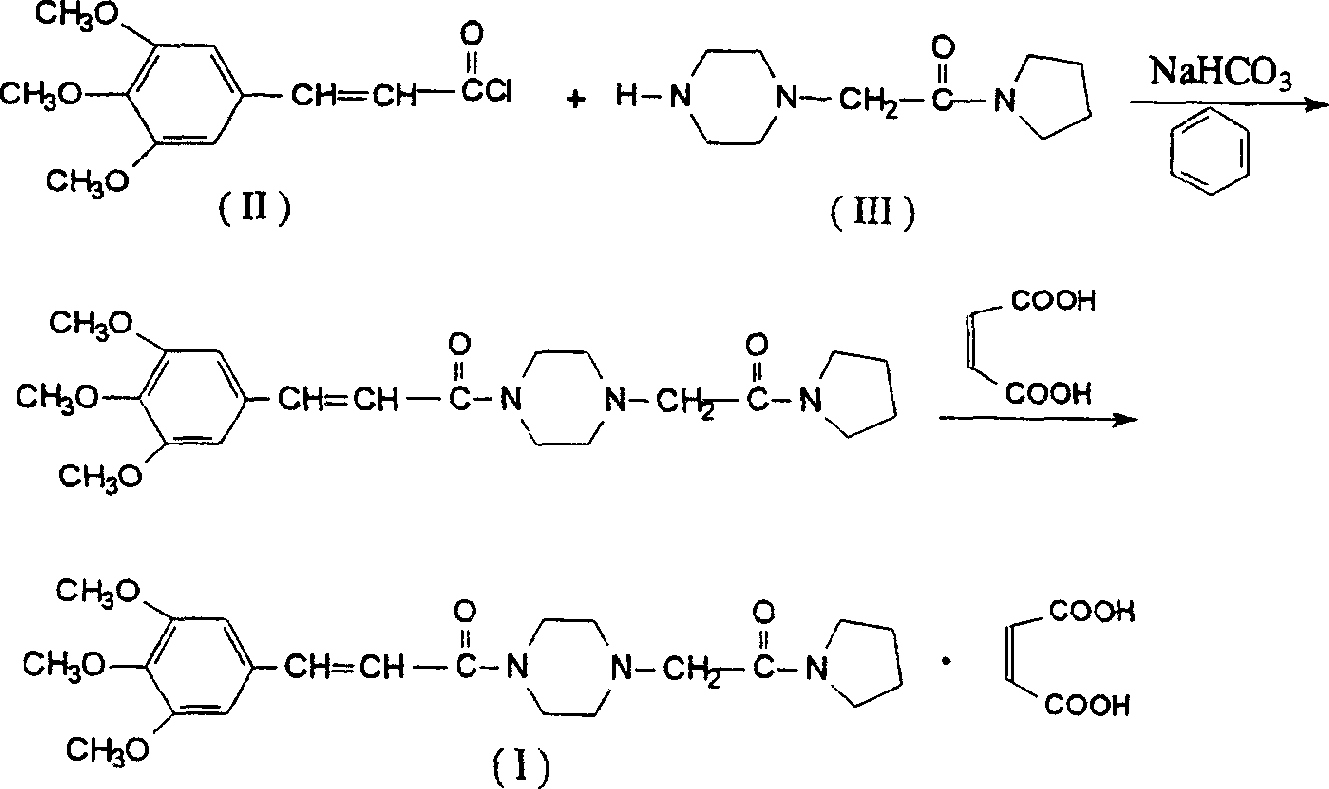

[0056] The synthesis of embodiment 1 cinepazide maleate:

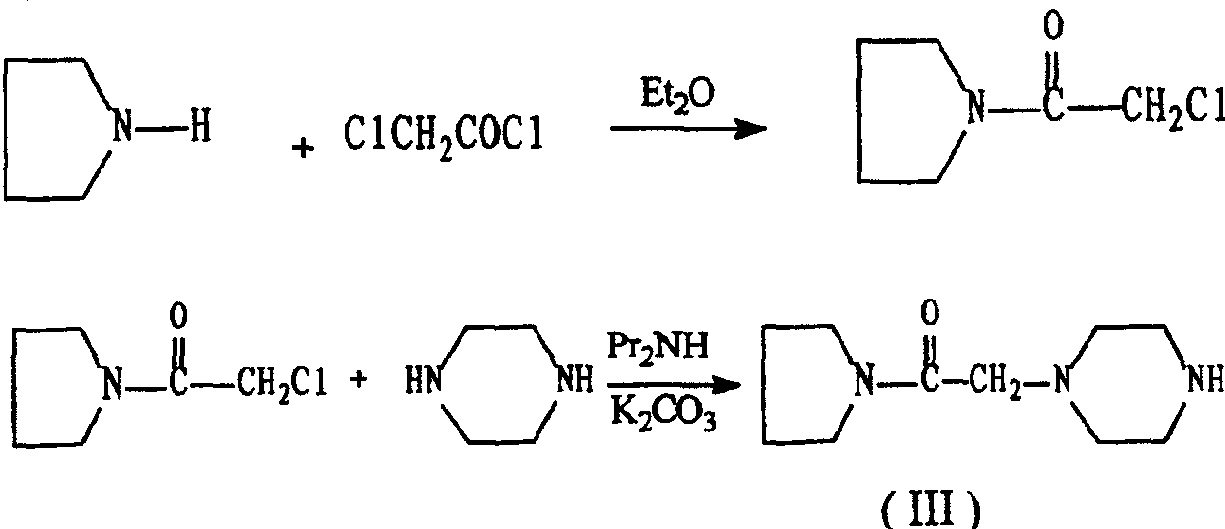

[0057] 1) synthesis of chloroacetylpyrrolidine

[0058] Reaction formula:

[0059]

[0060] operate:

[0061] Slowly add 300 g of tetrahydropyrrole into a solution of 230 g of chloroacetyl chloride in 1,400 g of dichloromethane under stirring at 10°C. After the addition, continue to stir at room temperature for 2 hours, heat and recover the dichloromethane, and wash the residue with 300 g of ethyl acetate. Dissolve the ester, add 1400g of petroleum ether at 60-80°C, and cool. Tetrahydropyrrole hydrochloride crystallized out, recovered by filtration, and reused after alkalization. The filtrate was washed with 400ml of saturated brine, dried over anhydrous magnesium sulfate, filtered and concentrated to obtain a colorless liquid, which solidified at room temperature to obtain 492g of chloroacetylpyrrolidine, mp. 40-46°C, yield 80%.

[0062] 2) 1-piperazine acetylpyrrolidine:

[0063] Reaction formula:

[0064] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com