Polyetheylene moulding plastic suitable as a pipe material with excellent processing properties

A molding compound, ethylene technology, used in rigid pipes, tubes, thin material processing, etc., can solve problems such as low melt strength, uneven pipe wall thickness, and continuous instability in extrusion processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

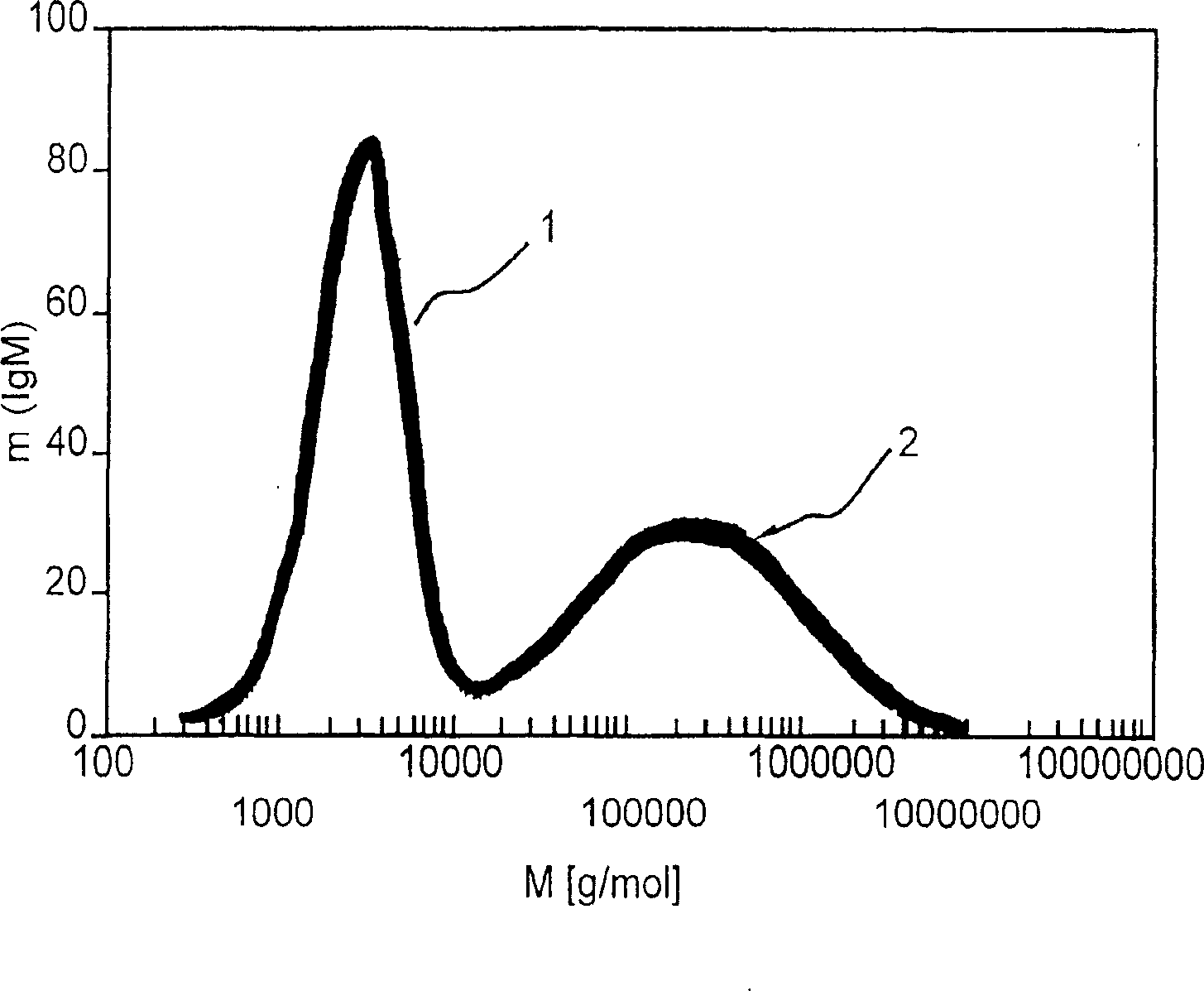

Image

Examples

Embodiment 1-9

[0034] The first bimodal ethylene polymer (A) is prepared according to the specifications of WO91 / 18934, adopting the Ziegler catalyst whose composition is a made in the operation step 2.2 in Example 2, the preparation operating conditions of the polymer (A) are listed in Table 1 below.

[0035] Reactor I

[0036] The melt flow index MFI of the prepared ethylene polymer (A) 5 / 190℃ A 0.49 dg / min, density d A It was 0.948 g / cc and the comonomer content was 1.5% by weight (based on the total weight of higher molecular weight components).

[0037] Then prepare the second bimodal ethylene polymer (B) according to the instructions of EP-B-0003129. For this purpose, under constant temperature conditions of 85 ° C, in the presence of the Ziegler catalyst described in EP-B Example 1, with stirring, at 6 6.7 kg of ethylene / h and 0.24 kg of 1-butene / h were introduced into the diesel with a boiling range of 130-170° C. placed in the reaction tank within 1 hour. After the r...

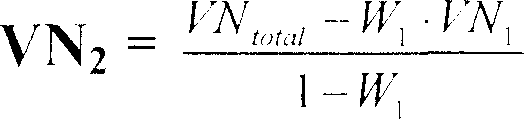

Embodiment 10-12

[0047] In order to determine the homogeneity of the mixture (no spots), the following three molding compounds were prepared:

Embodiment 1

[0048] Example 10 is the molding compound of Example 1, ie pure polymer (A).

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com