Shuttle fiber laser

A fiber laser and shuttle technology, used in lasers, phonon exciters, laser parts, etc., can solve the problem of no flexible fiber replacement, and achieve the effect of improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

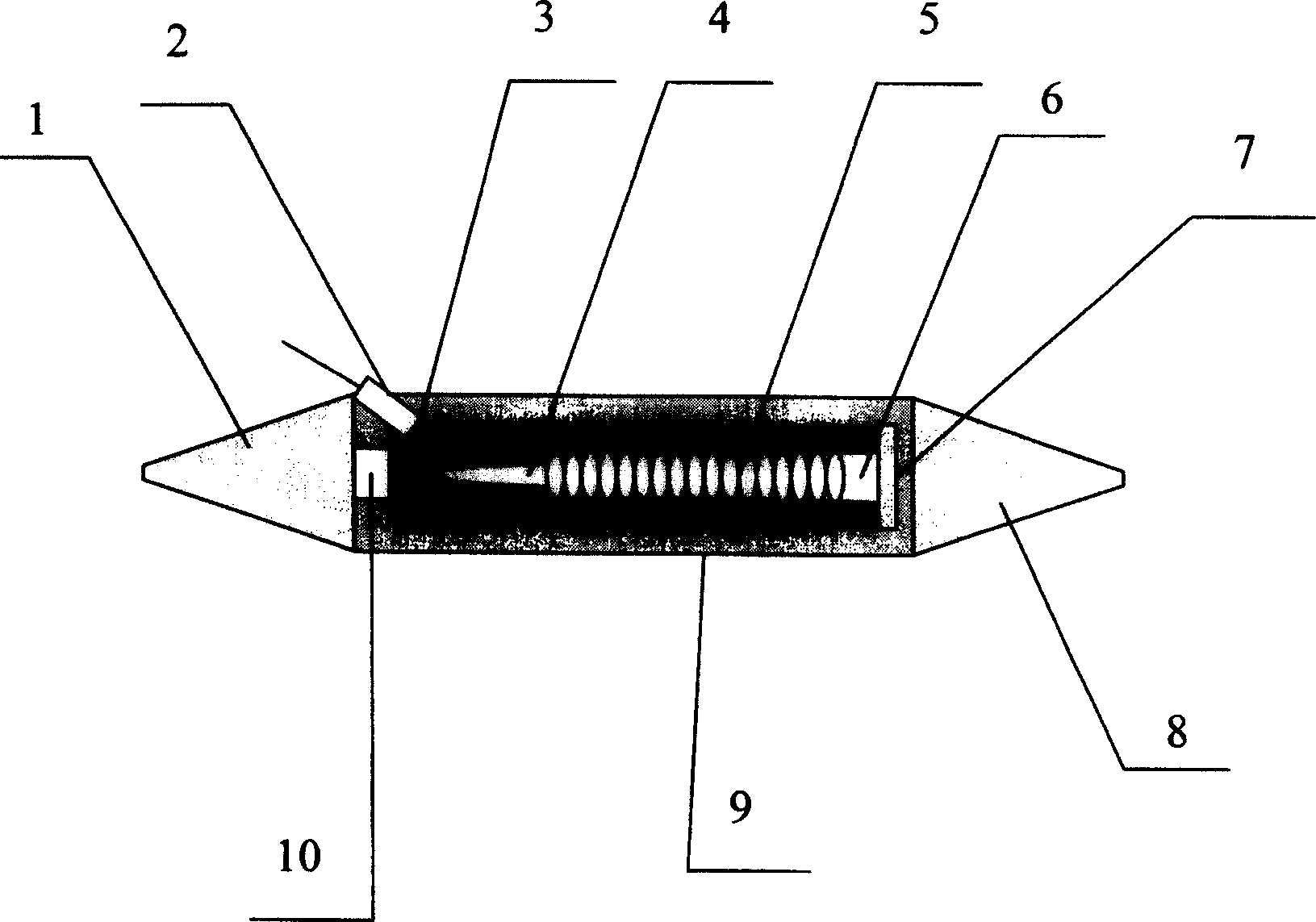

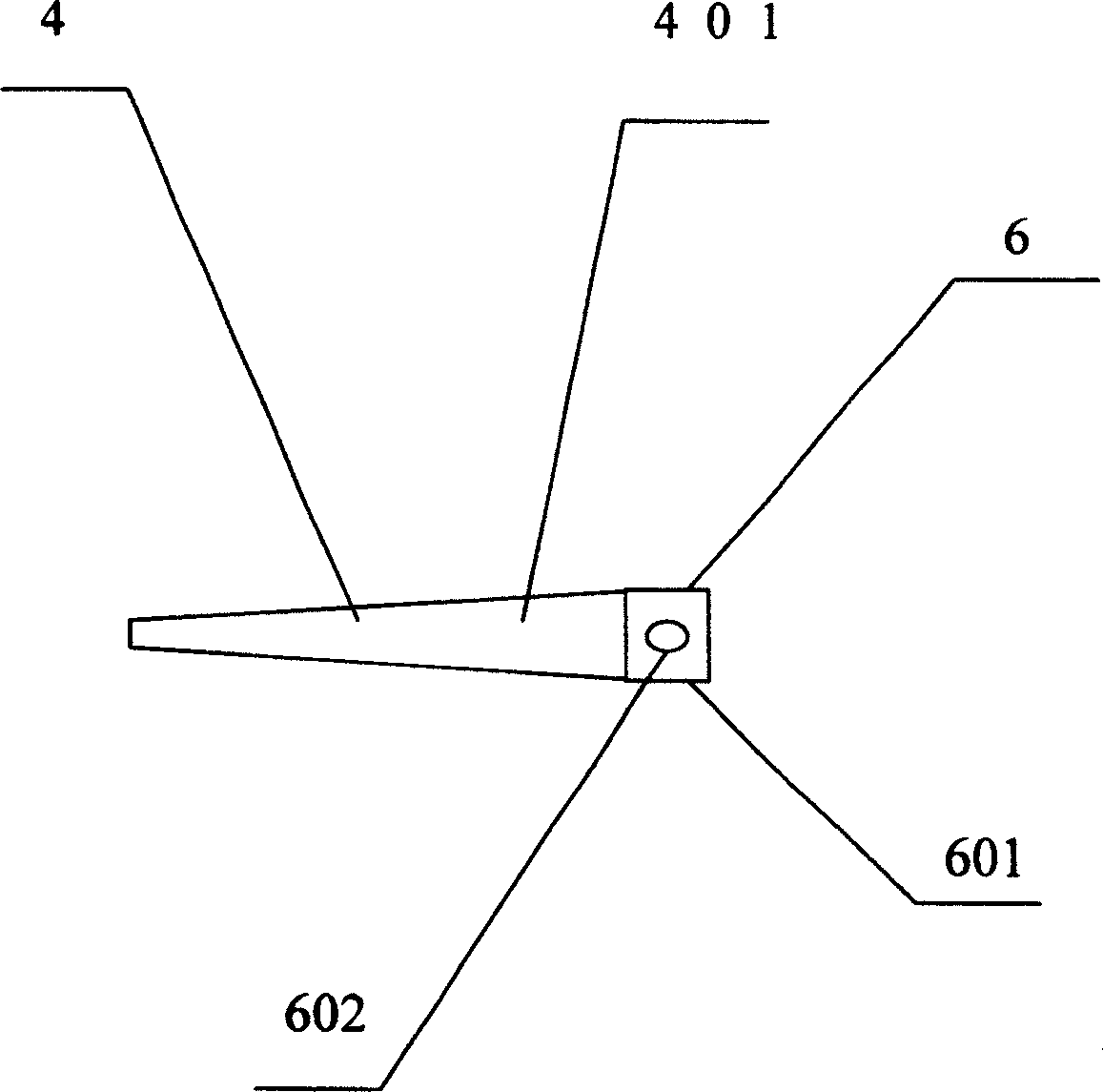

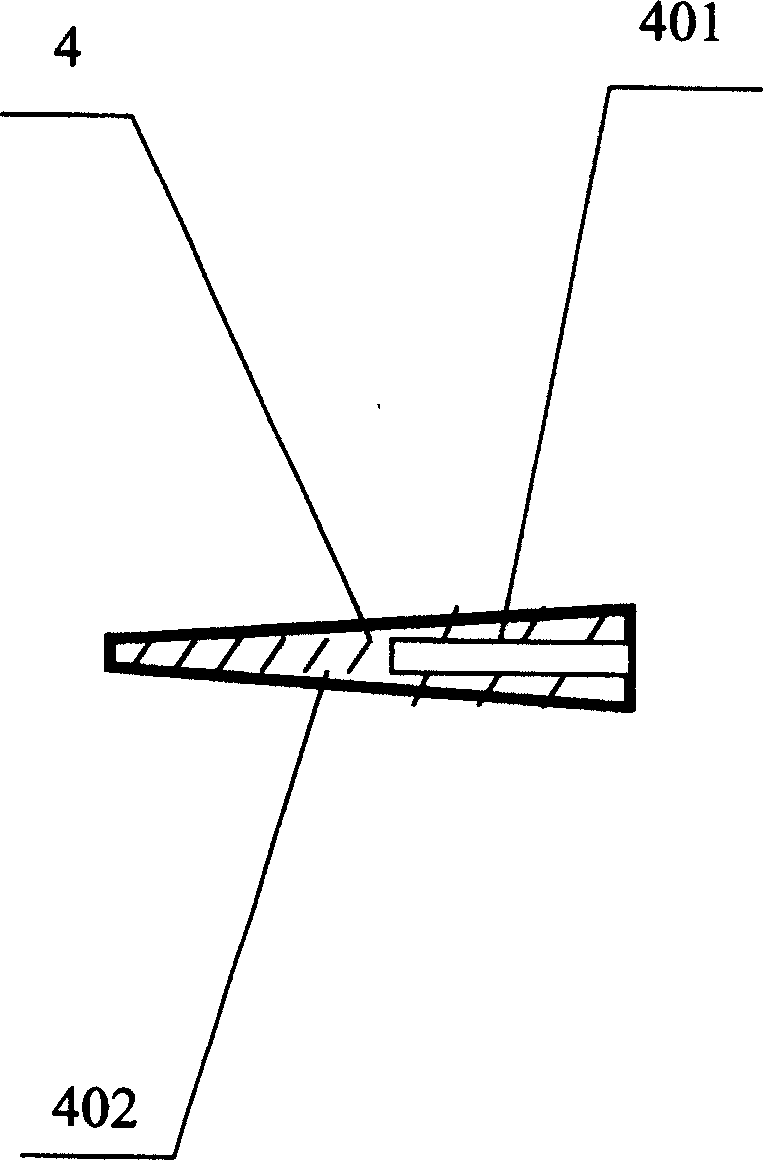

[0030] see first figure 1 , figure 1 It is a structural schematic diagram of the best embodiment of the shuttle fiber laser of the present invention. As can be seen from the figure, the shuttle fiber laser of the present invention includes, the most core element is an optical fiber 5, a weft tube pump source 4, and the fiber 5 is wound around the weft tube pump source 4, the weft tube pump source 4 is inserted on the support 603 of the weft tube pump source support 6, and the support 603 is fixed on the bracket support 601, and the weft tube pump source support 6 is supported by the weft in the weft tube support support 601. The tube bracket support hole 602 is passed through the weft tube base cross bar 701 and installed on the weft tube pump source base 7. The power supply 8 is the shuttle tip at the other end of the shuttle to directly provide energy for the weft tube pump source 4. The weft tube pump The source outer tube 402 and the weft tube pump source empty tube 401 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com