Method for maintaining ink-jet printing head

An inkjet print head, print head technology, applied in printing and other directions, can solve the problems of aggravation, no solution, print head contamination sensitivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

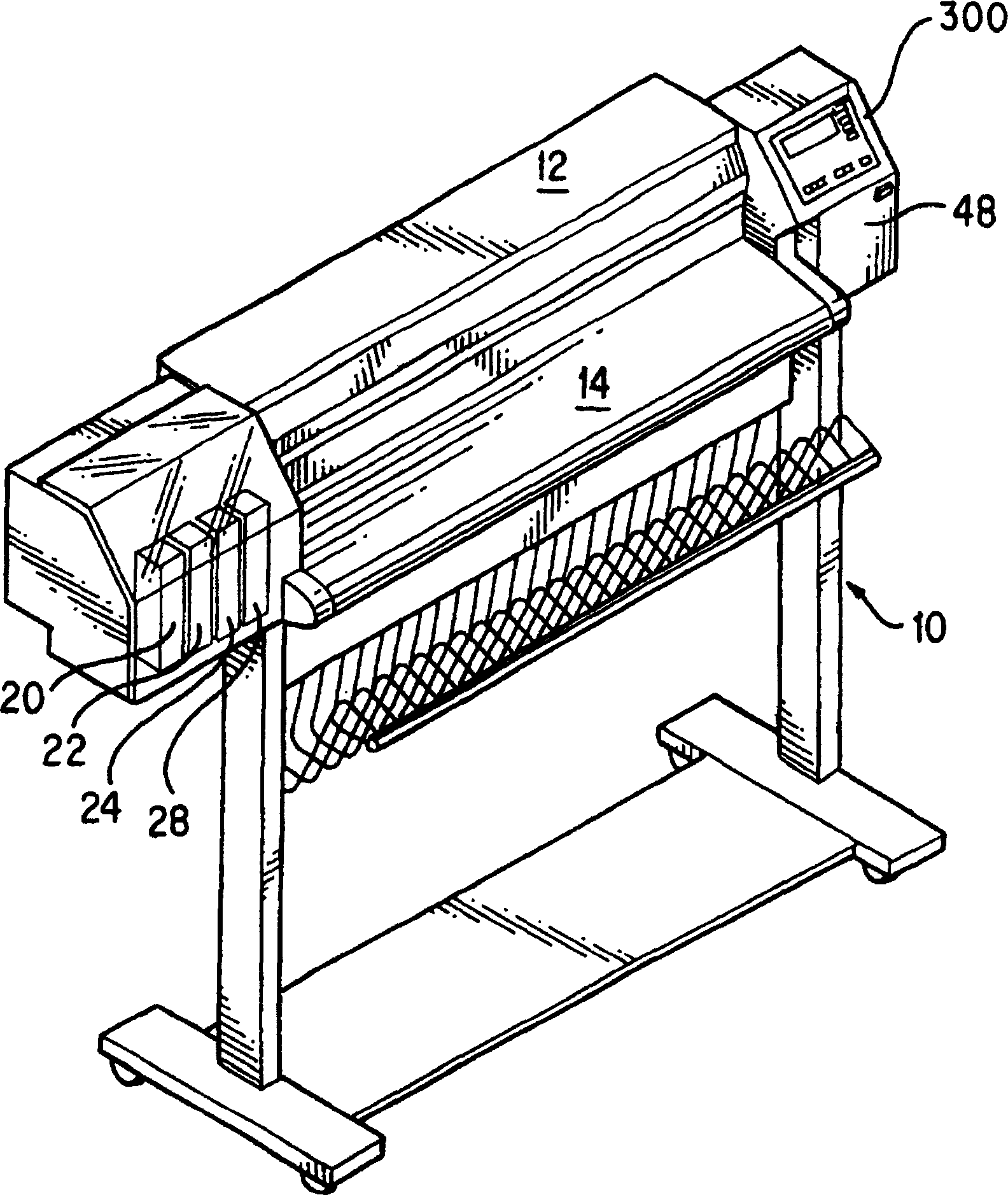

[0050] figure 1 A large format printer 10 is shown which includes a laterally movable printhead carriage closed by a cover 12 extending over a generally horizontally extending platen 14 upon which print media The top of the board is discharged into a catch basket. On the left side of the platen are four detachable ink containers 20, 22, 24, 26, which are connected to the four detachable ink containers on the movable carriage through a detachable flexible tube device which will be described later. Inkjet printheads provide ink.

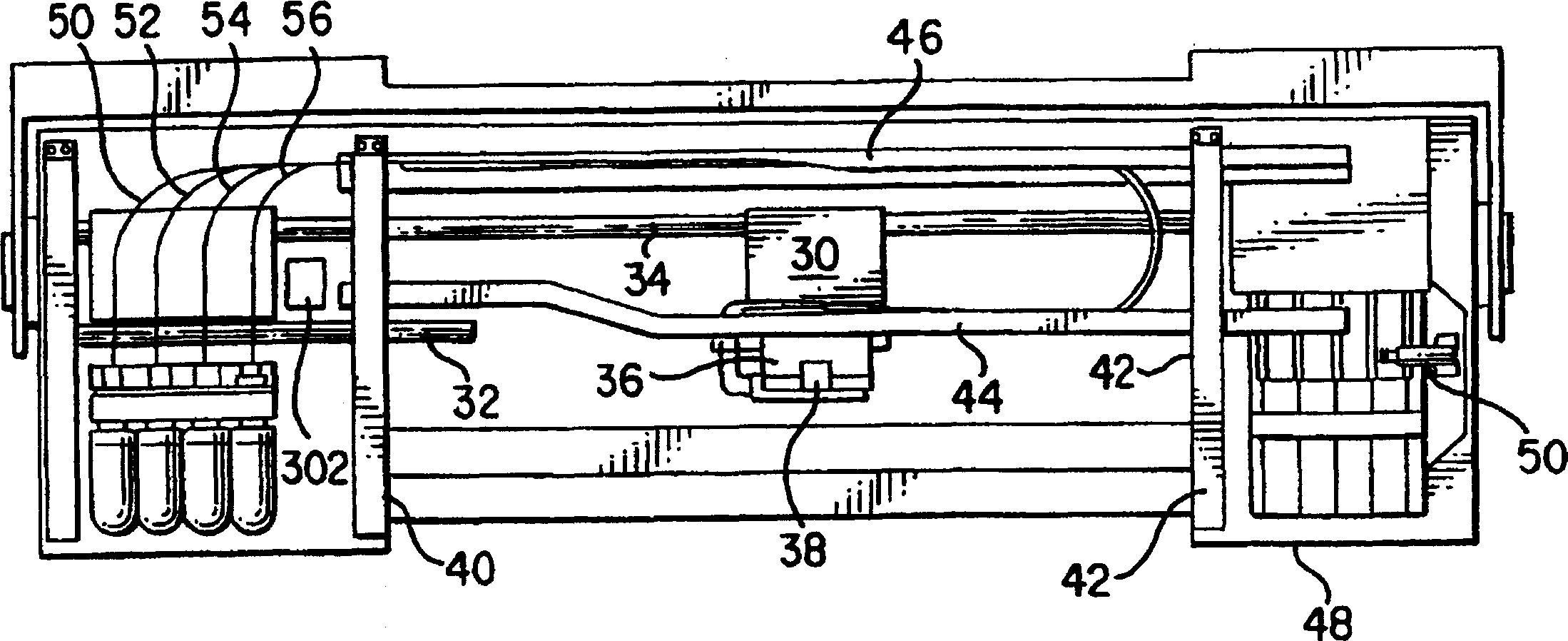

[0051] exist figure 2 Shown in plan with the carriage cover 12 removed, it can be seen that the printhead carriage 30 is mounted on a pair of transversely extending sliders or guides 32, 34 which in turn are secured to the frame of the printer superior. Also affixed to the frame of the printer are a pair of tube guide support bridges 40, 42 from which the front and rear tube guides 44, 46 are suspended. The printhead carriage 30 has a pivotable p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com