Rock tip spanner

A technology of swinging head and driving head, which is applied in the field of swinging head wrench, which can solve the problems of affecting the torque value of the wrench, being unable to pivot relative to each other, and easily cracking or destroying the meat wall of the stressed section of the head.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

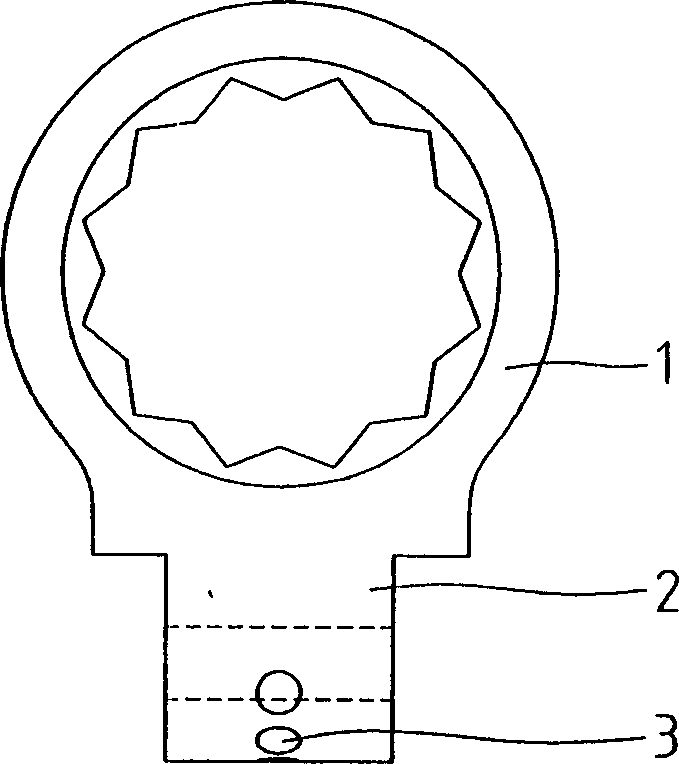

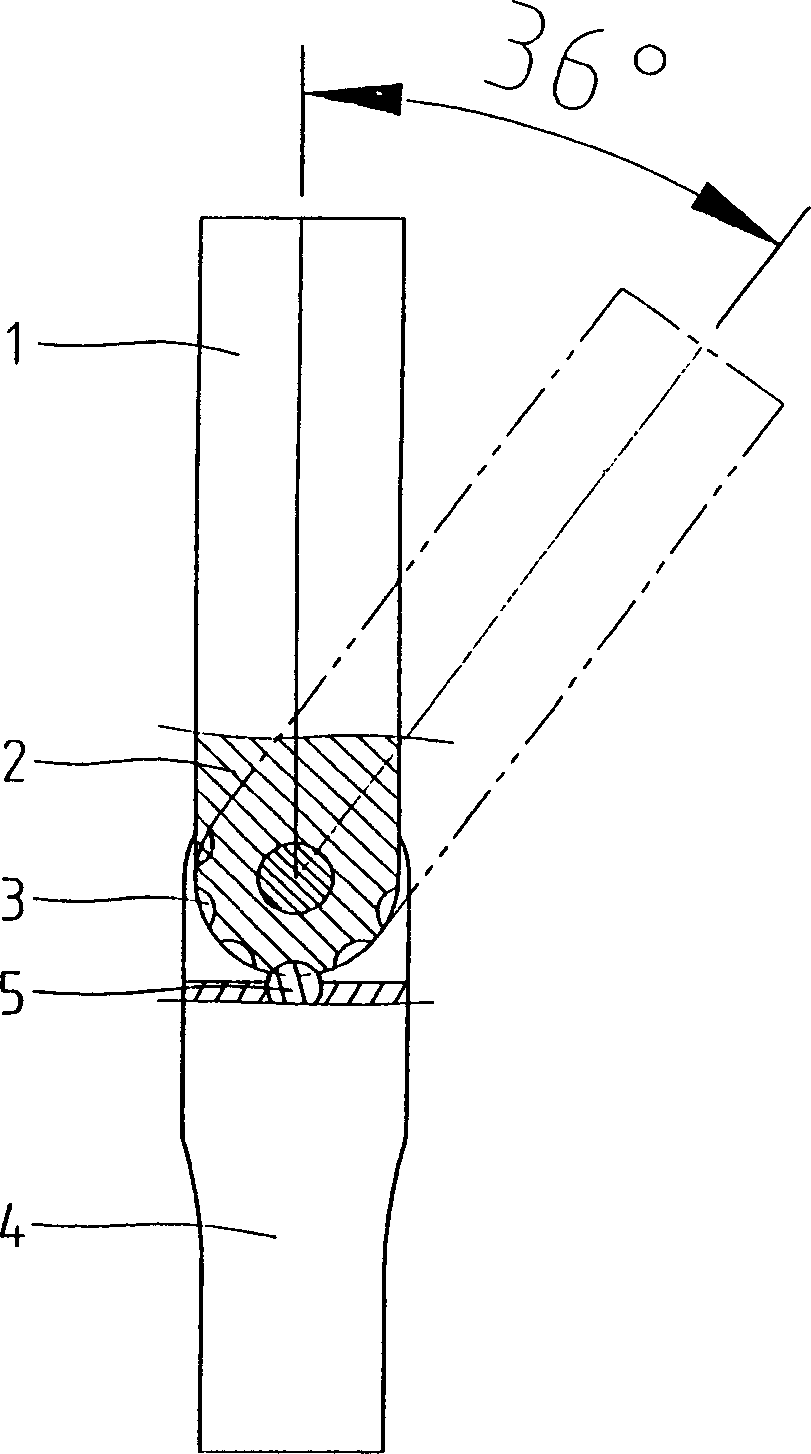

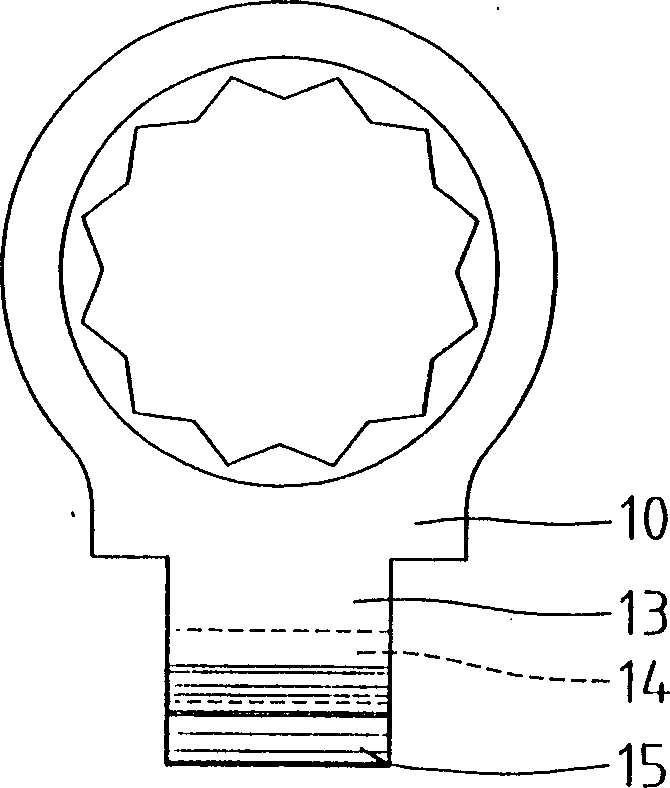

[0041] refer to Figure 7 , 8. The swing head wrench 30 of the first embodiment of the present invention includes: a driving head 40 , a handle 50 and a locking mechanism 60 . One end of the driving head 40 is pivotally mounted on the handle 50 . The locking mechanism 60 is disposed in the handle 50 and can selectively limit the relative pivotal relationship between the driving head 40 and the handle 50 .

[0042] The driving head 40 includes a first end and a second end, and the first end is provided with a ratchet ring 41 for accommodating a screw and a bidirectional ratchet mechanism (not shown). A generally convex pivot portion 43 is provided at the second end thereof, and a pin hole 44 is formed transversely at the middle section of the pivot portion 43 . Also refer to Figure 9 , the pivot portion 43 includes two first sections 431 and a second section 432 disposed between the two first sections 431 . The second section 432 is provided with teeth, which in the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com