Bearing stand

A bearing seat and bearing technology, applied in the direction of bearing components, shafts and bearings, pipeline laying and maintenance, etc., can solve problems such as hose damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

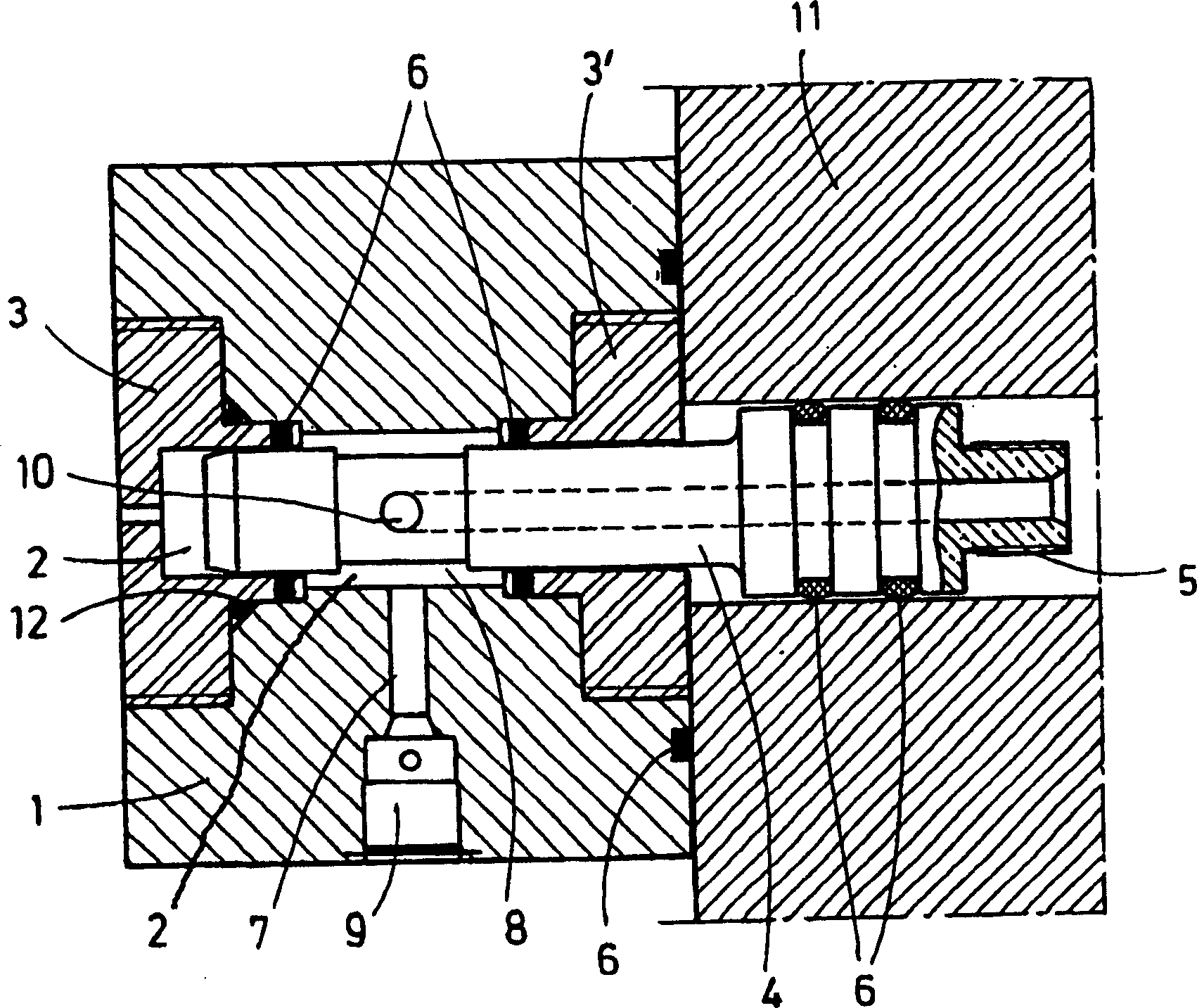

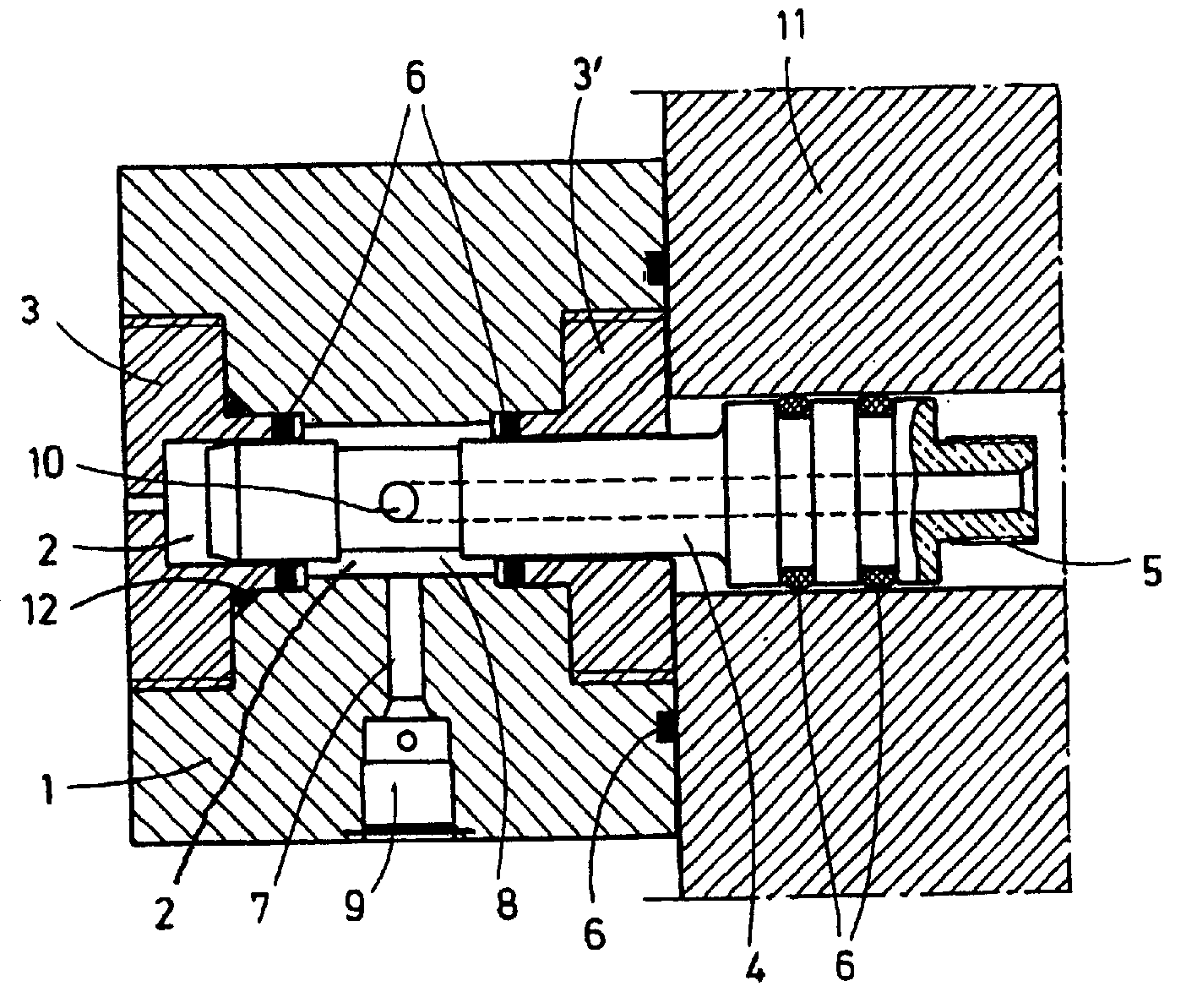

[0008] The figure shows a connection block 1 with a central hole 2 . Bearings 3 , 3 ′ are mounted in the central bore 2 and hold the connecting pipe 4 . The connecting pipe 4 is closed at one end and has a connection 5 at the open end for a line (not shown) or a hose (not shown). Here, the connection 5 and the hose connection connected to the connection 5 are supported in the bearing housing 11 on the connecting pipe 4 .

[0009] The connecting pipe 4 is sealed in the central bore 2 or in the bearings 3 , 3 ′ by a seal 6 . A radial bore 7 is provided in the connection block 1 and ends in an annular channel 8 . At the free end of the radial bore 7 there is a snap-action coupling 9 . The connecting pipe 4 has at least one radial opening 10 which communicates the annular channel 8 with the interior of the connecting pipe 4 .

[0010] Thus, hydraulic medium can be fed to the joint 5 of the connecting pipe 4 via the snap-action coupling 9 , the radial bore 7 , the annular chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com