Experimental device for rotatable valve of engine

An experimental device and engine technology, applied in the direction of engine testing, measuring equipment, machine/structural component testing, etc., can solve problems such as deteriorating combustion, affecting intake air volume, singleness, etc., and achieve the effect of increasing vortex intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but this should not be used as a limitation to the protection scope of the claims of the present application.

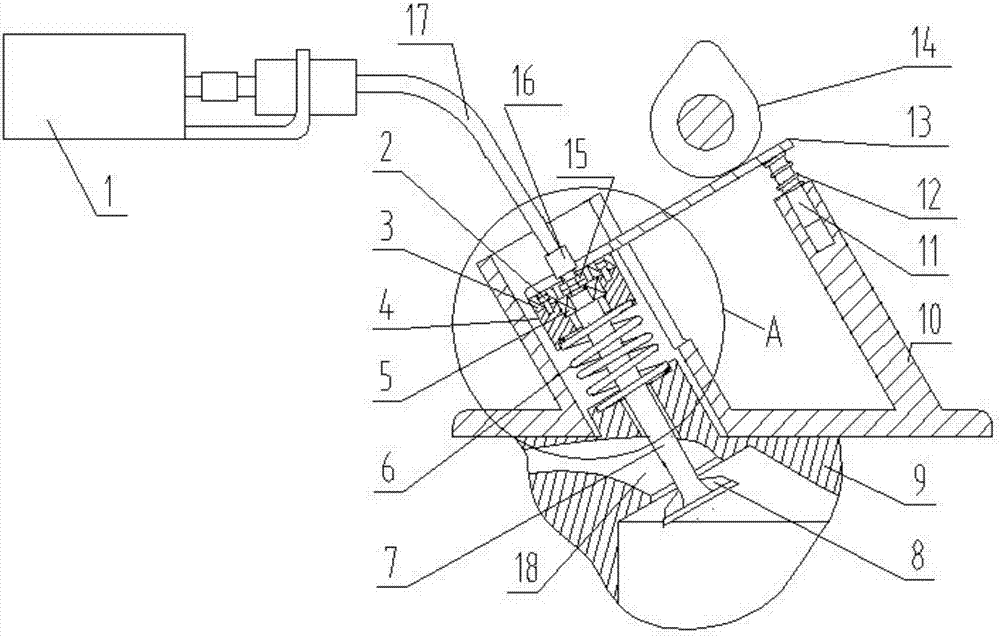

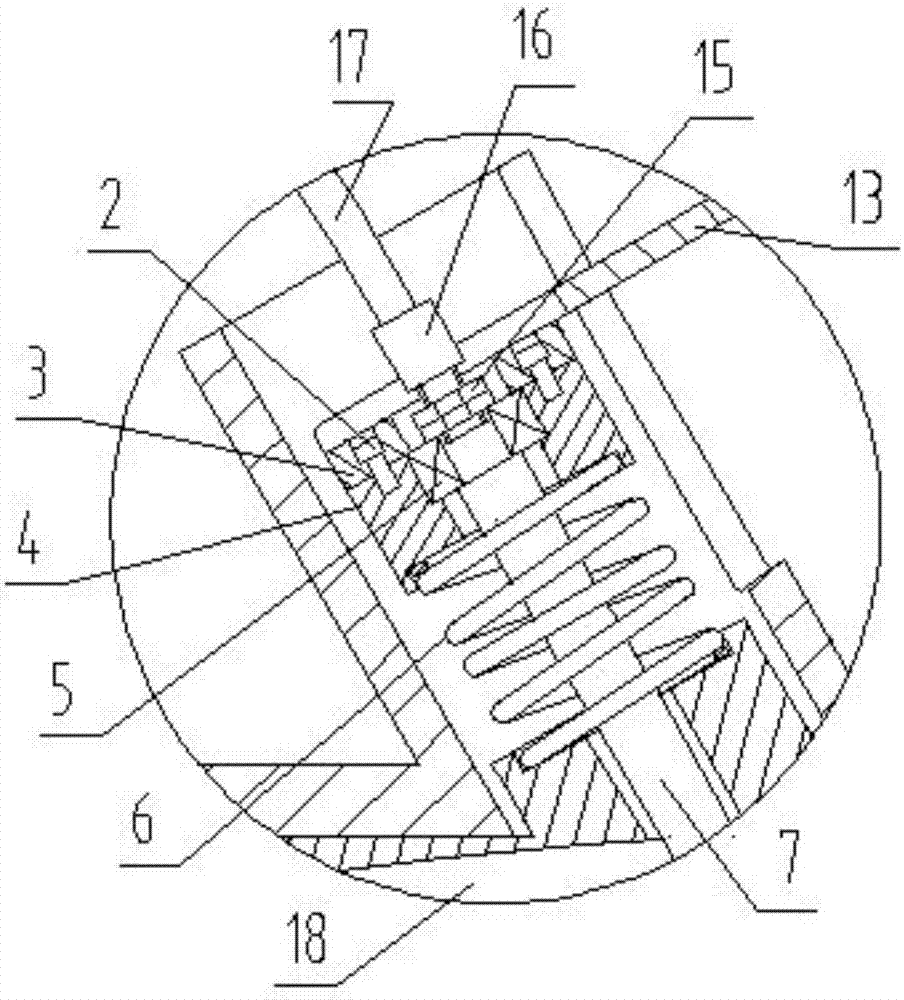

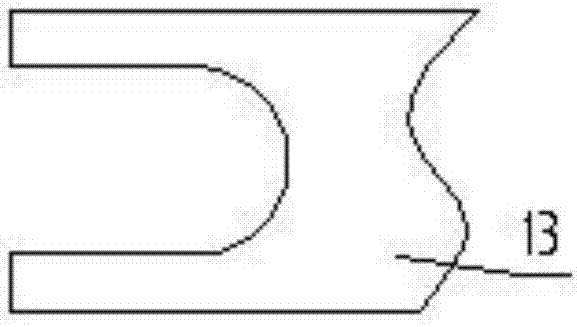

[0017] Engine swivel valve experimental device of the present invention (abbreviation device, see figure 1 and figure 2 ) includes speed regulating motor 1, bearing gland 3, bearing seat 4, bearing 5, hexagon socket bolt 2, lock nut 15, valve spring 6, valve with ridge 7, cylinder head 9, bracket 10, guide post 11, guide Column spring 12, pressure plate 13, intake cam 14, joint 16 and flexible shaft 17;

[0018] The output shaft of the speed-regulating motor 1 is connected to the flexible shaft 17, and the lower end of the flexible shaft 17 is connected to the tail of the valve 7 through the joint 16. When the speed-regulating motor 1 is started, the valve 7 can be driven to rotate; the tail of the valve 7 is equipped with a bearing 5, The be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com