Eccentric lifting appliance and lifting method for marine high-pressure dual-fuel main engine cylinder cover exhaust valve

An exhaust valve, dual-fuel technology, applied in the direction of load suspension components, transportation and packaging, safety devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

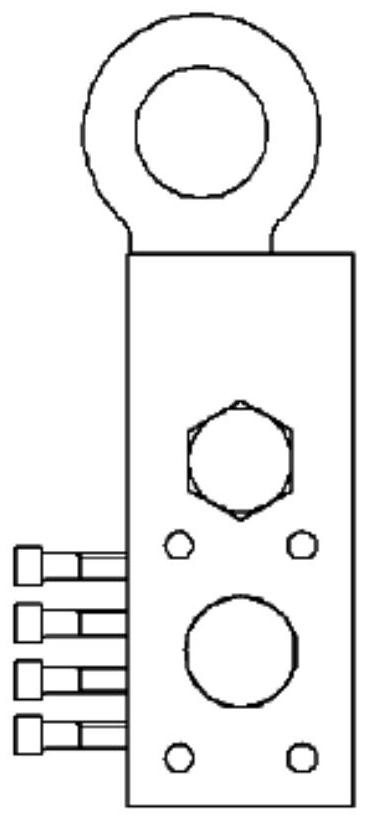

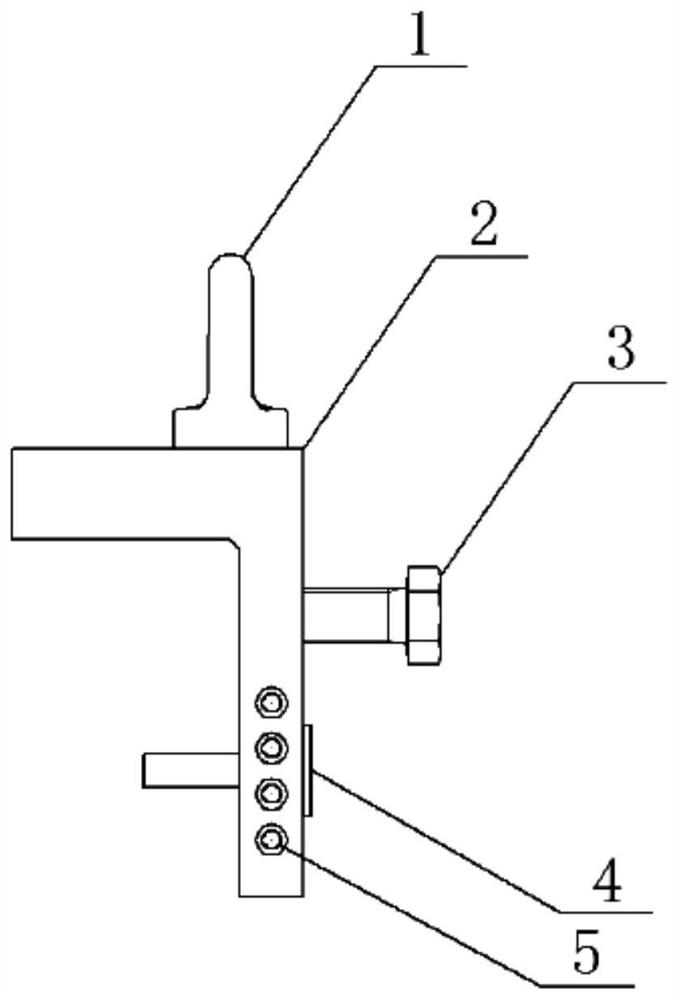

[0029] Please refer to figure 1 with figure 2 , the eccentric spreader includes a hanging plate 2 , an eyebolt 1 , a connecting bolt 3 , a bolt 4 and four fixing bolts 5 .

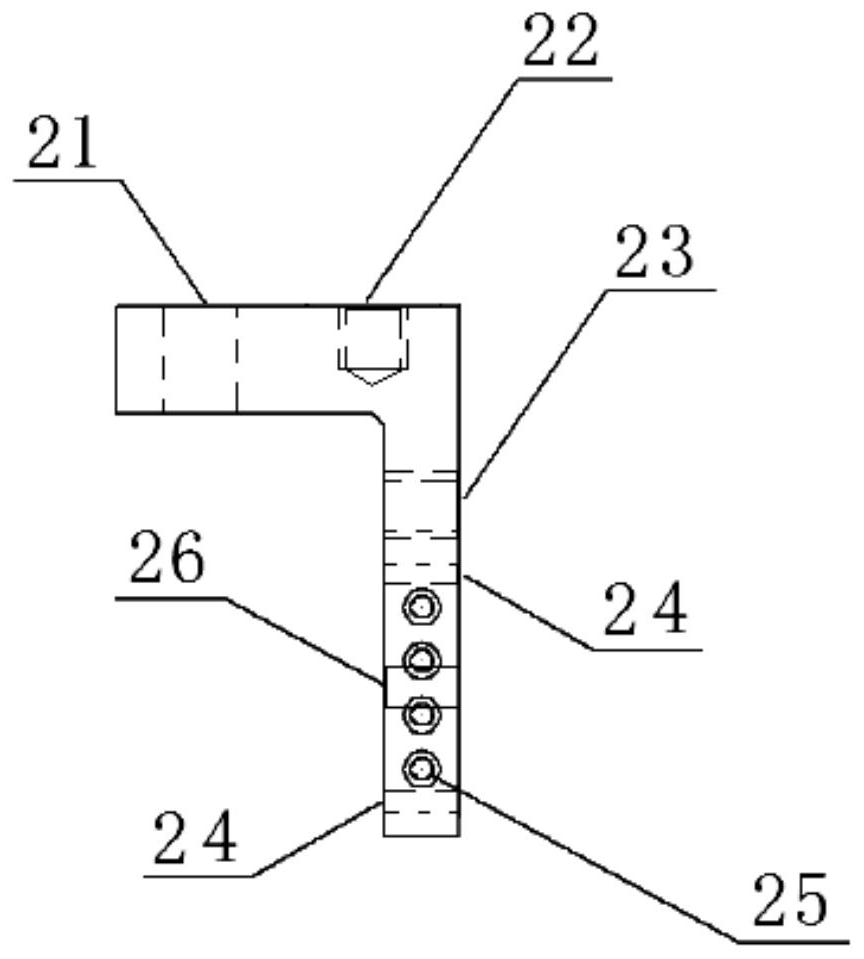

[0030] see image 3 , the suspension plate 2 includes a horizontal horizontal plate portion and a vertical plate portion extending downward from one end of the horizontal plate portion. The horizontal plate portion is provided with a fixing through hole 21 for passing through the connecting bolt 3 and an eyebolt threaded hole 22 for connecting the eyebolt 1 , and the vertical plate portion is provided with a pin for passing through the bolt 4 Holes 26 and four fixing holes 24 for passing the fixing bolts 5.

[0031] The lifting point of the eccentric spreader is the eye screw 1, which is screwed into the eye threaded hole 22 on the hanging plate 2; the connecting bolt 3 is screwed into the top threaded hole for Connect the eccentric spreader with the exhaust valve, when using the eccentric spreader, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com