Zinc boiler nose online position adjusting device

A technology for adjusting device and furnace nose, applied in coating, metal material coating process, hot dip plating process, etc., can solve the problems of cumbersome, no dynamic monitoring, levelness error can not be found in time, etc., to achieve simple and safe operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The zinc boiler nose online position adjustment device according to the present invention will be further described according to the specific embodiments of the present invention and the accompanying drawings, but this description does not constitute an improper limitation of the present invention.

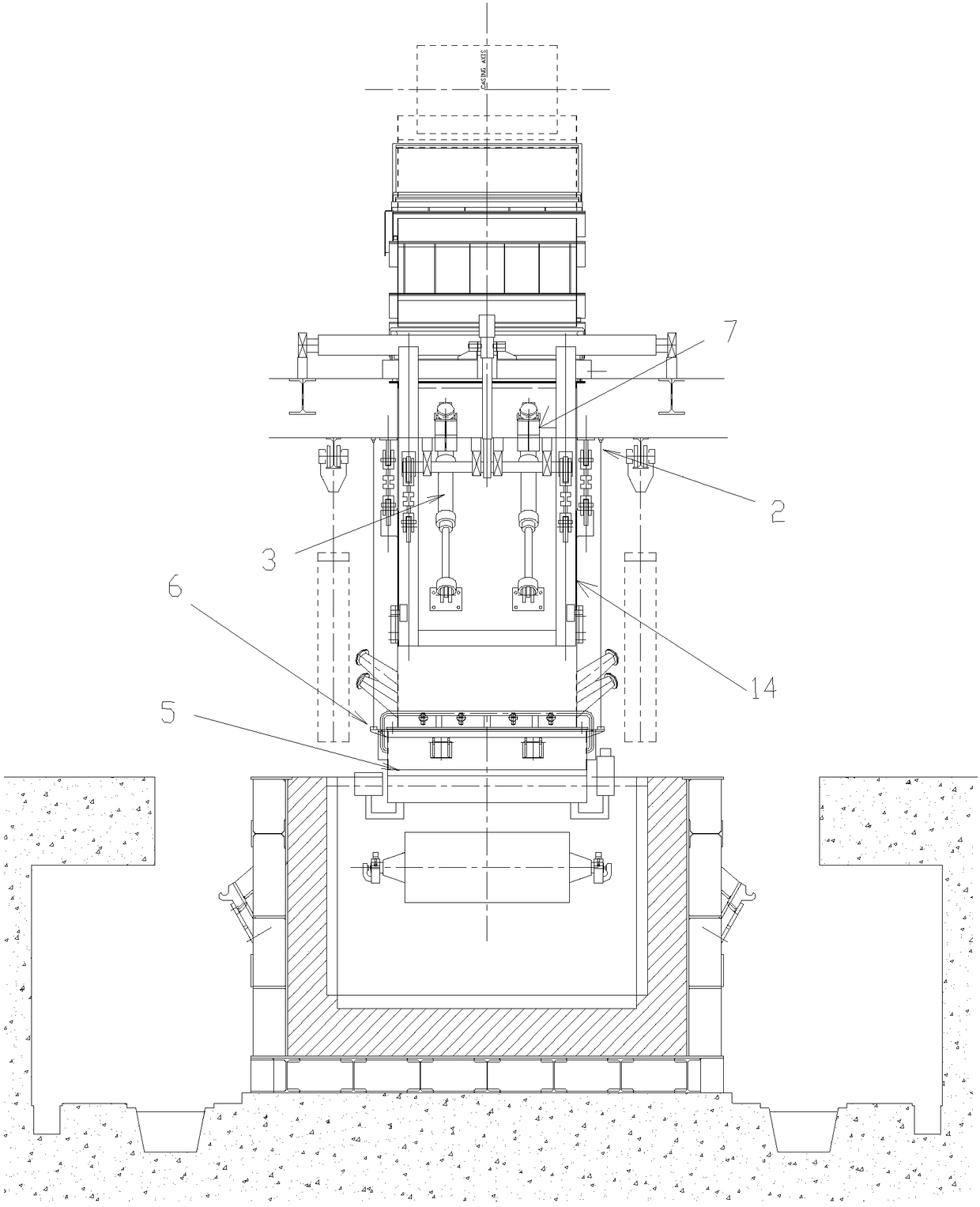

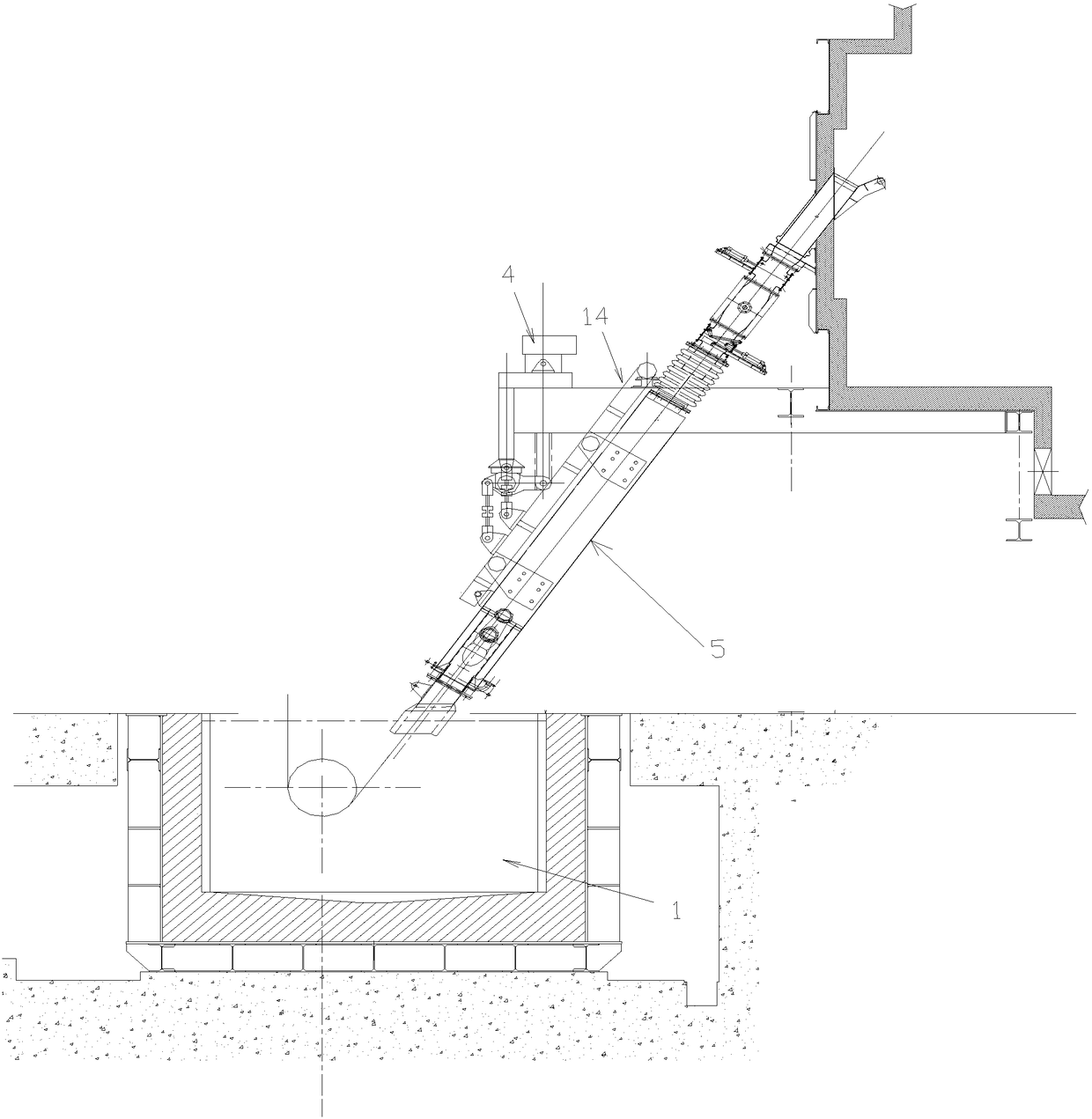

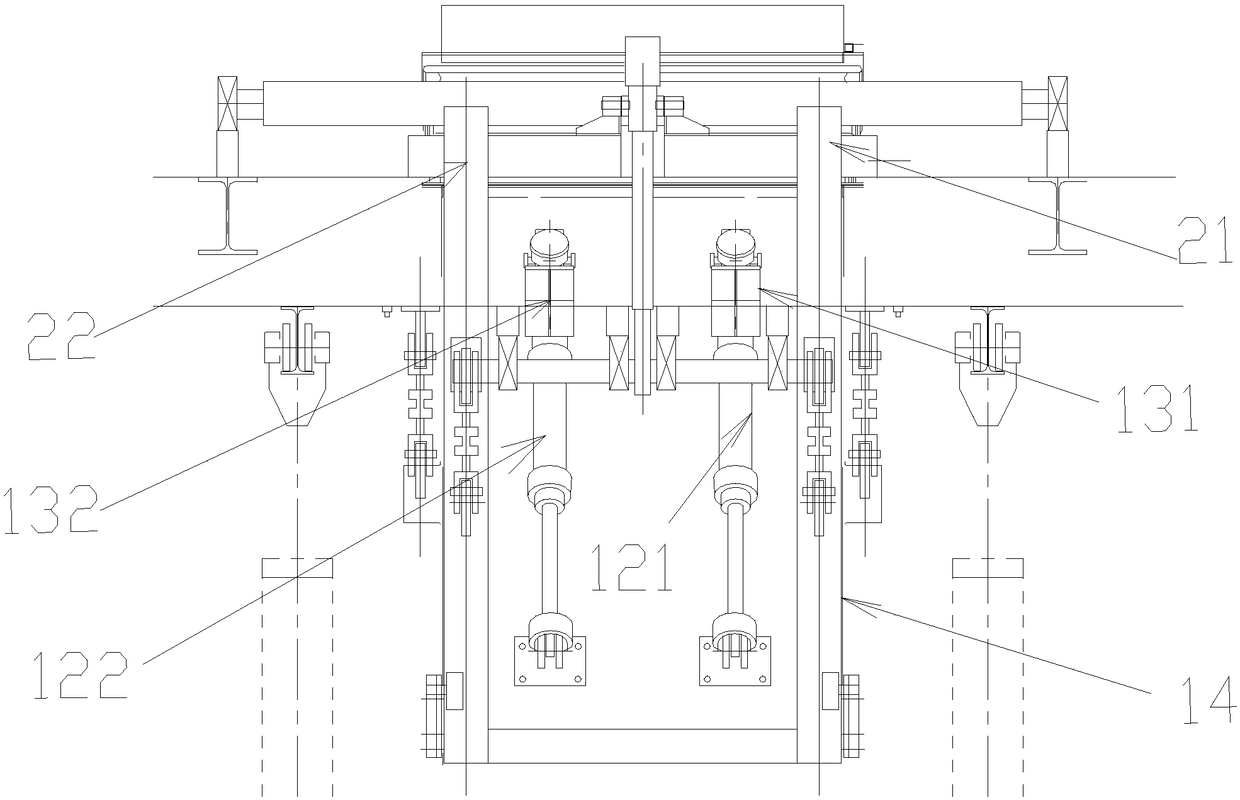

[0040] figure 1 It is a structural schematic diagram of an embodiment of the zinc boiler nose online position adjustment device according to the present invention. Such as figure 1 shown, and if necessary combined with figure 2 , The zinc boiler nose online adjustment device of the present invention includes a furnace nose body 5 , an online measurement mechanism 2 , a telescopic adjustment mechanism 3 , a frame 14 and a controller 7 . Wherein, the furnace nose body 5 is used to clean up the zinc slag in the zinc pot 1 , and the lower end of the furnace nose body 5 is provided with a measurement reference plane 6 . After the online measuring mechanism 2 measures the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com