A fabric leveling machine, a fabric leveling integrated machine and a fabric leveling method

A technology of leveling machine and all-in-one machine, applied in the direction of construction, building structure, etc., can solve the problems of human injury, manual influence of cloth speed and quality, and high labor intensity of operators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

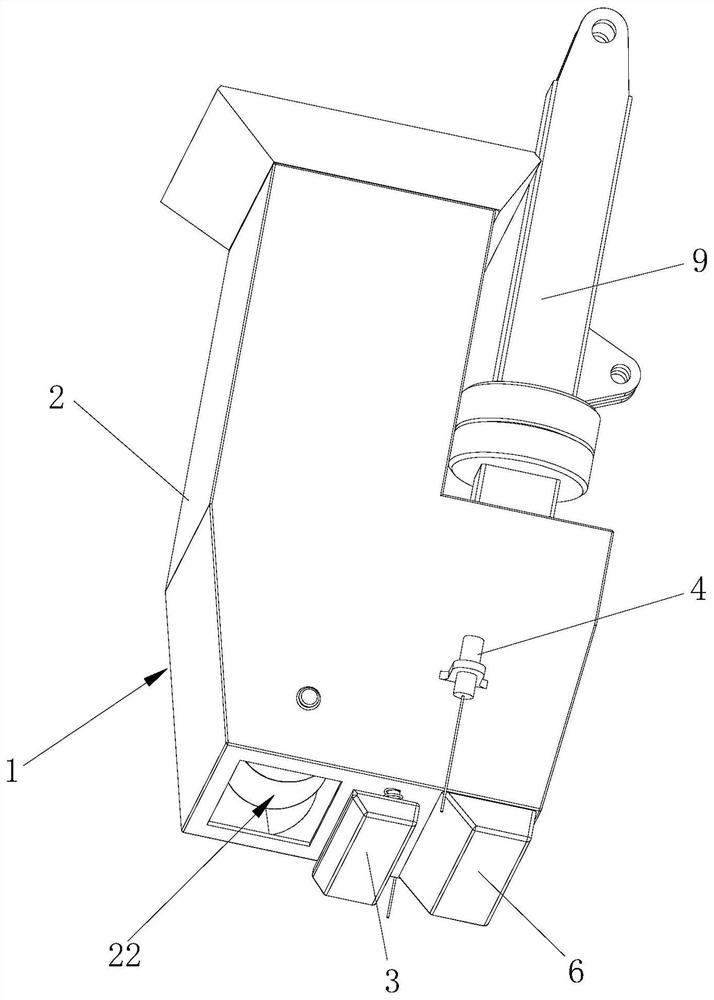

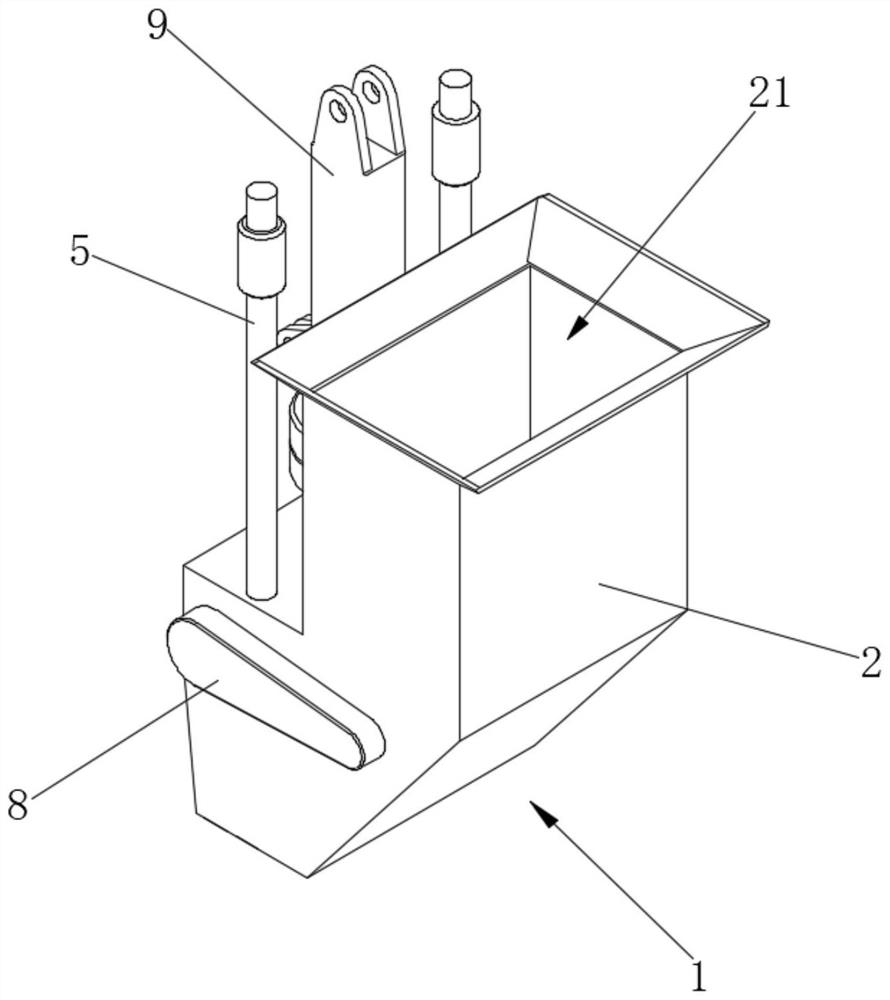

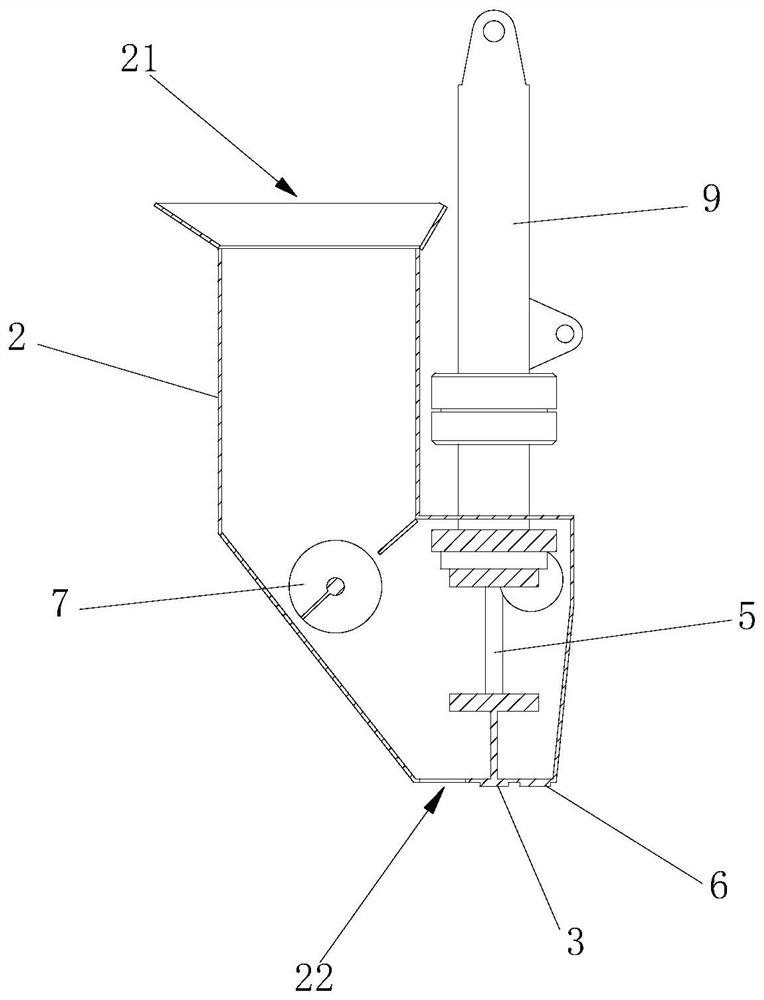

[0080] Such as Figure 1-Figure 4 As shown, the present embodiment provides a cloth leveling machine 1, the cloth leveling machine 1 includes a slurry container 2, a vibrating mechanism located in the slurry container 2 and a detection assembly located outside the slurry container 2 . Wherein, the slurry container 2 can hold the slurry, the slurry enters from the slurry inlet 21 at its upper end, flows out to the cloth area from the slurry outlet 22 at its lower end, and the vibrating mechanism will flow out from the slurry outlet 22 through its own vibration. The slurry is vibrated in the cloth area, and the detection component is used to detect the level of the slurry in the cloth area. In the process of leveling the cloth, after the slurry flows out from the slurry outlet 22, the vibrating mechanism will vibrate it in the cloth area. At the same time, the detection component detects the level of the slurry, and adjusts the vibrating mechanism in real time according to the ...

Embodiment 2

[0090] Such as Figure 5 As shown, this embodiment provides an all-in-one fabric leveling machine, including an execution device and a moving mechanism that drives the fabric leveler 1 up and down and moves along a predetermined route on a horizontal plane, wherein the execution device includes the fabric leveling machine provided in Embodiment 1. Machine 1.

[0091] Further, the moving mechanism includes a truss 10 and a climbing frame 11, wherein the truss 10 is arranged laterally, one end is slidingly connected with the cloth leveling machine 1 along the extension direction of the truss 10, and the other end is provided with a matching device for maintaining the balance of the two ends of the truss 10. Weight 16. The climbing frame 11 is vertically arranged, and the first section 111 of the climbing frame 11 is connected with the wall and can drive the whole moving mechanism to climb along the wall. Section 112 is connected to truss 10 and is located between fabric levele...

Embodiment 3

[0098] This embodiment provides a fabric leveling method, using the fabric leveling all-in-one machine provided in Embodiment 2, including the following steps:

[0099] Spread the slurry on the fabric area;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com