Seal device and segmented exhaust pipe with same

A sealing device and exhaust pipe technology, which is applied to the sealing device, muffler device, exhaust device and other directions of the engine, can solve the problems of sintering at the interface, stuck at the interface of the exhaust pipe, cracks in the exhaust pipe, etc. Axial movement friction and wear, improve axial adjustability, ensure reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

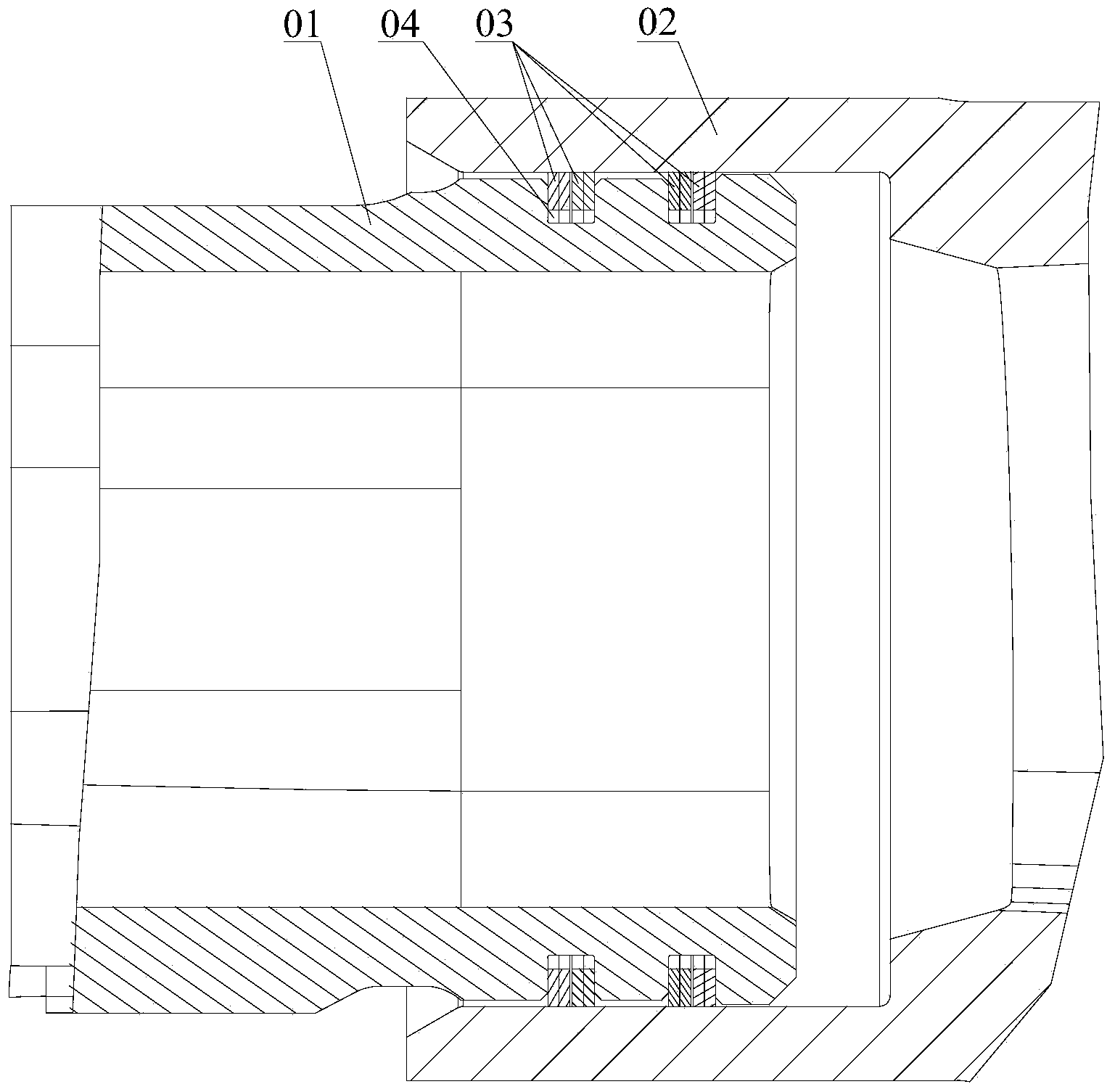

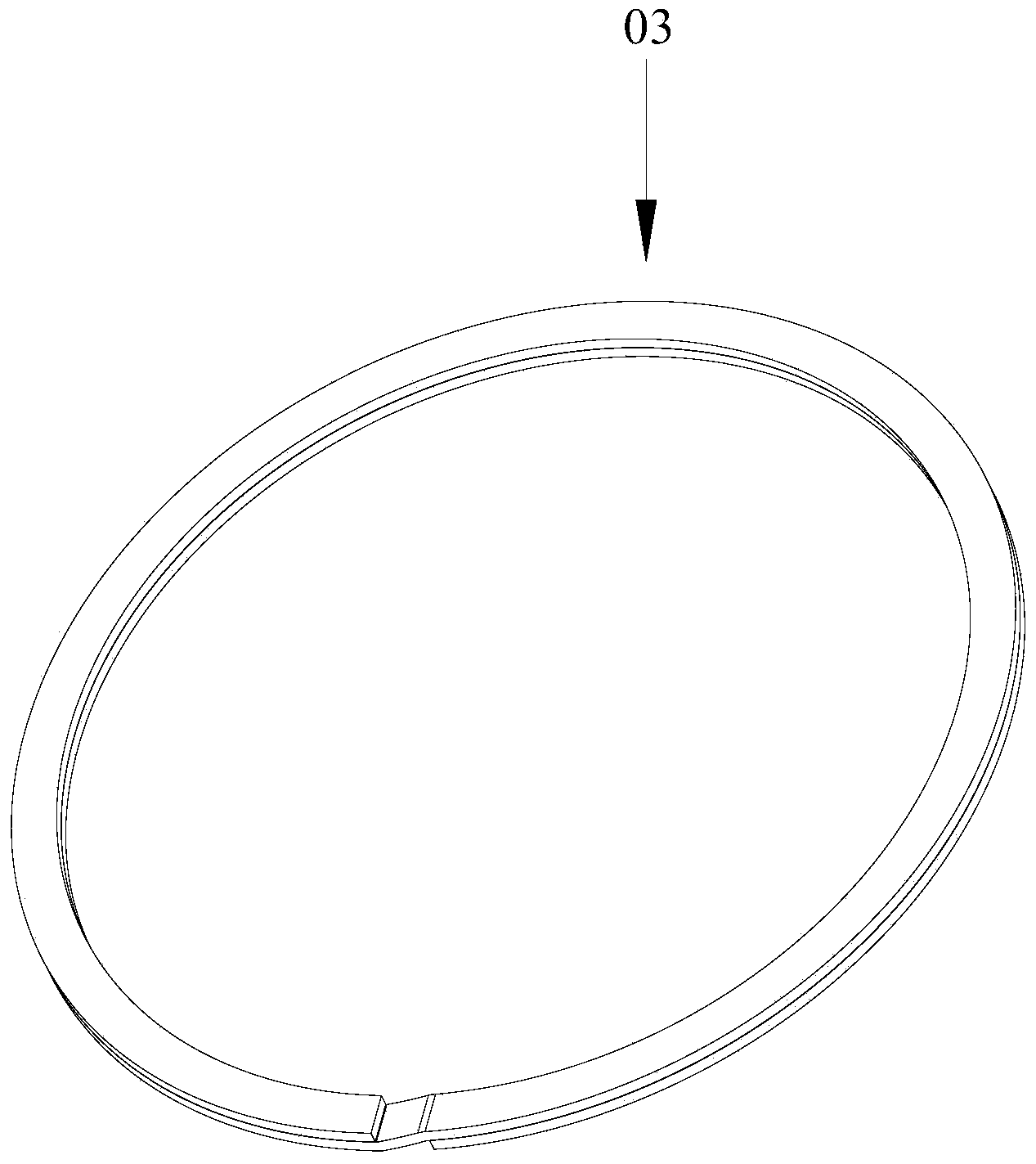

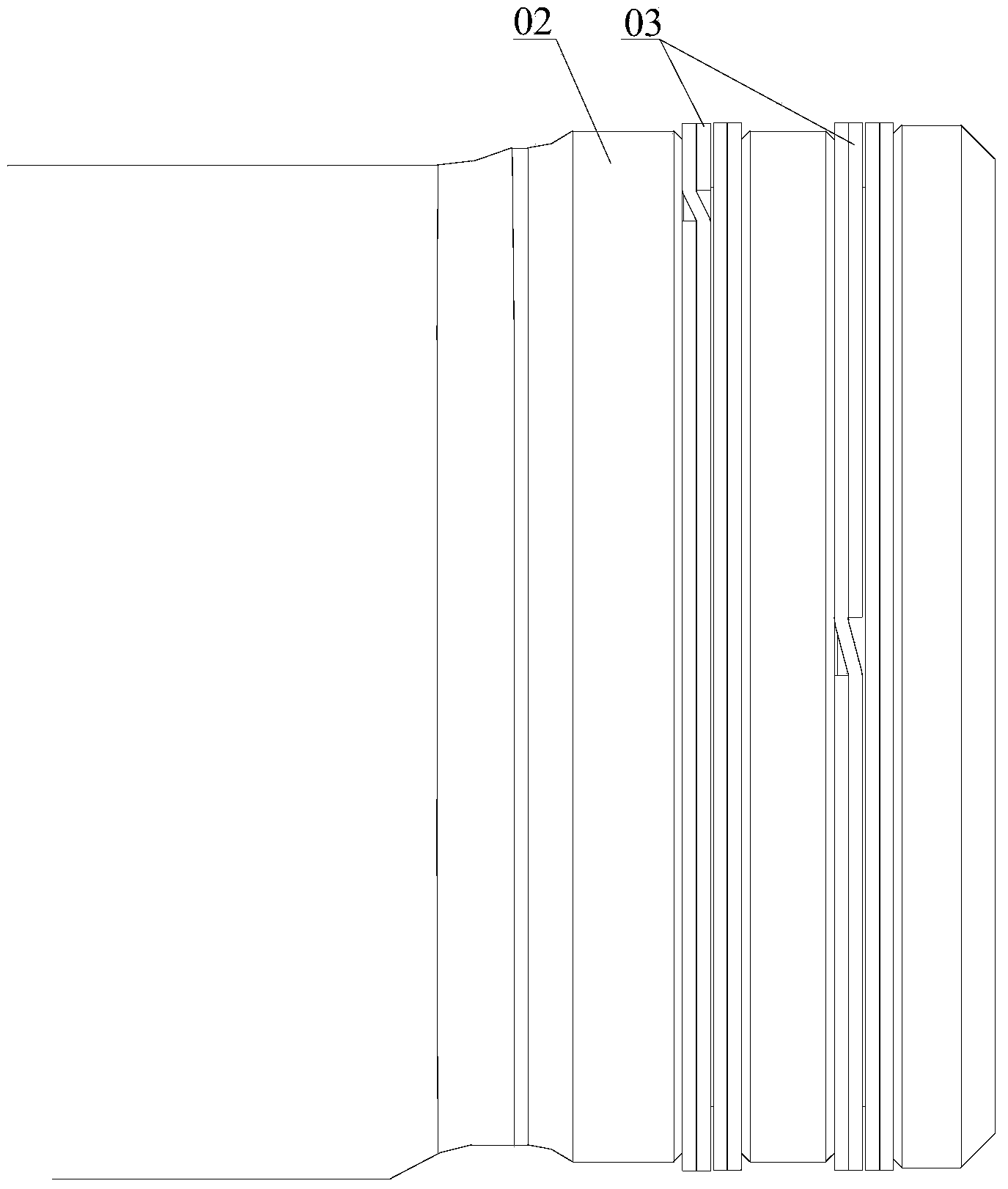

[0034] Based on the problems existing in the sealing method of the segmented exhaust pipe provided by the prior art, the present invention finds another way, and its core is to provide a new type of sealing device, so as to effectively solve the problem of high and low temperature changes and vibration of the existing segmented exhaust pipe. It is easy to leak air under working conditions and improve the working performance of the segmented exhaust pipe. In addition, another core of the present invention is to provide a segmented exhaust pipe with the sealing device.

[0035] In order to enable those skilled in the art to better understand the solution of the present invention, the implementation manner will be specifically described below in conjunction with the accompanying drawings.

[0036]The internal exhaust pipe and external exhaust pipe of the segmented exhaust pipe involved in this article are defined by the relative positional relationship of the installation when ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com