Knob for fixing instrument baseplate

一种旋钮、仪器的技术,应用在仪器的零部件、仪器、支承机器等方向,能够解决旋钮无法再转动、仪器底板不能被正确固定等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

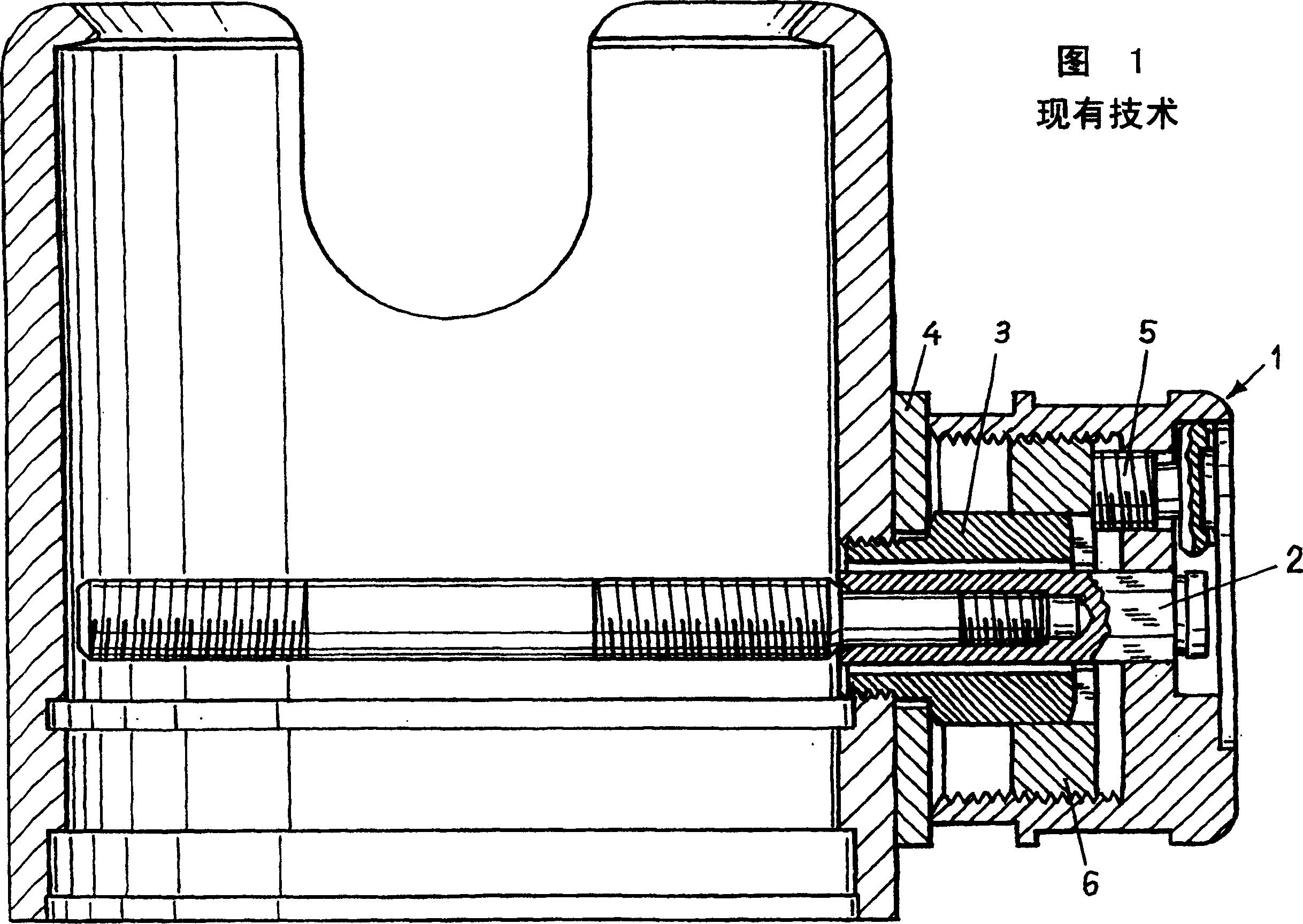

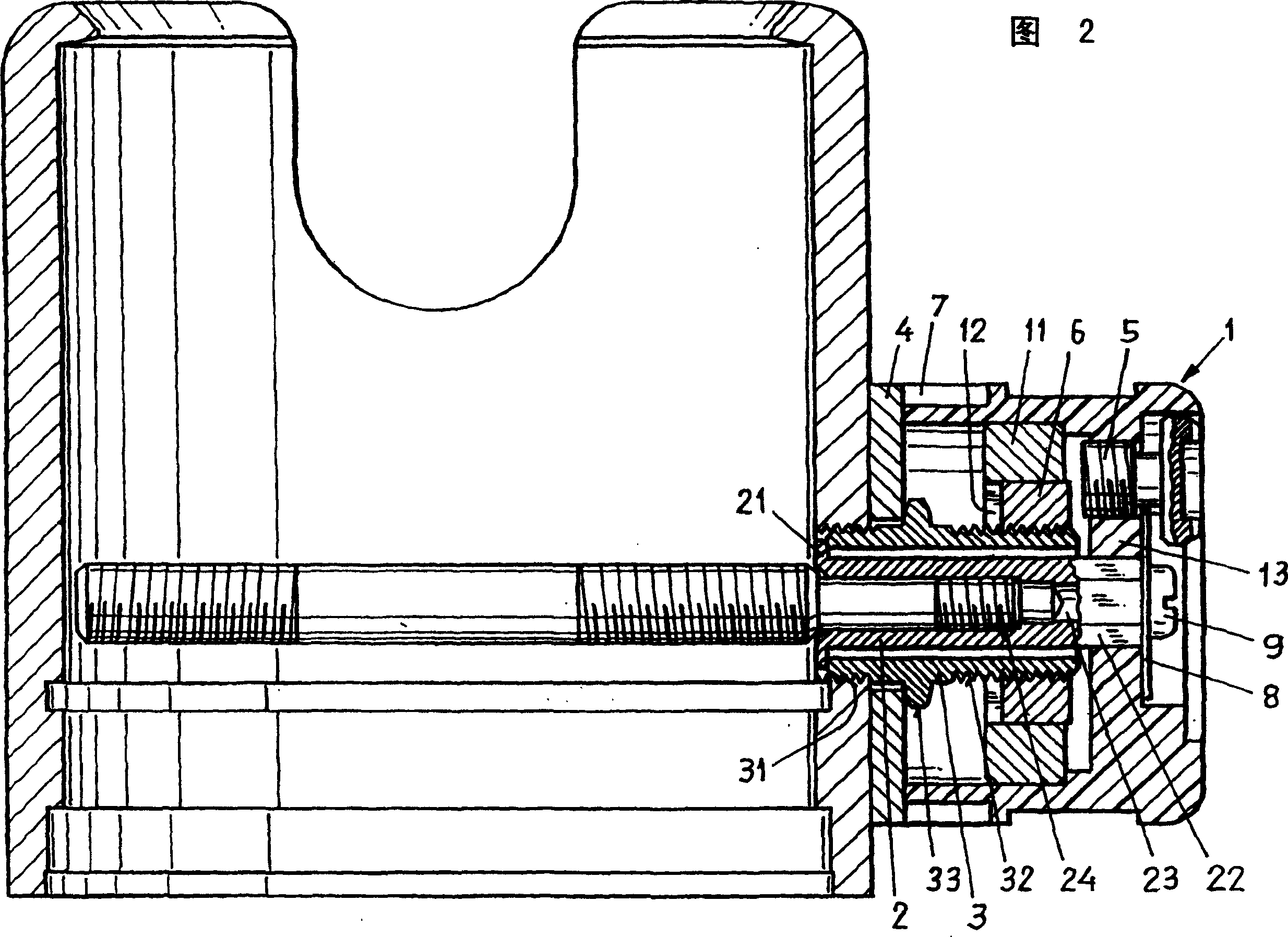

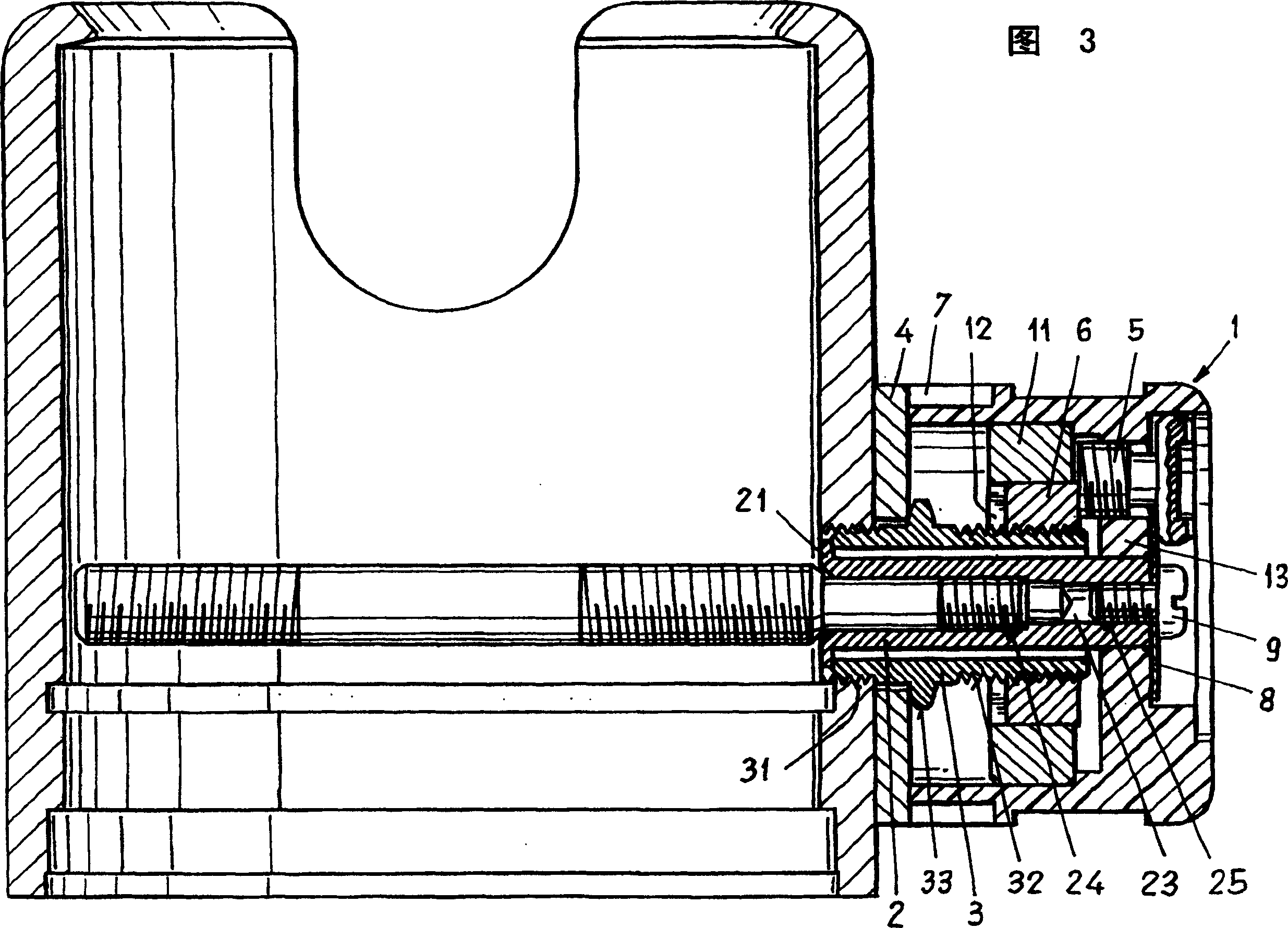

[0015] As shown in Figure 2, the knob includes a screw housing 1, a connecting piece that connects the screw housing 1 with the shaft, a sleeve 3, a cover 4, a screw 5 for adjusting the clamping force, and a The chuck 6, a ring scale 7 and a fixing screw to avoid missing components 8. The screw housing 1 is made of plastic or metal.

[0016] The screw housing 1 has a guide portion 11 with a hexagonal hole 12, which is fixed in the screw housing 1 and has a threaded hole in the bottom 13 of the housing. The connector 2 has a flange 21 at one end and a hexagonal portion 22 at the other end. It also has a through hole 23 with a first threaded section 24 and a second threaded section 25. The connecting piece 2 is screwed onto the shaft by the first threaded section 24. The sleeve 3 has a first threaded section 31, a second threaded section 32 and a hexagonal portion 33 and it is fixed to the housing by the first threaded section 31. The sleeve 3 surrounds the connector 2 and abuts aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com