Telescopic supporter for driving tool of fastening component

A fastener driving and supporting device technology, applied in the direction of nailing tools, manufacturing tools, hitting tools, etc., can solve problems such as tool jamming and work failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

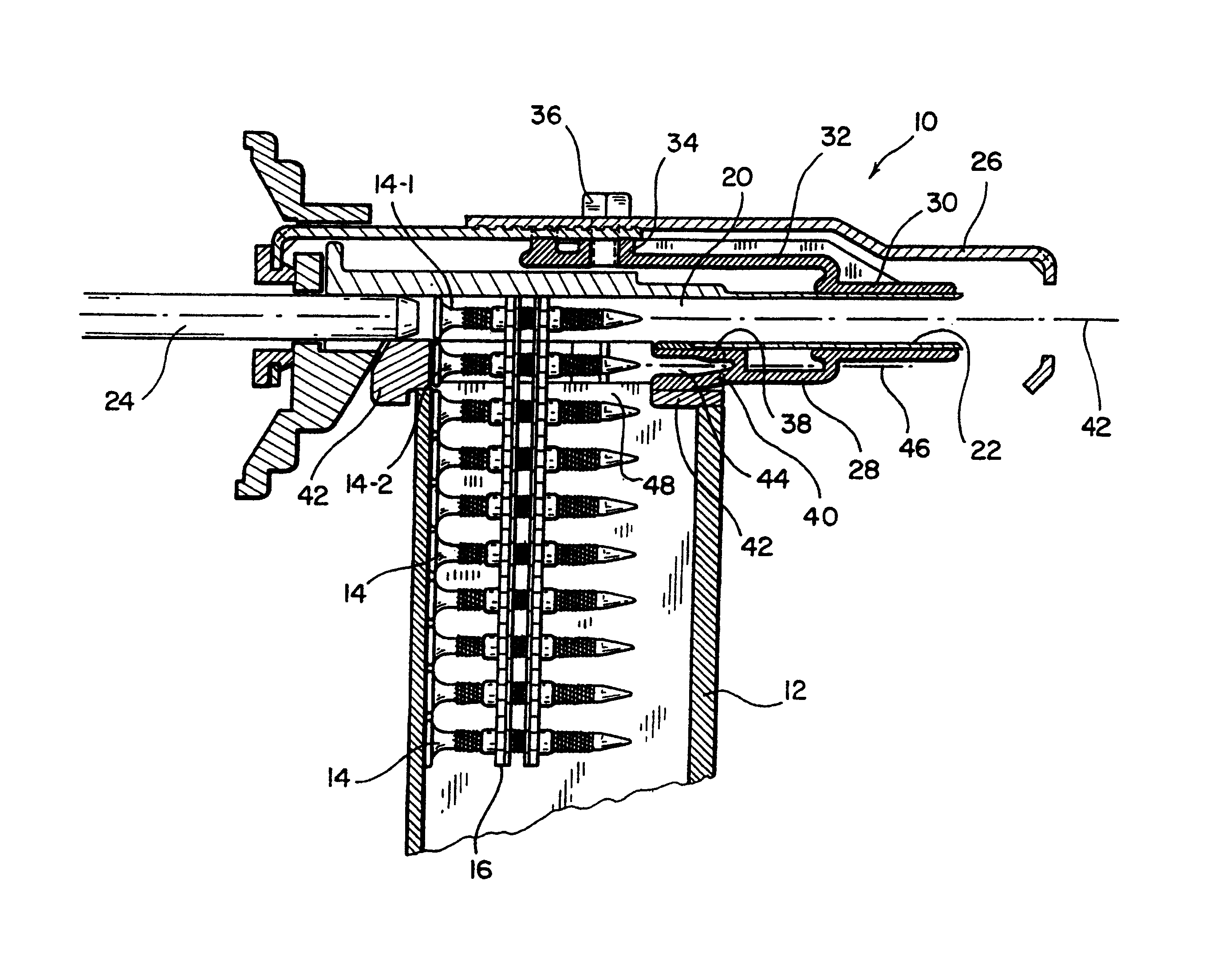

[0014] In conjunction with the accompanying drawings, other objects, features and accompanying advantages of the present invention can be fully understood through the following detailed description. In several drawings, the same reference numerals designate the same or corresponding components, wherein:

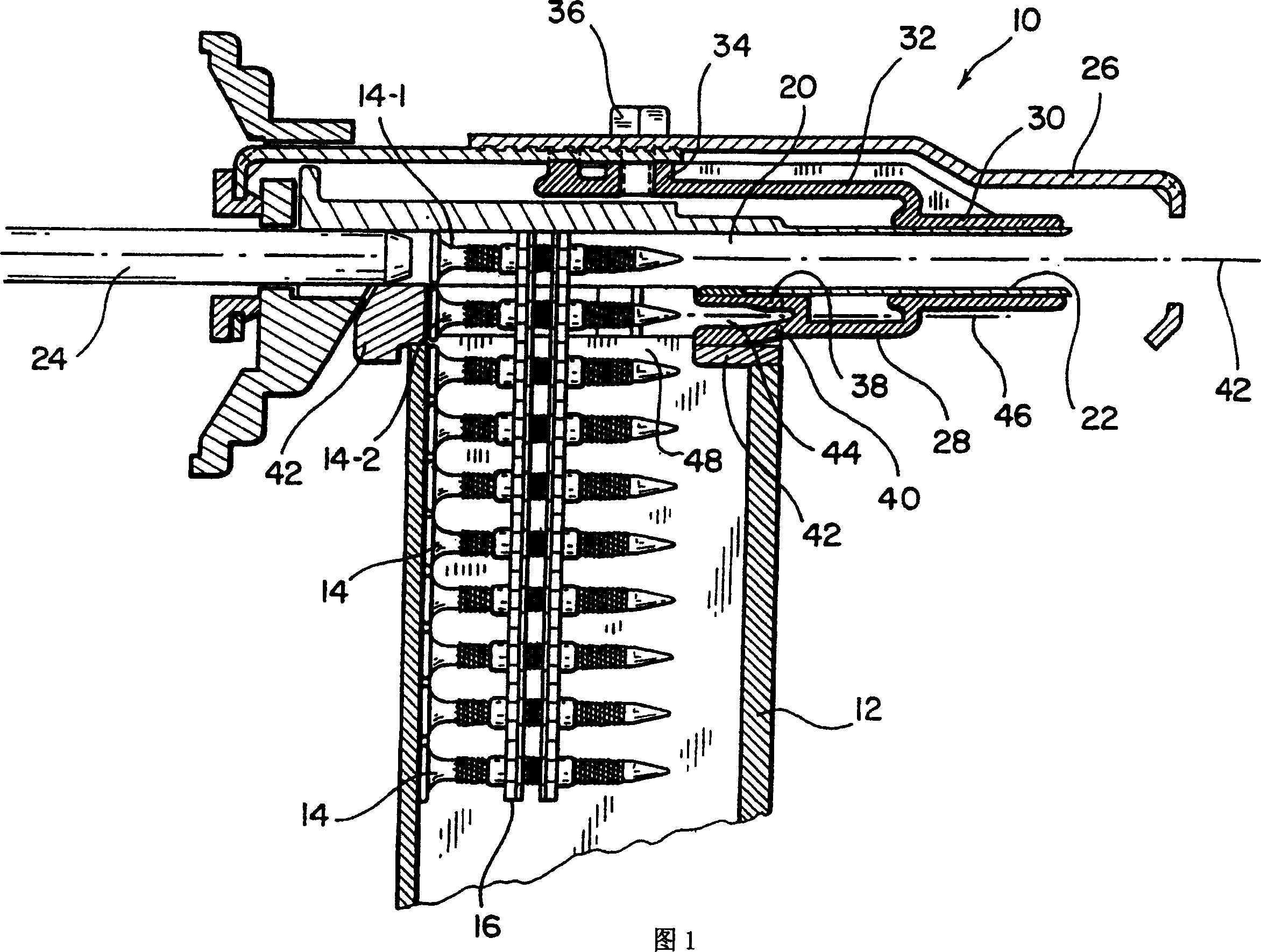

[0015] Figure 1 is a partial vertical cross-sectional view of a fastener driving tool showing a new and improved support device constructed in accordance with the teachings and principles of the present invention and in contact with a workpiece engaging probe or workpiece is operatively coupled to a workpiece, shown in the figure as the tool engages the probe or workpiece contact and the support fixedly mounted thereon as the tool moves forward toward the substrate to be driven into the fastener Move backwards to the previous situation.

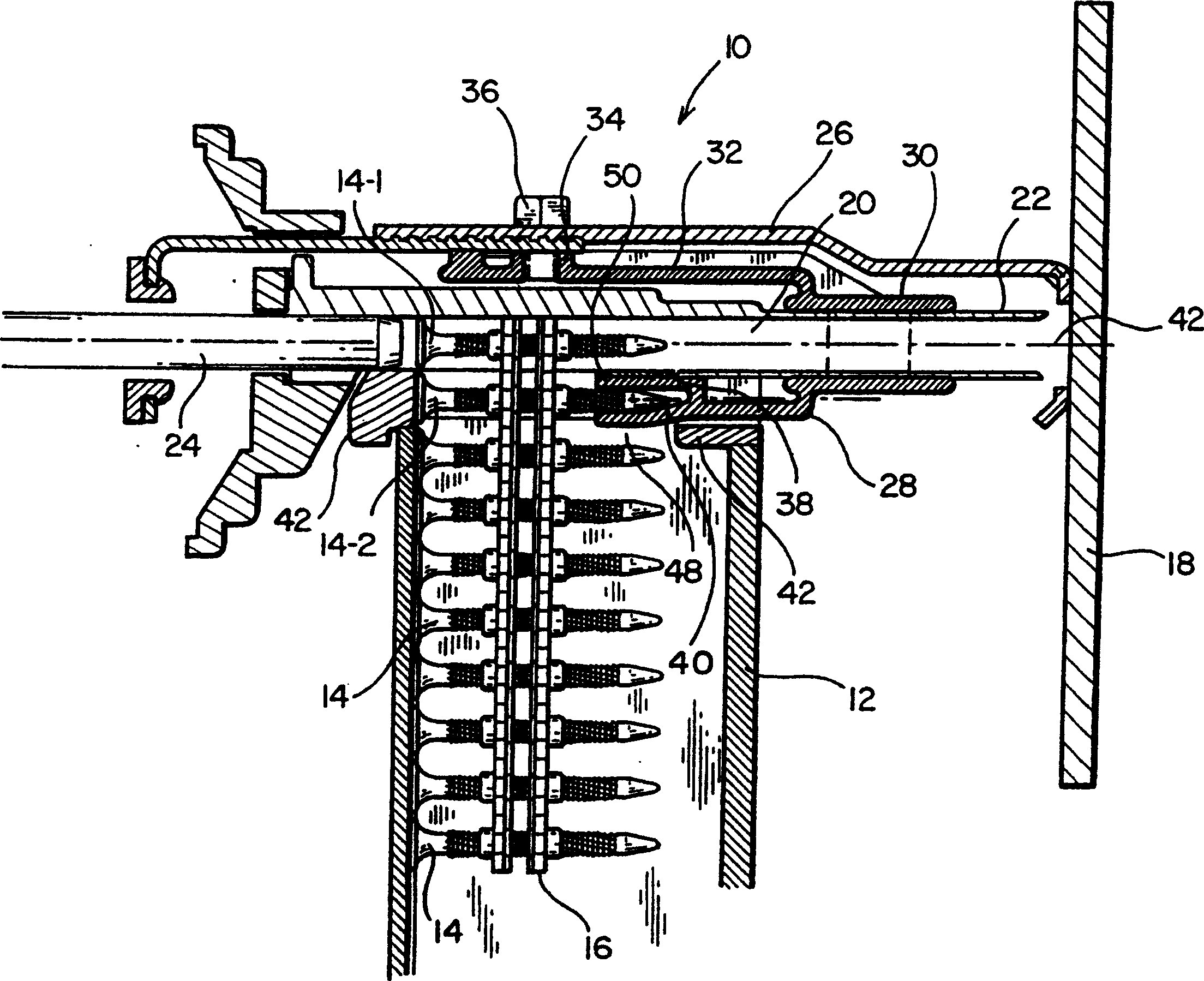

[0016] figure 2 is a partial vertical cross-sectional view similar to FIG. 1 showing a fastener driving tool having new and improved suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com