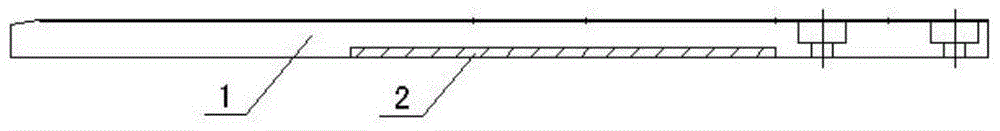

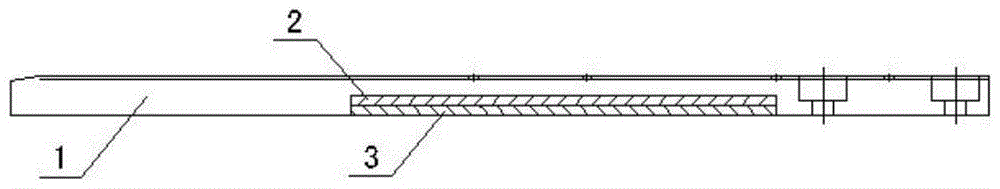

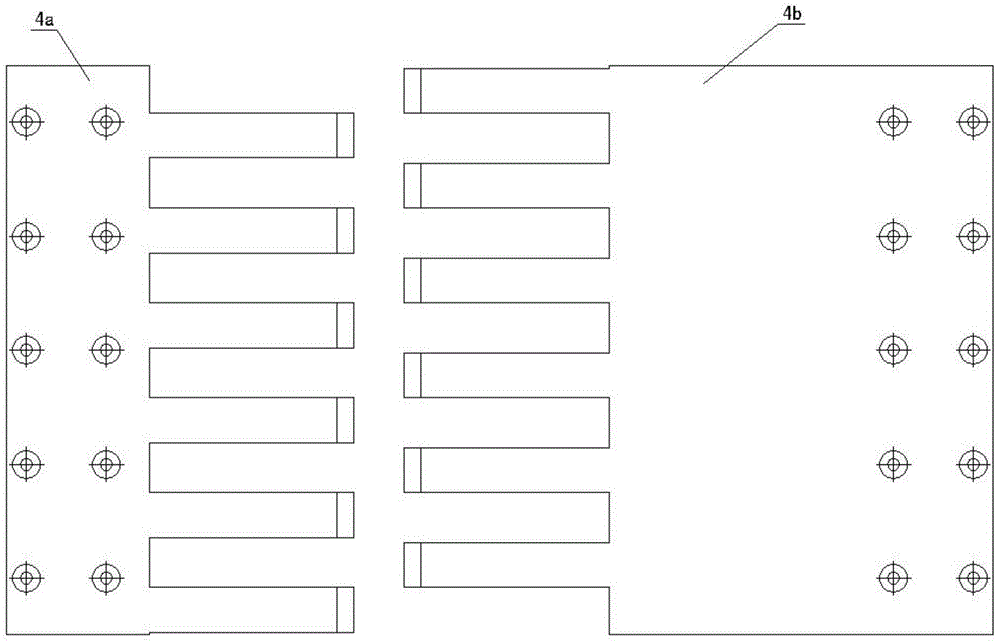

A self-adaptive multi-directional displacement composite structure telescopic device for highway bridges

A composite structure and expansion device technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as damage to expansion joints, achieve comfortable driving, simplify construction methods and technical requirements, and facilitate installation and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Get raw materials by weight:

[0041] Ultra-high molecular weight polyethylene UHMWPE is 95 parts,

[0042] 2.5 parts of carbon black, 1 part of carbon fiber, and 1.5 parts of mica powder;

[0043] All the raw materials are fully stirred and mixed evenly, and hot-pressed and formed respectively as the bottom layer of the surface layer, and the elastic polymer adhesive, metal anchor bolt fasteners and the steel plate cushion layer are superimposed and assembled in layers.

Embodiment 2

[0045] Get raw materials by weight:

[0046] Ultra-high molecular weight polyethylene UHMWPE is 90 parts,

[0047] High-density polyethylene HDPE is 3 parts,

[0048] Polyethylene glycol PEG is 2 parts,

[0049] 2 parts of carbon black, 3 parts of glass fiber;

[0050] All raw materials are fully mixed and hot-pressed as the surface layer; the bottom layer is made of cast polyurea products;

[0051] Firstly, the elastic polymer adhesive and metal anchor bolt fasteners are used to superimpose the surface layer and the steel plate cushion layer in layers to form a composite body, and then the raw materials of the bottom surface layer and the composite body are cast and compounded.

Embodiment 3

[0053] Get raw materials by weight:

[0054] Ultra-high molecular weight polyethylene UHMWPE is 90 parts,

[0055] High-density polyethylene HDPE is 4 parts,

[0056] 2 parts of polypropylene PP, 1 part of carbon black, 2 parts of glass fiber and 1 part of quartz powder;

[0057] All raw materials are fully mixed and hot-pressed as the surface layer, and the bottom layer is made of cast polyurethane products;

[0058] Firstly, the elastic polymer adhesive and metal anchor bolt fasteners are used to superimpose the surface layer and the steel plate cushion in layers to form a composite body, and then the raw materials of the bottom surface layer and the composite body are cast and compounded.

[0059] The invention is adapted to multi-directional deformation and high weather resistance and high wear resistance by virtue of the material properties of high molecular polymer. In addition to having the vertical stiffness and compression deformation of ordinary expansion joints, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com