Production of activated carbon from dregs from longoze saponin production

A technology for preparing activated carbon and turmeric saponin, which is applied in the field of preparing activated carbon, can solve the problems of affecting product yield and quality, large amount of medicine required for impregnation, poor solution wettability, etc., and achieves strong ability to remove or separate certain substances, Effect of improving activation performance and improving surface chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention uses turmeric saponin production residue to prepare the step of the method for gac comprising:

[0024] (1) Place the turmeric saponin production residue in a carbonization furnace, and carbonize at a temperature of 250-350°C for 0.5-1 hour;

[0025] (2) putting the product obtained in step (1) into ZnCl with a weight concentration of 20% to 60% 2 Soaked in the solution of 12~24 hours, the weight solid-liquid ratio of step (1) gained product and solution is 1: 1.5~3;

[0026] (3) Place it in an activation furnace, and activate it for 1-2 hours at a temperature of 500-600°C;

[0027] (4) Boil with about 20% sodium hydroxide for 20 minutes, then wash with water until the pH value is 7-8;

[0028] (5) Dried in a drying oven at 100-150°C to obtain a finished product.

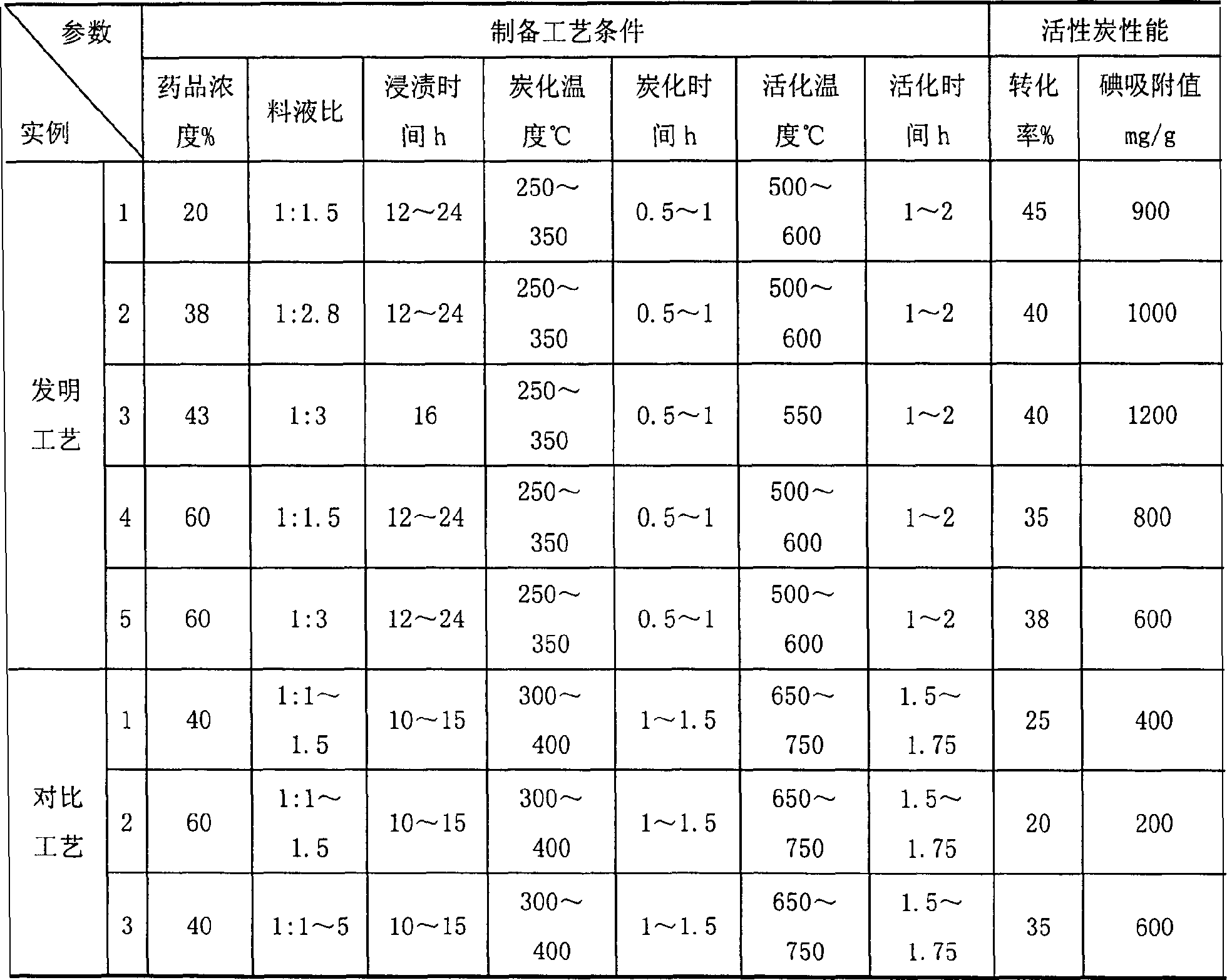

[0029] The specific embodiments 1-5 of the method of the present invention are shown in Table 1.

[0030] Contrast process scheme 1,2 in table 1 is the disclosed method of Chinese pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com