A kind of hemp/high-strength polyester reinforced composite fabric material and preparation method thereof

A technology of high-strength polyester and composite fabrics, applied in the direction of fabrics, chemical instruments and methods, textiles, etc., can solve the problems of low comprehensive performance, poor user safety and high preparation cost, and achieve good wettability, good strength performance, and special-shaped structure. Excellent effect for curved fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

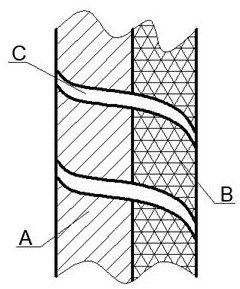

[0045] In order to more clearly illustrate the technical solutions in the embodiments of the present invention, the drawings that need to be used in the description of the embodiments will be briefly introduced below. Obviously, the drawings in the following description are only some embodiments of the present invention. For those skilled in the art, other drawings can also be obtained based on these drawings without creative effort.

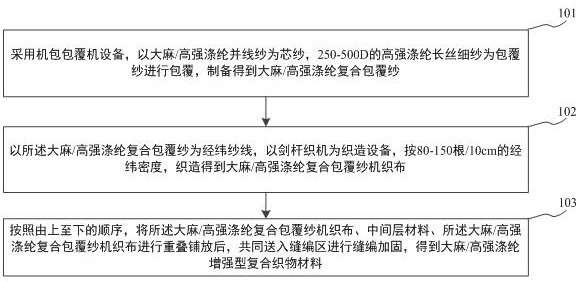

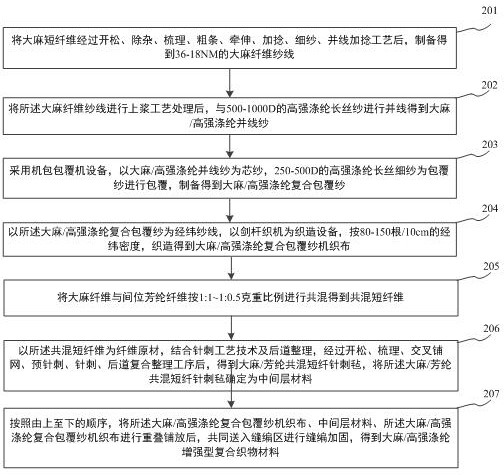

[0046] figure 1 It is a method flowchart of a method for preparing a hemp / high-strength polyester reinforced composite fabric material shown according to an exemplary embodiment, such as figure 1Shown, the preparation method of this hemp / high-strength polyester reinforced composite fabric material comprises:

[0047] Step 101: Using machine wrapping machine equipment, hemp / high-strength polyester doubling yarn is used as the core yarn, and 250-500D high-strength polyester filament spun yarn is used as the covering yarn for covering to prepare h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com