C/SiC-ZrC-TiC-Cu composite material and preparation method thereof

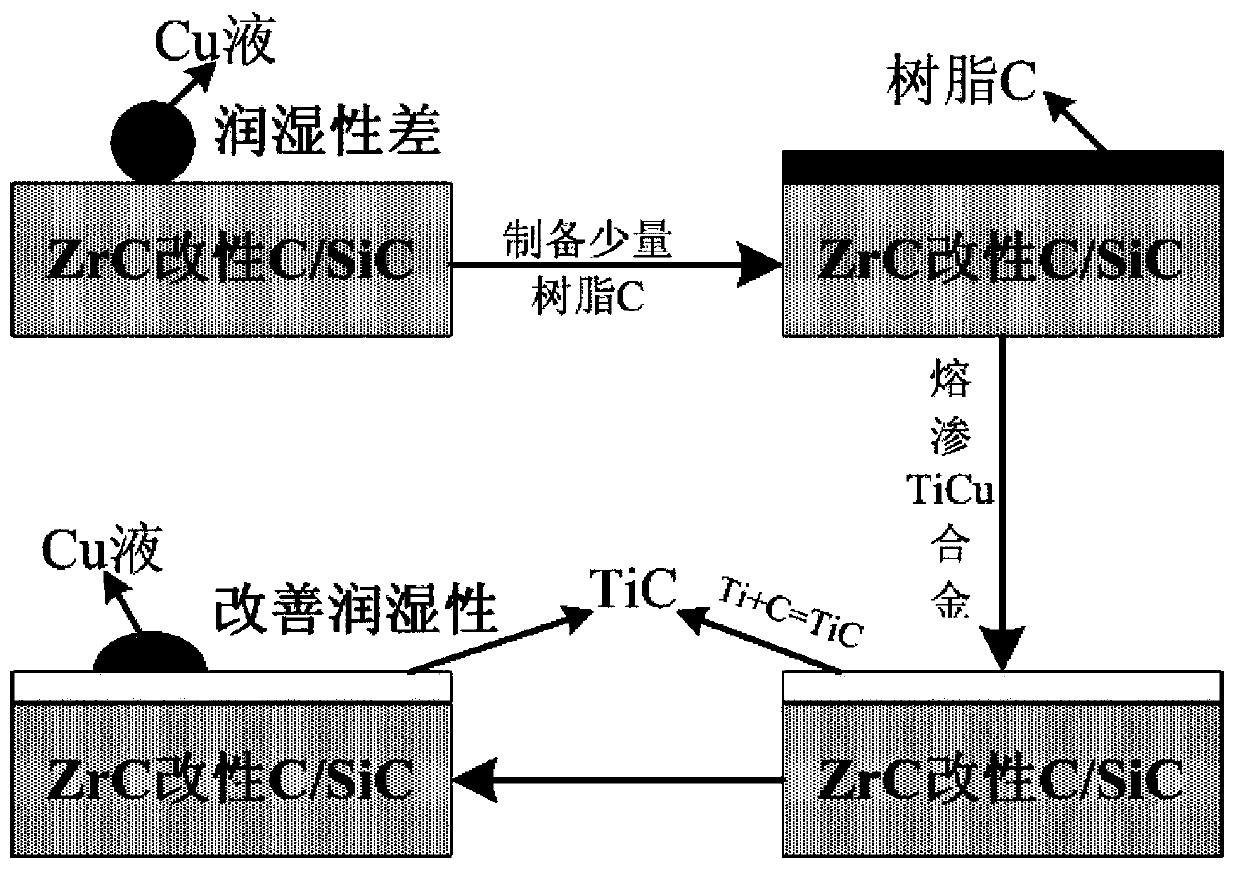

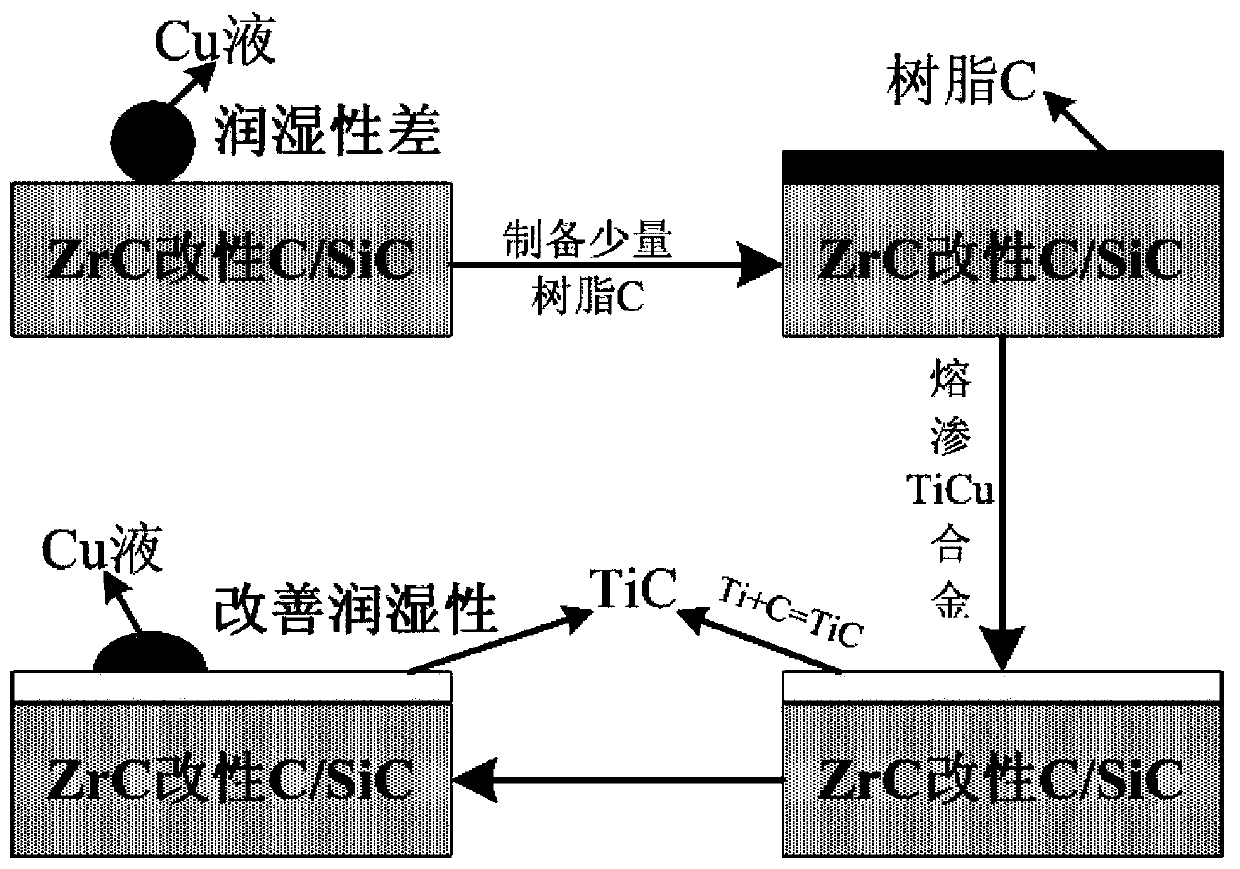

A sic-zrc-tic-cu, composite material technology, applied in the field of C/SiC-ZrC-TiC-Cu composite material and its preparation, can solve the problem of high infiltration equipment requirements, affecting Cu wettability, and insufficient reaction and other problems to achieve the effect of improving ablation resistance, improving wettability, and overcoming poor wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention provides a kind of preparation method of C / SiC-ZrC-TiC-Cu composite material in the first aspect, and this preparation method comprises the following steps:

[0036] (1) Provide C / SiC-ZrC composite materials for subsequent preparation steps

[0037] In this step, the C / SiC-ZrC composite material can be prepared by existing methods, but it is preferable to ensure that the density of the C / SiC-ZrC composite material is 1.2 to 1.7 g / cm 3 , for example, can be 1.2g / cm 3 , 1.3g / cm 3 , 1.4g / cm 3 , 1.5g / cm 3 , 1.6g / cm 3 , 1.7g / cm 3 . The C / SiC-ZrC composite material used as the skeleton of the subsequent infiltration Ti-Cu alloy should have certain mechanical properties and also have certain porosity. If the density is too high, the mechanical properties are good but the porosity is small; if the density is too small, the porosity is large but Insufficient mechanical properties, the present invention preferably has 1.2~1.7g / cm 3 The C / SiC-ZrC comp...

Embodiment 1

[0053] S1. Preparation of C / SiC-ZrC composite material

[0054] Put the carbon fiber needle-punched preform into the CVI-C furnace, and pass C 3 h 8 Mixed gas with Ar, deposited for 80 hours out of the furnace, then loaded into the CVI-SiC furnace, under vacuum and 1050 ° C, passed CH 3 Cl 3 Si, H 2 Mixed gas with Ar, deposited for 120 hours and released from the furnace to obtain a carbon fiber needle-punched preform with a double-layer composite interface layer of PyC on the inner layer and SiC on the outer layer, and then subjected to high temperature treatment at 1700 ° C for 2 hours.

[0055] Using silicon-zirconium ceramic precursor impregnating agent, vacuum impregnation-pressure curing-1000°C high-temperature pyrolysis was performed on the high-temperature-treated carbon fiber needle-punched preform to prepare a C / SiC-ZrC composite material with a density of 1.31g / cm 3 .

[0056] S2. Preparation of C / SiC-ZrC composite material with C matrix

[0057] Aminophenol a...

Embodiment 2

[0062] Preparation method is basically the same as Example 1, except that:

[0063] In S2, a C / SiC-ZrC composite with a C matrix at a weight gain of 5% was ensured.

[0064] After infiltration, the obtained C / SiC-ZrC-TiC-Cu sweating cooling material has a density of 3.09g / cm 3 , the bending strength is 186MPa, and the line ablation rate of acetylene flame ablation for 60s is 0.0008mm / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com