Metallic iron and aluminum oxide ceramic composite material with high temperature resistance and wear resistance and preparation method of metallic iron and aluminum oxide ceramic composite material

A technology of alumina ceramics and wear-resistant metals, which is applied in the field of high-temperature and wear-resistant metal iron and alumina ceramic composite materials and its preparation, can solve problems such as poor wettability, and achieve low cost, pure phase interface, and good interface bonding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

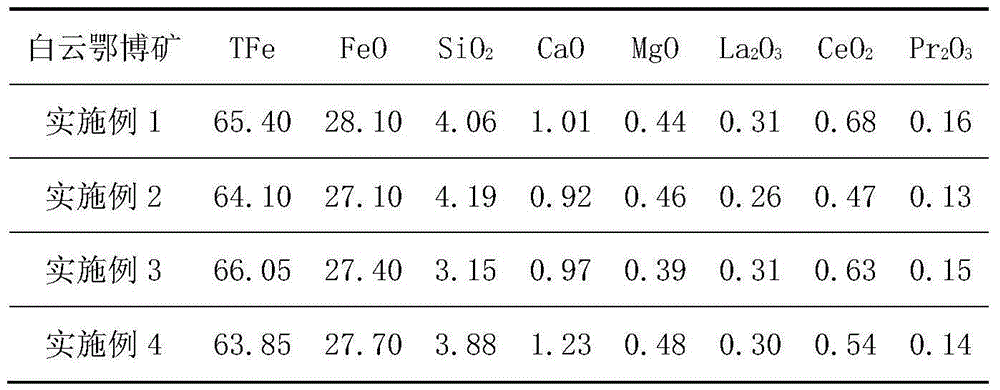

[0048] (1) Ingredients: Sieve to take dolomite, Al 2 o 3 Powder and activated carbon powder less than 74 micron materials are dried, the chemical analysis of Baiyun Obo mine is shown in Table 1, according to Baiyun mine, Al 2 o 3 The weight ratio of powder and carbon powder is 74 parts, 15 parts and 11.5 parts respectively, and the prepared powder is added into polyethylene glycol and absolute ethanol in a volume ratio of 2:1 to prepare a dispersant. 100cm 3 Add 83ml of dispersant to the material, moisten and mix in the ball mill for 48 hours, the ball-to-material ratio is 3:1, the speed of the ball mill: 100 rpm, and the material is mixed evenly; (2) tableting: take out the above-mentioned moistened and mixed ingredients Add 5% polyvinyl alcohol binder in weight percentage, according to every 10cm 3 Add 1.5ml of binder to the material and mix it evenly, then carry out tablet molding, the molding pressure is 5MPa, the holding time is 5 minutes, and pressed into a cylinder ...

Embodiment 2

[0053] (1) Ingredients: Sieve to take dolomite, Al 2 o 3 Powder and activated carbon powder less than 74 micron materials are dried, the chemical analysis of Baiyun Obo mine is shown in Table 1, according to Baiyun mine, Al 2 o 3 The weight ratio of powder and carbon powder is 70 parts, 21 parts and 10 parts respectively, and the prepared powder is added into polyethylene glycol and absolute ethanol in a volume ratio of 2:1 to prepare a dispersant. 100cm 3 Add 83ml of dispersant to the material, moisten and mix in the ball mill for 24 hours, the ball-to-material ratio is 10:1, the speed of the ball mill: 200 rpm, and the material is mixed evenly; (2) tableting: take out the above-mentioned moistened and mixed ingredients Add 5% polyvinyl alcohol binder in weight percentage, according to every 10cm 3 Add 1.5ml of binder to the material, mix it well, and then press it into a tablet. The molding pressure is 30MPa, and the holding time is 5 minutes, and it is pressed into a cy...

Embodiment 3

[0058] (1) Ingredients: Sieve to take dolomite, Al 2 o 3 Powder and activated carbon powder less than 74 micron materials are dried, the chemical analysis of Baiyun Obo mine is shown in Table 1, according to Baiyun mine, Al 2 o 3 The weight ratio of powder and carbon powder is 72 parts, 18 parts and 10.5 parts respectively, and the prepared powder is added to the volume ratio of glycerin and absolute ethanol to prepare a dispersant at a ratio of 2:1. 3 Add 83ml of dispersant to the material, moisten and mix in the ball mill for 36 hours, the ball-to-material ratio is 8:1, the speed of the ball mill: 250 rpm, and the material is mixed evenly; (2) tableting: take out the above-mentioned moistened and mixed ingredients Add 5% polyvinyl alcohol binder in weight percentage, according to every 10cm 3 Add 1.5ml of binder to the material and mix it evenly, and then press it into a tablet. The molding pressure is 15MPa, and the holding time is 1 minute, and it is pressed into a cyli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com