Chromatographic separatory

A technology for chromatographic separation and switching devices, which is applied in the field of chromatographic separation devices, can solve the problems of expensive chromatographic separation devices, and achieve the effect of reducing pressure specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

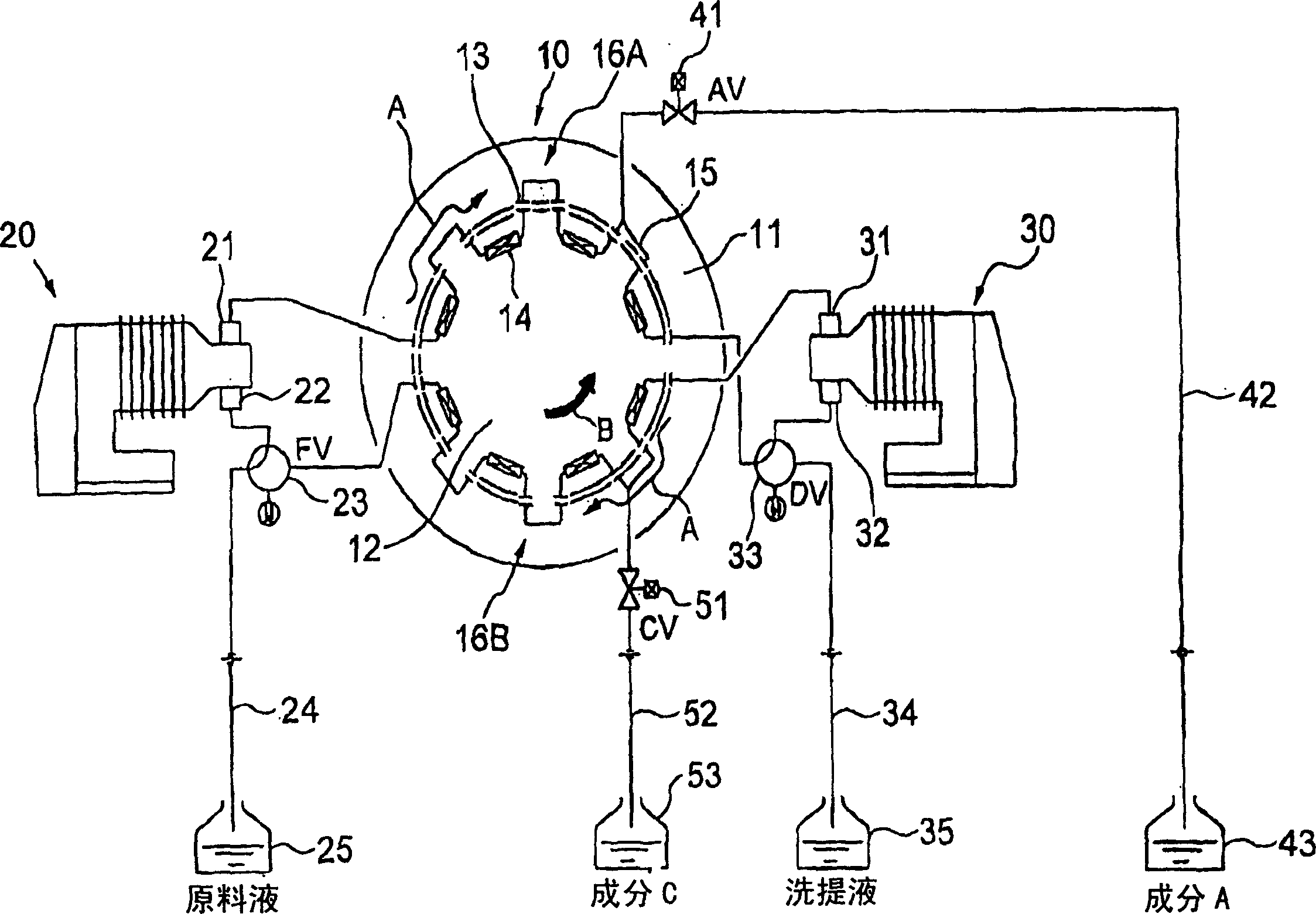

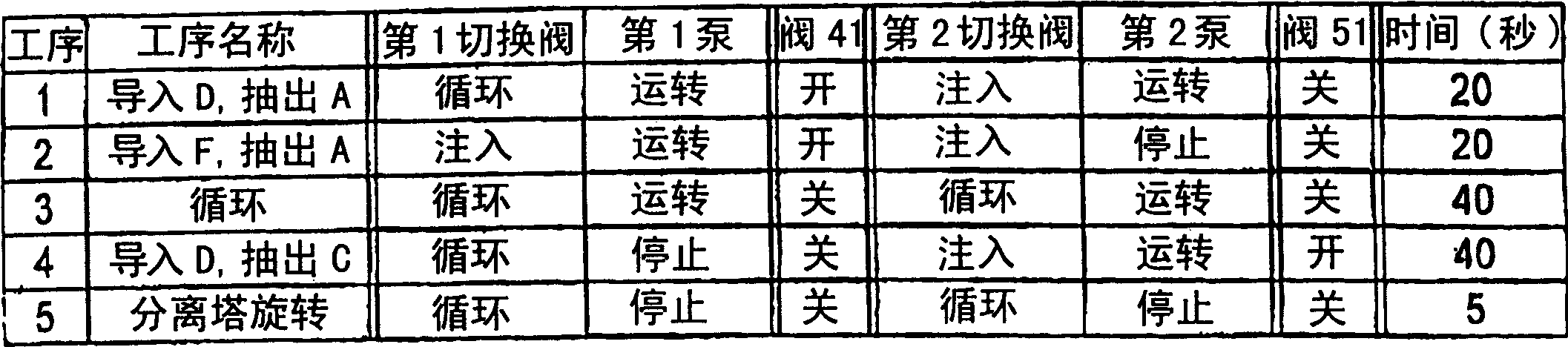

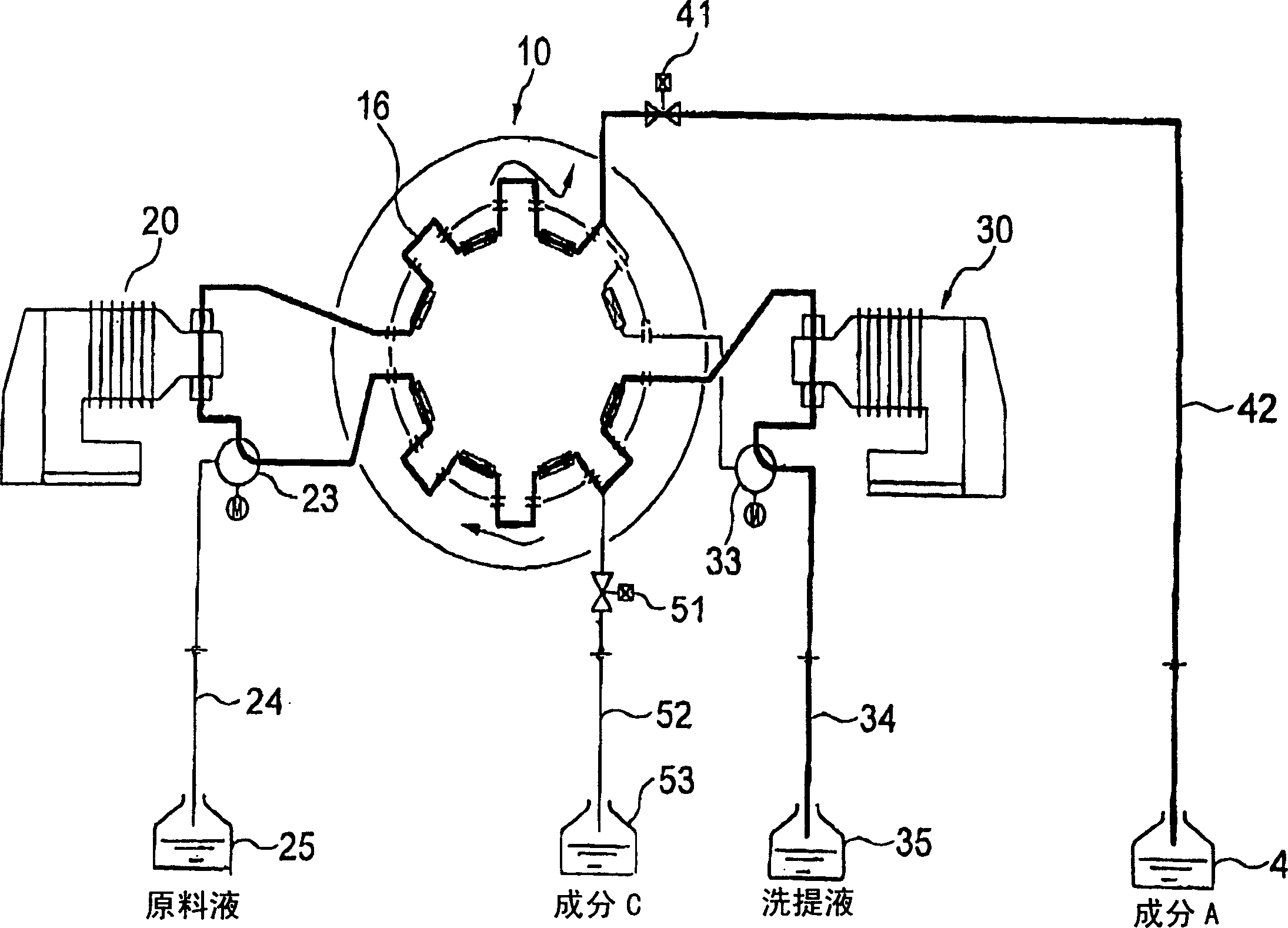

[0025] Embodiments of the present invention will be described in detail below with reference to the drawings. figure 1 It is a model block diagram of the intermittent moving layer chromatography separation device (hereinafter referred to as the separation device) in the embodiment of the present invention. This separation device has two pumps 20, 30, and is provided with a switch to select any one of the circulation mode in which each pump is inserted into the circulation path and the liquid injection mode connected to the liquid injection pipe on the suction port of each pump. Valve 23, 33.

[0026] In this separation device, in one process, by selecting the first and second switching valves 23, 33 to the circulation mode, the eight columns 14 filled with adsorbent pass through the nozzles 13 of the rotary valve 10 and the first and second pumps. 20 and 30 form a circulation path 16 connected in a circular shape. The liquid flow in the circulation path 16 is in the directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com