Automobile exhaust manifold air inlet connector installation hole drilling tool

A technology for air intake joints and automobile exhaust, applied in positioning devices, clamping devices, manufacturing tools, etc., can solve problems such as increasing the cost of cylinder equipment, affecting drilling accuracy, and piston rod vibration, so as to achieve easy implementation and reduce costs and the effect of occupying space and preventing severe shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

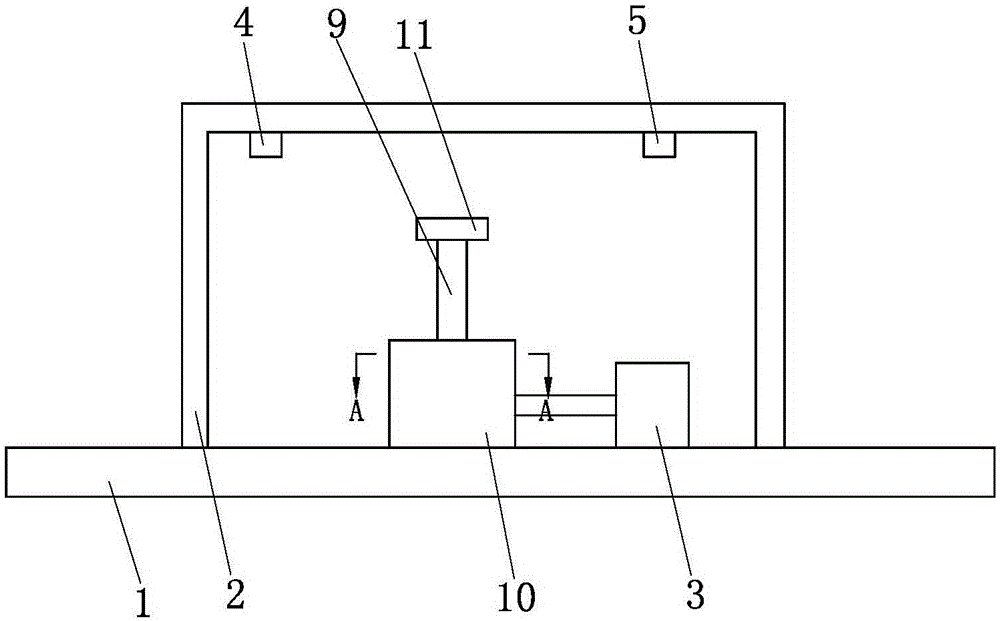

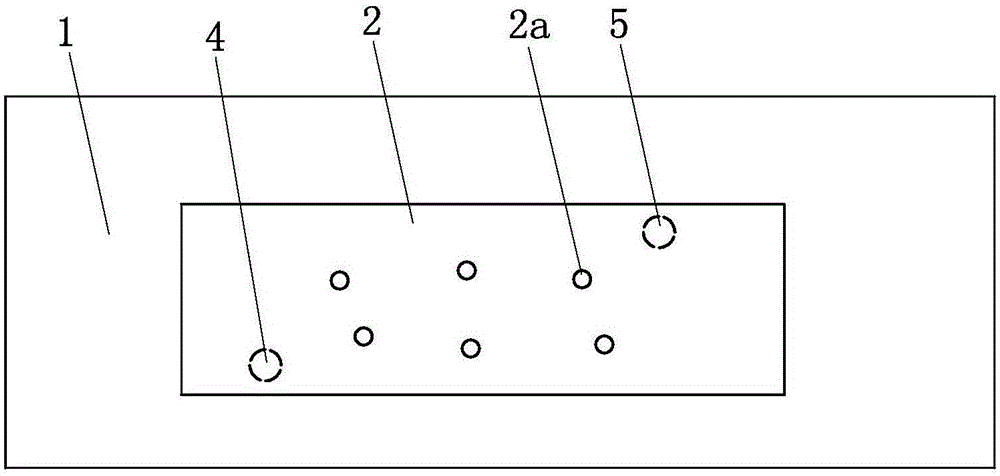

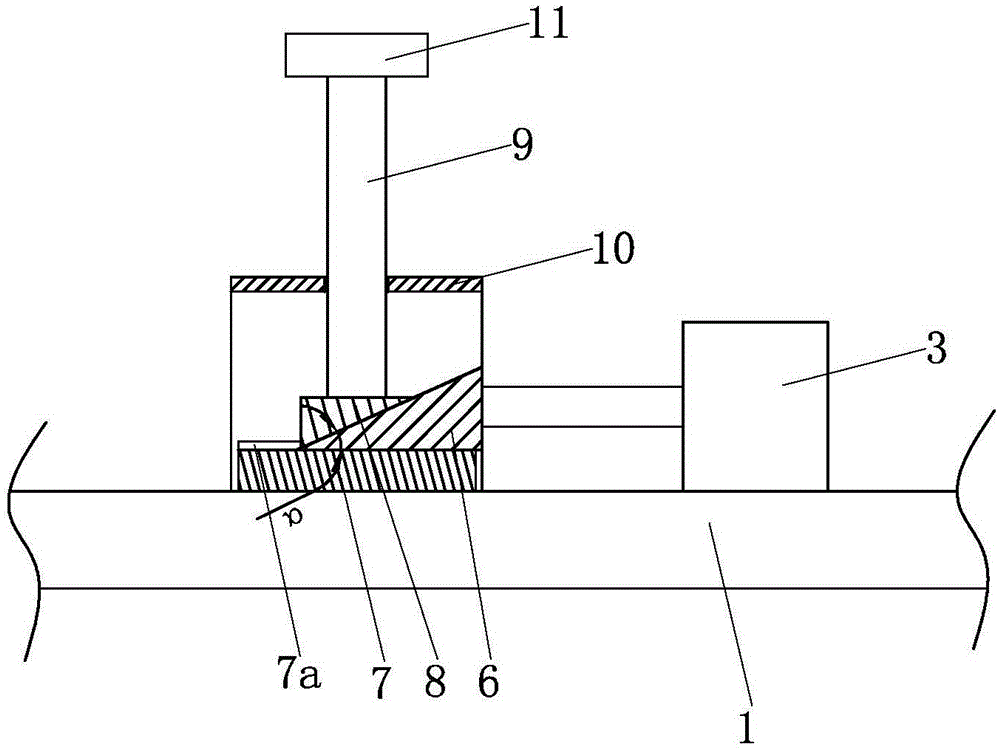

[0015] Such as figure 1 , 2 And shown in 3, a kind of installation hole drilling tool of automobile exhaust manifold inlet joint mainly consists of horizontal base plate 1, door beam 2, cylinder 3, first positioning pin 4, second positioning pin 5, lower wedge-shaped block 6. The guide block 7, the upper wedge block 8, the vertical lifting rod 9, the door-shaped part 10 and the tight plate 11 are formed. Wherein, the horizontal base plate 1 is a rectangular plate, and its material is Q235, and the horizontal base plate 1 is fixed on the workbench of the vertical drilling machine through T-bolts and a pressure plate. The upper surface of the horizontal base plate 1 is vertically fixed with a portal beam 2 and a cylinder 3, wherein the lower ends of the two vertical sides of the portal beam 2 are fixed to the upper surface of the horizontal base plate 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com