Environmental protection artificial leather and its manufacturing method

A technology of artificial leather and manufacturing method, applied in textiles and papermaking, etc., can solve problems such as pollution of the environment by organic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

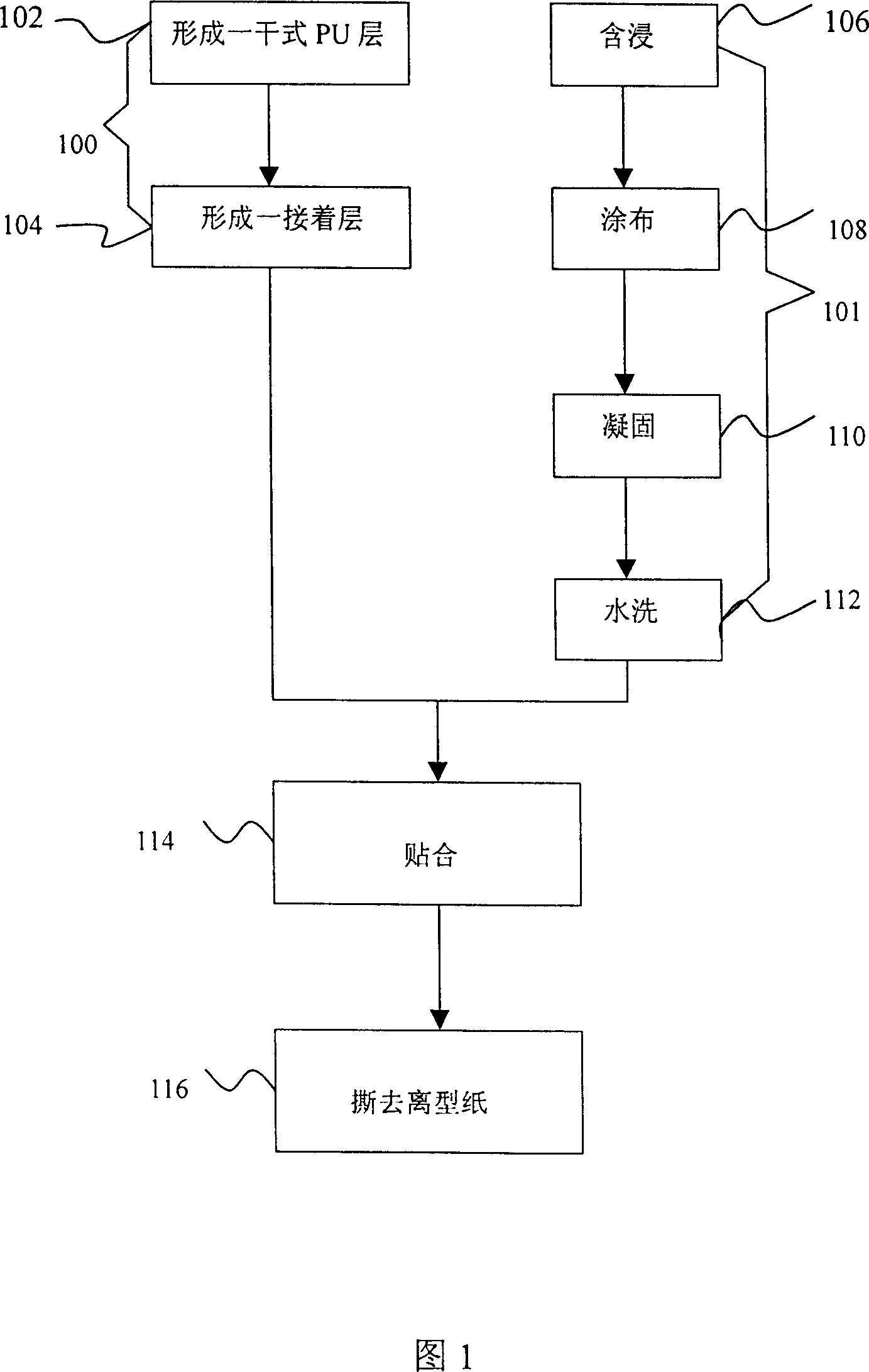

Method used

Image

Examples

Embodiment

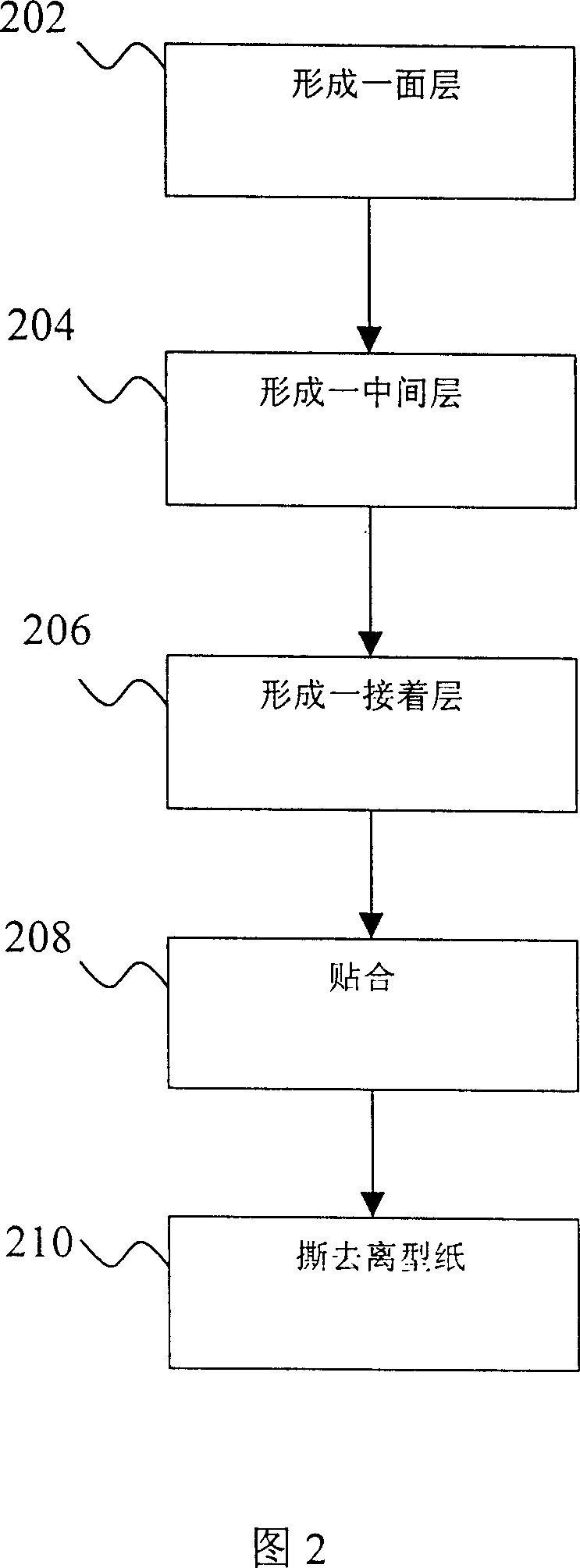

[0034] A solvent-free polyurethane resin coating with a polyurethane resin solid content of 50% by weight is coated on a release paper, wherein the viscosity of the resin coating is controlled at 1300cps / 30°C. This water-soluble polyurethane resin paint was dried in an oven at 120° C. to form one surface layer.

[0035] Apply a layer of high-solid polyurethane resin coating on the dried surface layer, wherein the coating contains polyurethane resin with a solid content of 98% and additives (interface agent, hardener and colorant, etc.) mixed in a 5:1 manner, And its viscosity is controlled at 25000cps / 30℃. The high-solid polyurethane resin coating was dried and hardened in an oven at 160° C. to form an intermediate layer.

[0036] A layer of solvent-free polyurethane resin coating added with water-based bridging agent is coated on the hardened intermediate layer to form an adhesive layer. Then use an oven to dry the solvent-free polyurethane resin coating of the adhesive lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com