Distributor for exhaust gas turbine with axial flow

An exhaust gas turbine, axial flow technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of components stuck and self-locking, etc., to achieve simple adjustment force, simple and reliable guide vane adjustment, and work reliability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

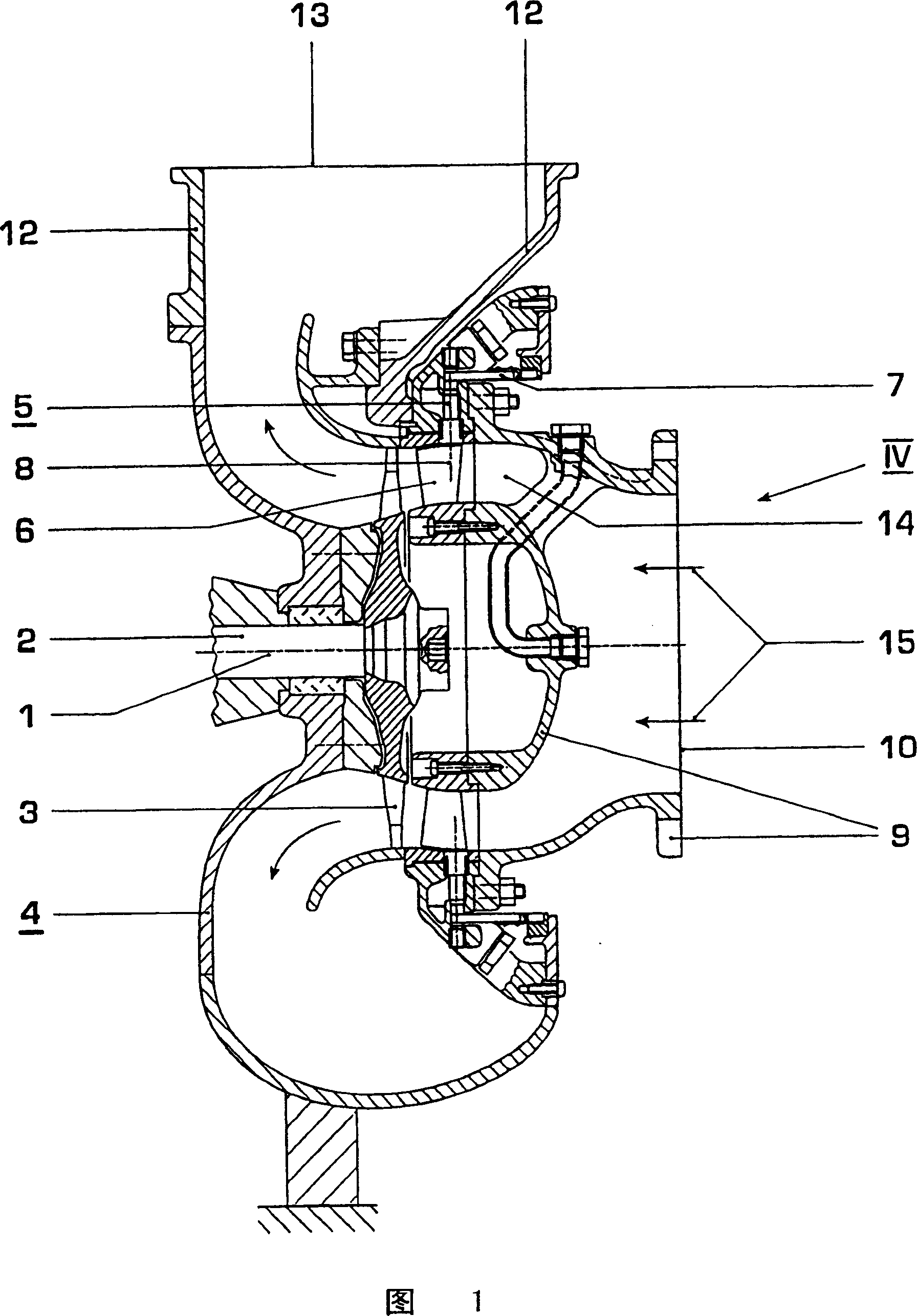

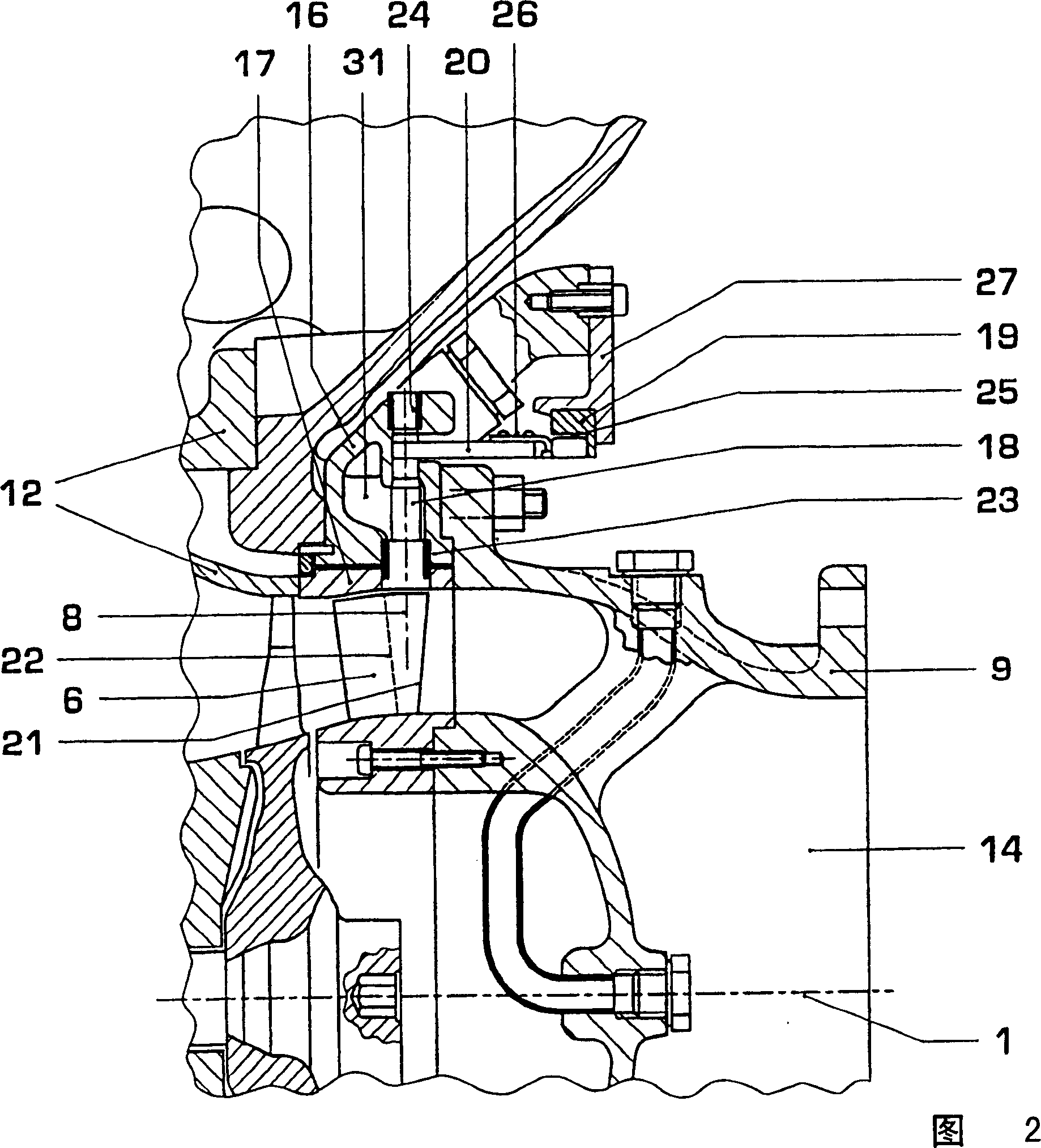

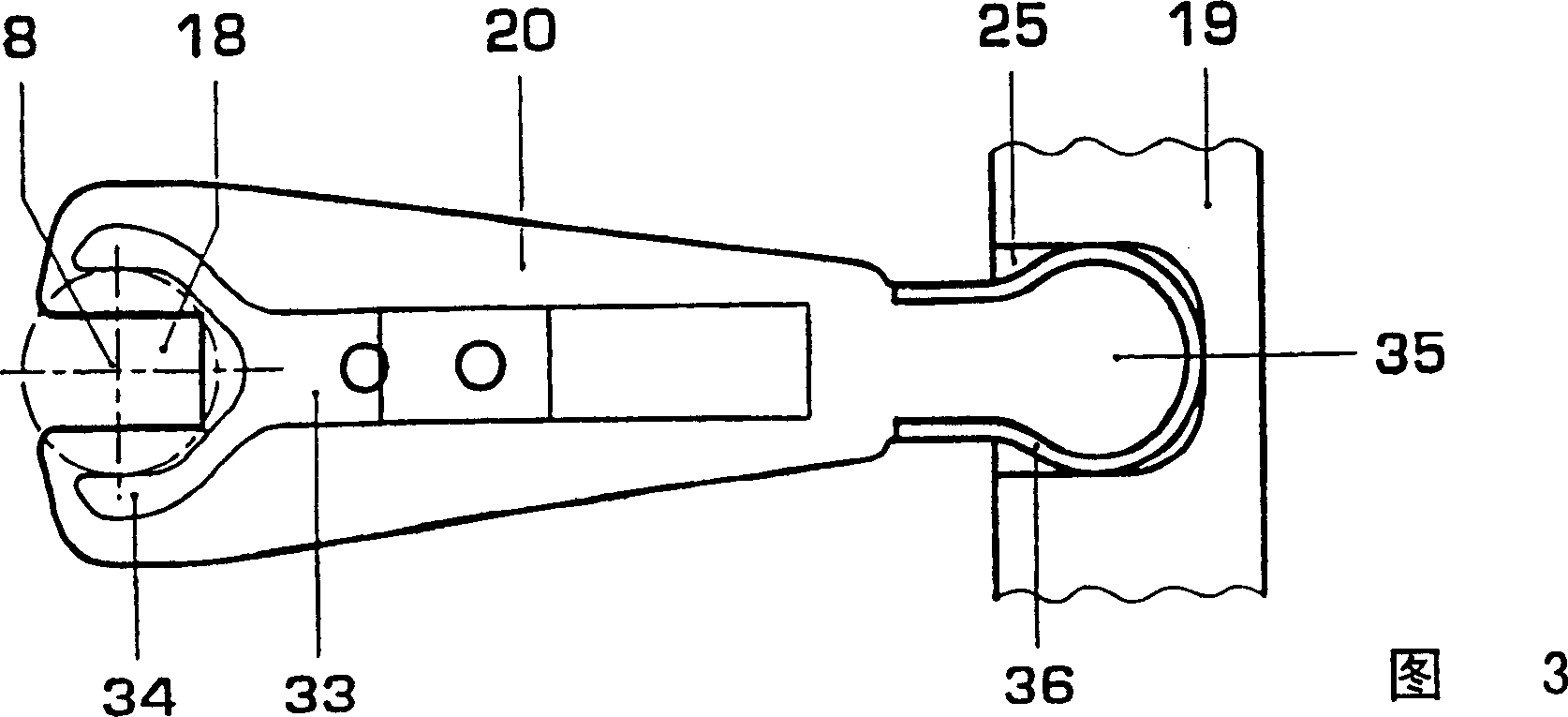

[0019] In all figures, the same symbols refer to parts having the same function. FIG. 1 shows only the turbine part of the exhaust gas turbocharger with the exhaust gas turbine. The exhaust gas turbine has a rotor 2 rotatable about an axis 1 with a turbine wheel and rotor blades 3 fastened thereto, as well as a turbine housing 4 and an axisymmetrically arranged rotor with adjustable guide vanes 6 to the turbine axis 1 ring and a spout 5 of a rotating device 7. By rotating them about a radially extending axis 8 , the guide vanes 6 can each be pivoted into any angular position between two end positions.

[0020] The rotor 2 leads airtight from the turbine housing 4 to a bearing point (not shown) and is mounted on the left-hand end in FIG. 1 with a compressor wheel, not shown in FIG. 1 .

[0021] The turbine housing 4 comprises an inlet housing 9 with an axisymmetrically arranged inlet 10 and an outlet housing 12 with a radially oriented outlet 13 . A flow channel 14 defined b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com