Handheld tin soldering device

A hand-held, soldering technology, applied in the direction of tin feeding device, auxiliary device, welding equipment, etc., can solve the problems of waste, difficult handling of tin liquid, difficult control of the amount of tin wire, that is, the feeding amount, etc., to achieve safe and convenient use process, The effect of convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

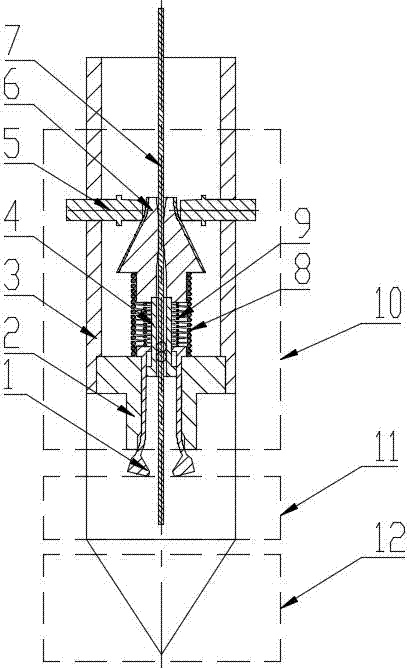

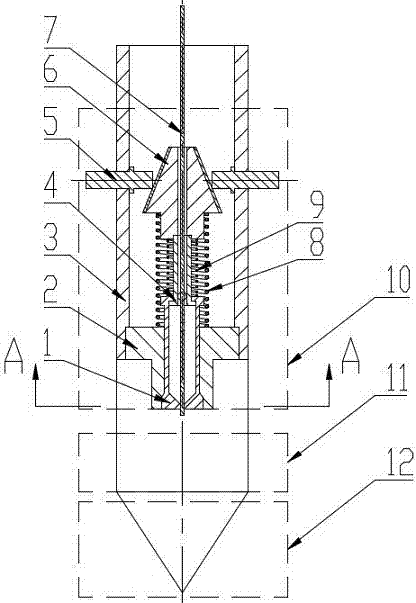

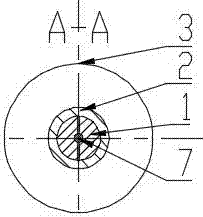

[0023] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 3 , a hand-held soldering device, including a feeding device 10, a heating device 11, and a tin outlet device 12, characterized in that: the feeding device 10 includes a lower chuck 1, a locking hoop 2, a heat insulation shell 3, an inlet For the piston 4, button 5, upper chuck 6, return spring 8 and feed spring 9, the lower chuck 1 is composed of two scapular elastic hollow heads and a cylindrical hollow tail. There is a step on the cylindrical hollow tail, so The elastic hollow heads of the two shoulder blades can be divided into two parts (such as image 3 shown), can enter and exit the locking hoop 2, when the elastic hollow heads of the two shoulder blades enter the locking hoop 2, the tin wire 7 will be clamped; the upper chuck 6 is an elastic tapered hollow chuck, The upper chuck 6 is fixedly connected to the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com