Fold-out exterior vehicle part

A folding, vehicle technology, applied in the direction of vehicle parts, superstructure, superstructure sub-assembly, etc., can solve the problems of surface defects in the casting process and the inability to obtain surface processing, and achieve weight saving, light weight, and high-quality surface processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention relates to outwardly folding exterior vehicle parts intended to withstand pressure. In the present application, an exterior vehicle part means a vehicle part that is wholly or partially visible when the vehicle is viewed from the outside. In a preferred embodiment of the invention, the exterior vehicle part is a grille panel and the vehicle is a heavy truck.

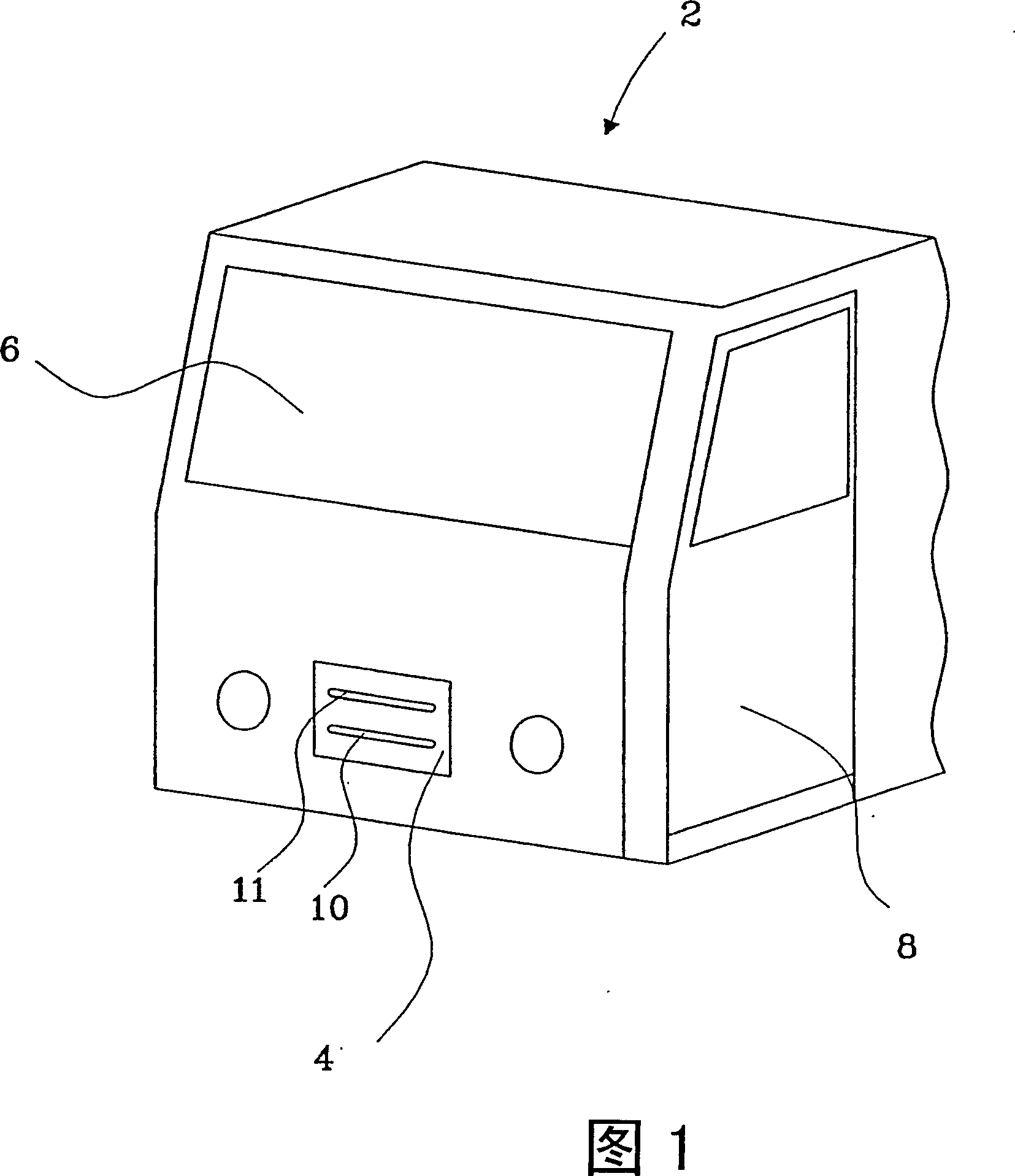

[0017] Fig. 1 is a schematic diagram of a cab 2 of a heavy-duty vehicle, especially a truck, where the cab 2 includes an outwardly folding grille panel 4, a windshield glass 6, and two doors (only drawn) that are respectively arranged on one side of the cab 2 One comes out, namely the left door 8). When the grille panel 4 is in the retracted state, it acts as a part of the vehicle body. The grille member 4 may optionally be provided with one or more channels 10, 11 through which cooling air is directed to a radiator (not shown) located under the cab.

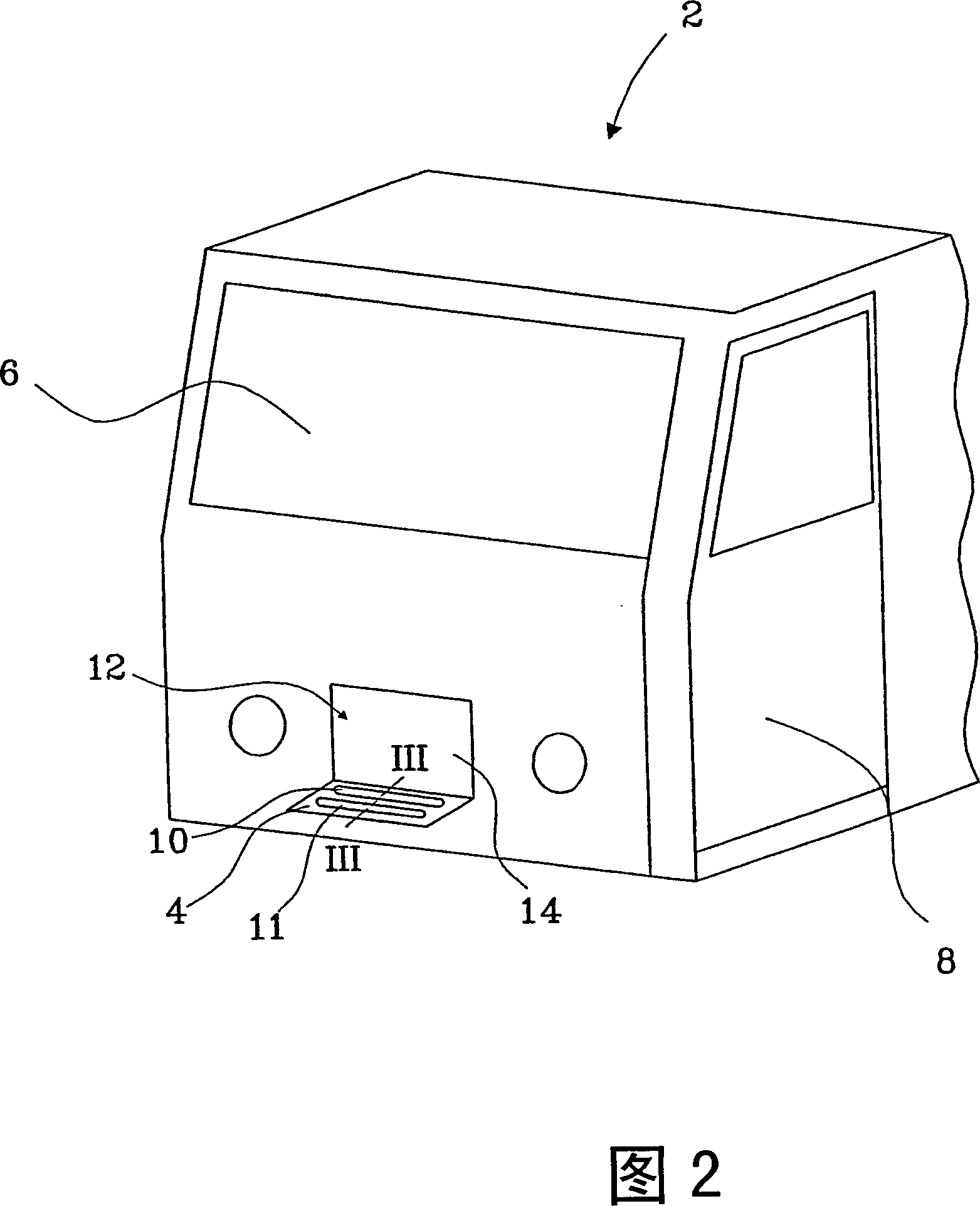

[0018] Fig. 2 is a schematic view of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com