Blind

A technology of shutters and shutters, applied in the field of shutters, can solve the problems of high price, management, transportation trouble, volume increase, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

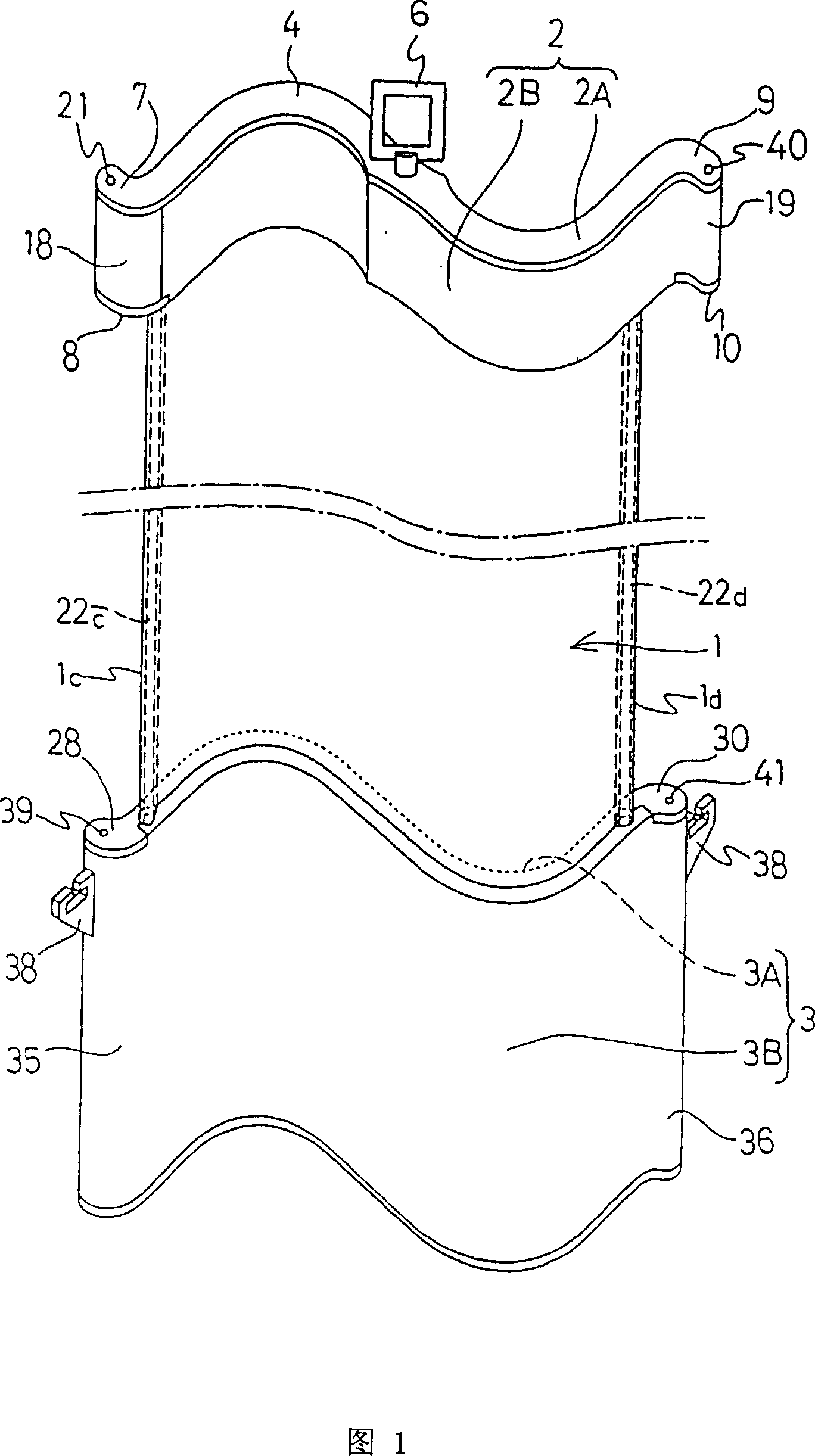

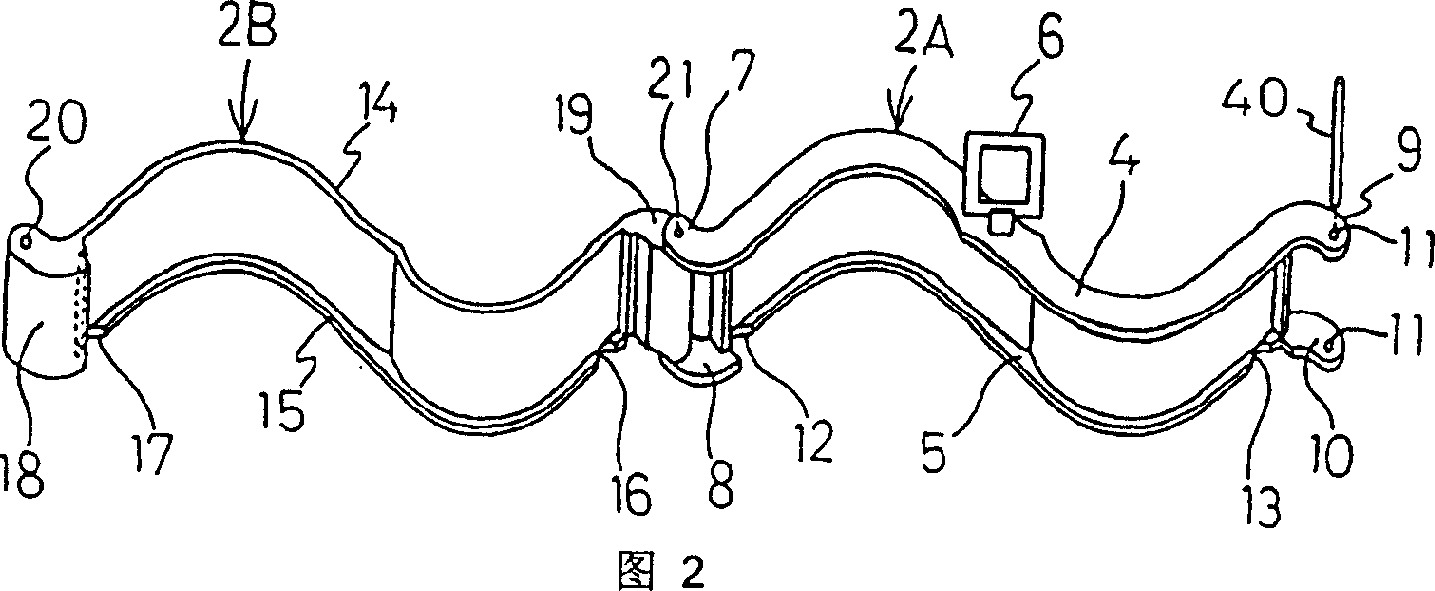

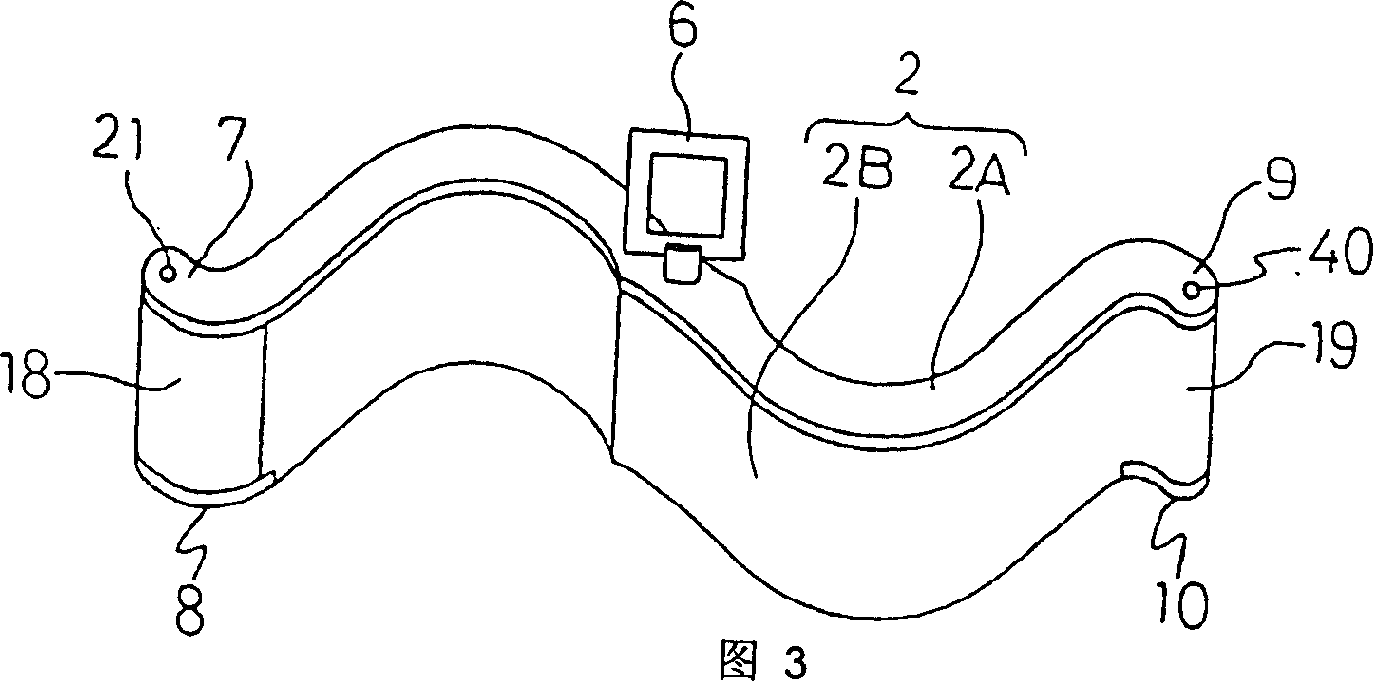

[0043] In order to describe this invention in detail, it demonstrates based on drawing.

[0044] 1 to 12 are diagrams showing a first embodiment of the present invention. Fig. 1 is a diagram showing one louver in a louver to which the present invention is applied. The louver 1 is made of a strip-shaped cloth woven from polyester fiber, which is no different from a flat strip-shaped cloth alone. However, after hanging, in order to make the horizontal section width The shape in which at least one side edge points in a different direction with respect to the middle part, for example, the cross-section is S-shaped, becomes a stable state, and the shape is stabilized by durable pressing performed by steam heating. Left and right balance weights 22c and 22d having flexibility are inserted into left and right sheath portions 1c and 1d formed on the left and right edges of the louver 1 .

[0045] Then, at the same time as the upper ends of these left and right balance weights 22c, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com