Pipe joint

A technology for tubes and female joints, applied in the direction of engine components, liquid fuel feeders, machines/engines, etc., can solve problems such as incorrect assembly, lengthening of the retainer, and lengthening of the housing 15

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Hereinafter, the pipe joint of the present invention will be described in detail with reference to the drawings.

[0050] 1st form of implementation

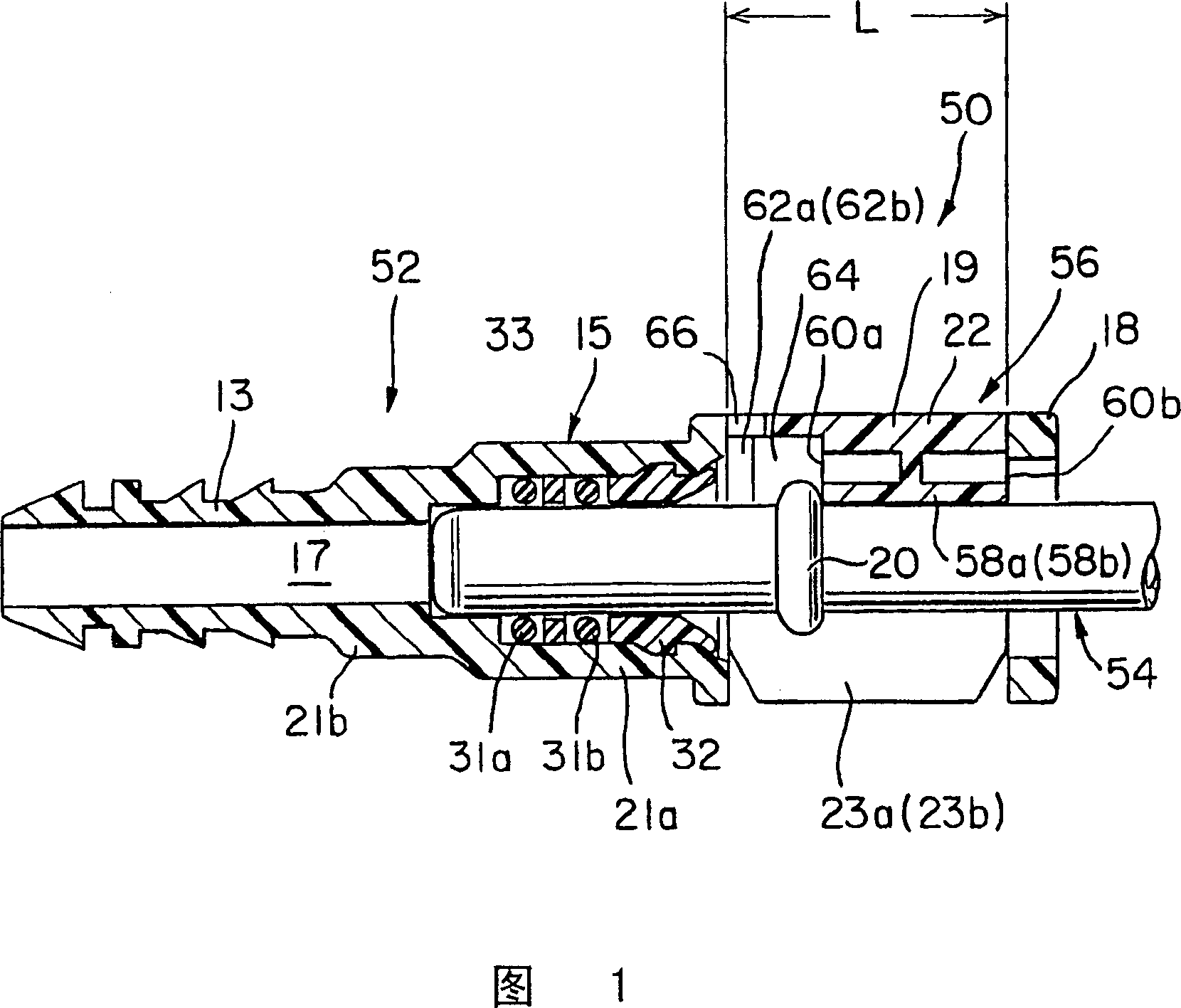

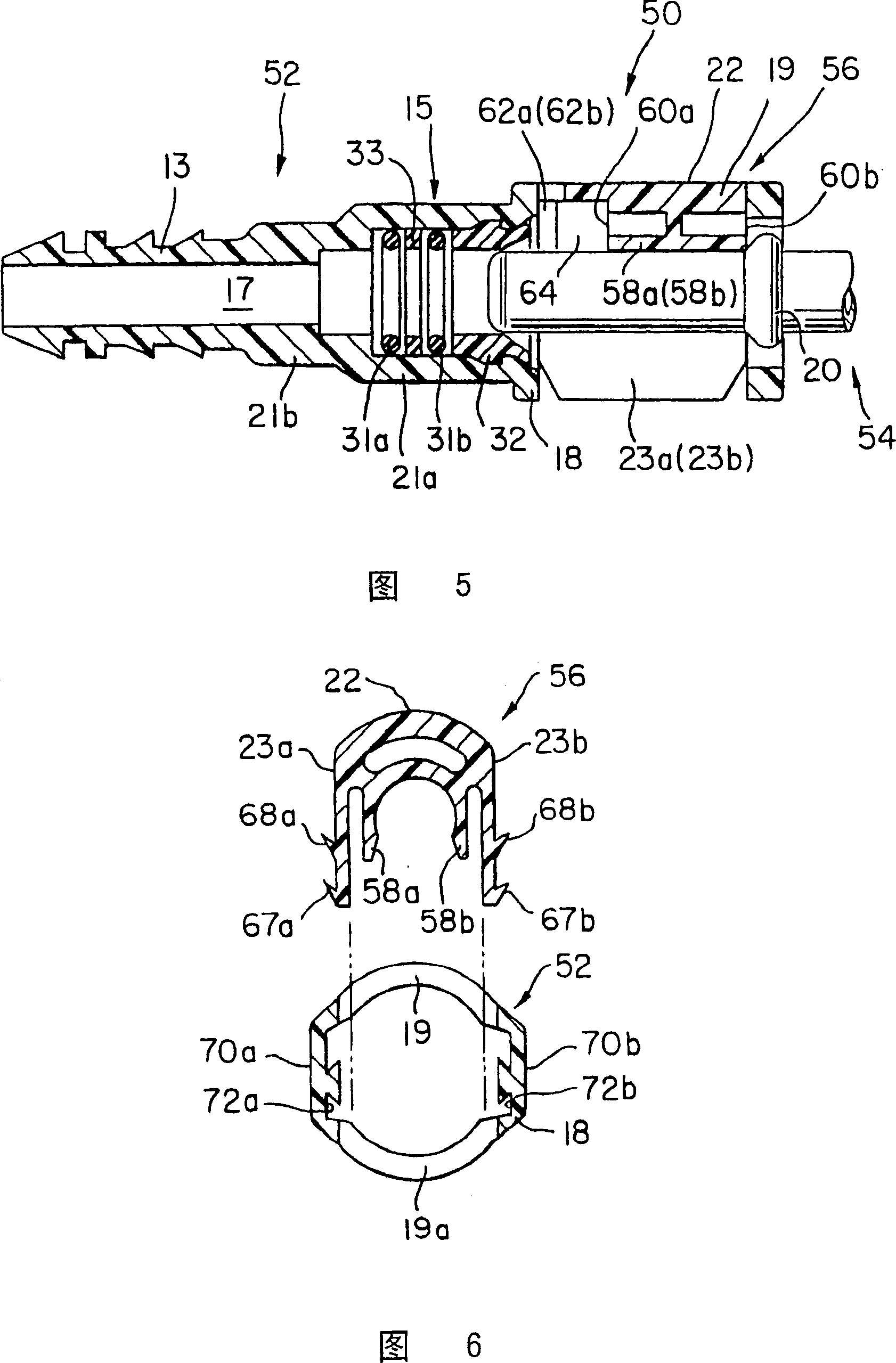

[0051] Fig. 1 is a longitudinal sectional view showing a pipe joint according to a first embodiment of the present invention. The female joint member 52, male joint member 54, and retainer 56 constituting the pipe joint 50 of the first embodiment are the same as the female joint member 12 and male joint member 14 of the conventional quick connector shown in FIGS. 9 and 10 . , The retainer 16 has members having the same constituent elements, and the same reference numerals are used for the same constituent elements to omit the detailed description thereof, and the different parts will be described in detail below.

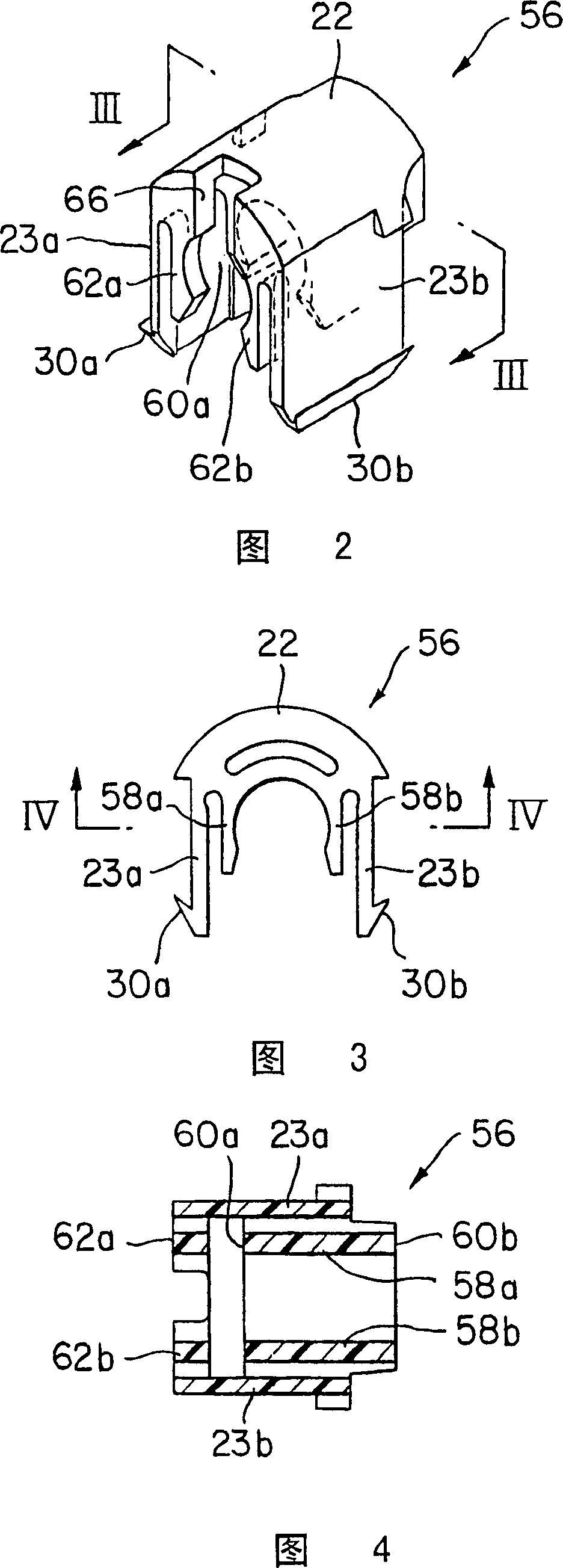

[0052] As shown in FIGS. 2 and 3 , the holder 56 is an integrally formed plastic U-shaped member, and the main body 22 of the holder 56 has legs 23a, 23b extending parallel to both sides. Inside the legs 23a,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com