Electric motor for hand toolroom machines

A technology of electric motors and tools, applied in the field of electric motors, can solve the problems of troublesome and time-consuming removal of carbon brushes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

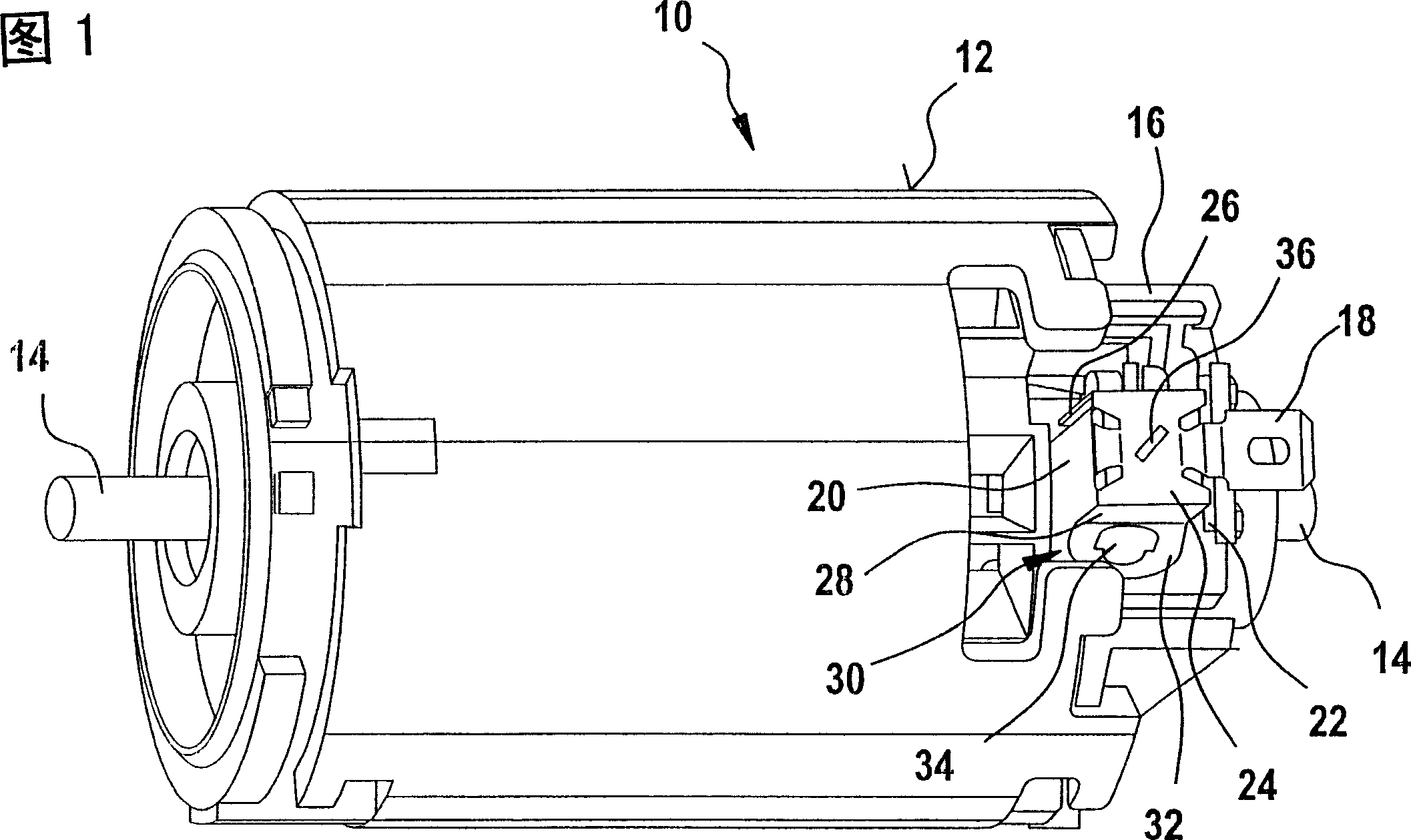

[0022] FIG. 1 shows an electric motor 10 having a housing 12 in the form of a cylindrical shell made of sheet metal with a rotor (not shown) inside and whose motor shaft 14 projects outwardly from the ends of the electric motor 10. out. On the right in the viewing direction, the electric motor 10 has a carbon brush plate 16 on the end side, which is flanged to the housing 12 . The carbon brush plate 16 is penetrated at its center by the other end of the motor shaft 14 .

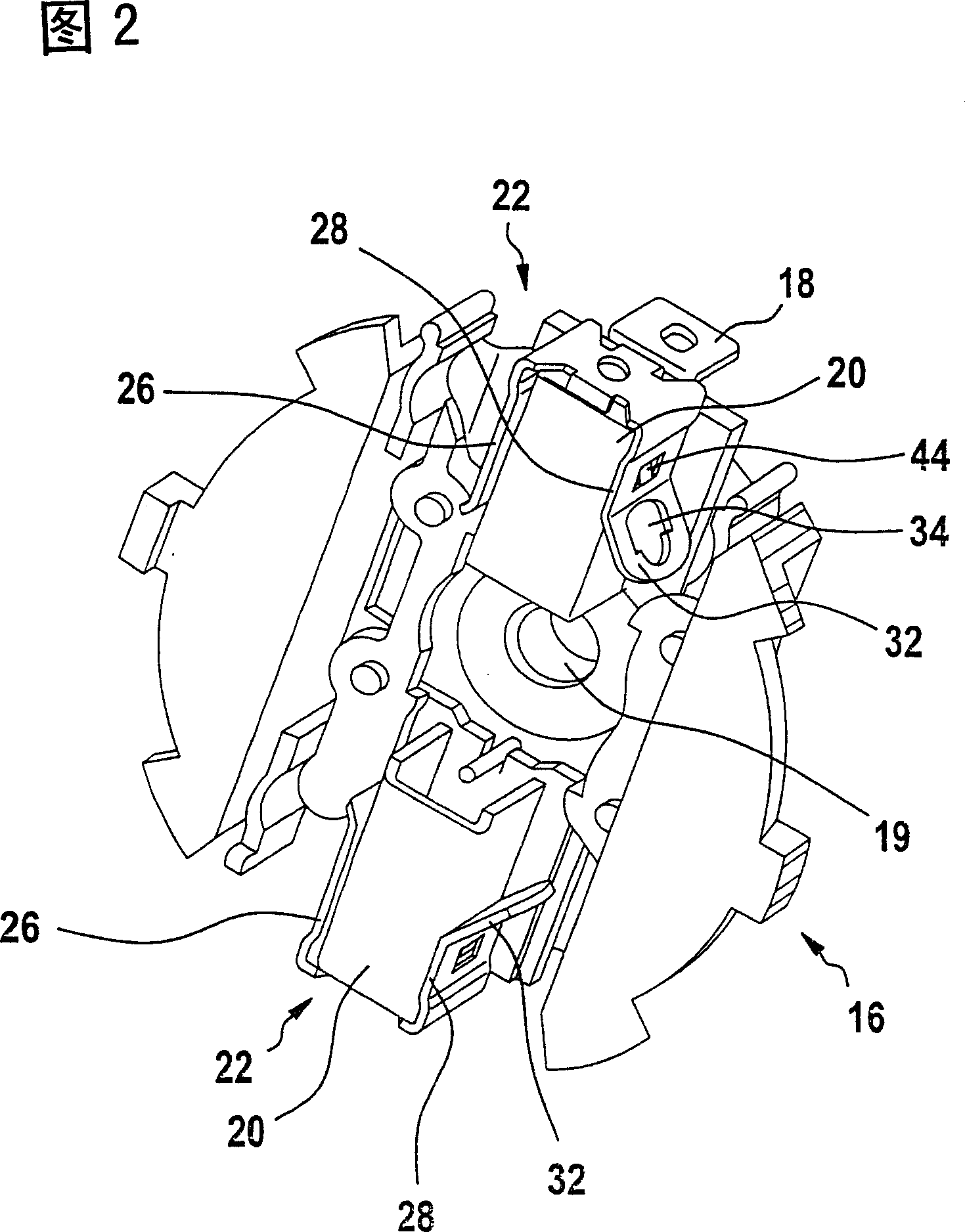

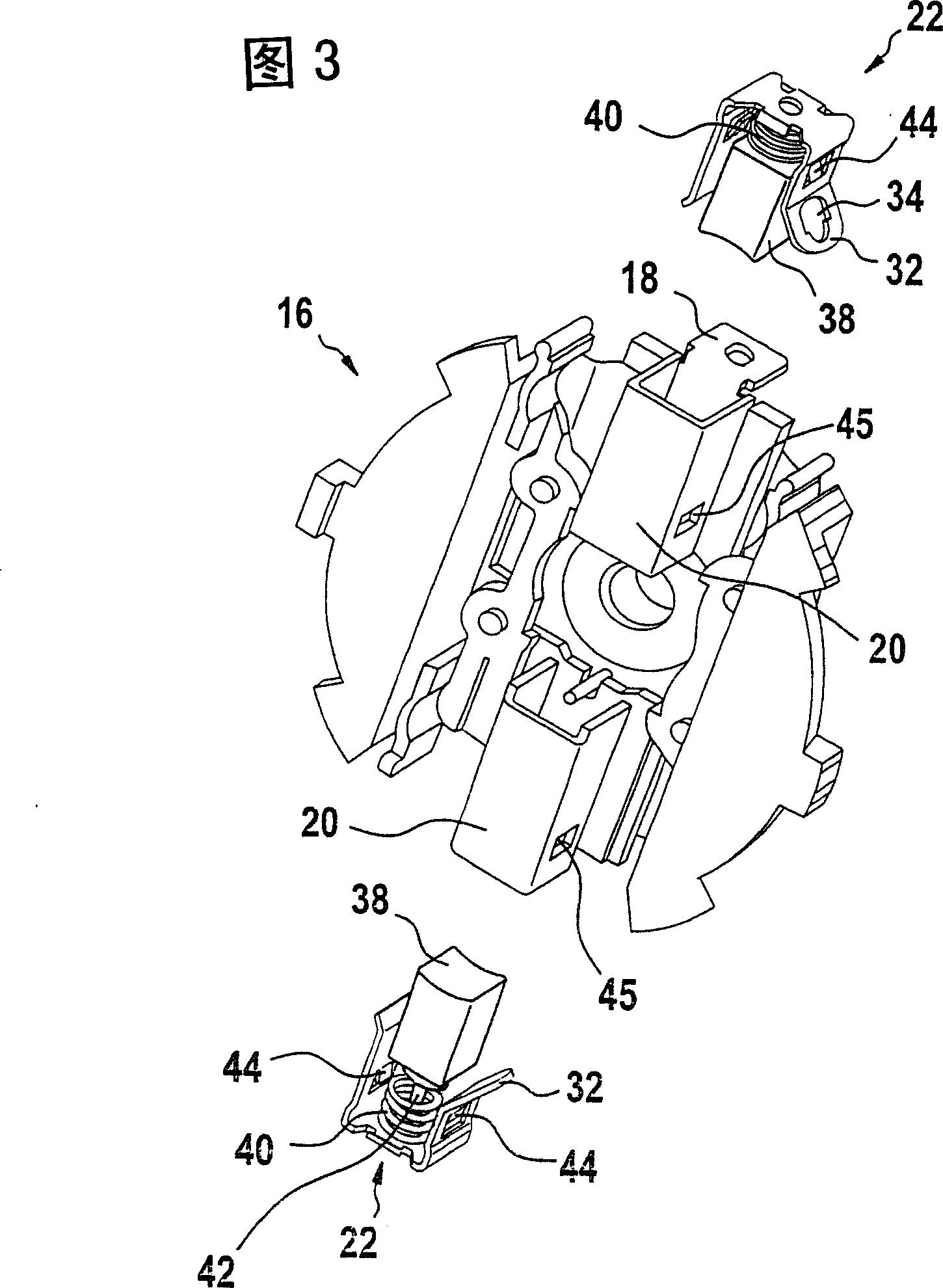

[0023] Two brush holders 20 protrude radially outward from the carbon brush plate 16 on two opposite sides, only the upper brush holder being visible. Each brush holder has an axially outward contact tongue 18 for connecting a cable, not shown, to a power supply, not shown. The brush holders 20 are each closed externally by a locking cap 22 consisting of a cover 24 with two lateral legs 26 , 28 which are secured to the brush by means of spring tongues 44 laterally offside. Grip 20 on. The one leg 28 has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com