Refrigerating storage cabinet

A technology for storage and cooling pipes, which is applied to household refrigeration devices, coolers, lighting and heating equipment, etc. It can solve problems such as high maintenance costs, inability to repair welding positions, and poor refrigeration, so as to improve reliability and inhibit freezing growth , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

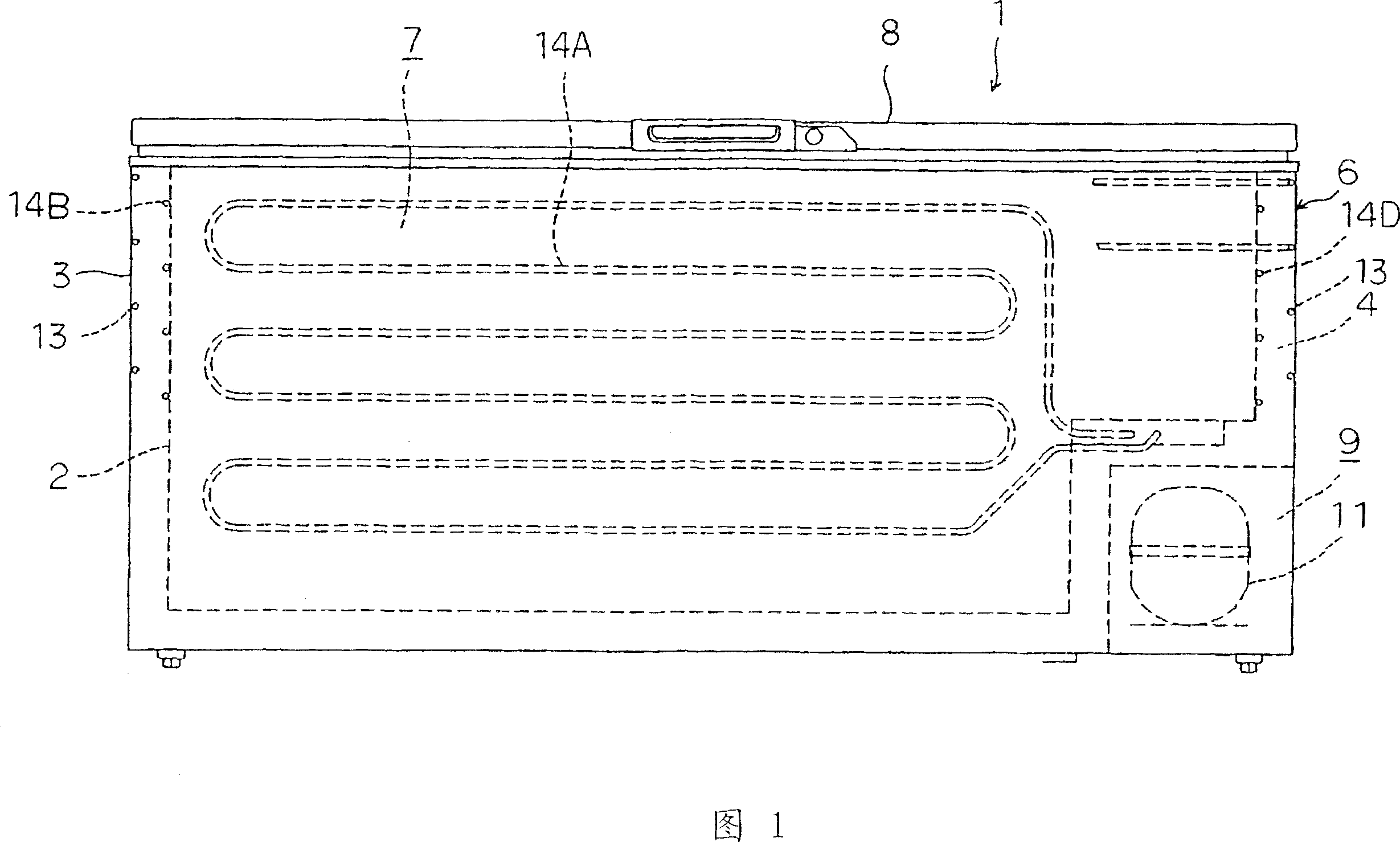

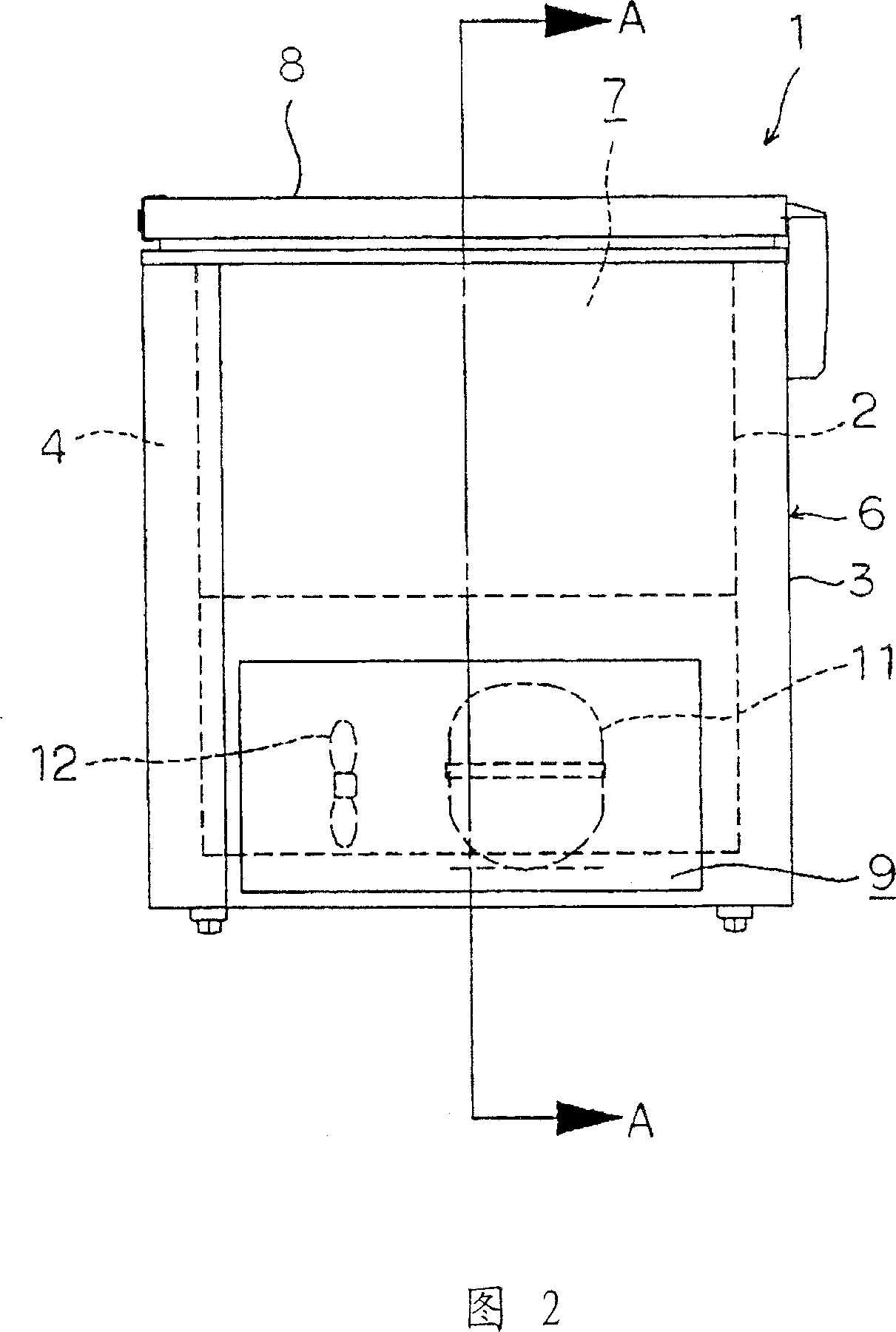

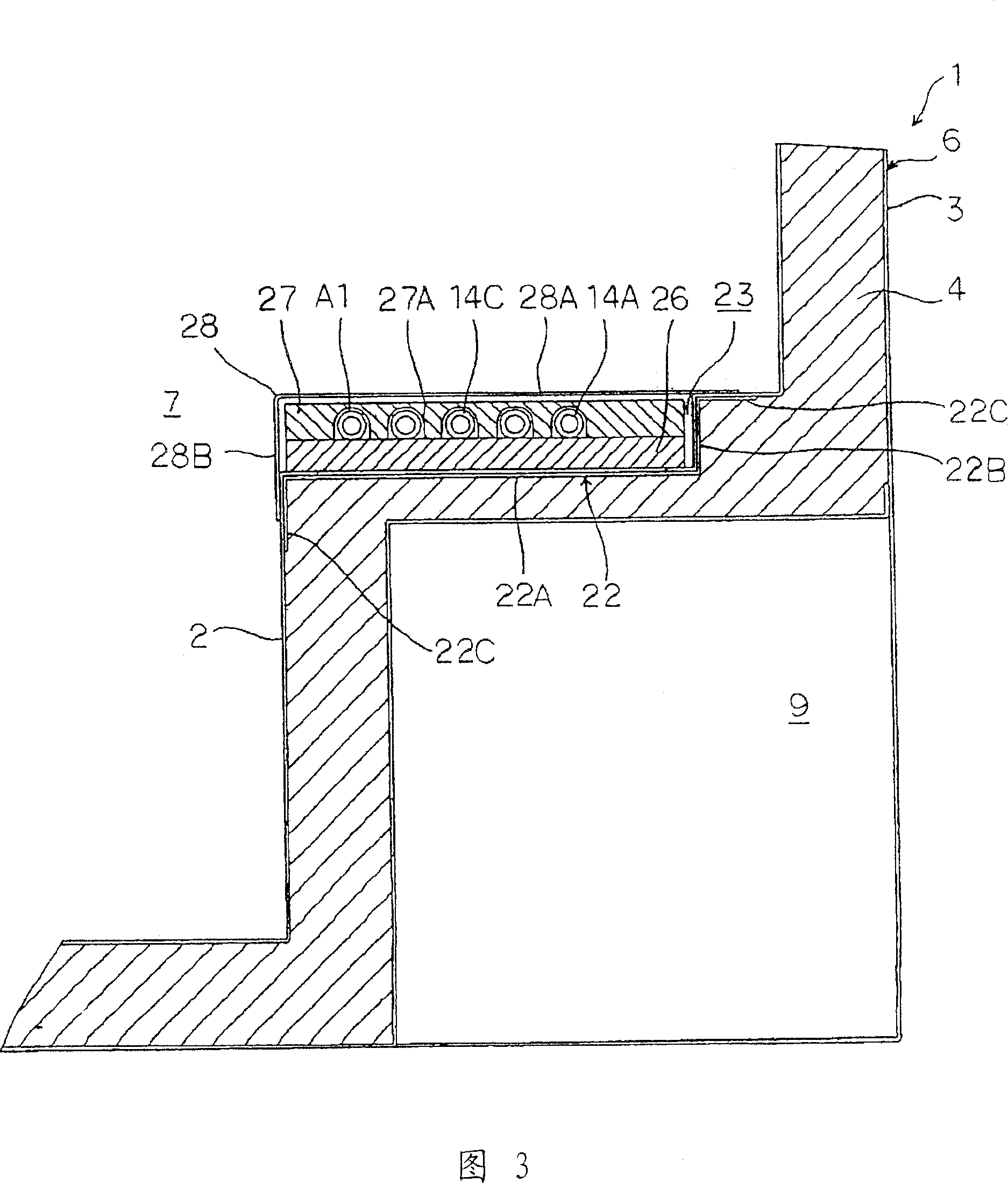

[0028] 1 is a front view of a freezer 1 as an embodiment of the refrigeration storage of the present invention; FIG. 2 is a side view of the freezer 1; FIG. 3 is a cross-sectional view along line A-A of FIG. The freezer 1 of the embodiment is a so-called freezer-type freezer with an upper opening, and includes a heat-insulating box 6 consisting of an aluminum inner box 2 with an upper opening and a steel plate outer casing with an upper opening. The box 3 is composed of on-site foaming to prevent filling between the two boxes 2, 3 with a heat insulating material 4 (hereinafter referred to as a foamed heat insulating material) and the like; the above-mentioned heat insulating door 8 is closed and formed freely The upper surface of the storage room 7 in the inner box 2 is opened.

[0029] An equipment room 9 is formed on the outside of one side (toward the right side) of the heat insulating box 6, and a compressor 11 and a blower 12 constituting a refrigerant circuit of a refrig...

Embodiment 2

[0048] Fig. 5 shows a second embodiment of the present invention. At this time, a plurality of through holes (communication portions) 31 . . . are formed on the bottom surface 22A of the partition plate 22 . In addition, the cooling pipes 14A to 14D, the pipes C1 , A1 introduced into the notch 21 have the welding position W . The cover 32 has a tubular shape, the package is bent along the peripheral surface of each tube, and a slit 32A is formed on the upper surface across the longitudinal direction. Thereby, the cover 32 can observe the welding position W... by opening the notch 32A.

[0049] With such a structure, after the above-mentioned first air leak test is performed, the heat-insulating box adhesion prevention sheet 33 is arranged on the upper surface of the notch 21 (the position formed between the inspection plate 28 and the cooling pipe 14A, etc.), so that The heat insulating foam material 4 is not bonded to the jig. In this state, the inner box 2 is put into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com