Color splitting prism assembly

A dichroic prism and prism technology, applied in prisms, color TV, color photography, etc., can solve the problems of reducing the luminous efficacy of prism components, shortening the back focus, etc., to shorten the back focus, reduce the optical path, and improve the color purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

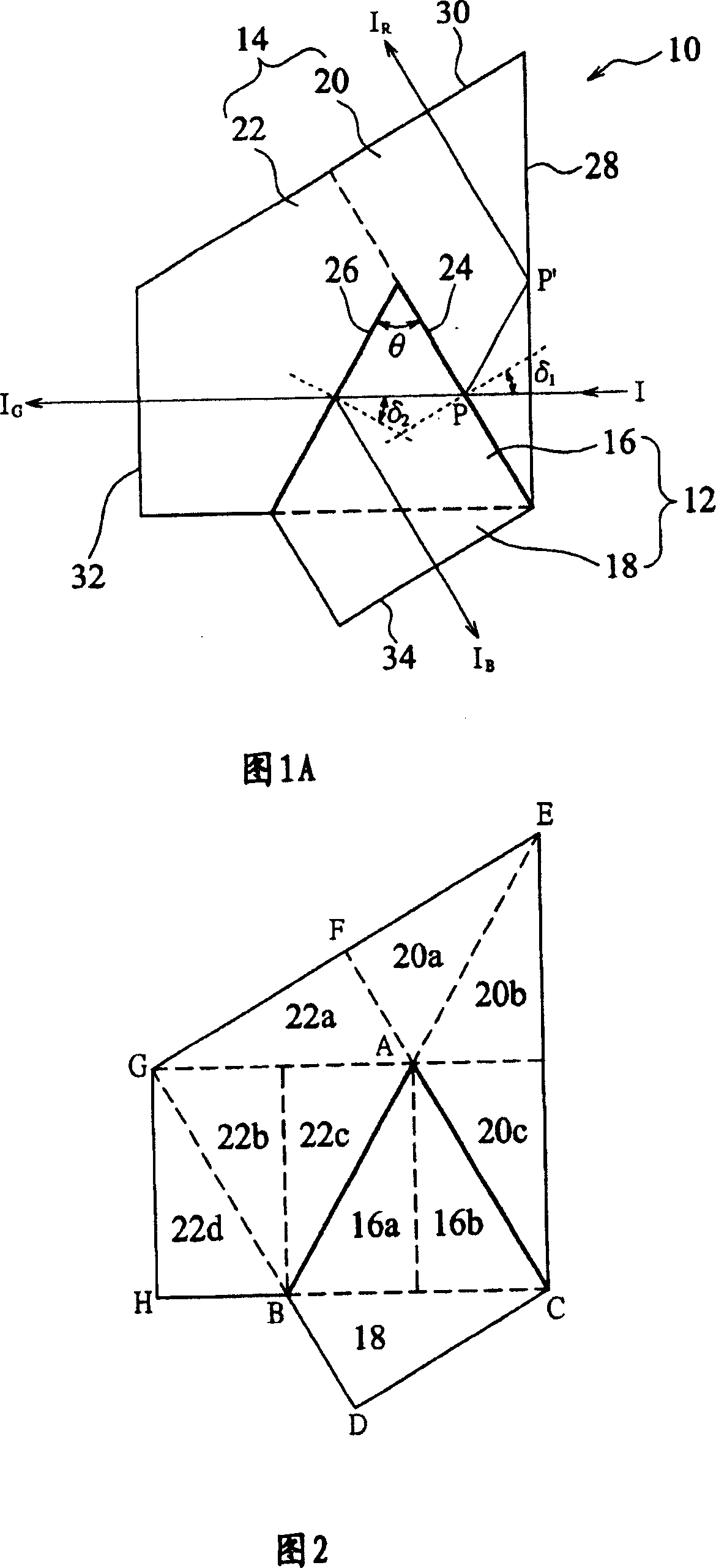

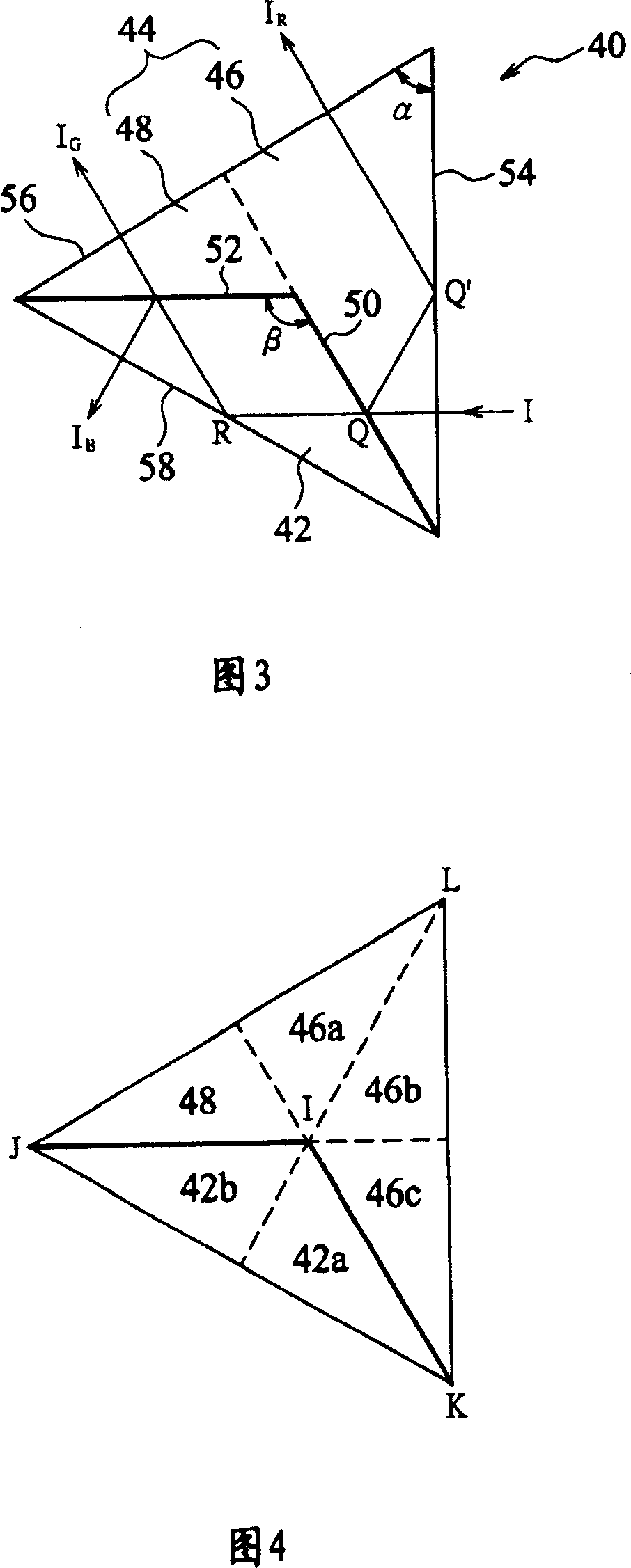

[0017] FIG. 1A is a schematic plan view showing a dichroic prism group 10 according to an embodiment of the present invention. The dichroic prism group 10 is used to separate the incident white light (white light) into three different color components, for example, the sequentially separated red light I shown in the figure R and Blu-ray I B , Green Light I G Three primary colors (primary color).

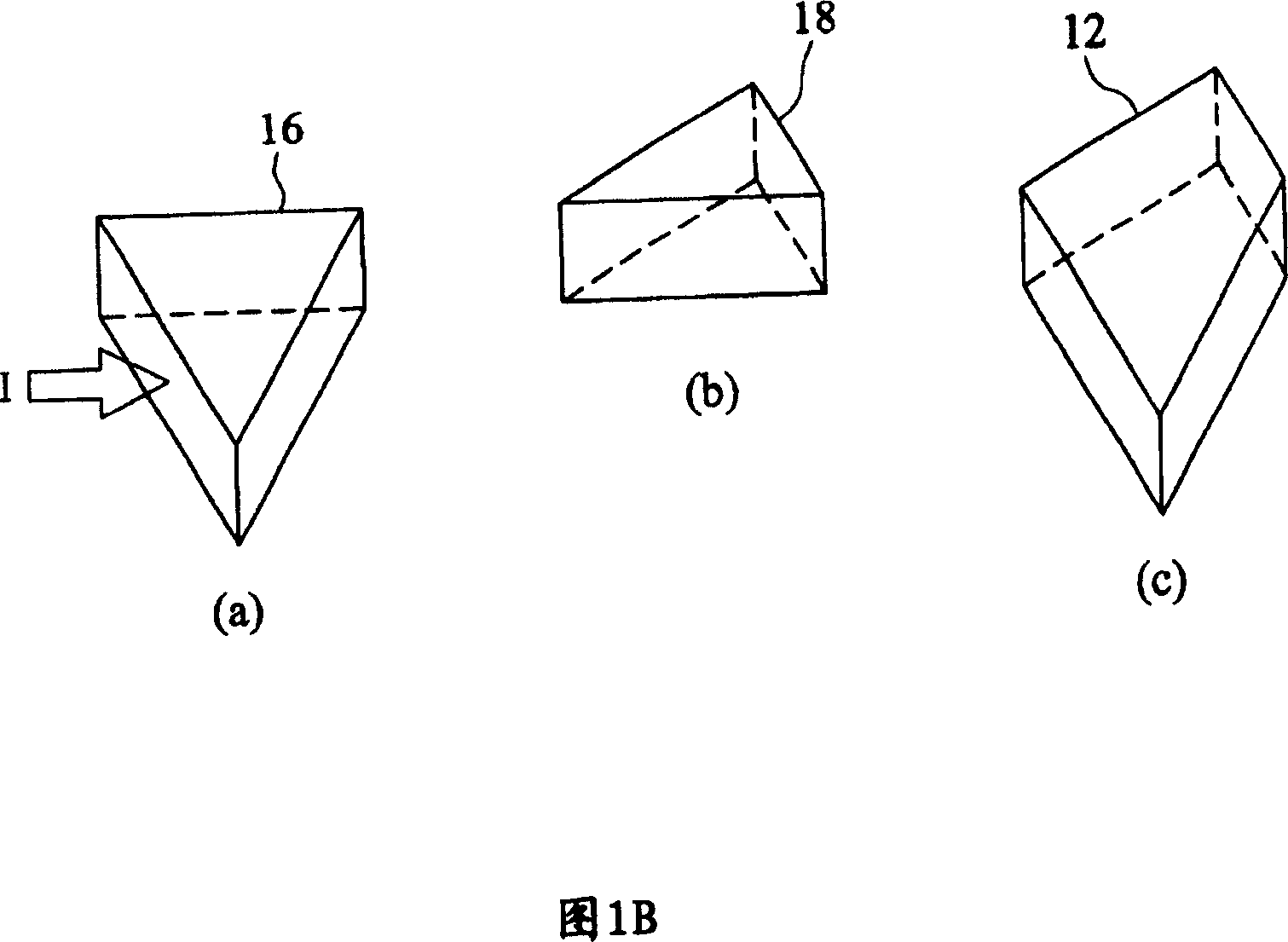

[0018] According to this embodiment, the dichroic prism group 10 is composed of two prism blocks 12 and 14 . The prism block 12 is in the shape of a quadrangular prism, which can be formed by combining a triangular prism 16 and a rectangular prism 18 . FIG. 1B is a perspective view showing the components of the above-mentioned triangular prism (a), rectangular prism (b), and quadrangular prism (c), so as to clearly show the three-dimensional shapes of various prisms used in the present invention. As shown in Figure 1B, the "triangular prism" of the present invention is defined as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com