Thermostatic mixing valve with arrangement to increase mixing effect

A mixing valve and constant temperature technology, which is applied in the direction of temperature control, temperature control, and instruments without auxiliary power supply, and can solve problems such as affecting work, instability, and reducing the maximum flow rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Detailed description of the preferred embodiment

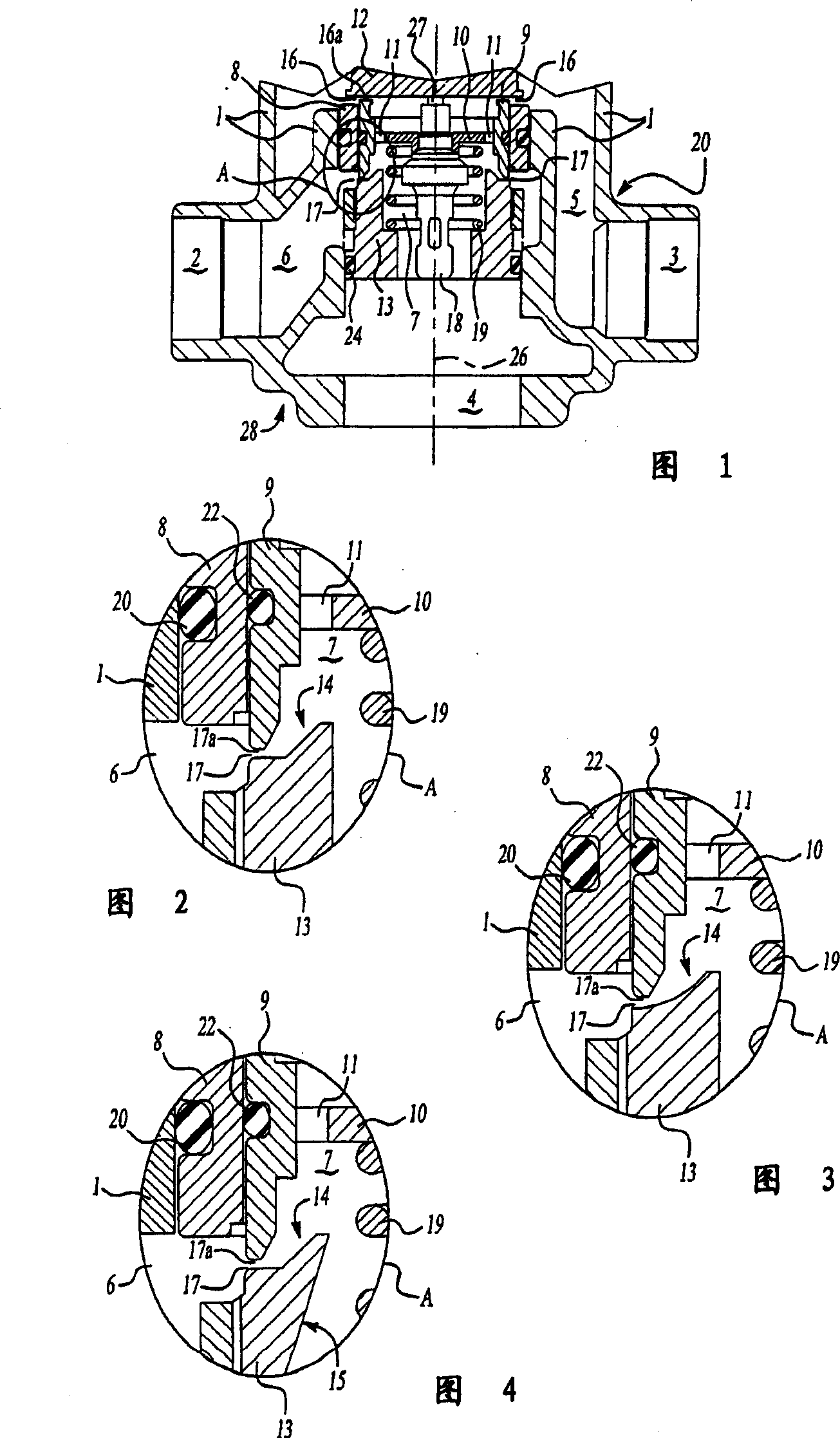

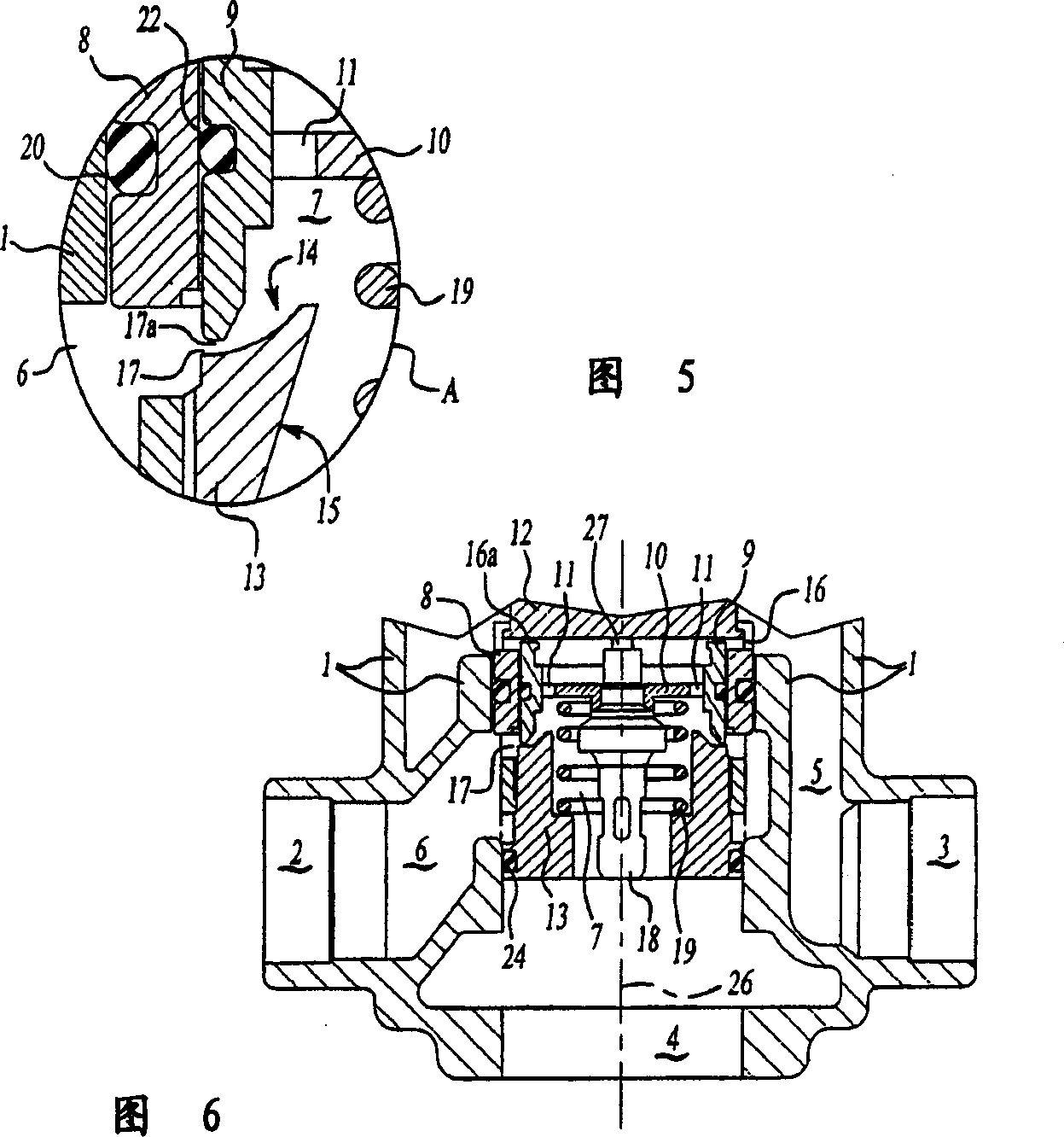

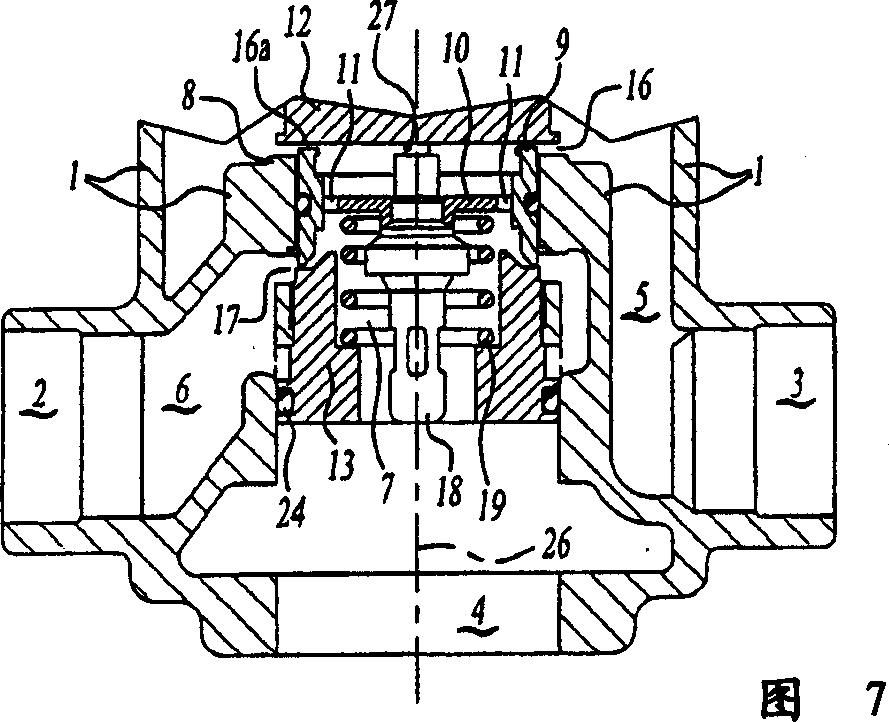

[0027] Referring now to FIG. 1, FIG. 1 is a partial sectional view of a thermostatic mixing valve introduced in an embodiment of the present invention. The operating handle and safety components of the thermostatic mixing valve and the parts for assembling the thermostatic mixing valve into the faucet located at the lower part of the thermostatic mixing valve are not shown, and these parts are not involved in the present invention. The thermostatic mixing valve comprises a valve body 1 with an inlet 2 for introducing hot water, an inlet 3 for introducing cold water and an outlet or discharge 4 for outputting mixed water at a regulated temperature. Connecting conduits 5 and 6 lead from the inlets 2 and 3 respectively to deliver cold and hot water to the mixing chamber 7 .

[0028] The mixing chamber 7 is delimited by an annular peripheral wall 8 . A valve 9 is slidably mounted in the peripheral wall 8 with a partition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com