Variable diameter cylinder

A cylindrical, variable technology, used in printing, rotary presses, printing presses, etc., that can solve the problems of complex structure, undisclosed, braking, etc. of the fluid pressure system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

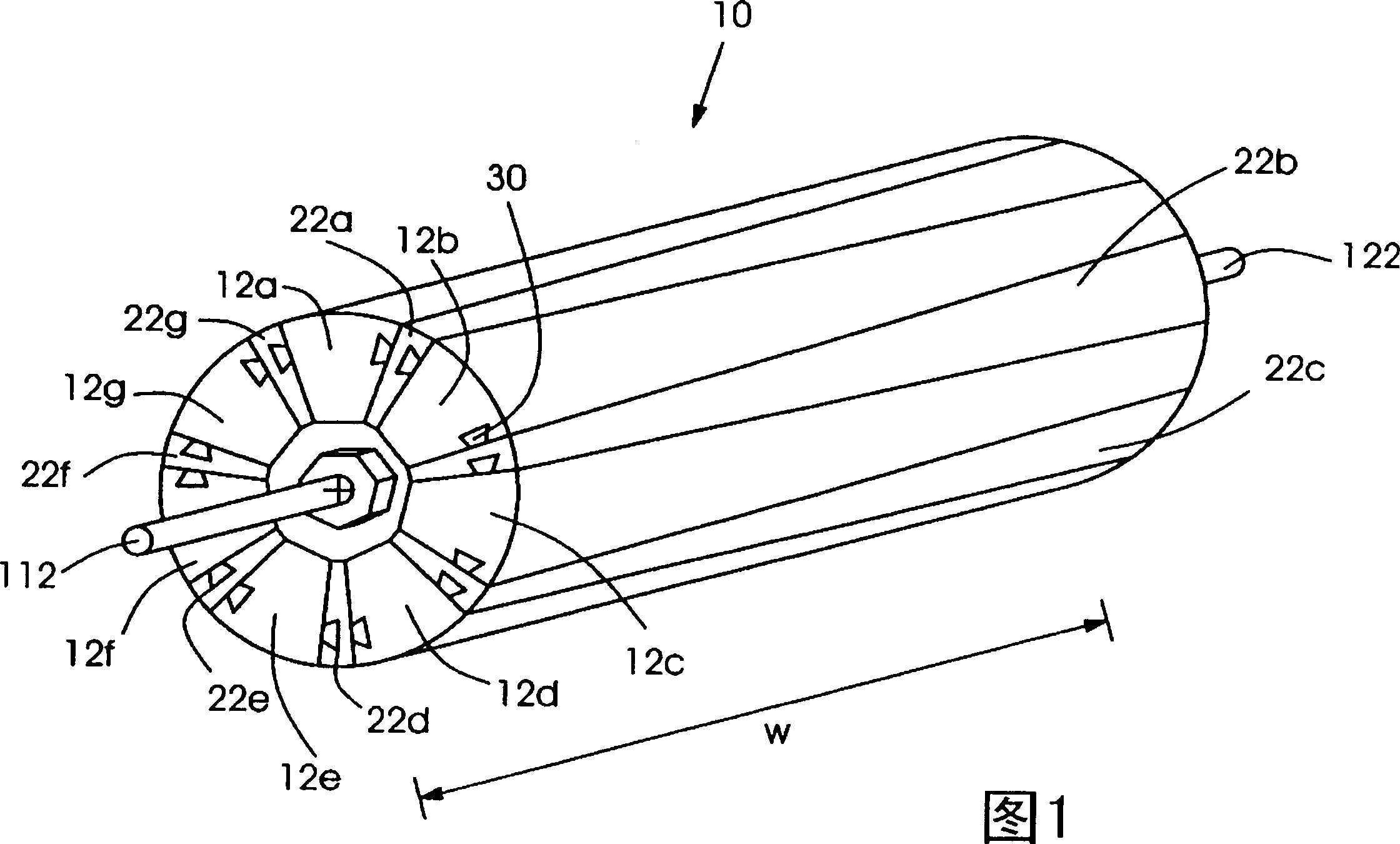

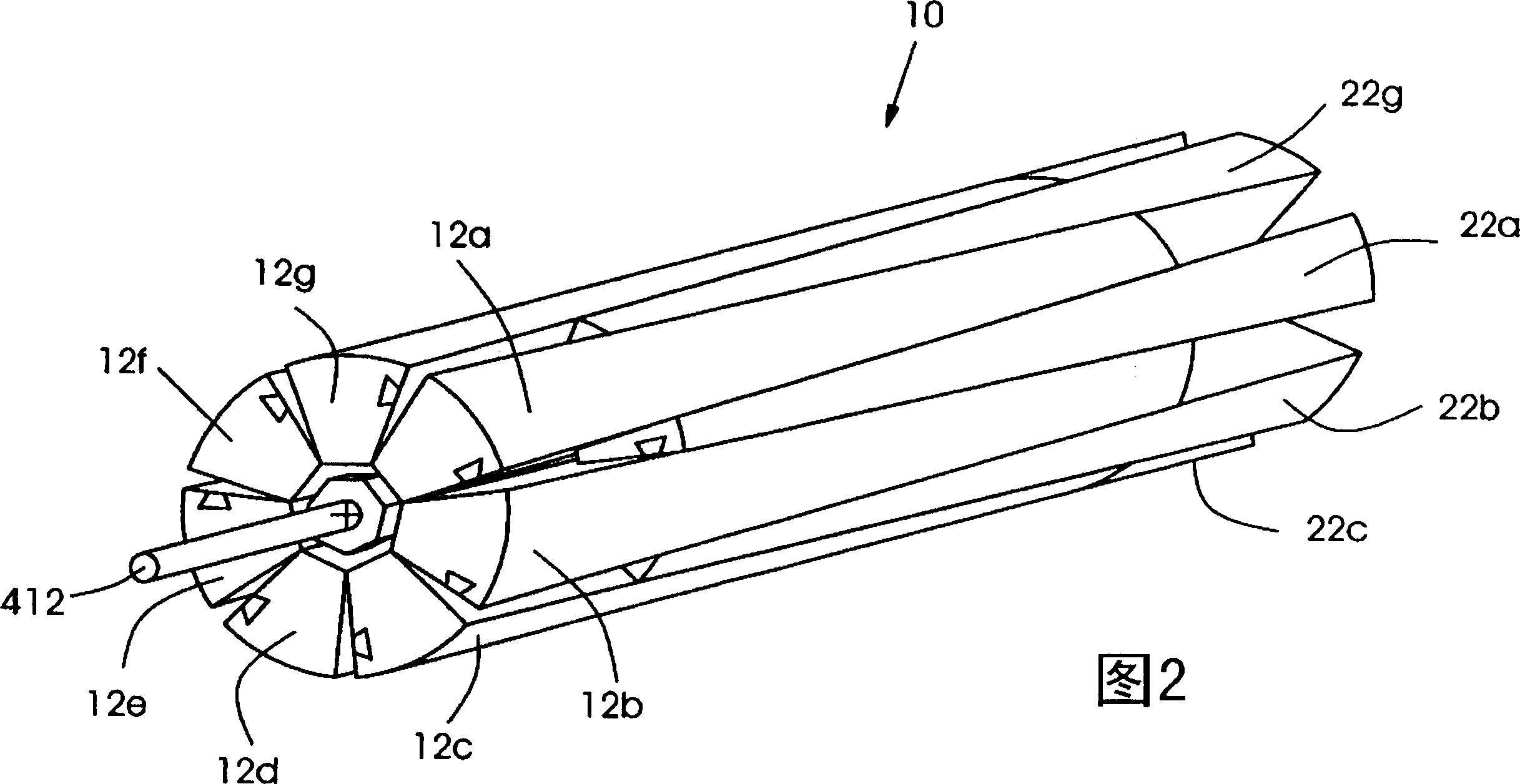

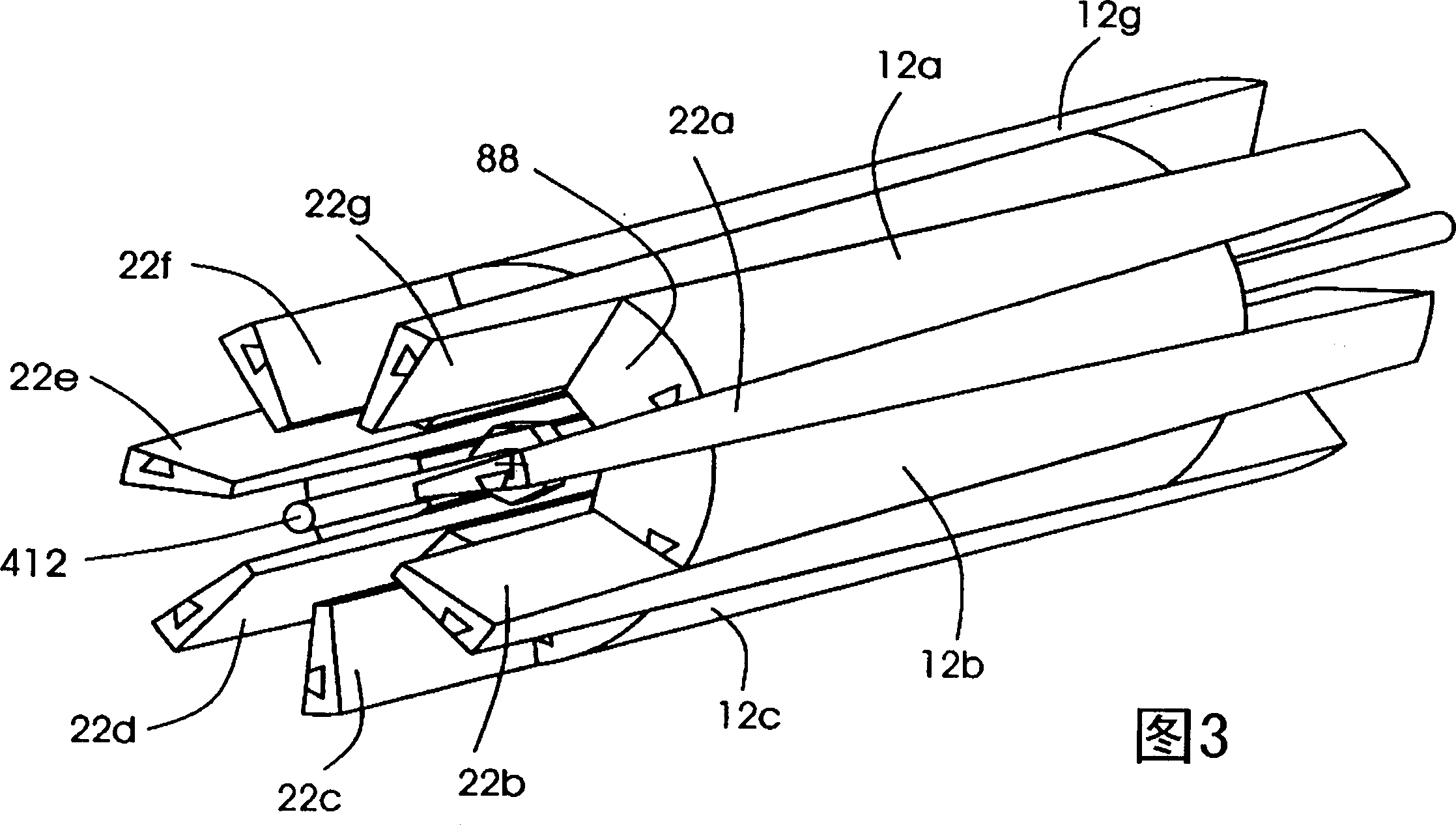

[0046] Fig. 1 has shown a cylinder 10 with width w, and this cylinder has first wedge-shaped member 12a, 12b, 12c, 12d, 12e, 12f and 12g, and second wedge-shaped member 22a, 22b, 22c, 22d, 22e, 22f and 22g. The first wedges 12a, 12b, 12c, 12d, 12e, 12f and 12g are all connected at their inner surfaces to a first common actuator 112 having seven arms, the seven An arm secures each first wedge axially, but allows radial variation. The second wedges 22 a , 22 b , 22 c , 22 d , 22 e , 22 f and 22 g are likewise fixed to a second common actuator 122 . The first and second wedges are connected to each other, for example by a dovetail joint 30, so as to be able to slide relative to each other. One possible embodiment of the actuator 112 is schematically detailed in FIG. 4 . The arm 212 of the actuator 112 is firmly connected to the first wedge. Arm 212 is also rigidly connected to a plate 312 which is rigidly connected to a shaft 412 . The shaft 412 has an external thread 413 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com