Automatic nail feeder

A nail feeding and automatic technology, which is applied to nail staple tools, manufacturing tools and other directions, can solve the problems of troublesome operation and high use cost of automatic tools, and achieve the effect of low use cost, improved work efficiency and work quality, and ingenious structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

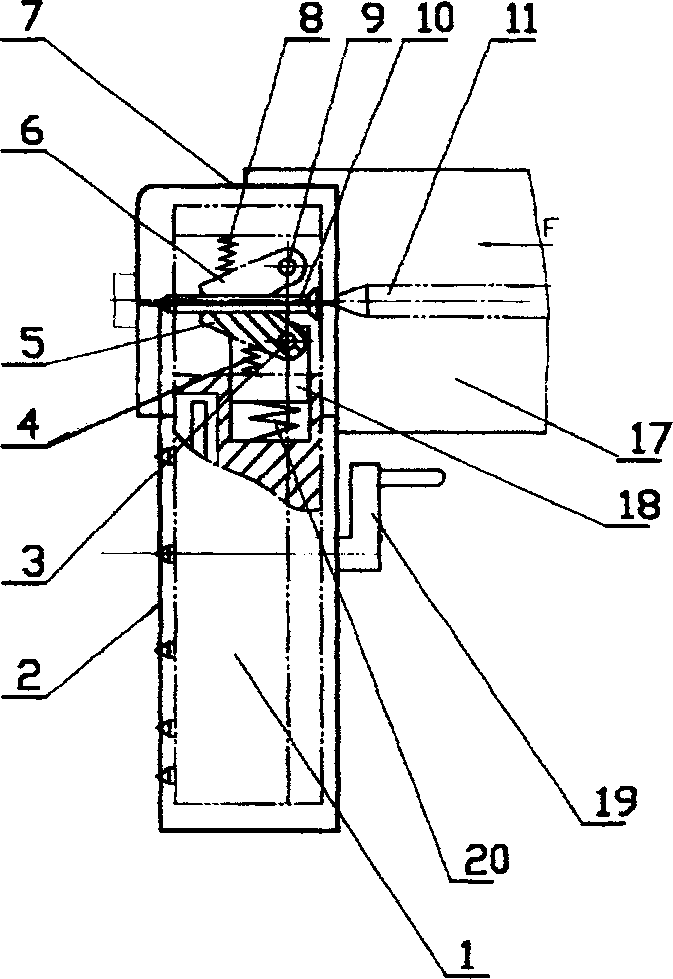

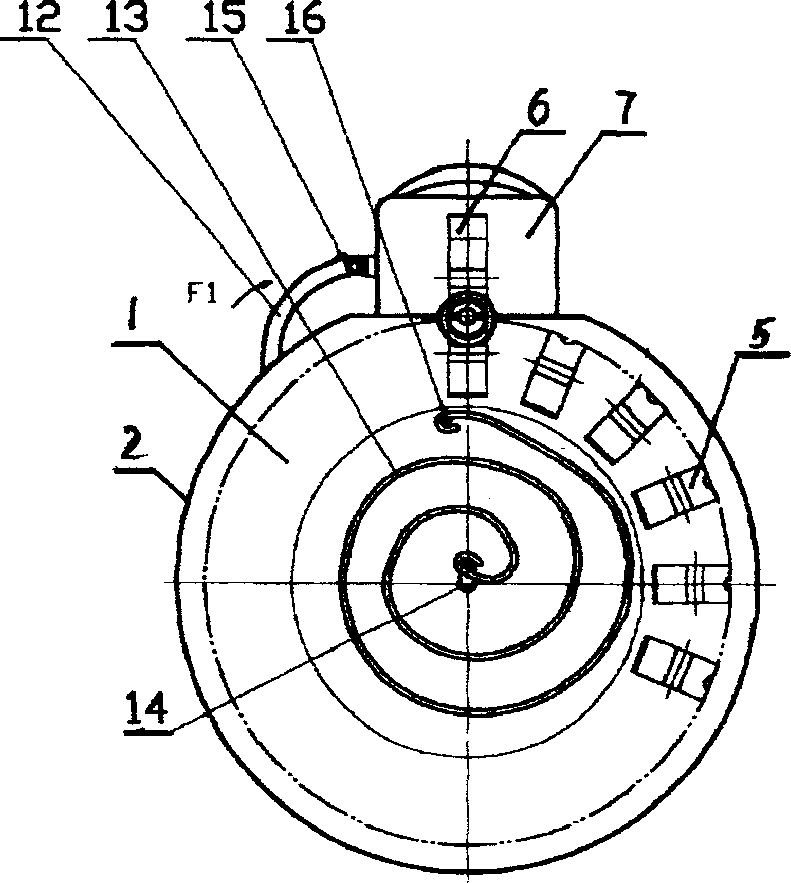

[0014] Embodiment 1: The nail feeder has a nail tray 1, the nail tray 1 is located below the gun head 7, the nail tray 1 is evenly distributed with a claw device, the nail tray 1 is connected with a shell 2, the nail tray 1 center is connected with coil spring 13.

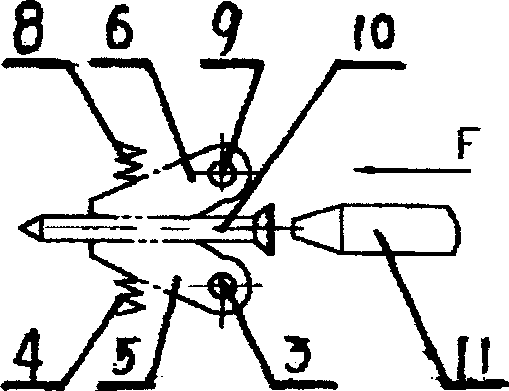

[0015] The gun head 7 is connected with the jaw B6, and one end of the jaw B6 is connected to the gun head 7 through the jaw B pin 9; the jaw B spring 8 is connected between the outer wall of the other end and the inner wall of the gun head 7. There is a protruding body, on which a pawl 12 is connected, and a torsion spring 15 is connected at the joint between the protruding body and the pawl 12 .

[0016] Nail support disc 1 is a circular disc, on a plane of the circular disc, there are concave concentric circles, a coil spring 13 is connected in the concentric circle, a coil spring shaft 14 is connected at the center of the circular disc, and the coil spring shaft 14 is connected with the center of the coil spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com