Automatic stir-frying machine

A cooking machine and automatic technology, applied in cooking utensils, household utensils, applications, etc., can solve the problems of large processing quantity, inability to overcome high-intensity labor, and difficulty in refining and delicious food

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

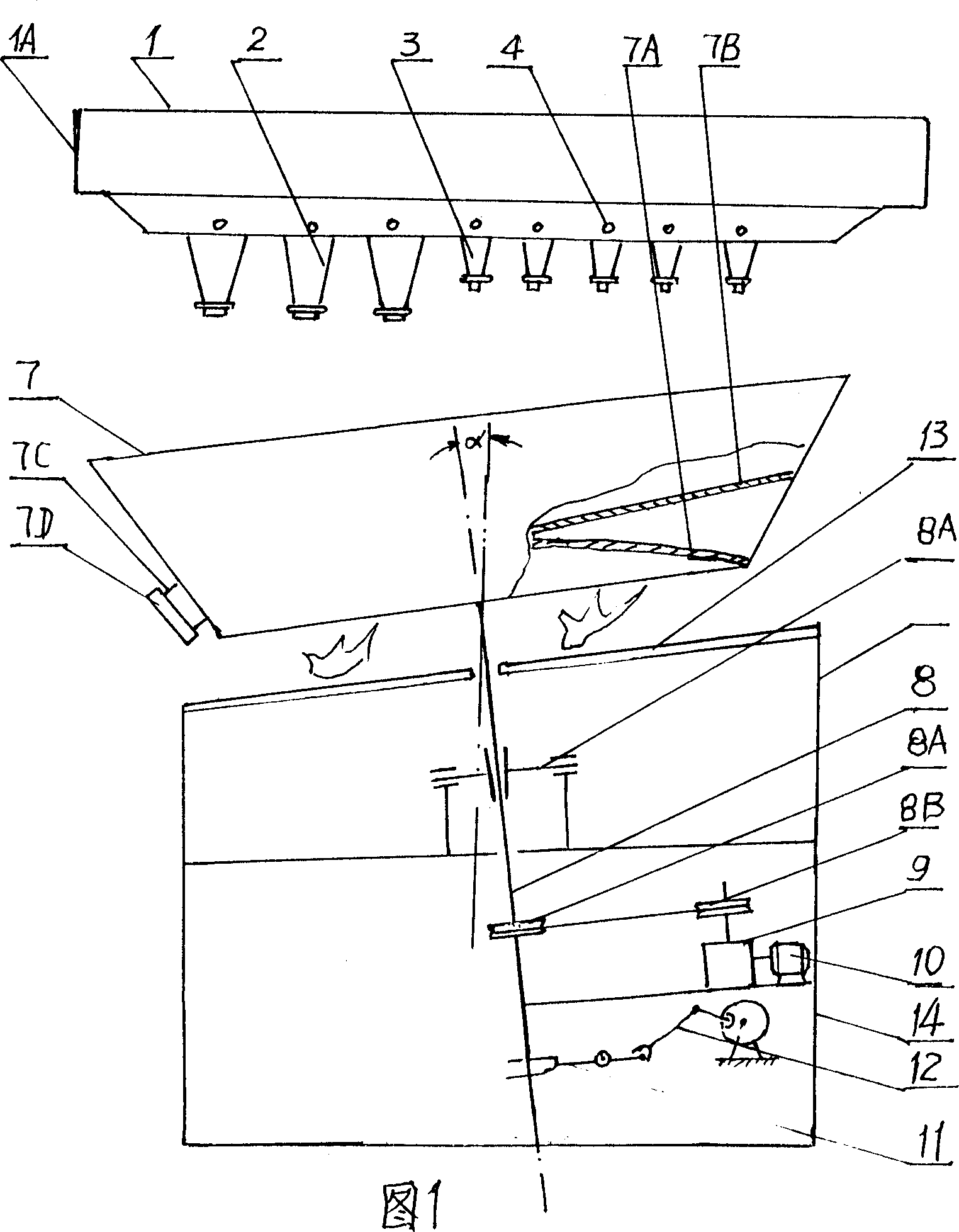

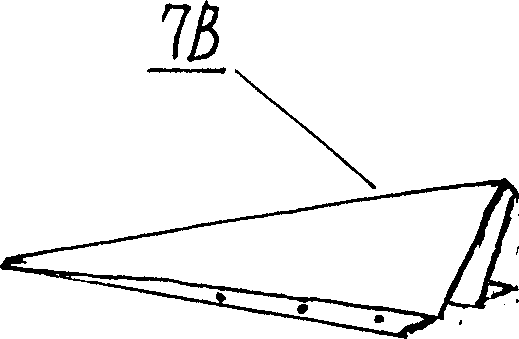

[0011] There is a prismatic protruding stirring wing 7B on the pot bottom 7 with a slightly convex shape. The rotation in the tilted state will cause the turning and rolling of the vegetables in the pot 7. If the forward and reverse are set alternately, the stirring effect will be more uniform. . However, if the single rotation mode is further improved to rotate on one side of the wok 7, and at the same time make the rotating shaft 8 perform a compound motion of reciprocating swing in the inclined plane that forms an angle α with the plumb line, then the dishes in the pot 7 will not only The rotation forms a tumbling downward at the highest point, and slides down to produce a stirring effect, and it can vibrate when the swing direction changes. Due to the inertial effect, the vegetable material produces a tumbling displacement along the swing direction, which greatly promotes the stir-fry. Strength and stirring effect. Therefore, in the design of the present invention, a cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com