Internal and external double-channel fin tube and heat exchange using said fin tube

A finned tube heat exchanger, finned tube technology, applied in the direction of heat exchanger types, indirect heat exchangers, fixed tubular duct assemblies, etc., can solve the problem of reducing heat transfer coefficient and efficiency of heat exchangers, The heat transfer and resistance calculation is troublesome, and the metal consumption of the non-heat exchange surface increases, so as to achieve the effect of improved heat transfer and resistance calculation accuracy, compact structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

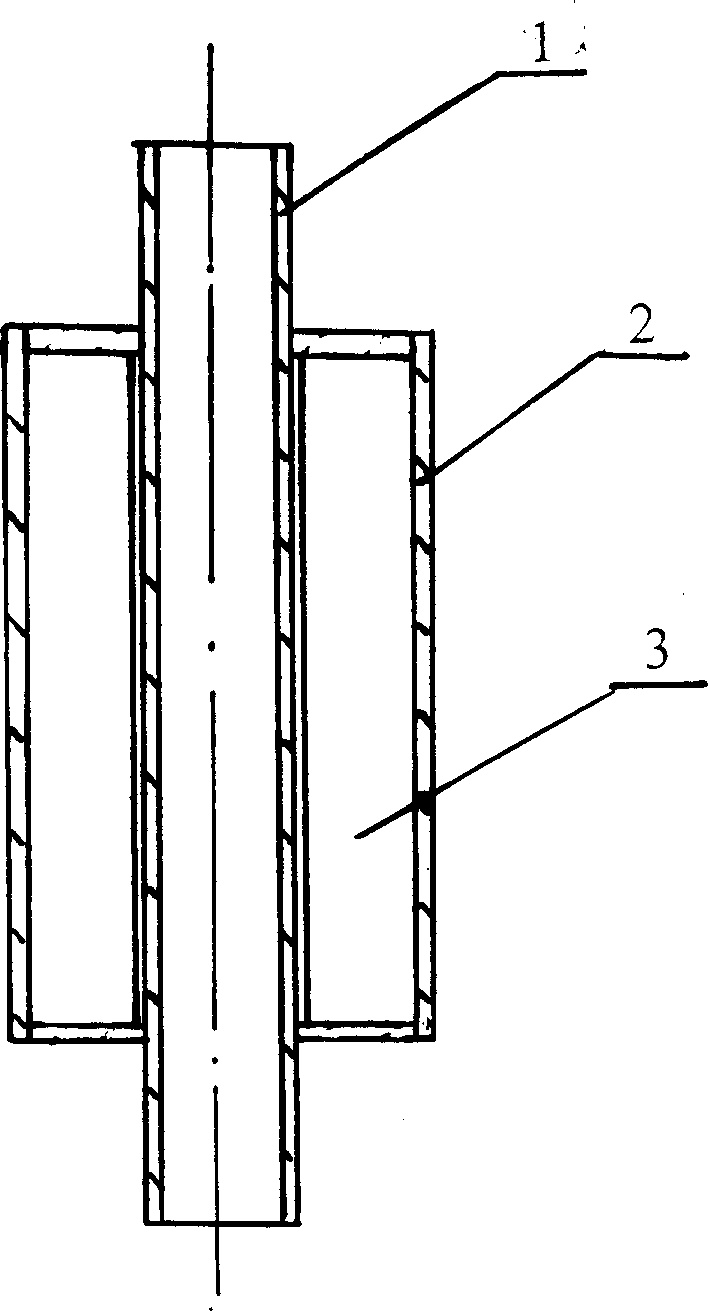

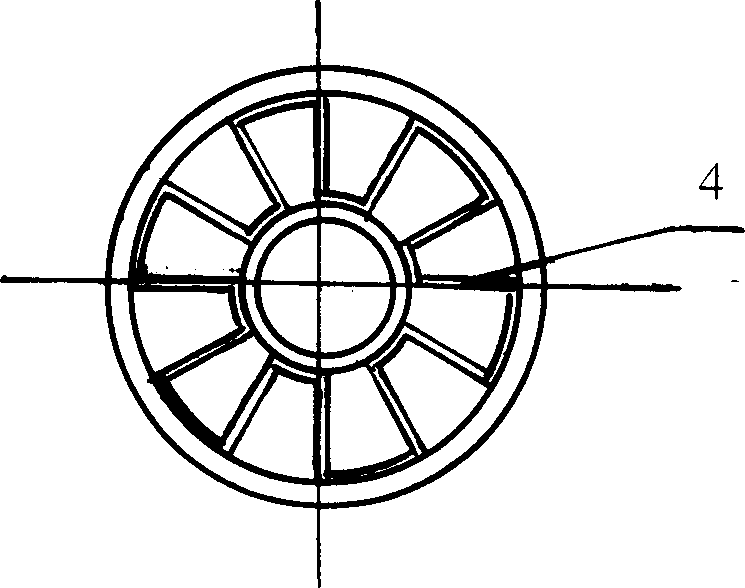

[0018] figure 1 , figure 2 It shows an embodiment of the finned tube with inner and outer double channels of the present invention. The finned tube is made of two kinds of circular tubes with different diameters nested together, and folded fins 5 are arranged in the annular channel between two adjacent tubes 1 and 2 , the circular channel in the inner hole of tube 1 is the inner channel, and the annular channel between tube 1 and tube 2 is the outer channel. In order to isolate the inner and outer channels conveniently, the inner channel is longer than the outer channel, and the longer part flows Both ends of the channel extend outwards to realize a type of finned tube with internal and external channels of the present invention.

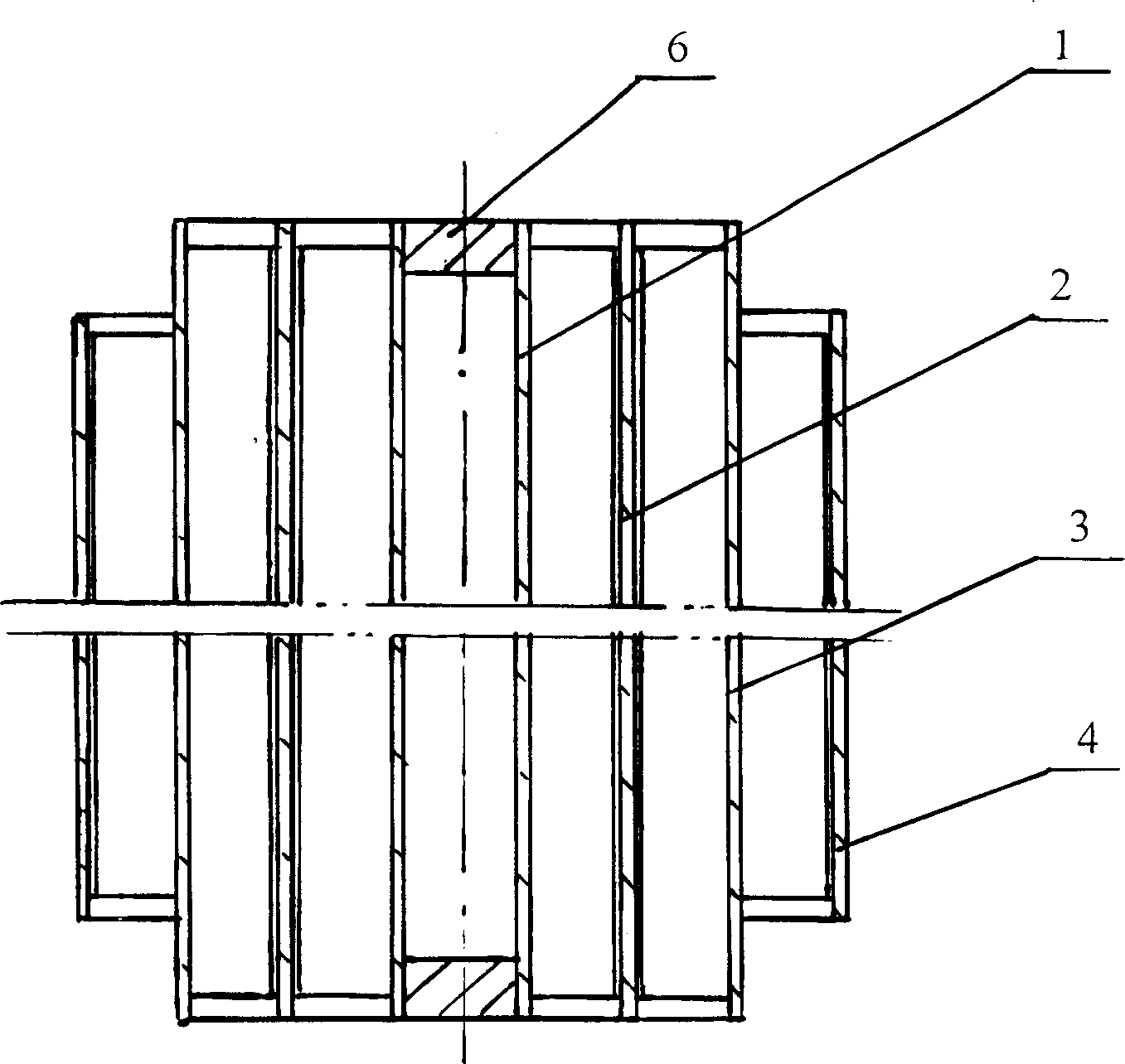

[0019] image 3 , Figure 4 Another embodiment of the finned tube with internal and external channels of the present invention is shown. The finned tube has four circular tubes of different diameters nested together, tube 1 and tube 2, tube 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com