Flyer with vertical launching and other advantages

A vertical take-off and aircraft technology, applied in the field of aircraft, can solve the problems of difficult control, high manufacturing cost, and high cost, and achieve the effect of reducing manufacturing cost, reducing high temperature resistance requirements, and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

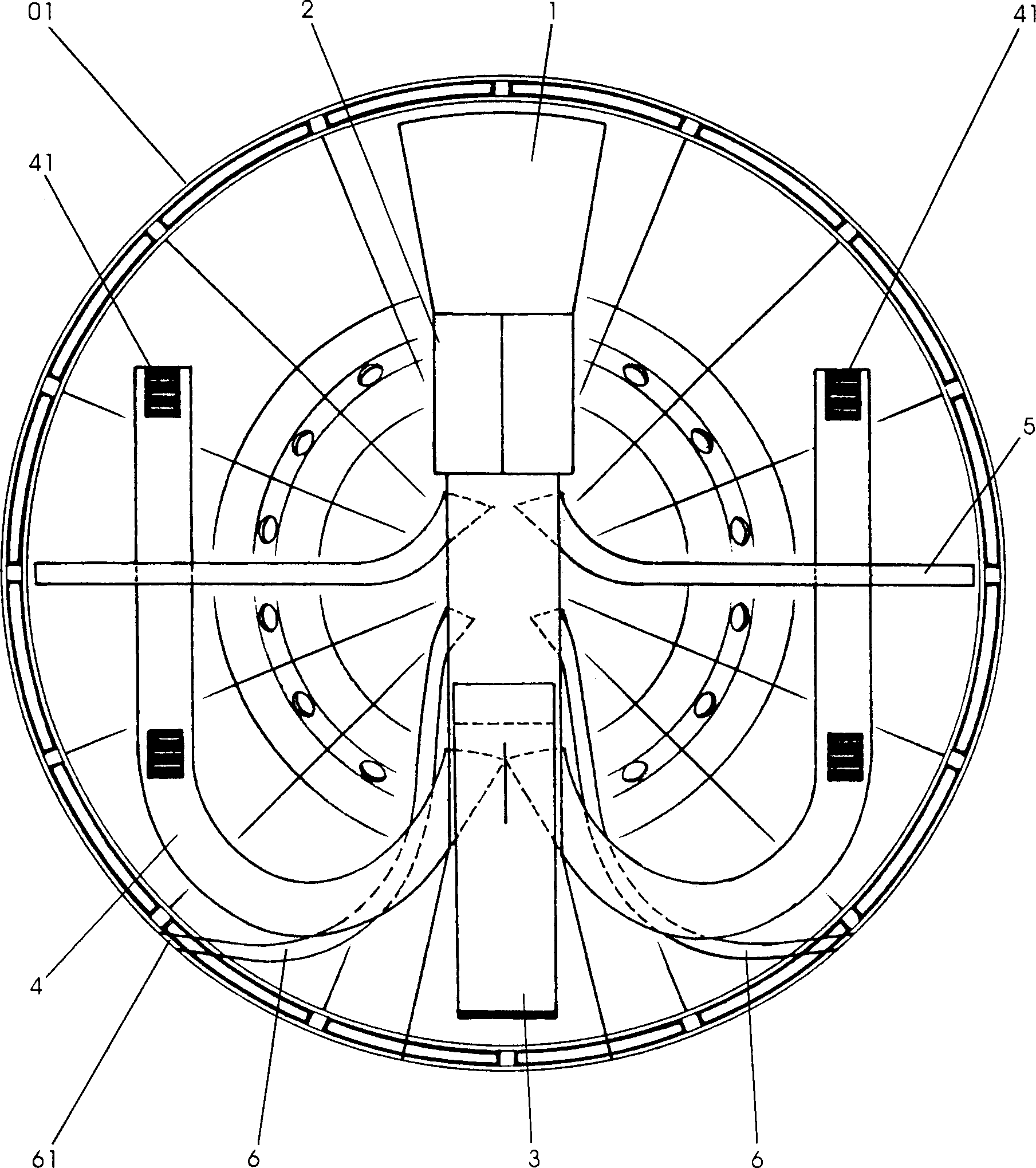

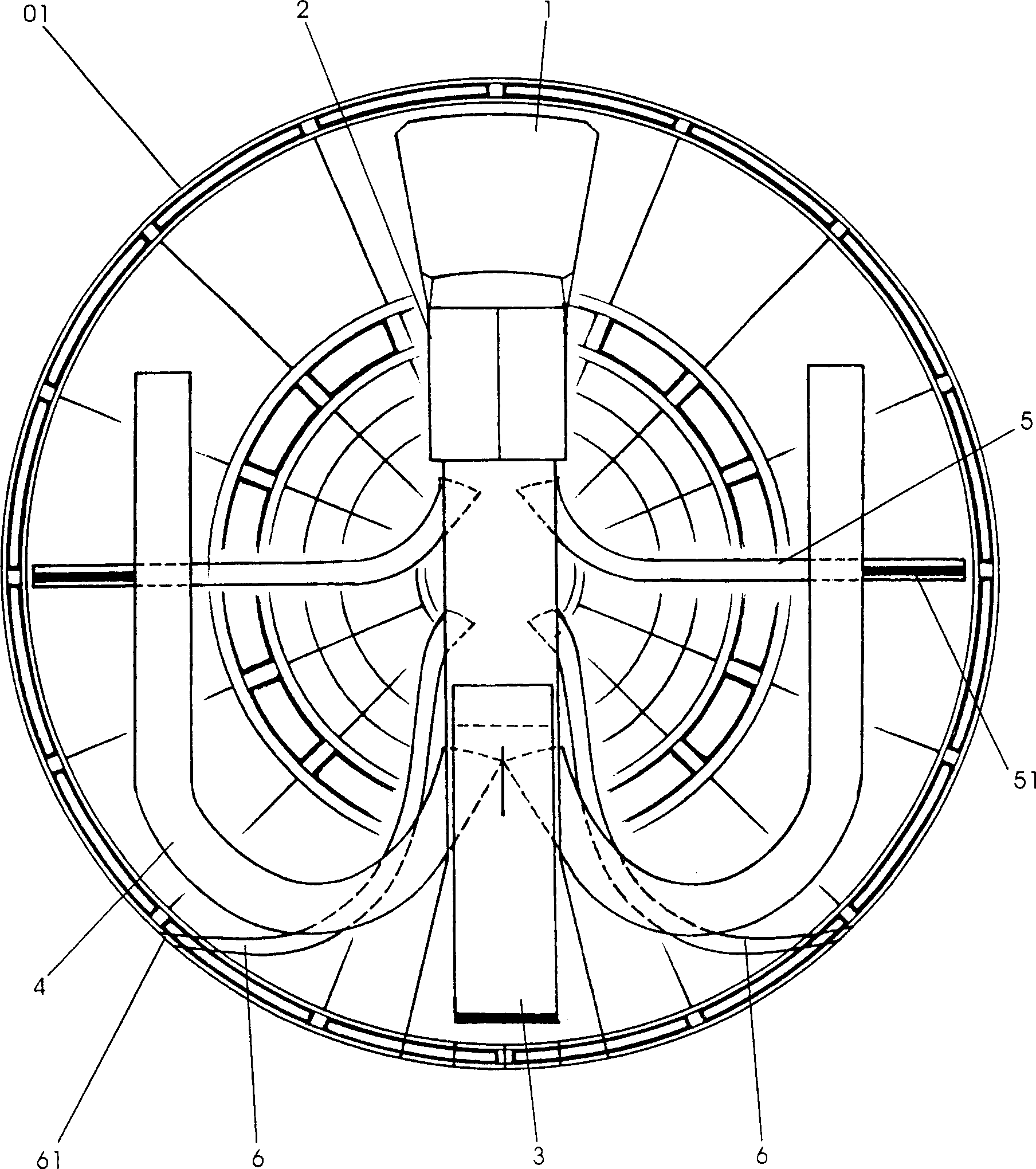

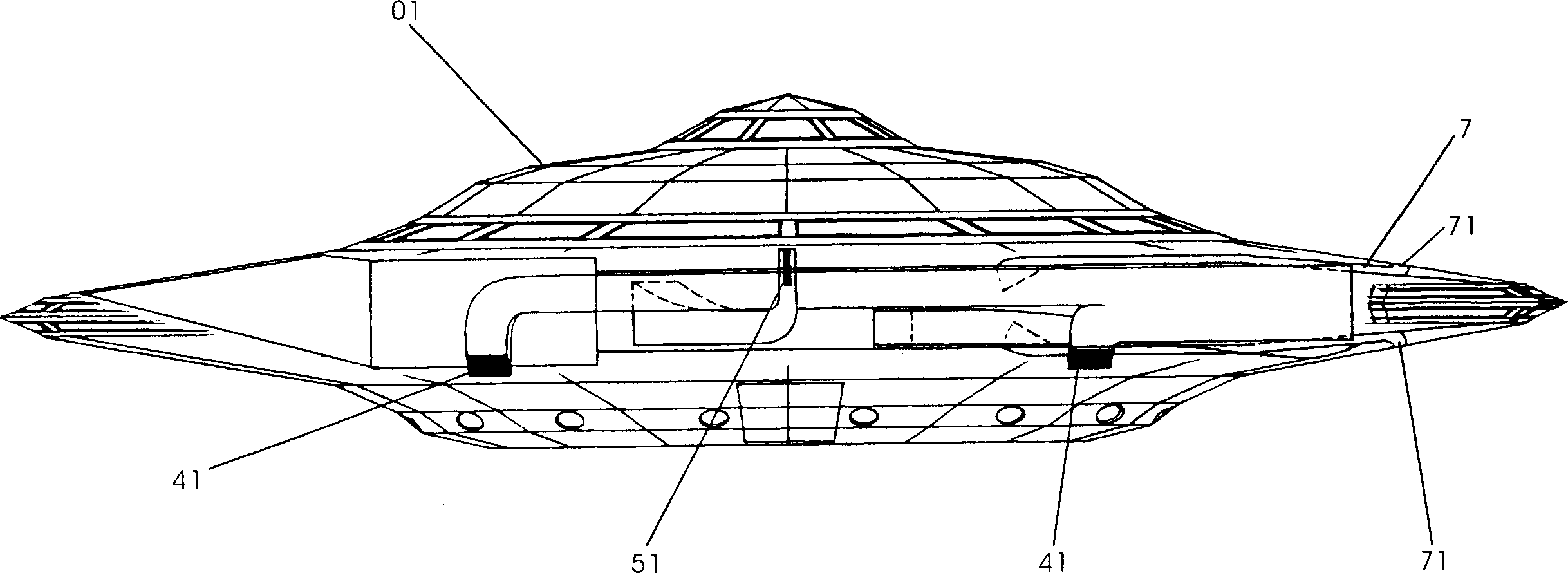

[0019] See attached Figures 1 to 4 , the front end of the body 01 of the disc shape or other shapes of the aircraft of the present invention is provided with an air inlet 1, and the turbofan engine 2 is connected between the air inlet 1 and the main exhaust pipe 3; two can be set here Or an engine 2, depending on the field of use and requirements; the straight main exhaust pipe 3 is arranged along the center of the body 01, and is connected with the main exhaust pipe 3 to provide an exhaust branch pipe for vertical take-off and landing of the aircraft 4; when the body 01 of the aircraft is naturally horizontal, the exhaust branch pipe 4 is distributed in a W shape in the horizontal direction; the exhaust port 41 opening at the tail end is downward, and the number of exhaust ports 41 can be set to one or two on each side. One; at this phase connection, be provided with a dividing plate 8 that divides the main exhaust pipe 3 into two ways; The air flow flows to the rear of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com