A kind of adjustment method of anode component frequency adjustment equipment

A technology for anode assembly and frequency adjustment, which is applied in the manufacture of electrode assemblies, electrical components, magnetrons, etc., can solve the problems of frequent adjustment of anode assemblies, reduce labor intensity of personnel, etc., achieve the effect of reducing operating experience requirements and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

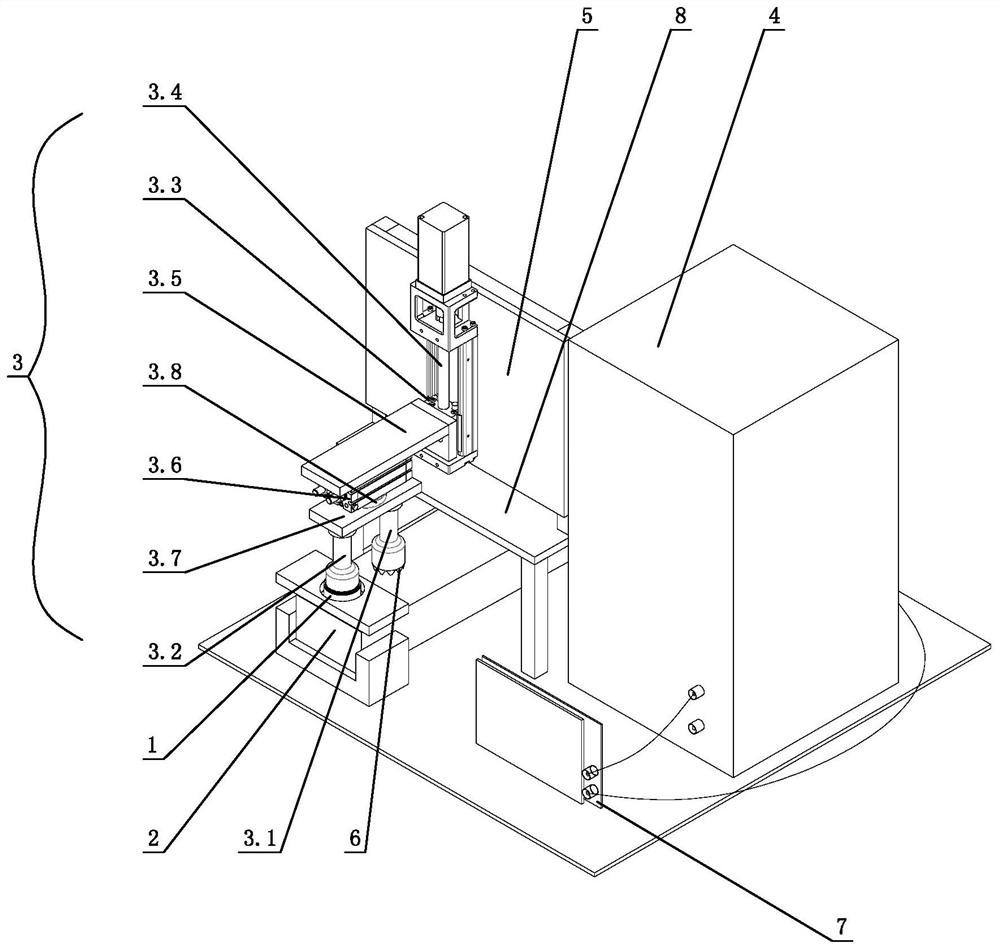

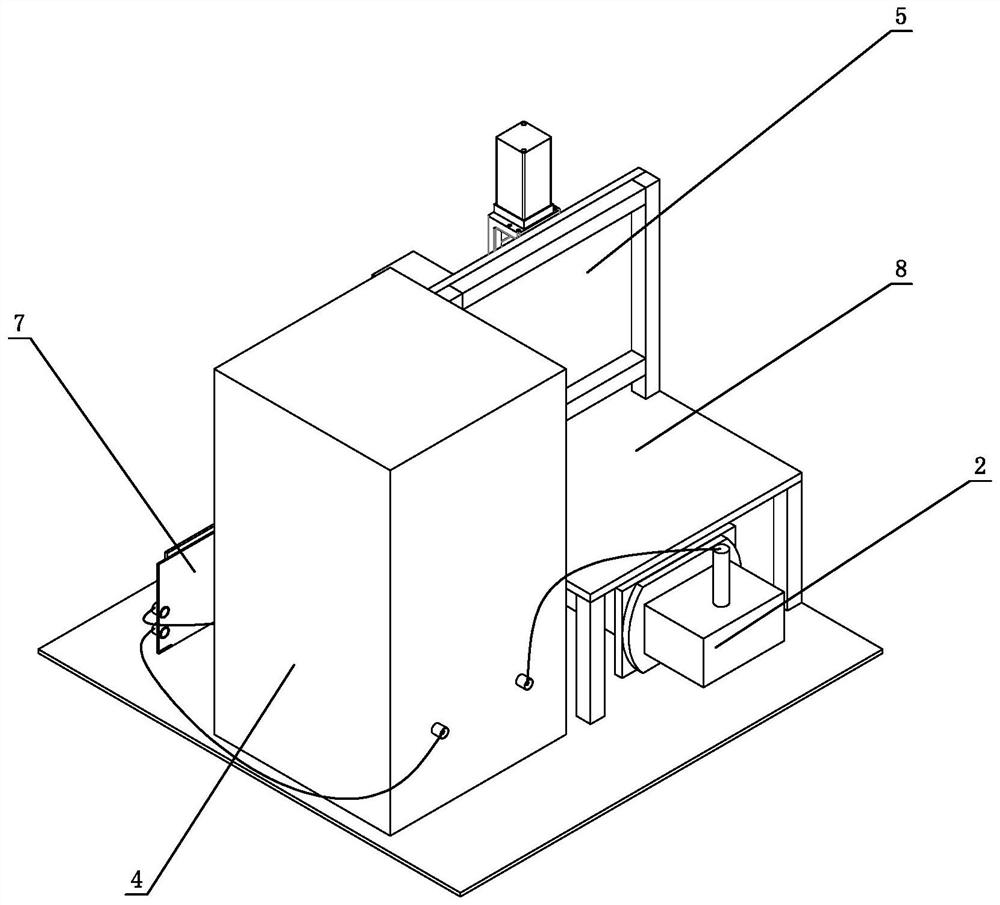

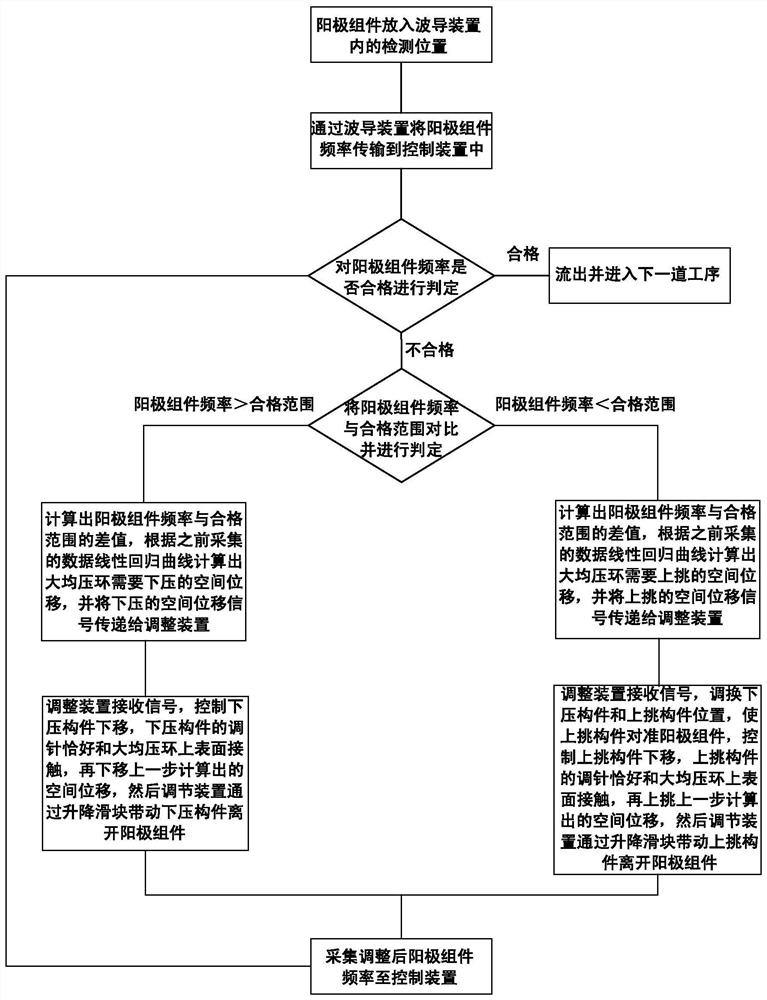

[0038] see Figure 1-Figure 2, an adjustment device for the frequency of an anode assembly, including a waveguide device 2 for detecting and transmitting the frequency value of an anode assembly 1, and an adjustment device 3 for adjusting the spatial displacement of a large pressure equalizing ring in the anode assembly 1, one side of the waveguide device 2 It is equipped with a control device 4 and a waveguide device for collecting, storing, analyzing and comparing the frequency value of the anode assembly 1 after each detection and adjustment, as well as collecting, storing, analyzing and comparing the spatial displacement data of the large pressure equalizing ring in the anode assembly 1 each time. 2. The adjustment device 3 forms a communication-type electrical connection with the control device 4 respectively. The adjustment device 3 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com