Patents

Literature

57results about How to "Low operating experience requirement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

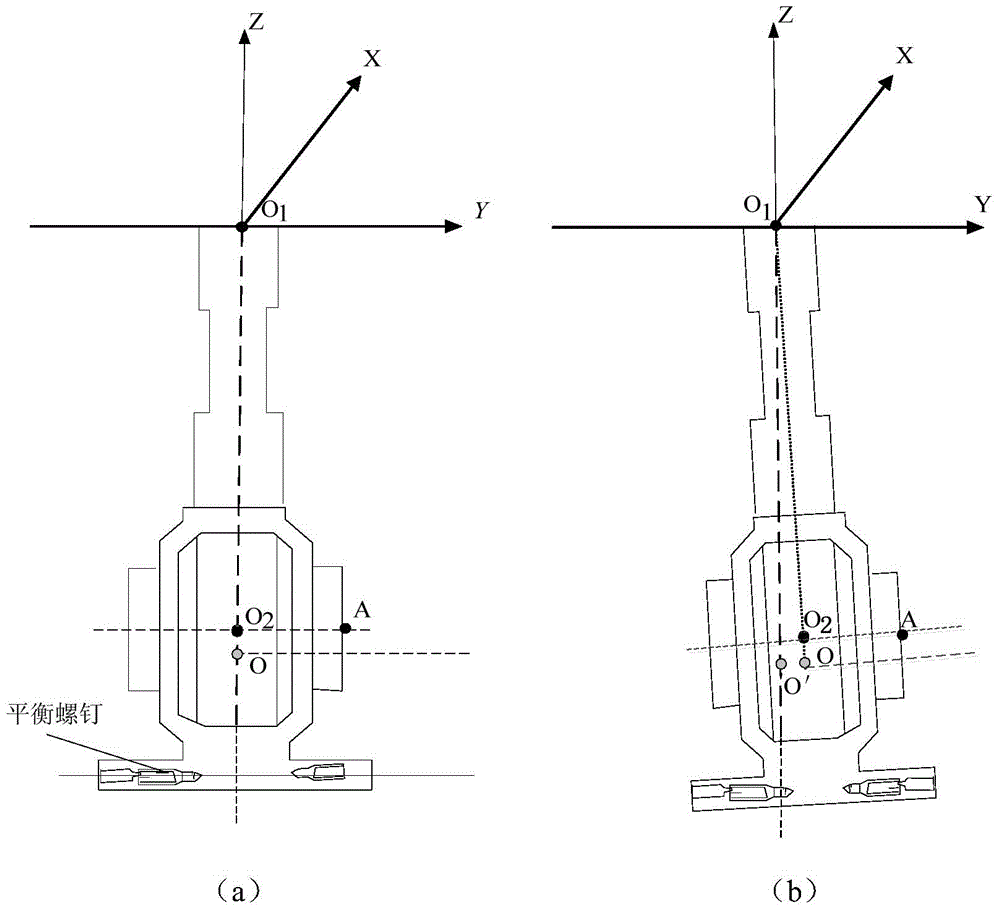

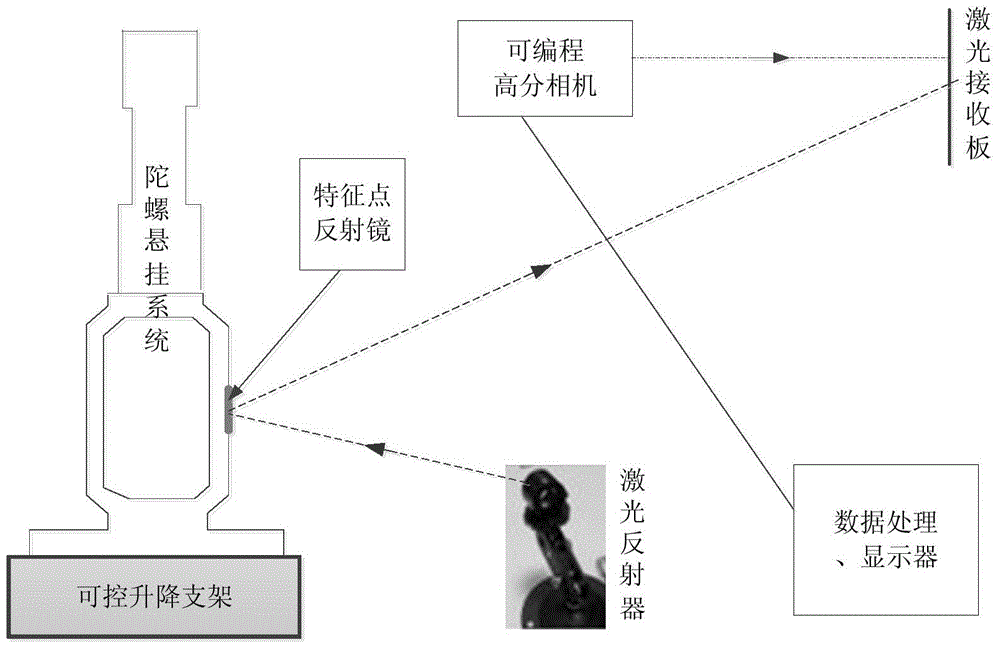

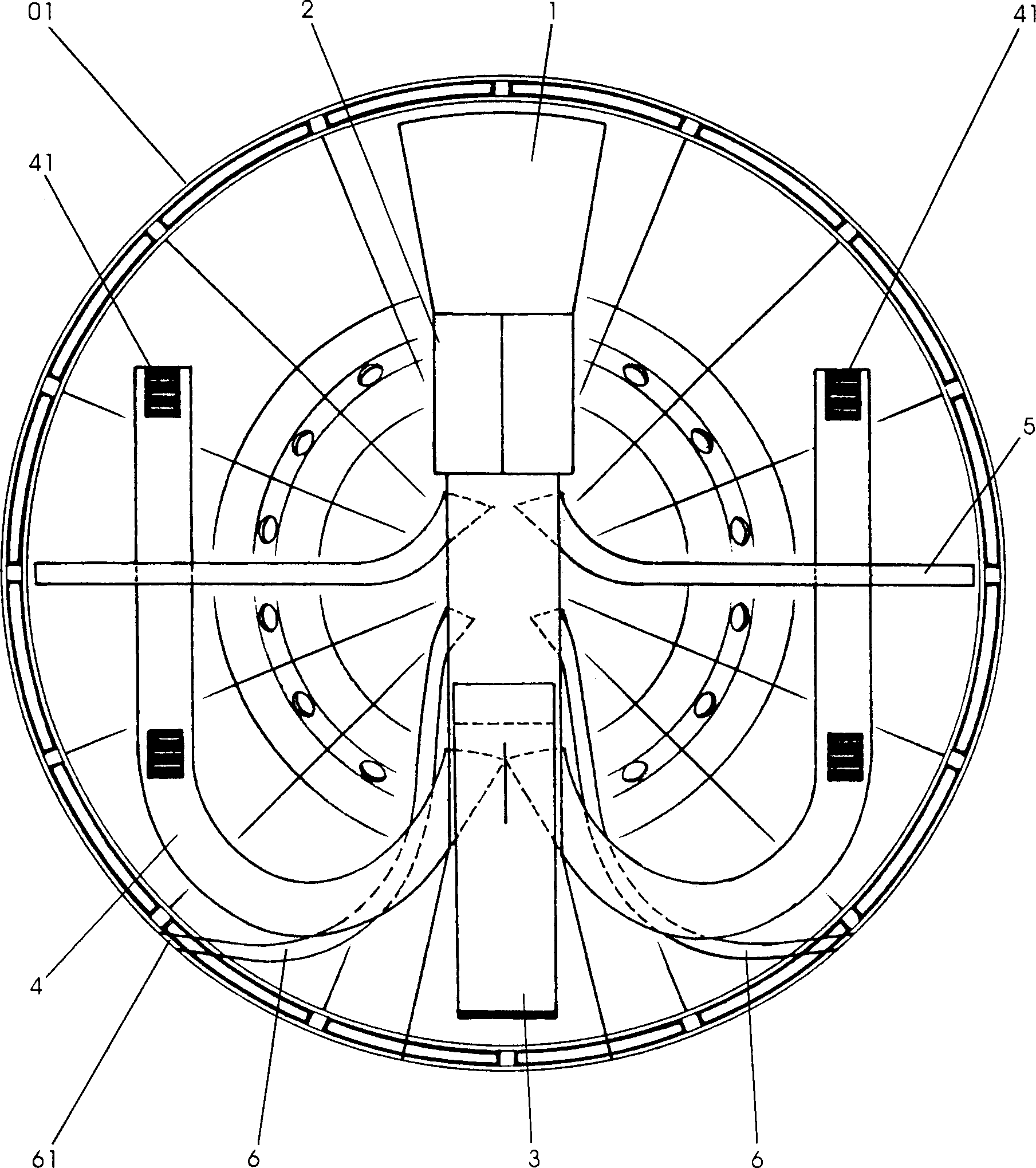

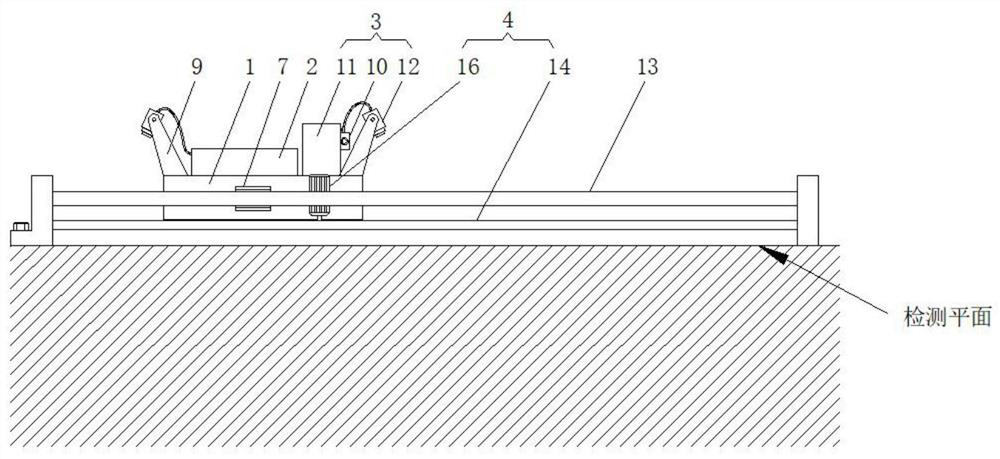

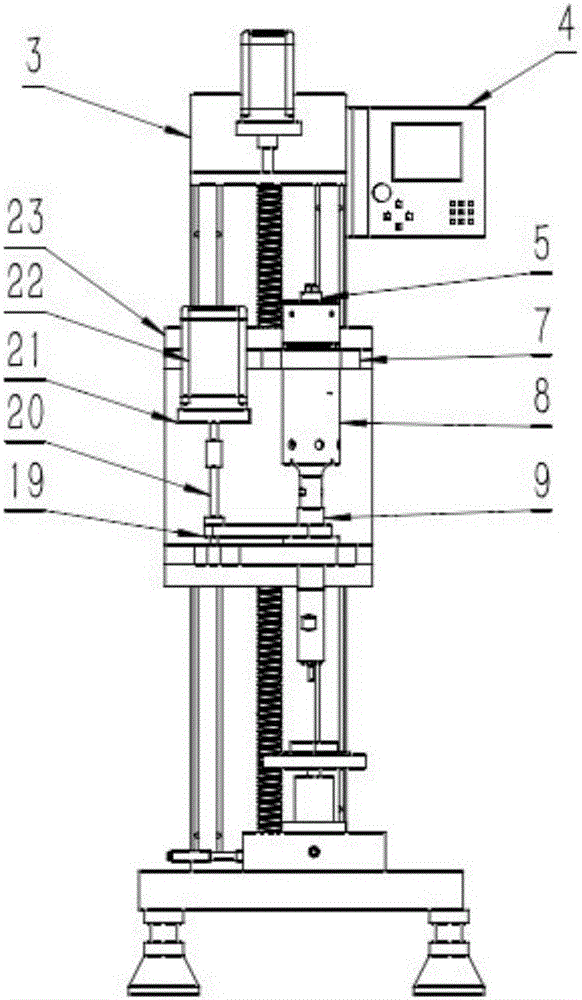

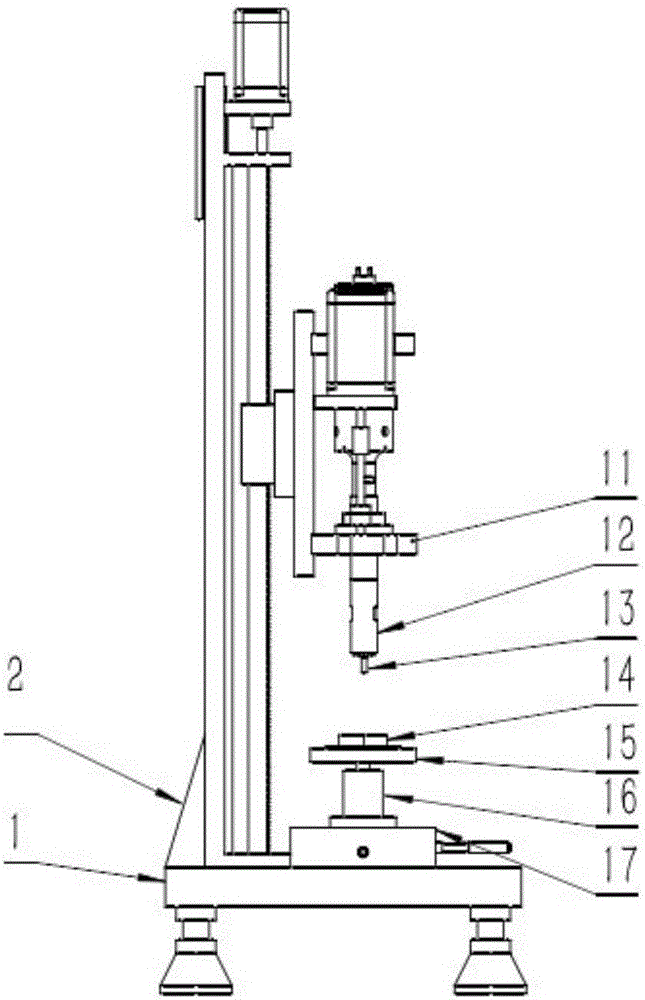

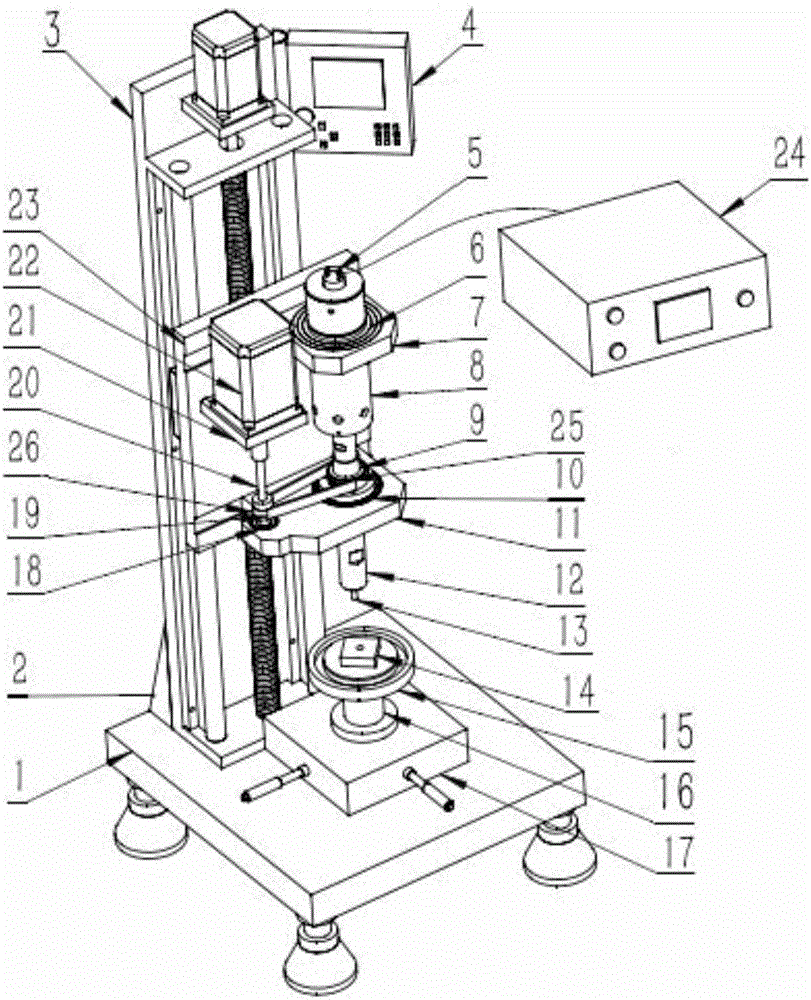

Static balance testing device and method of high-precision gyroscope suspension system

ActiveCN104655154AImprove performanceLow operating experience requirementStatic/dynamic balance measurementLaser transmitterGlass cover

The invention discloses a static balance testing device and method of a high-precision gyroscope suspension system. The device comprises a controllable lifting gyroscope suspension system support, a laser emitter, a receiving plate, a high-resolution programmable industrial camera, a positioning support of the high-resolution programmable industrial camera, a high-precision level meter, a transparent glass cover for protecting the suspension system, and a computer. Method comprises the following steps of accurately capturing the motion track of a feature point; calculating the static balance residual amount of a gyroscope suspending system by determining the motion track of the feature point, namely the gravity center deviation; and converting parameters which cannot be observed directly into observable parameters so as to provide a scientific basis for the determination of the static balance residual amount of the gyroscope suspending system. The determination of the static balance residual amount of the gyroscope suspending system can be used for providing the scientific basis for the research and production debugging of a high-precision gyroscope with the precision superior to + / -5s; the installation and debugging efficiency are improved; the requirement of the high-precision gyroscope on operation experience of installation and debugging personnel is lowered.

Owner:CENT SOUTH UNIV

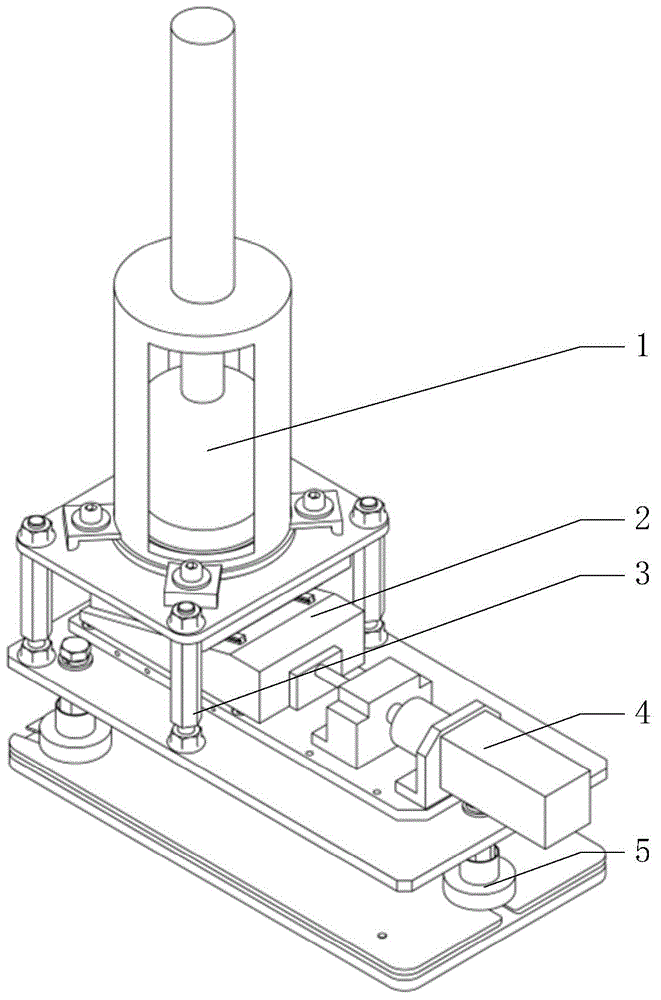

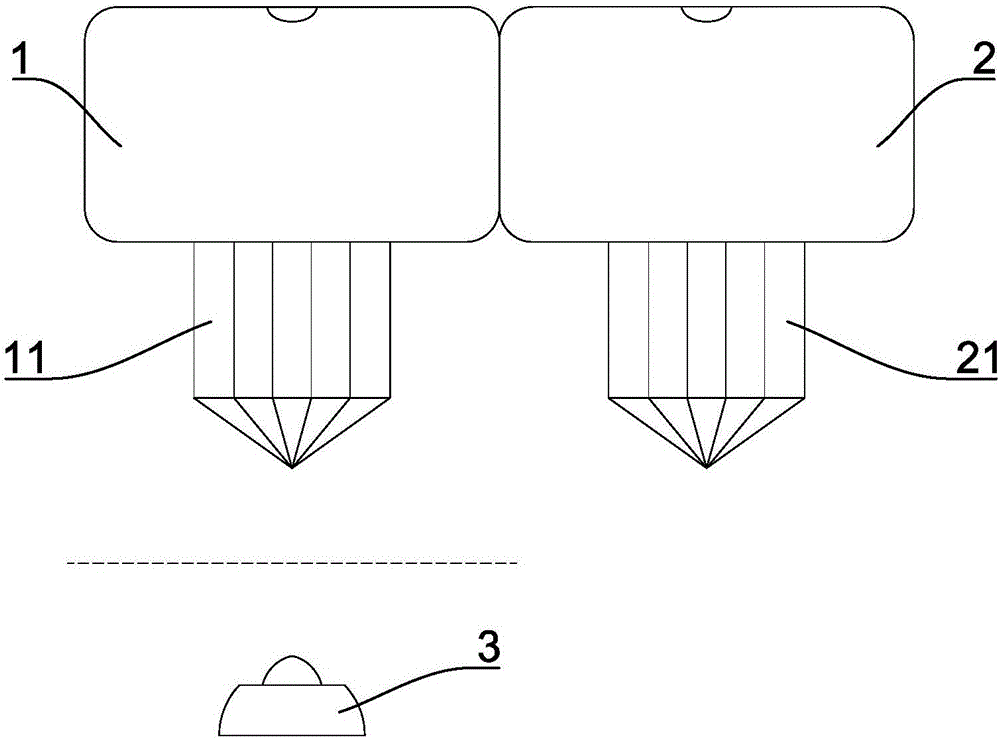

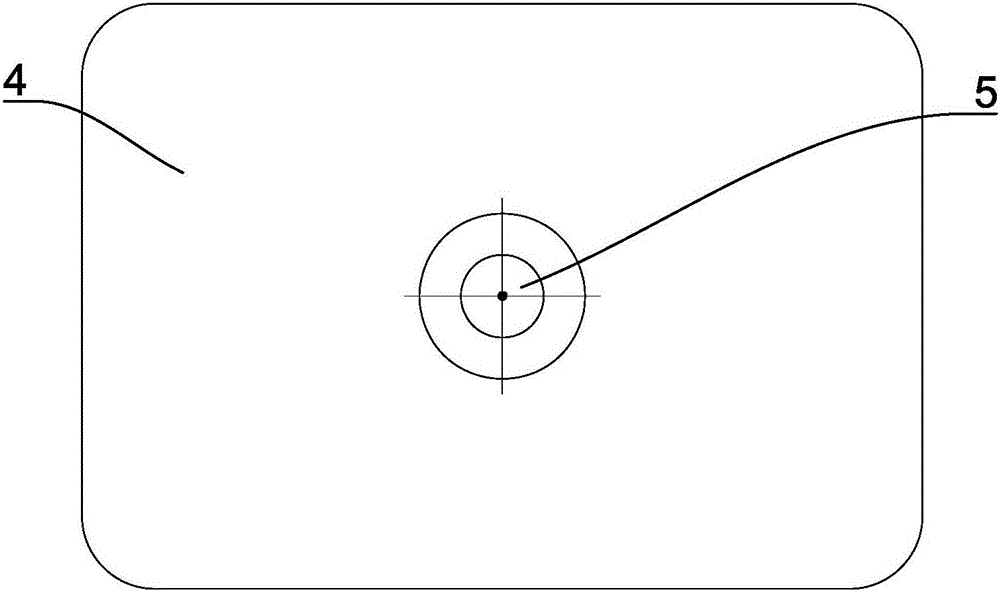

Nozzle calibration method of 3D printer

ActiveCN106335186AEasy to operateLow operating experience requirementAdditive manufacturing apparatusControl systemOptical axis

The invention discloses a nozzle calibration method of a 3D printer. The method comprises steps as follows: a calibration zone is established, and a camera with a perpendicular and upward optical axis is arranged in the calibration zone; the camera is connected with a control system of the 3D printer; a real-time display window corresponding to the calibration zone is established in the control system; a nozzle comprising a main nozzle and an auxiliary nozzle is integrally moved above the calibration zone; the nozzle is integrally moved in an x-y plane of the calibration zone and is observed through the real-time display window, the position of the main nozzle and the position of the auxiliary nozzle are acquired, and the relative distance between the main nozzle and the auxiliary nozzle is determined according to the position of the main nozzle and the position of the auxiliary nozzle and is recorded as (deltax, deltay); (deltax, deltay) is fed back to the control system and is used as a compensation parameter for the distance between the main nozzle and the auxiliary nozzle. The method has the advantages of being simple to operate, accurate in calibration and high in automation degree, and the problems that the printing quality and efficiency are affected due to large calibration errors caused by the fact that existing nozzle calibration manners are limited by operation experience are solved.

Owner:WUXI TIERTIME TECH CO LTD

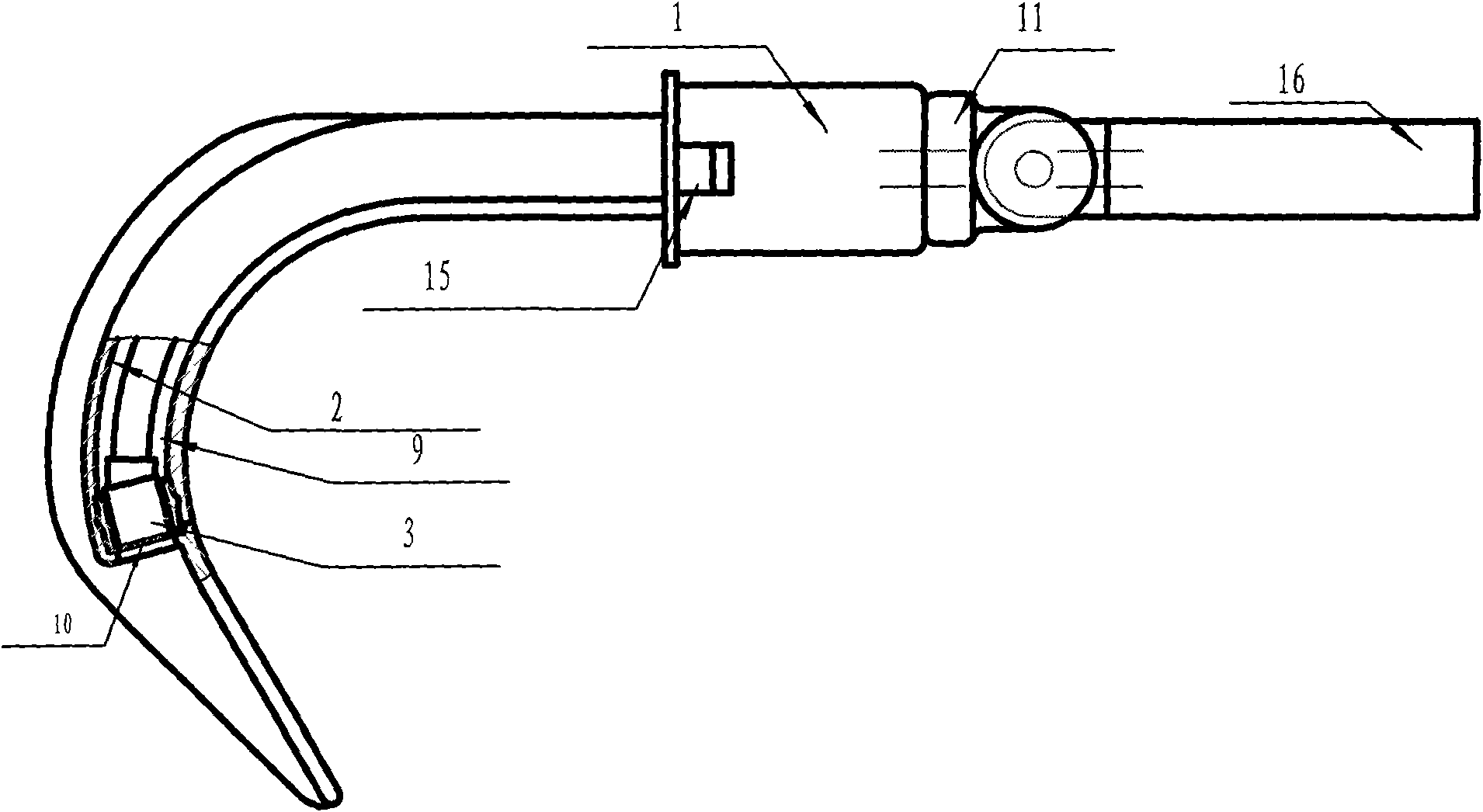

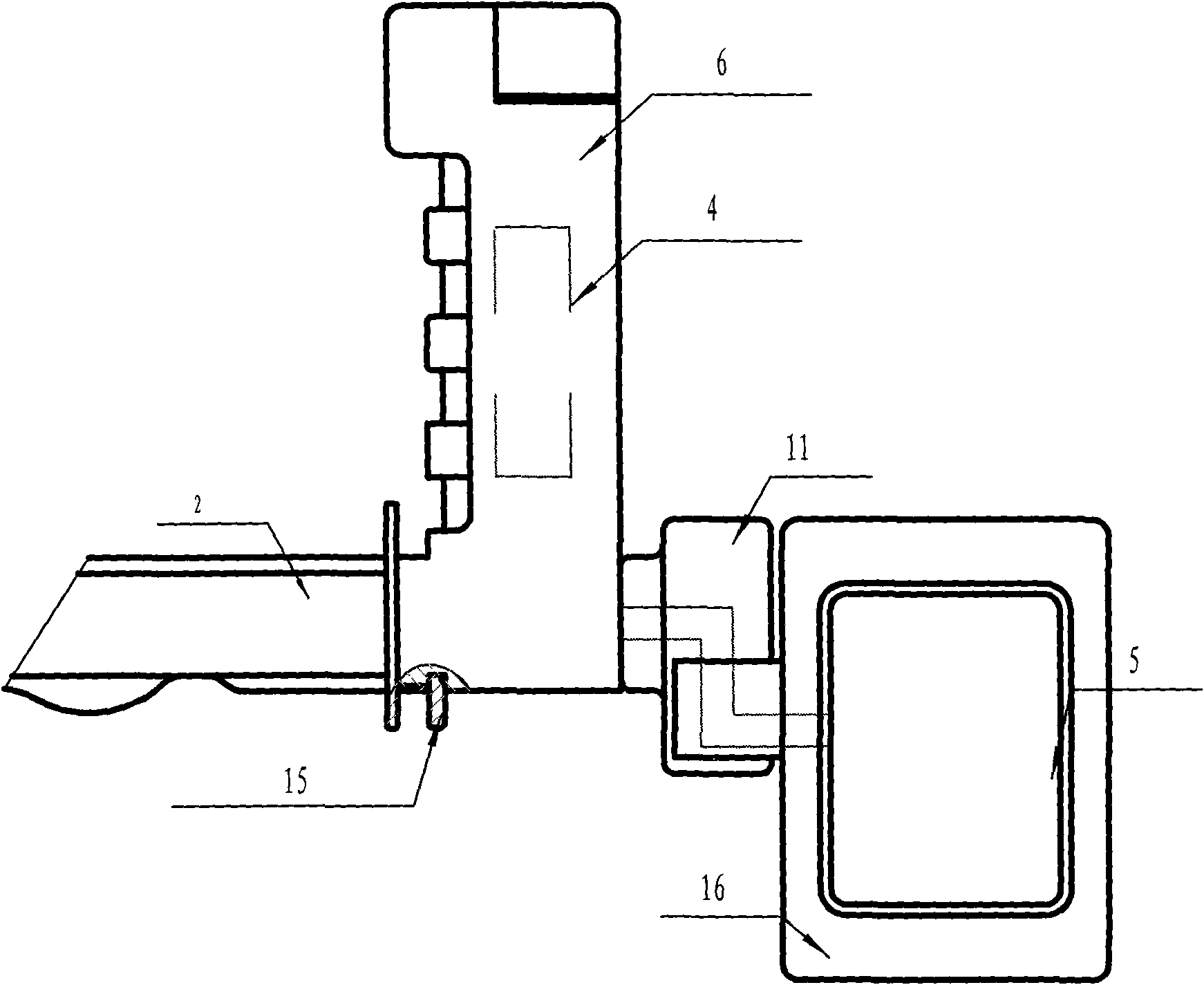

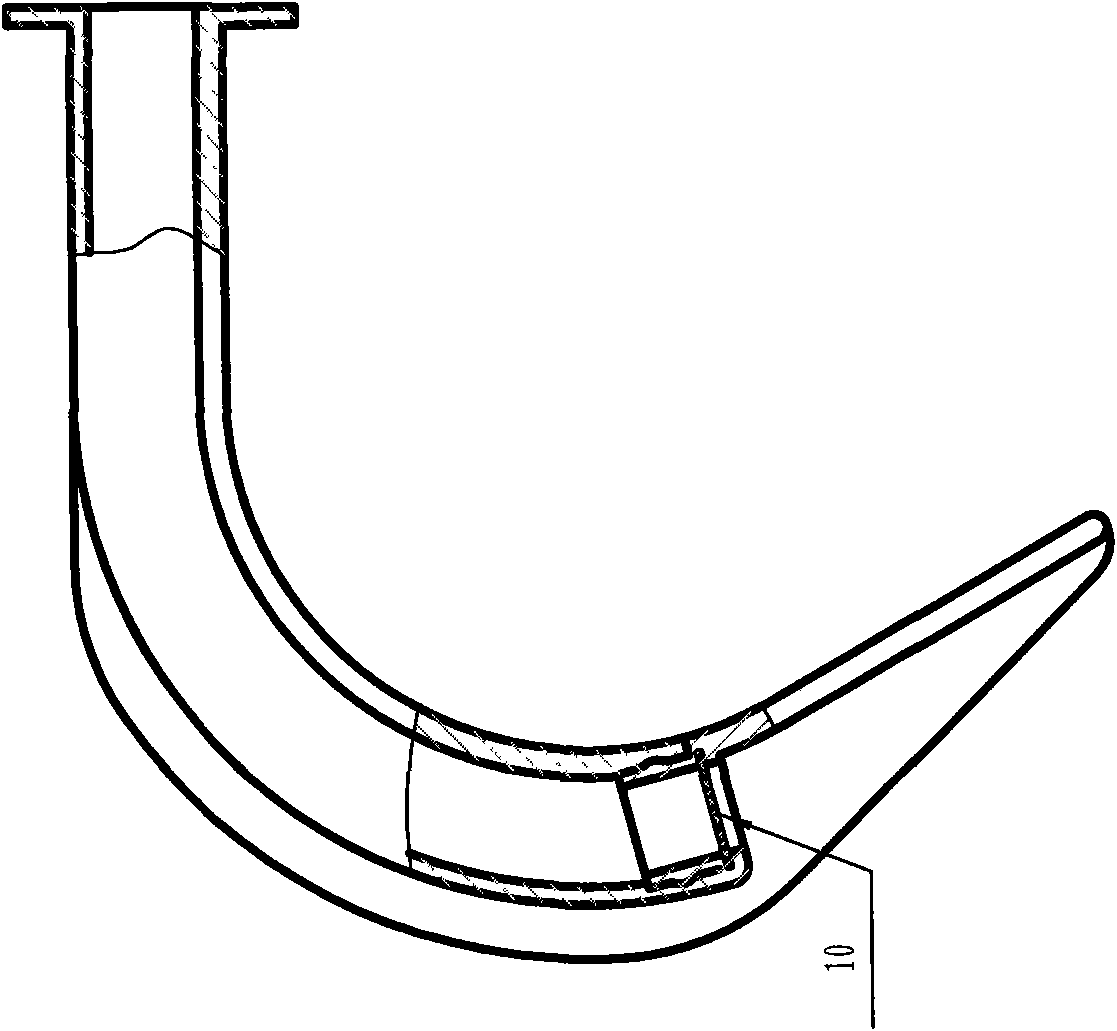

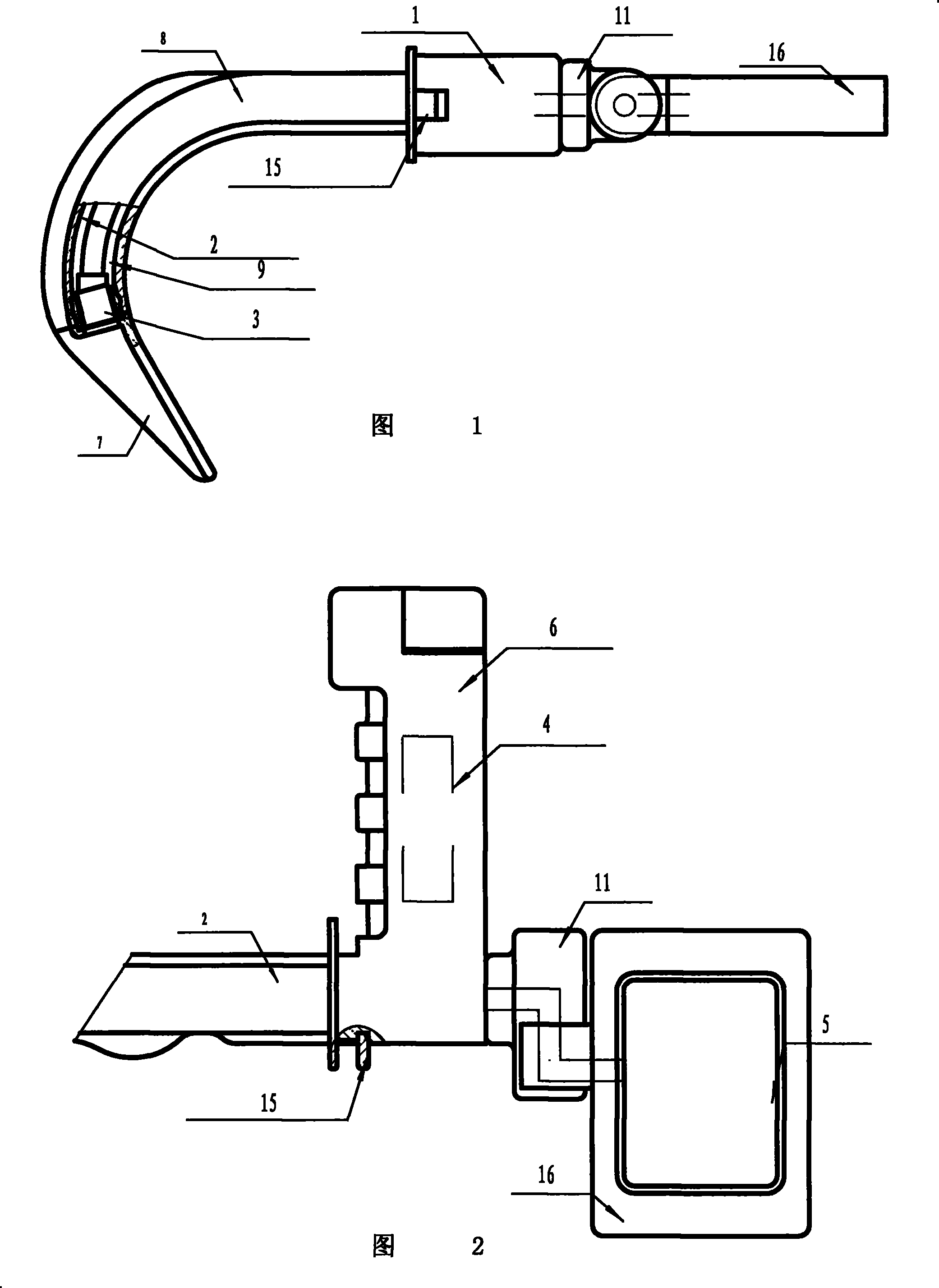

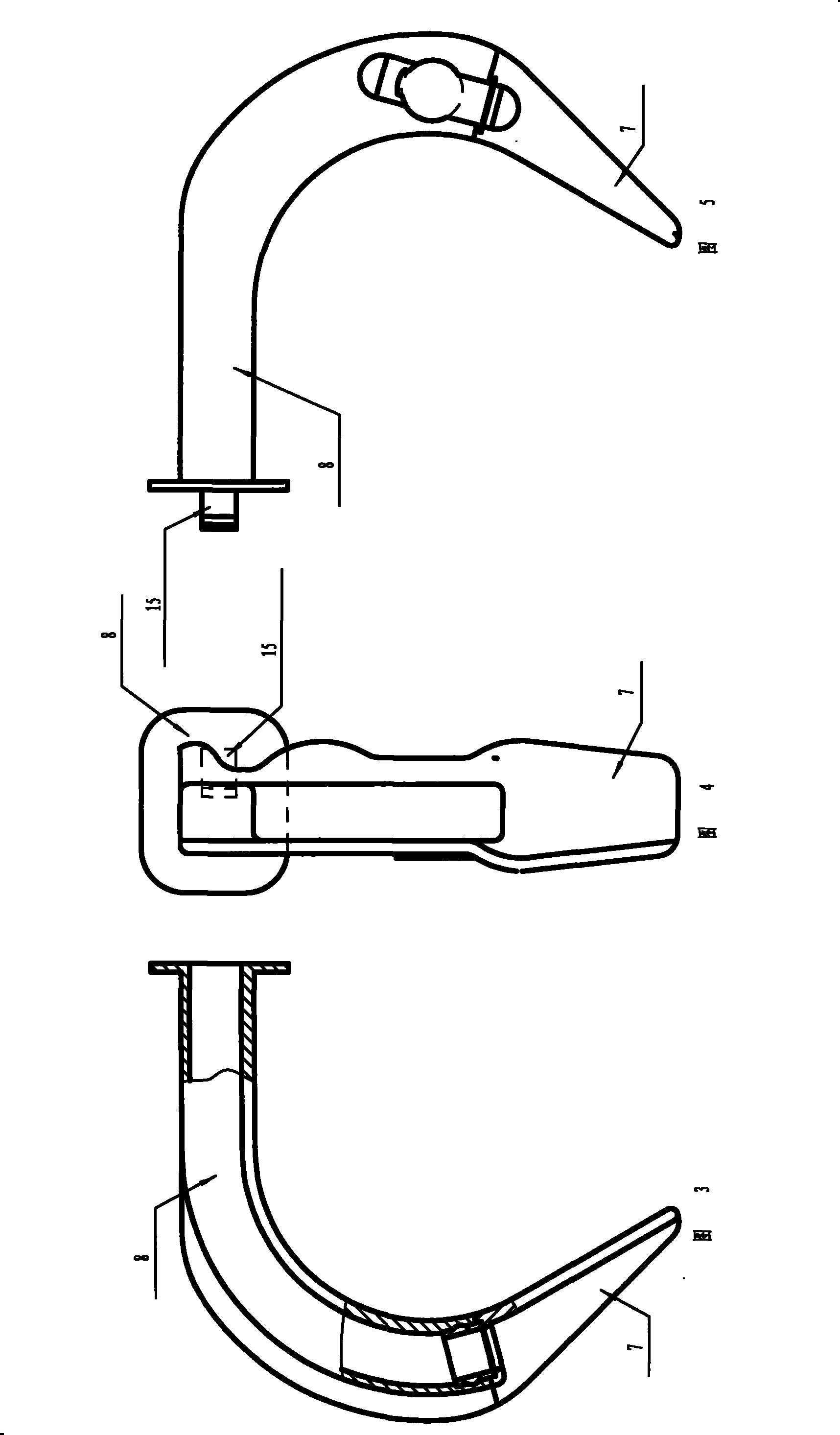

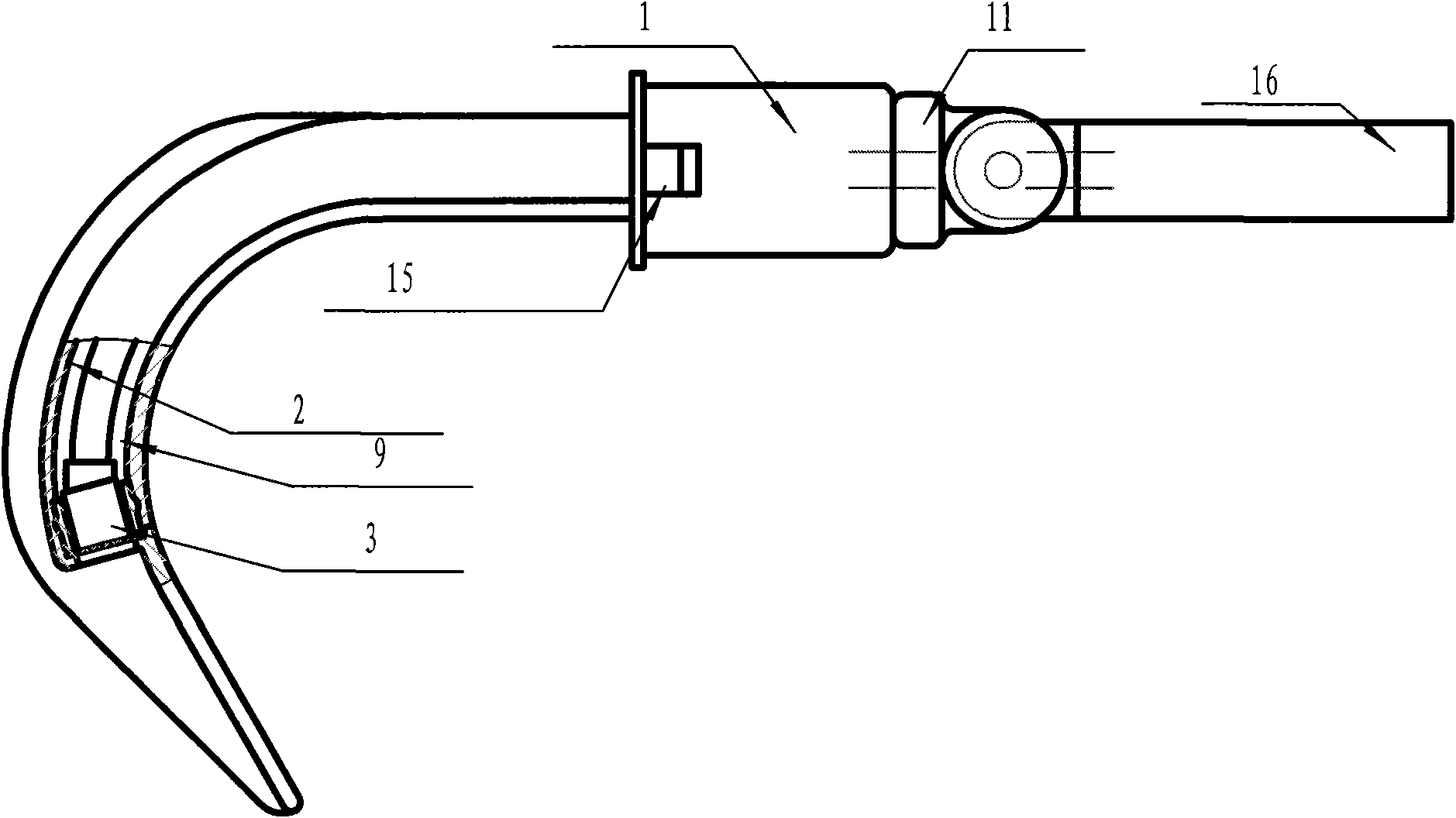

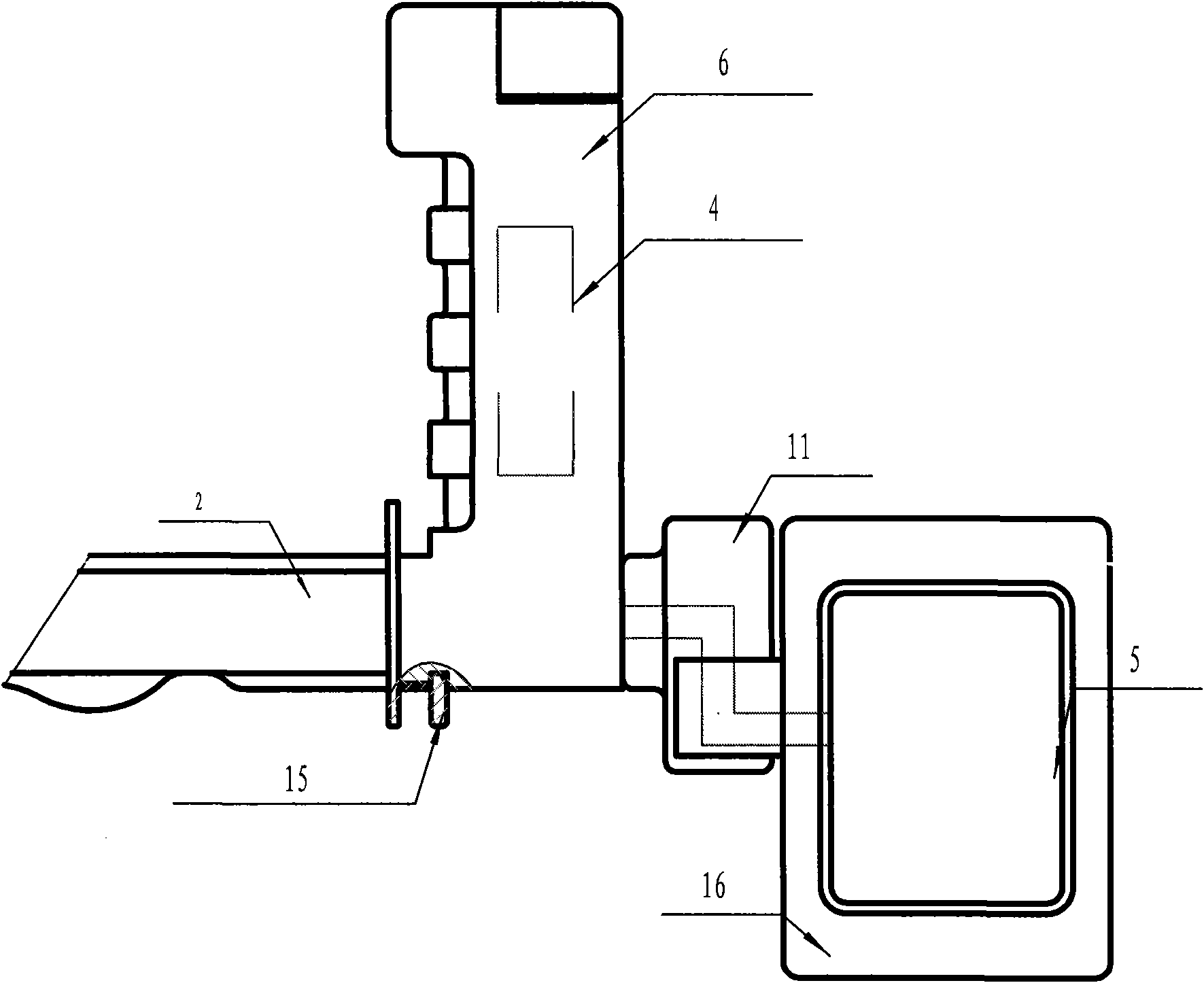

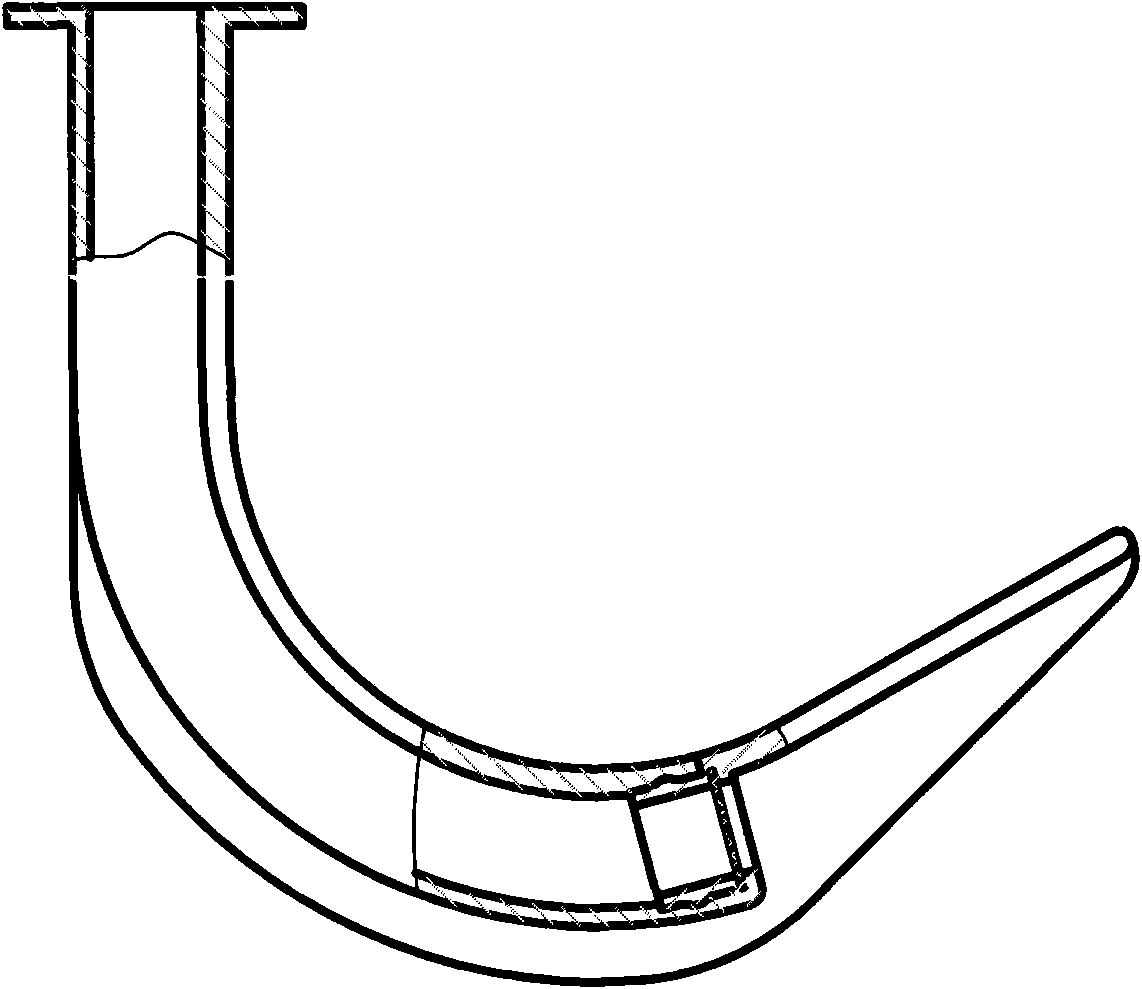

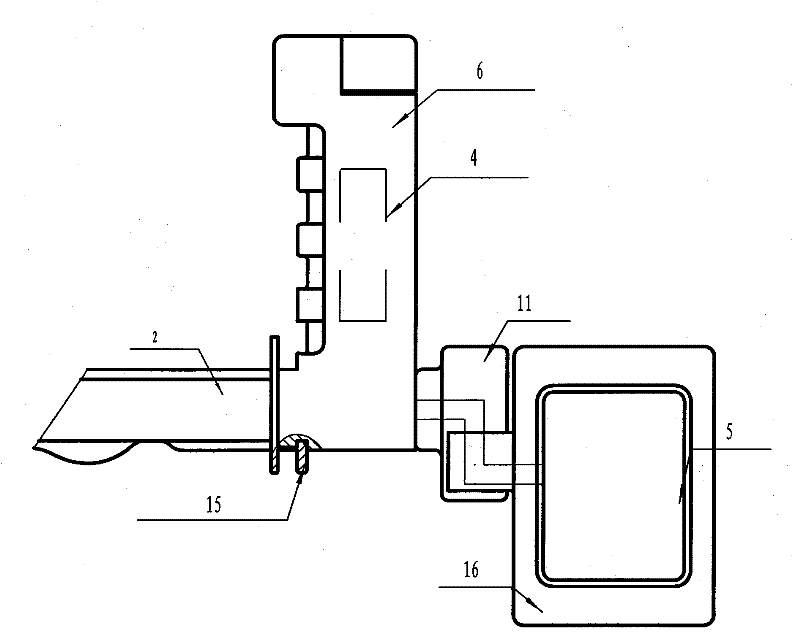

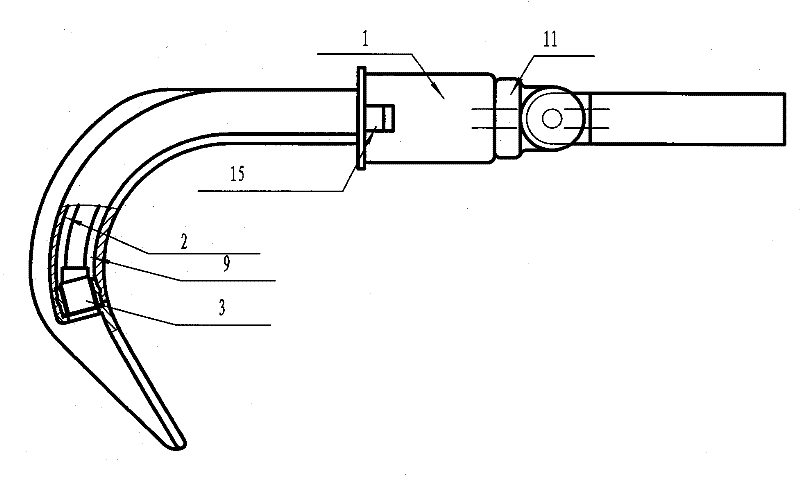

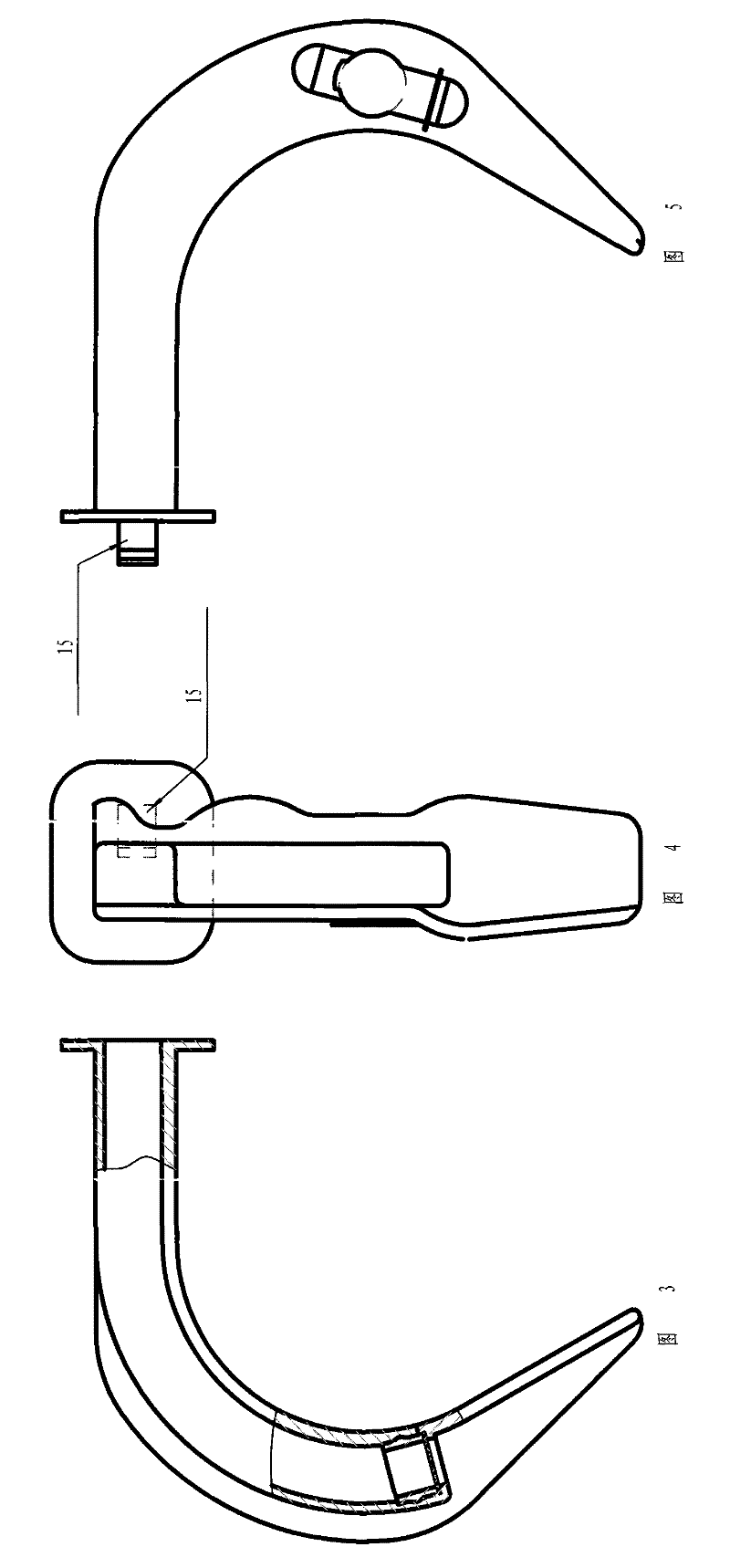

Electronic video laryngoscope with anti-mist function

InactiveCN101554321AShorten the vertical lengthAvoid getting stuck in the patient's chestRespiratorsBronchoscopesVideo laryngoscopeDisplay device

The invention provides an electronic video laryngoscope with anti-mist function. The laryngoscope comprises a bracket component, an arc oropharynx air duct and spatula assembly, an image shooting component, a cell box and a display, wherein the arc oropharynx air duct and spatula assembly is positioned on the front end of the bracket component; the image shooting component is positioned at the lower part of arc oropharynx air duct and spatula assembly; the image shooting component comprises a camera and an illuminating lamp; the display can be rotatably arranged on the rear end of the bracket component; the camera is connected with the display through a data wire; the cell box is connected with the illuminating lamp, the camera and the display through electric wires. The electric video laryngoscope also comprises a cell kit which can also be used as an operation handle; the cell box is arranged in the cell kit; the cell kit is arranged on the side of the bracket component; the camera and the illuminating lamp are arranged on the front end of a cavity of the image shooting component; and an optical protective lens applied with anti-mist antireflection coating is fixed on the top end of the cavity of the image shooting component. The electric video laryngoscope can effectively shorten the handle length, can be operated conveniently, has lower requirement on operation experience of a doctor, and has excellent anti-mist effect.

Owner:石学银 +1

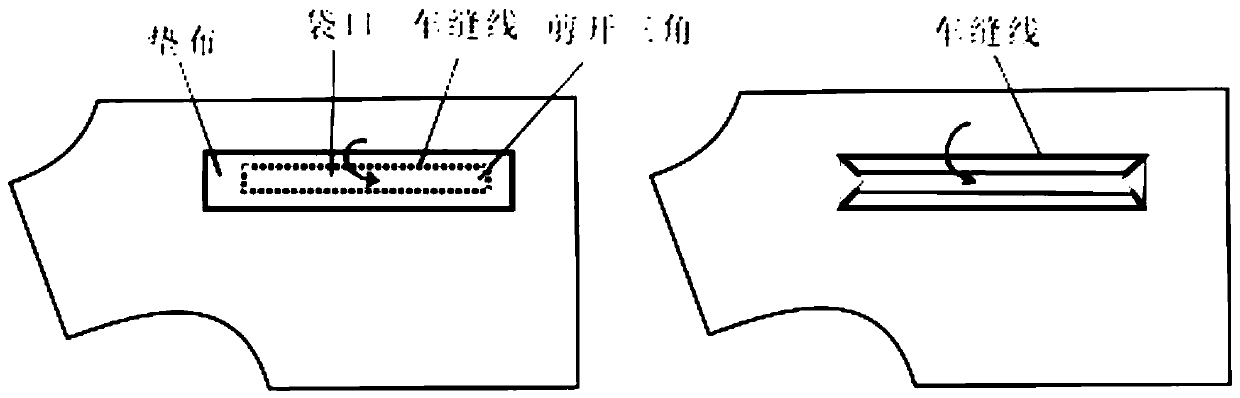

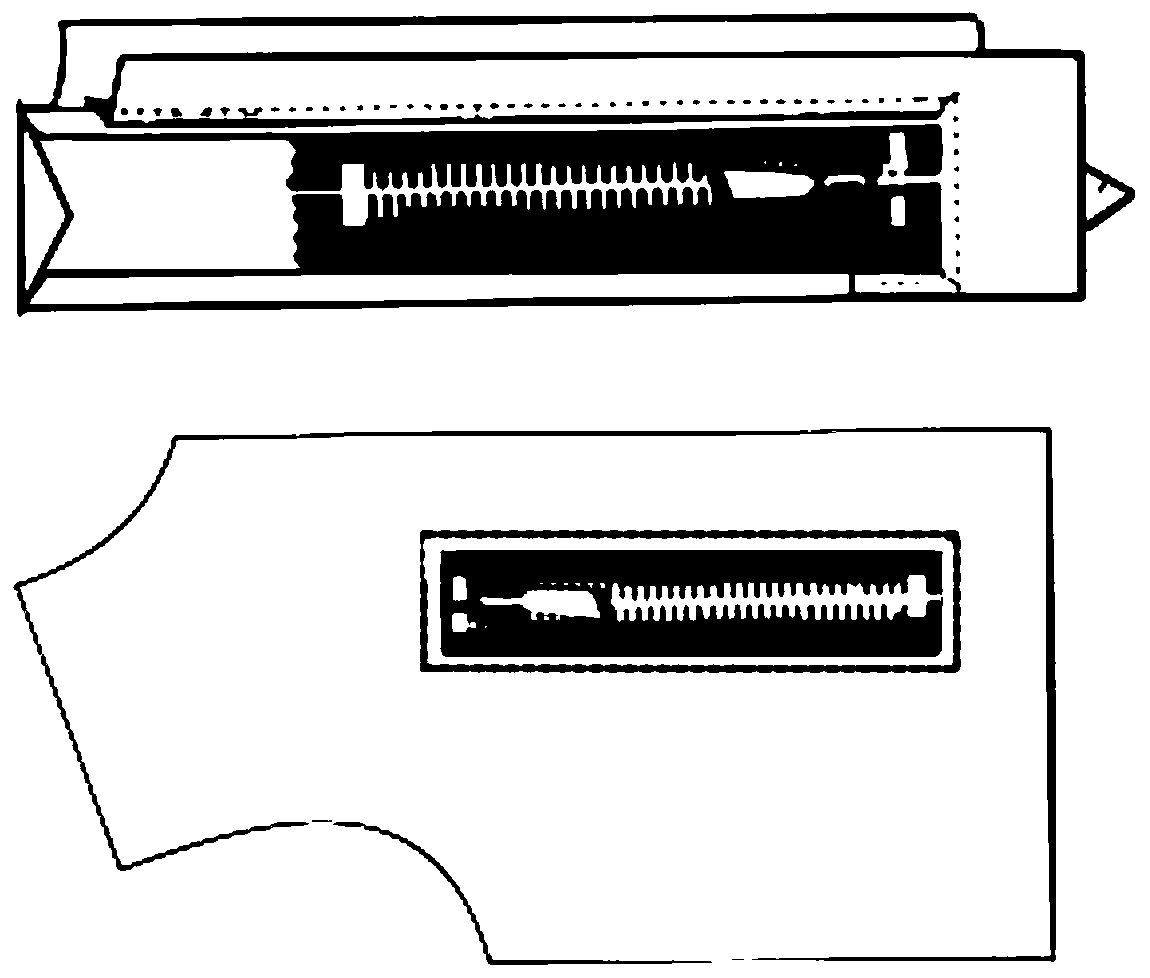

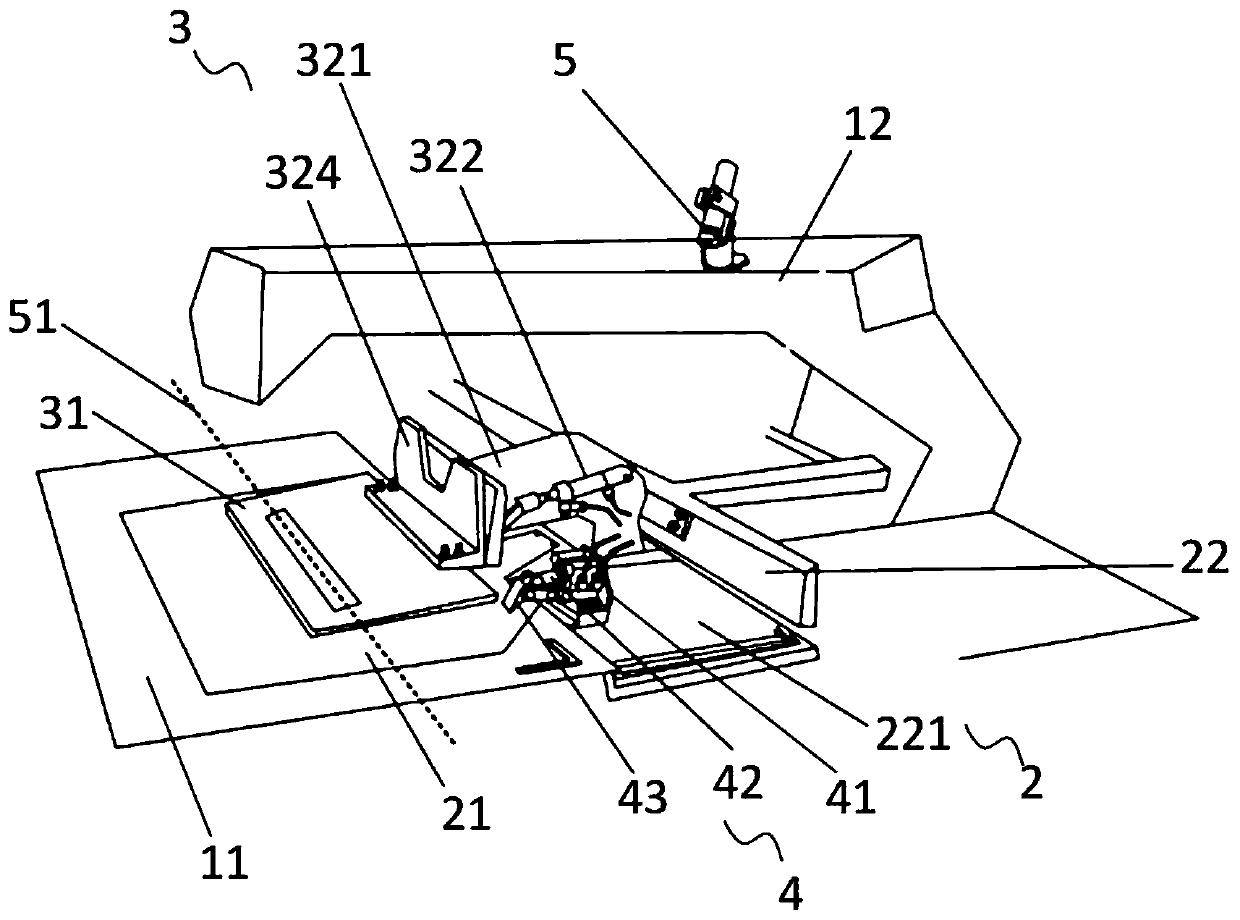

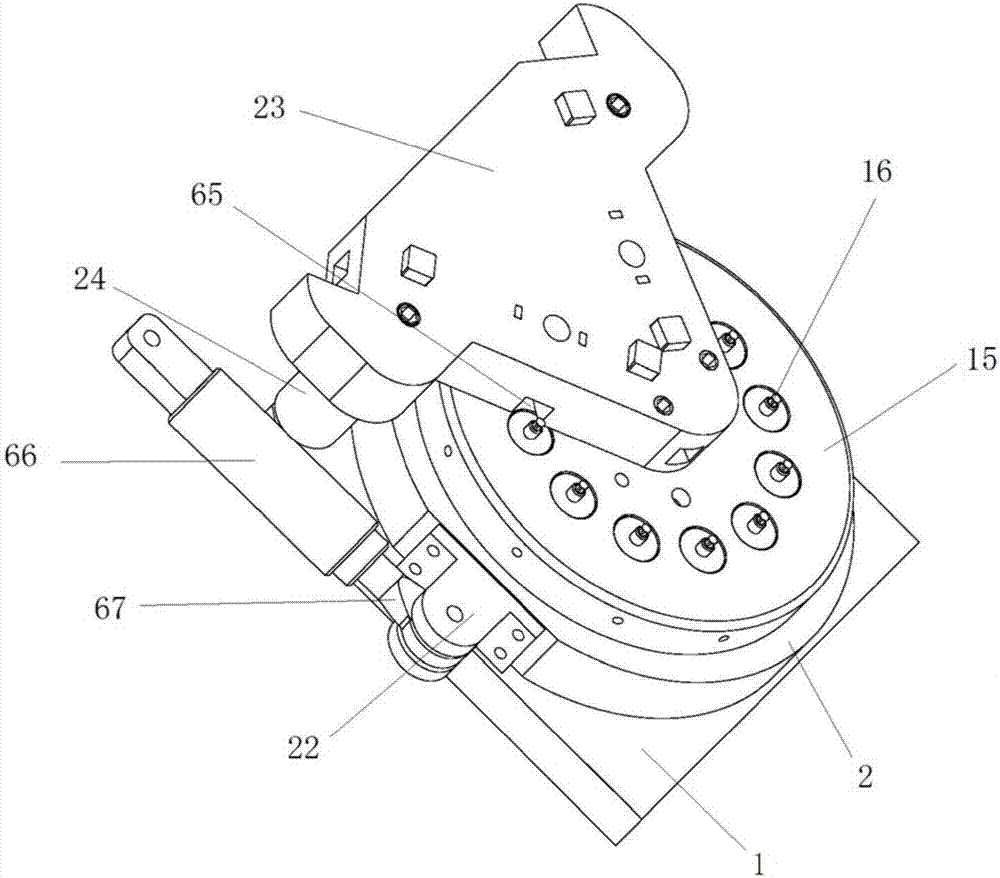

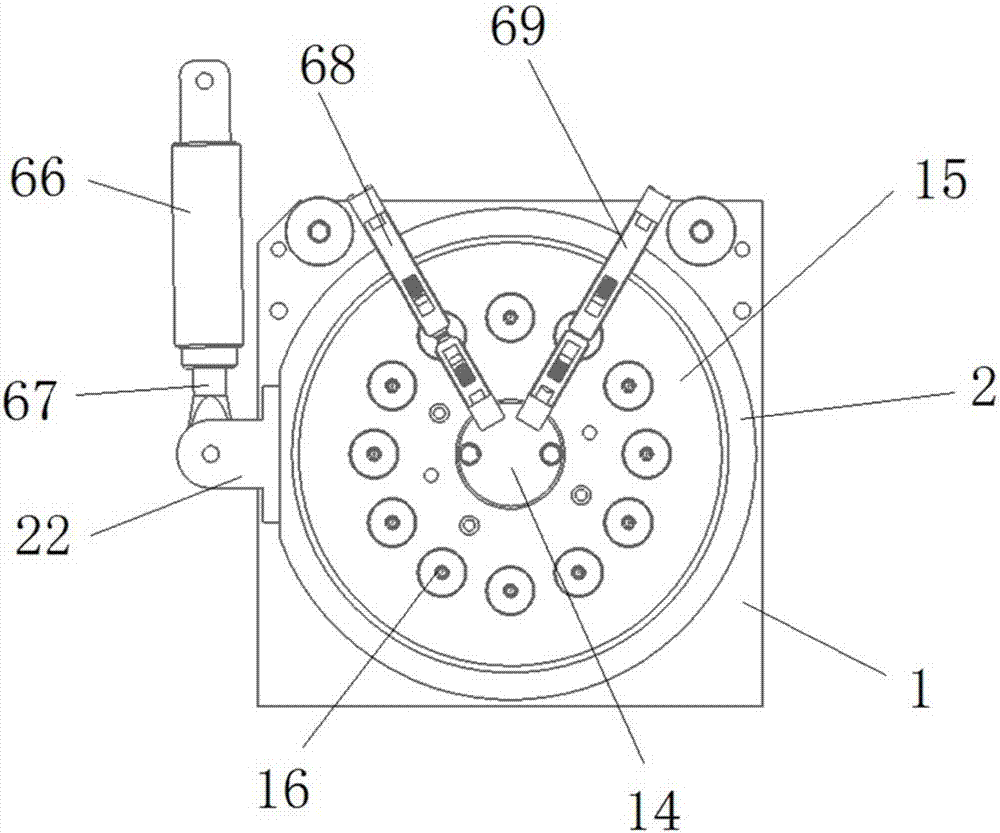

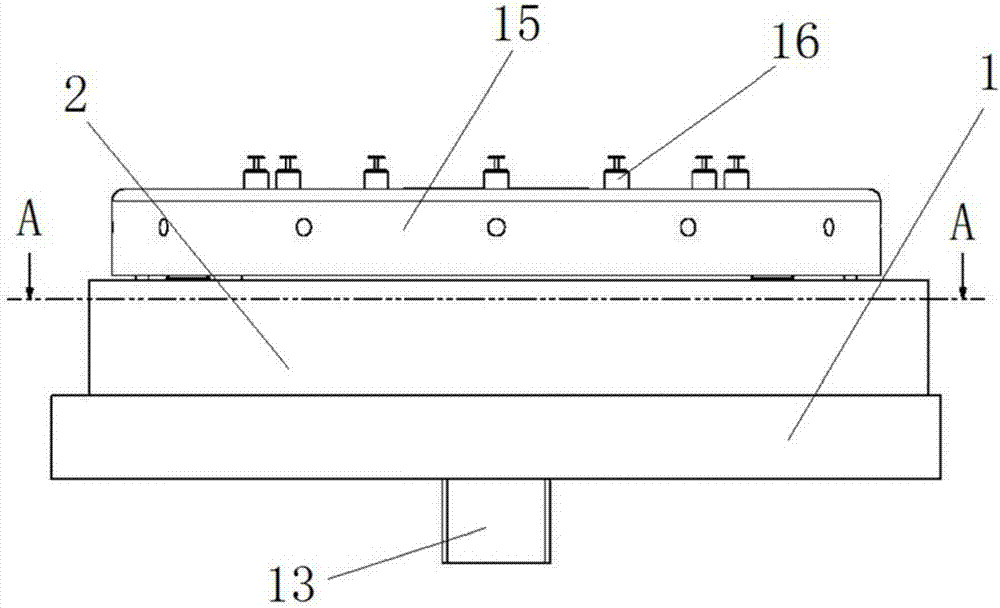

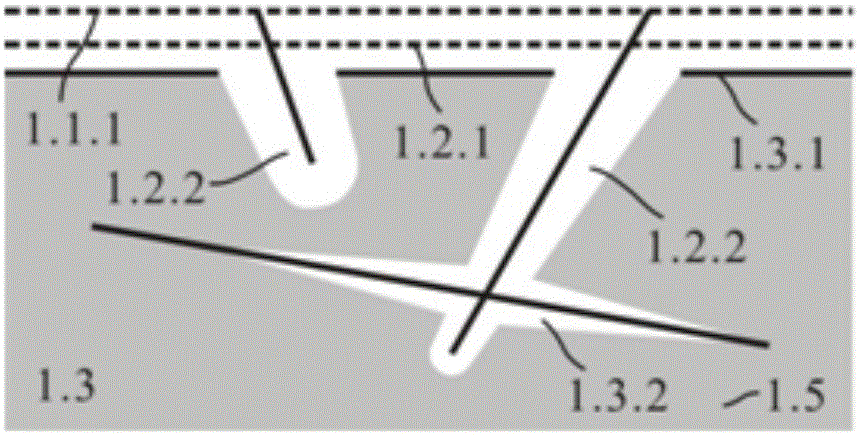

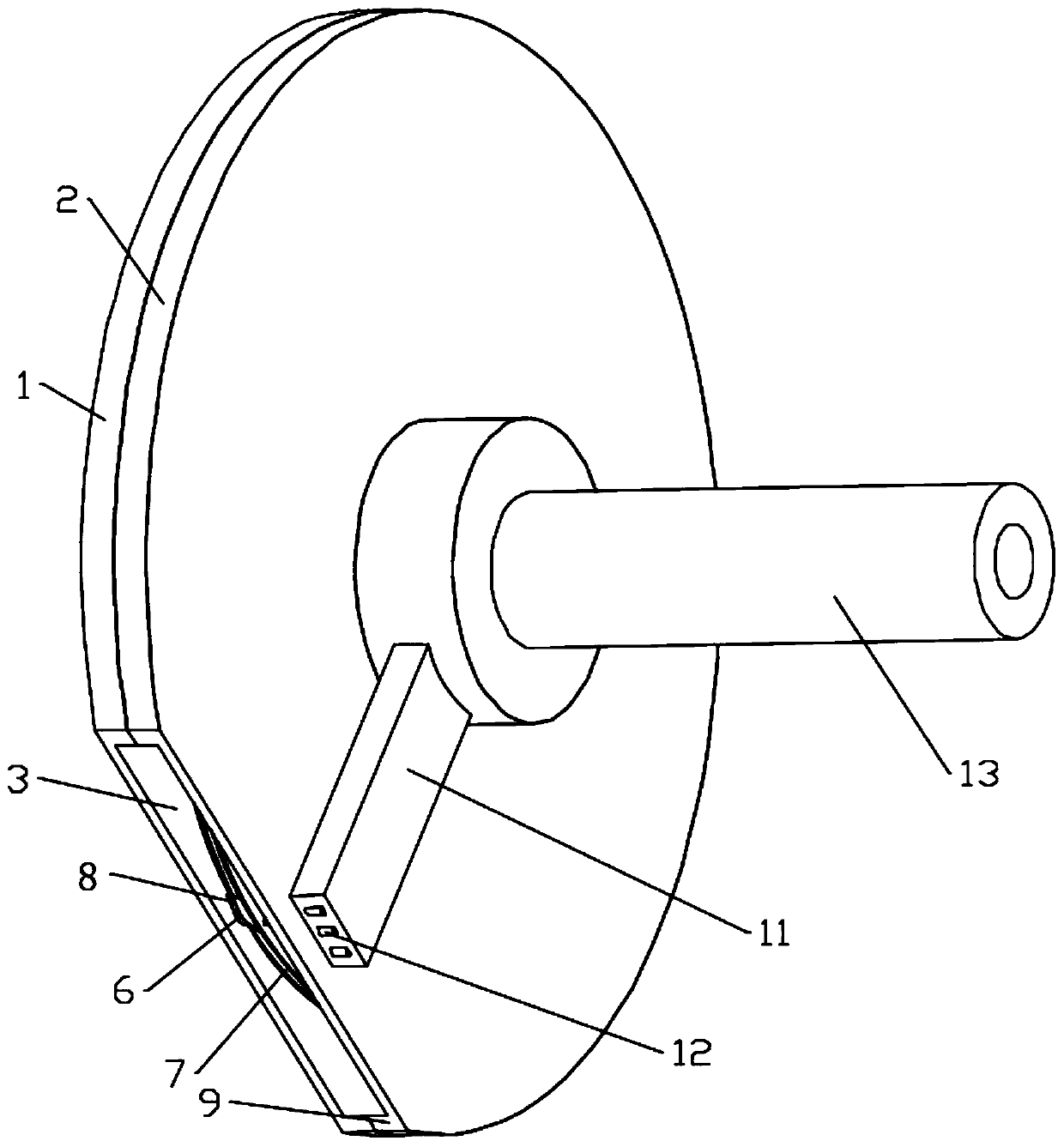

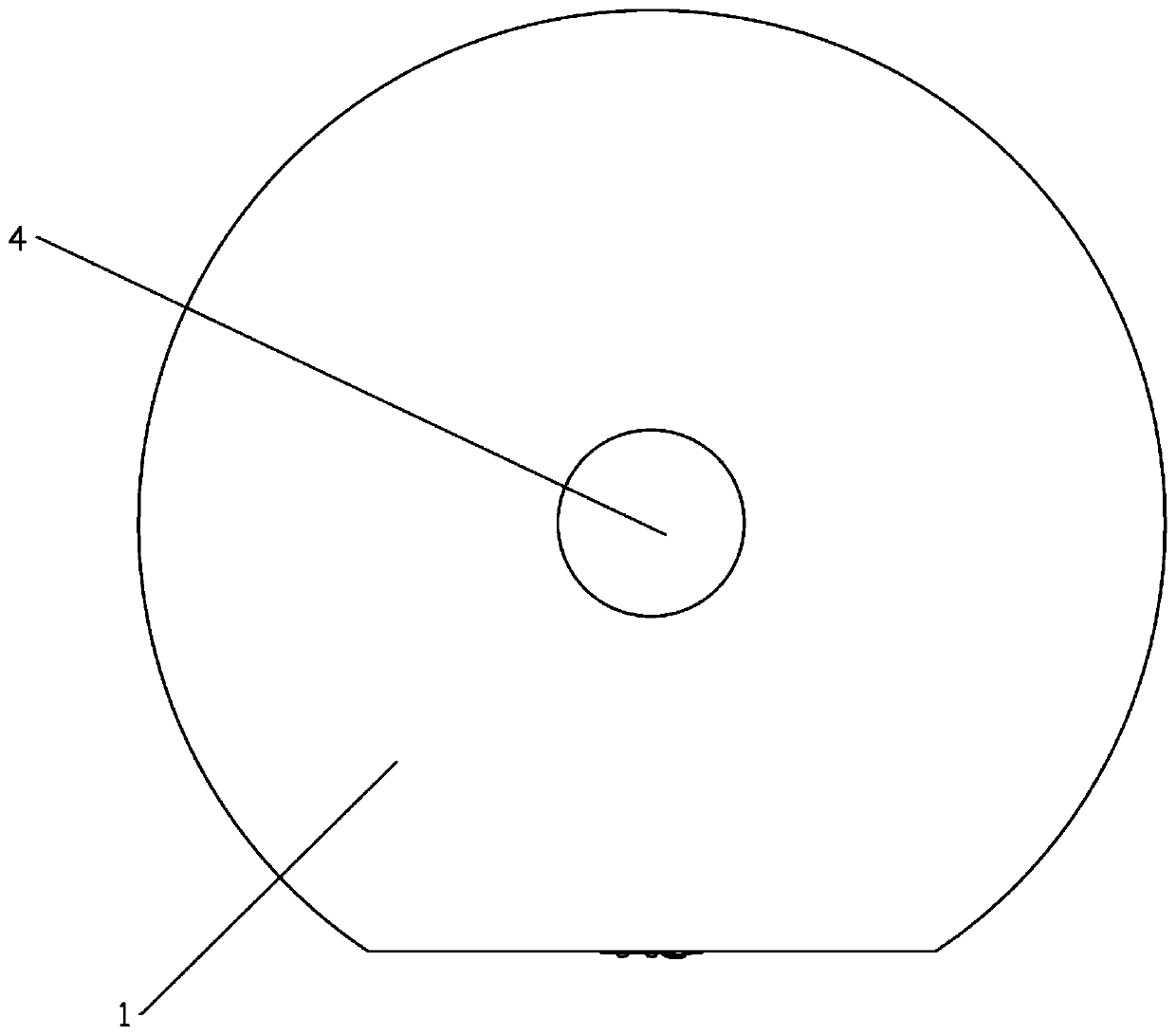

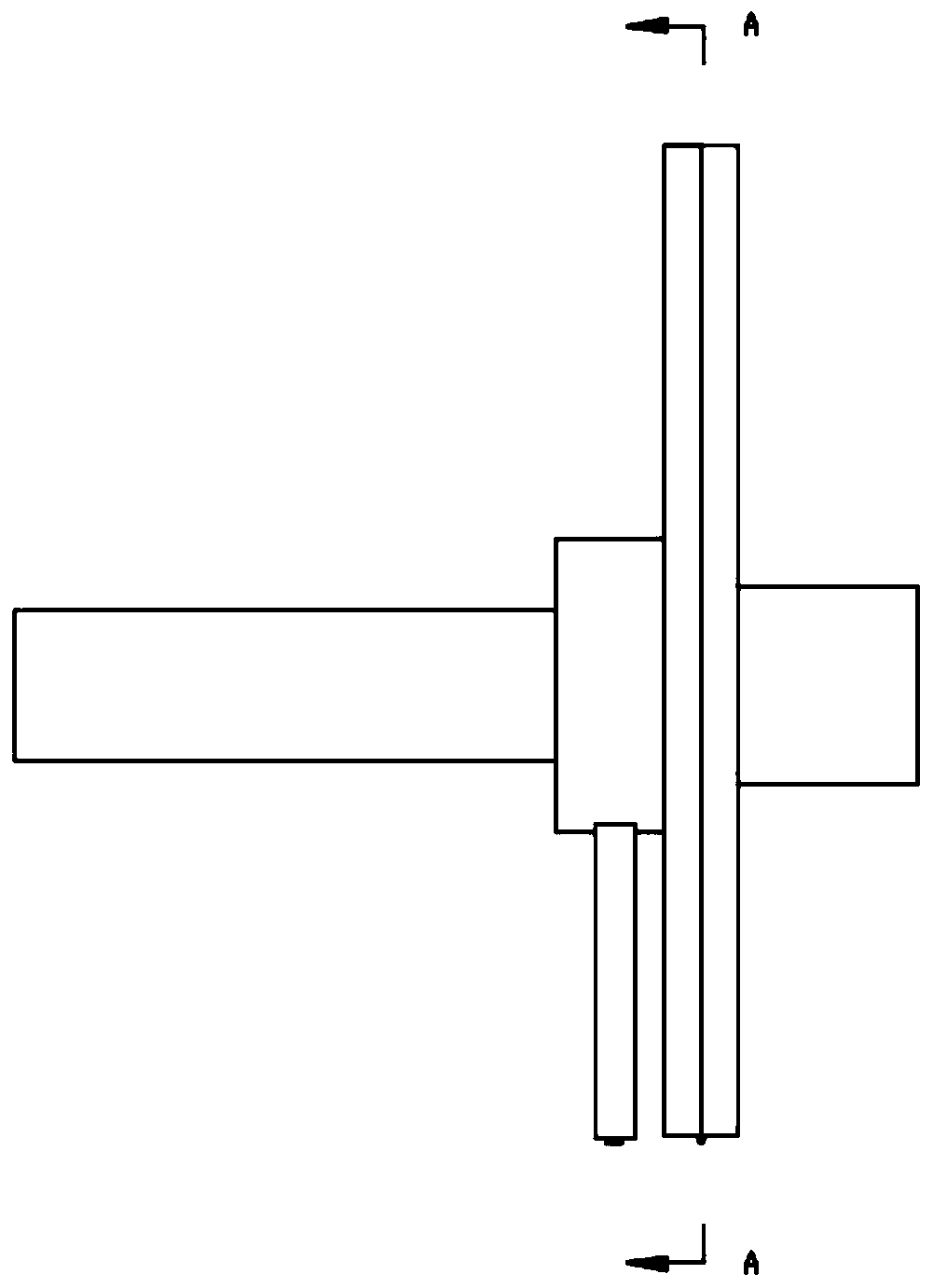

Pocket zipper sewing process and pocket zipper sewing equipment

ActiveCN110983656AThe operation process is simpleLow operating experience requirementWorkpiece carriersWork-feeding meansManufacturing engineeringMechanical engineering

The invention discloses a pocket zipper sewing process and pocket zipper sewing equipment. The pocket zipper sewing process comprises the following steps of breaking a linear notch in cloth to be sewn; defining a rectangular positioning part on the front surface of the cloth according to the size of a zipper; sewing a first cloth liner on the front surface of the cloth in the length direction; ina state that a zipper head faces the front surface of the cloth, laying one chain belt in the positioning part, enabling the side edge of a zipper tooth to be flush with one side edge of the positioning part, and sewing the chain belt and the cloth; in a state that the zipper head is pulled open, turning over the other chain belt, enabling the side edge of the zipper tooth to be flush with the other side edge of the positioning part, and sewing the chain belt and the cloth; connecting the wiring tail end of a third sewing thread to a first sewing thread; and pulling the zipper head. The pocketzipper sewing equipment is arranged based on the pocket zipper sewing process. By adopting the technical scheme, the operation of forming the zipper at a pocket is convenient, the sewing efficiency is high, the requirement on experience of an operator is not high, and the production benefit of an enterprise is improved.

Owner:XIAMEN ANTA SPORTS GOODS CO LTD

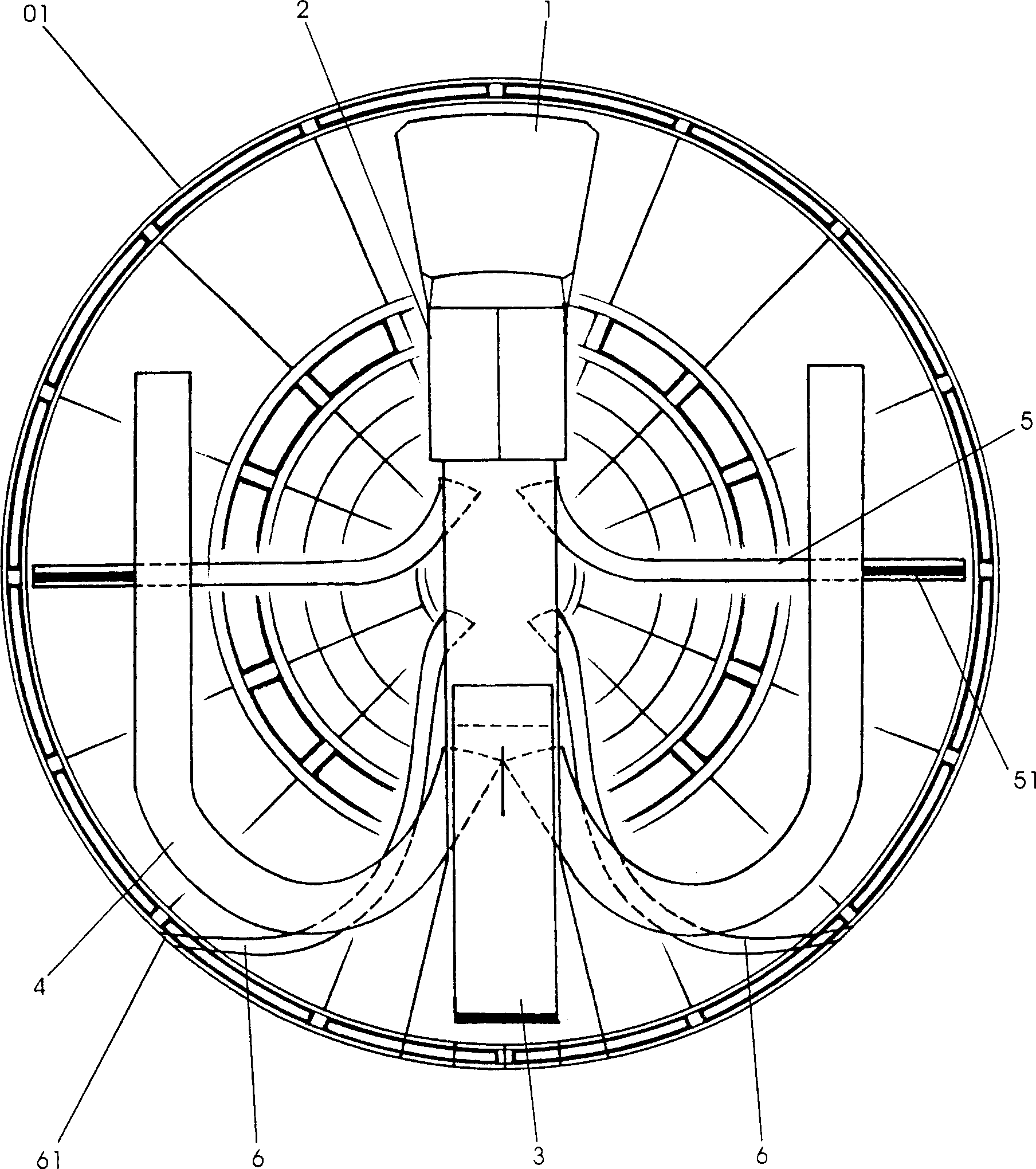

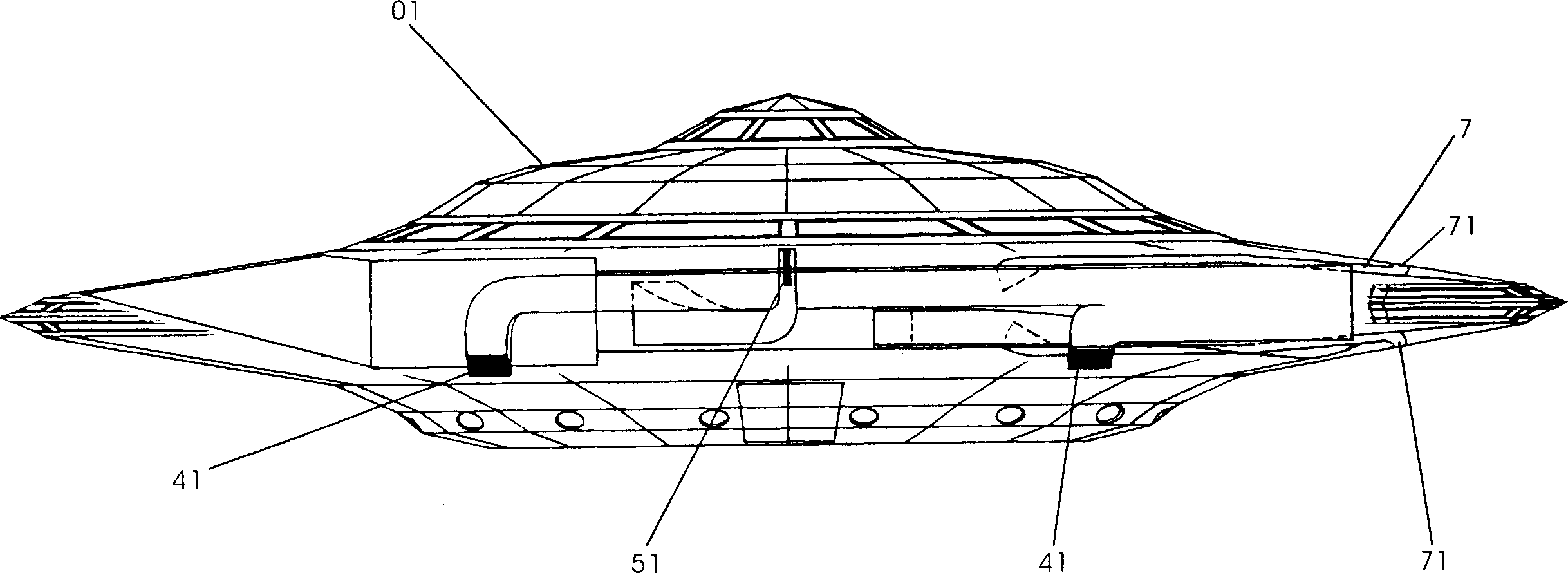

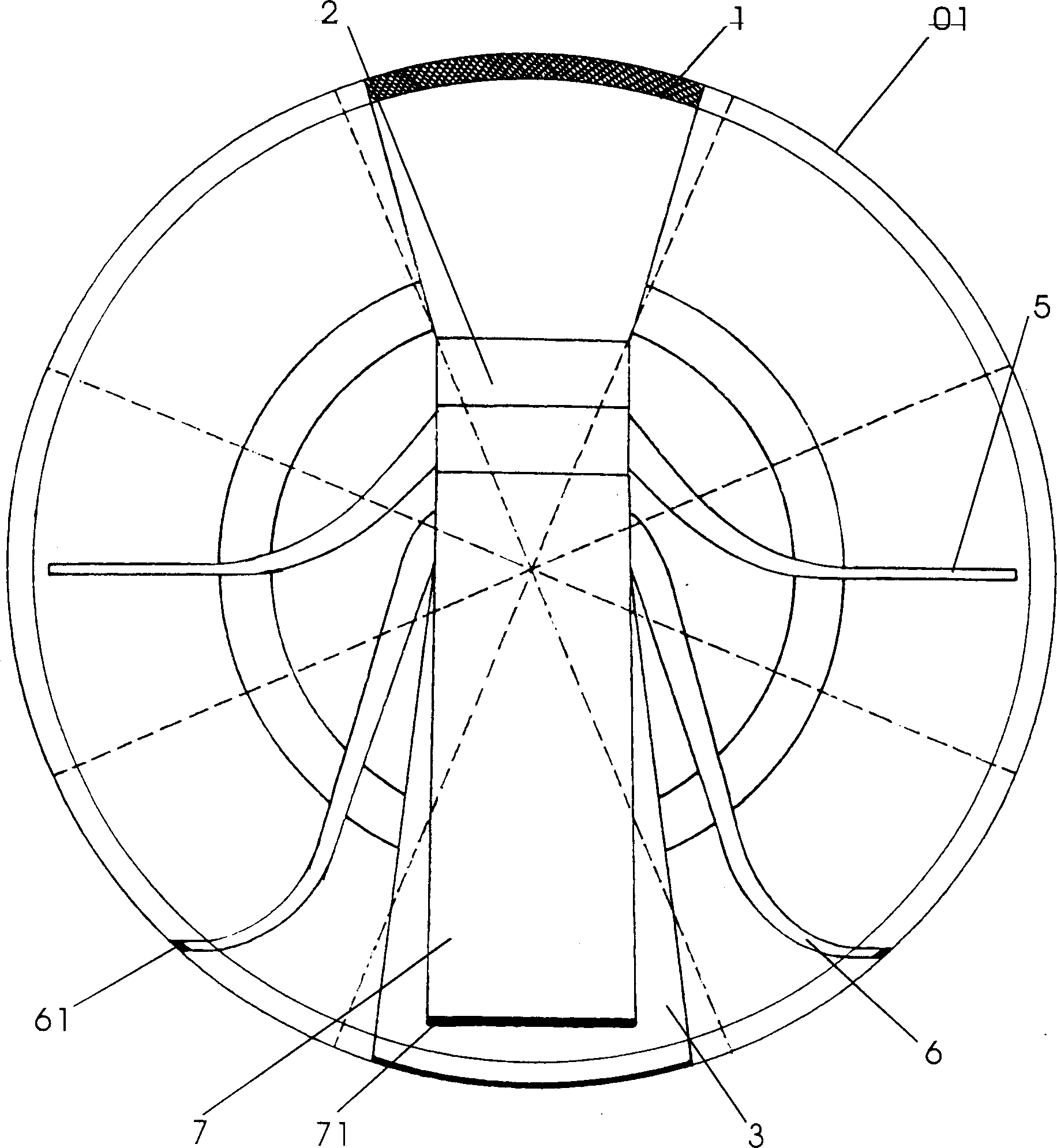

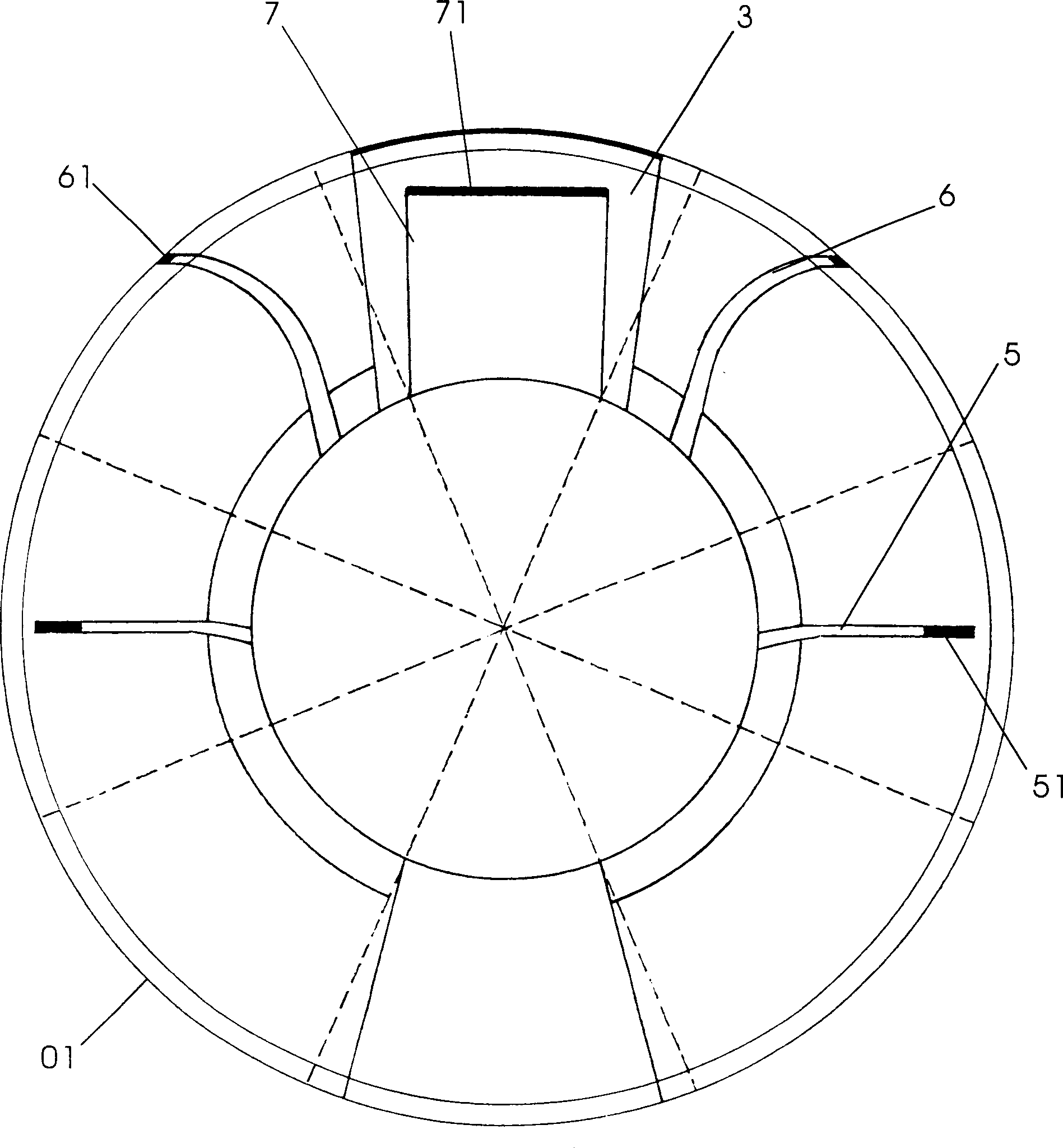

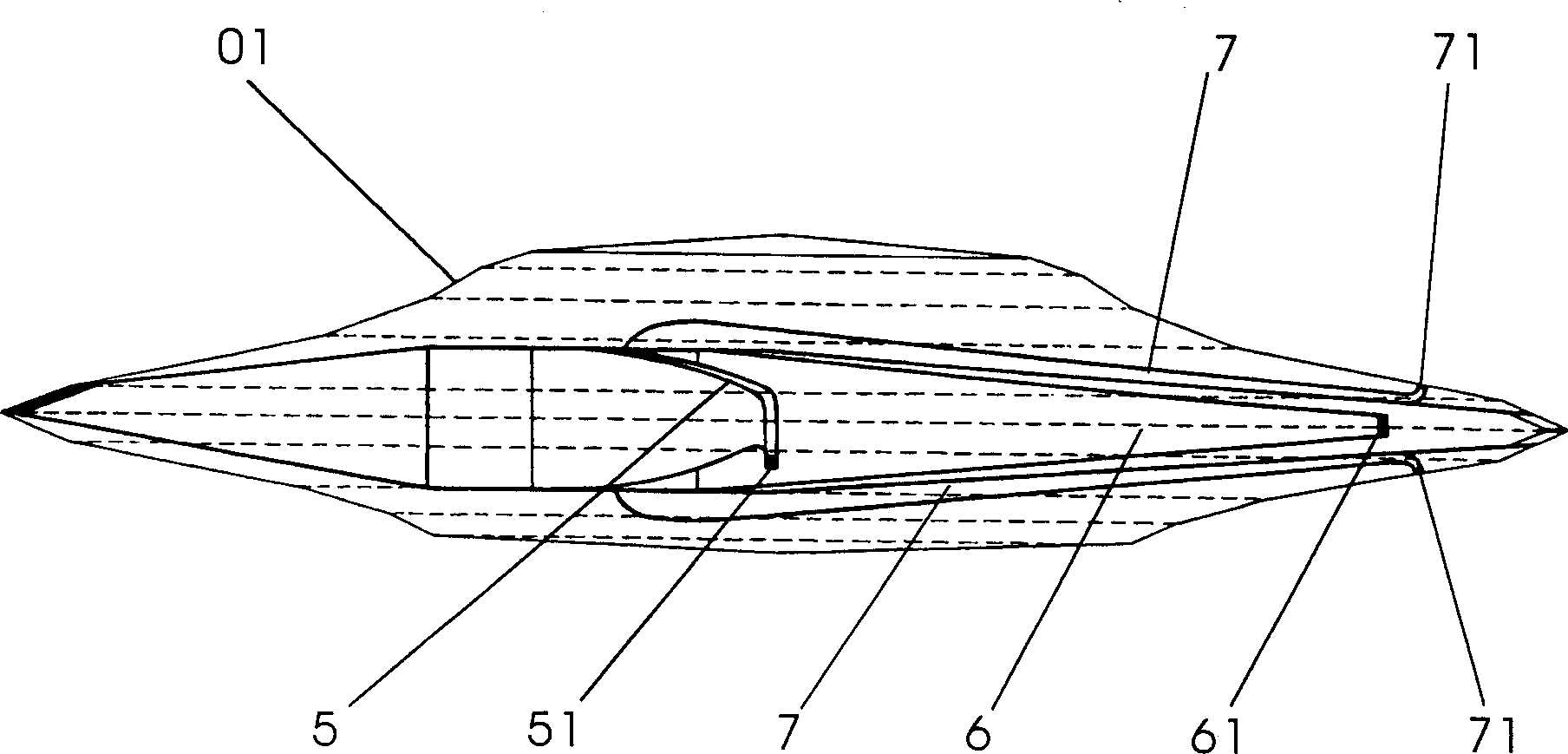

Flyer with vertical launching and other advantages

InactiveCN1403341ALow operating experience requirementReduce the requirements for high temperature resistance of materialsVertical landing/take-off aircraftsAviationExhaust pipe

The present invention relates to aeronautical and astronautic technology, and aims at solving the problems of vertical launching, etc. The technological scheme includes the air intake in front end of the main body, engine between the air intake and the main exhaust pipe, the straight main exhaust pipe set in the center, the branched exhaust pipe for vertical launching connected to the main exhaust pipe and with downward opening at the tail end. The present invention is simple in structure, low in cost and easy to control, and may be used widely in civil and military aviation.

Owner:金洪奎

Structure of controlling flying posture of aircraft

InactiveCN1405063ASensitive control of left and right flipControl left and right flipAircraft navigation controlFlight vehicleCivil aviation

The invention relates to a flying vehicle with a structure capable of controlling and regulating its flying form simply, quickly and flexibly. Its technical scheme is as follows; it has an exhaust piping which is connected with main exhaust piping and uses the main exhaust piping as shaft to control leftward and rightward turnover of flying vehicle, an exhaust piping for controlling leftward and rightward steering of flying vehicle and an exhaust pipe for controlling upward and downward flight of the flying vehicle. Said invention is easy to control and flexible, so that it can be extensively used in the fields of civil aviation, military affairs, flight model and toy, etc.

Owner:金洪奎

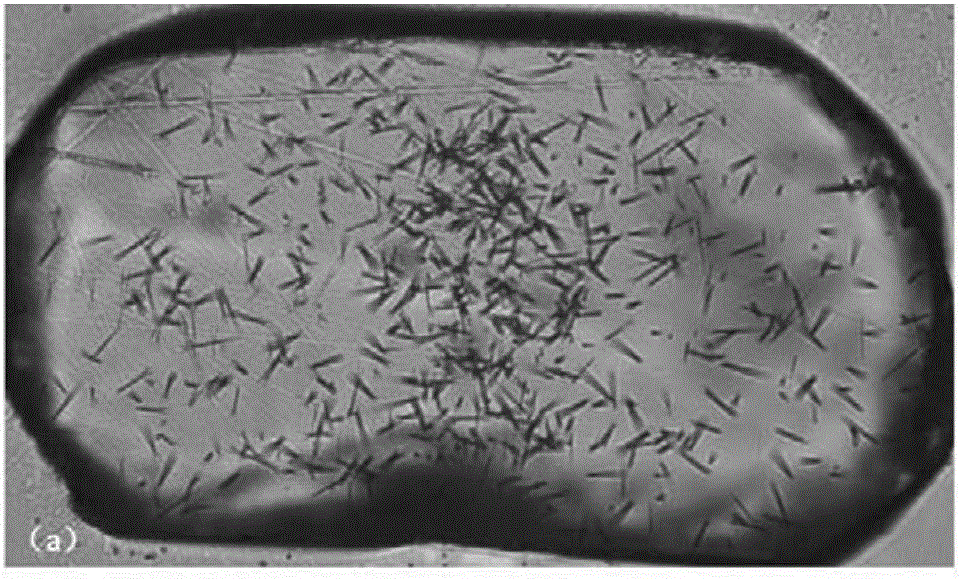

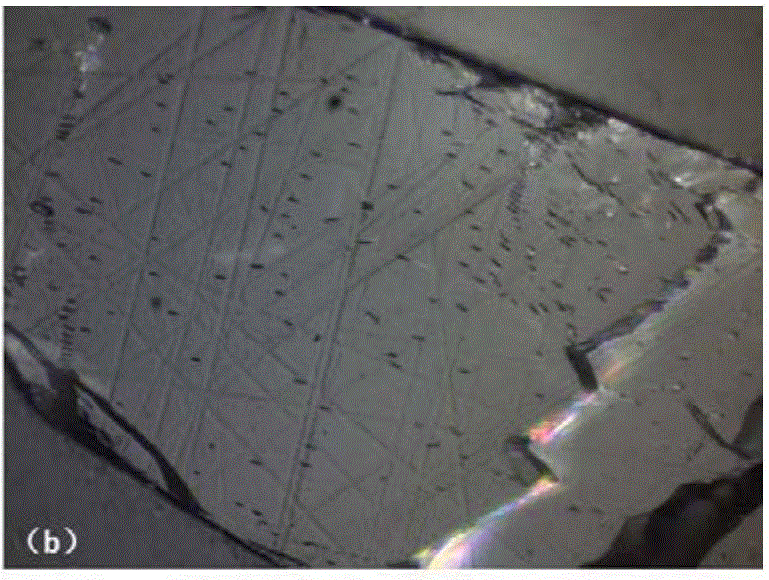

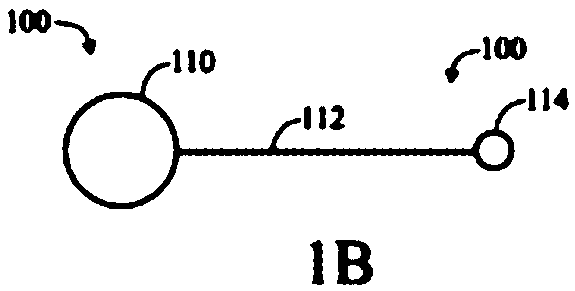

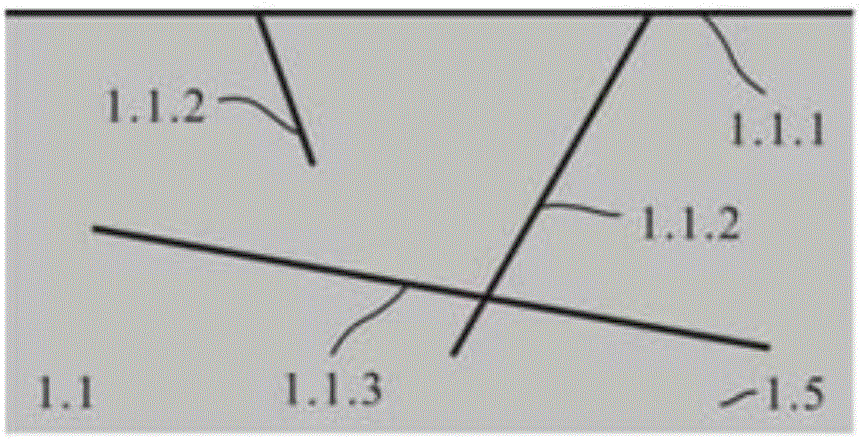

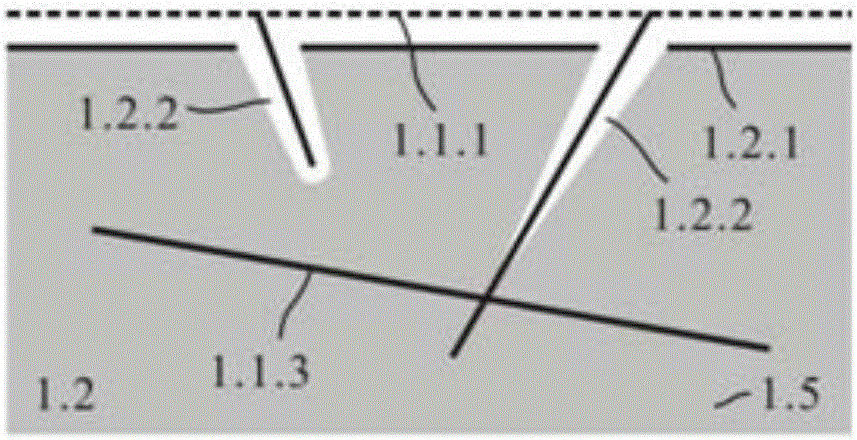

Method of analyzing fission track annealing degree of apatite by employing terahertz time-domain spectroscopy

ActiveCN106841096ALower operating experience requirementsSample preparation method is simplePreparing sample for investigationMaterial analysis by optical meansTerahertz time-domain spectroscopySpectroscopy

The invention relates to a method of analyzing the fission track annealing degree of apatite by employing terahertz time-domain spectroscopy. The method comprises the following steps of: performing heating and annealing experiments on various types of apatite samples, and putting the samples in a terahertz testing and analyzing device to be tested and analyzed to obtain an adsorption coefficient of the terahertz time-domain spectroscopy; representing the annealing degree subjected to the fission track of apatite in the samples by means of the adsorption index converted by the adsorption coefficient to establish a relationship plate between the adsorption index and the annealing temperature as well as the annealing time; and extrapolating experiment data to a geological history period according to the relationship plate, and analyzing the annealing degree of the to-be-tested sample and the annealing temperature and the annealing time subjected thereto. The method provided by the invention represents the fission track annealing degree of apatite for the first time by means of the absorption index of the terahertz spectroscopy, so that influence on the fission track research work caused by coarse grinding and improper polishing operations in a conventional method is avoided, and the requirement on the operating experience of an experimenter is reduced. The testing method is simple, the testing period is short, and the testing cost is low.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

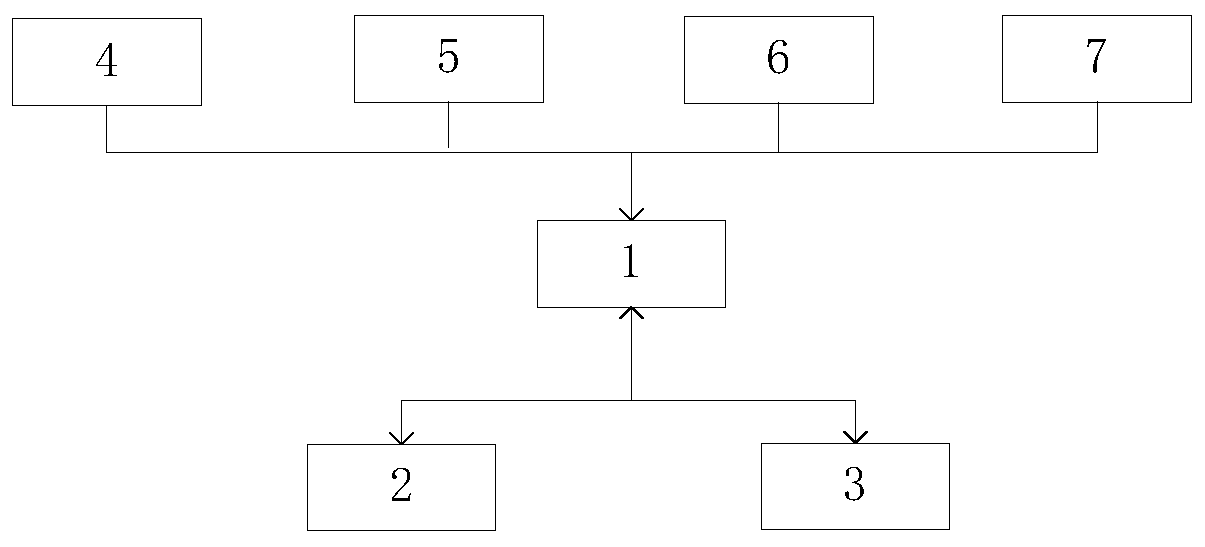

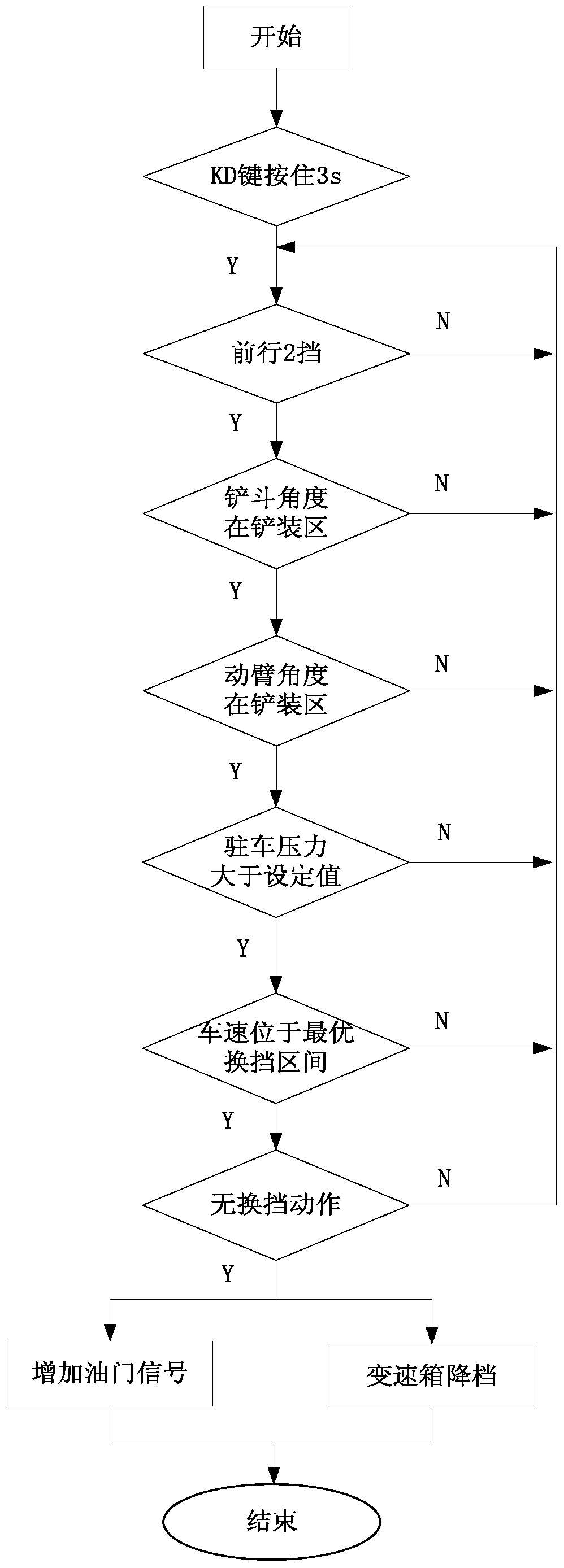

Loader shoveling operation gear control method, device and system

InactiveCN110206090AImprove work efficiencyImprove the level of intelligenceSoil-shifting machines/dredgersOperation pointOil consumption

The invention discloses a loader shoveling operation gear control method, device and system. The method comprises the steps: in the shoveling operation process of a loader, by obtaining the current speed of the loader, the gear state of a gearbox, the braking pressure, the angle of a bucket and an angle signal of a movable arm, judging whether the current braking pressure is greater than a pressure set value or not; judging whether the angle of the bucket and the angle of the movable arm are in a shoveling area or not; judging whether the current speed of the loader and the gear state of the gearbox are located in an optimal gear shifting interval or not; and according to the gear power information curve, obtaining the optimal gear shifting speed interval, pressing a KD key for 3s before the shoveling operation, then activating the system, when it is detected that the working state of the loader is at the optimal gear shifting operation point, increasing the rotating speed of an engine, and starting the gear shifting operation. The engine speed drop caused by load changes in the gear shifting process is prevented, the automatic KD function is realized in the shoveling operation process of the loader, the engine speed drop is prevented, the oil consumption is reduced, and the operation efficiency during shoveling is improved.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

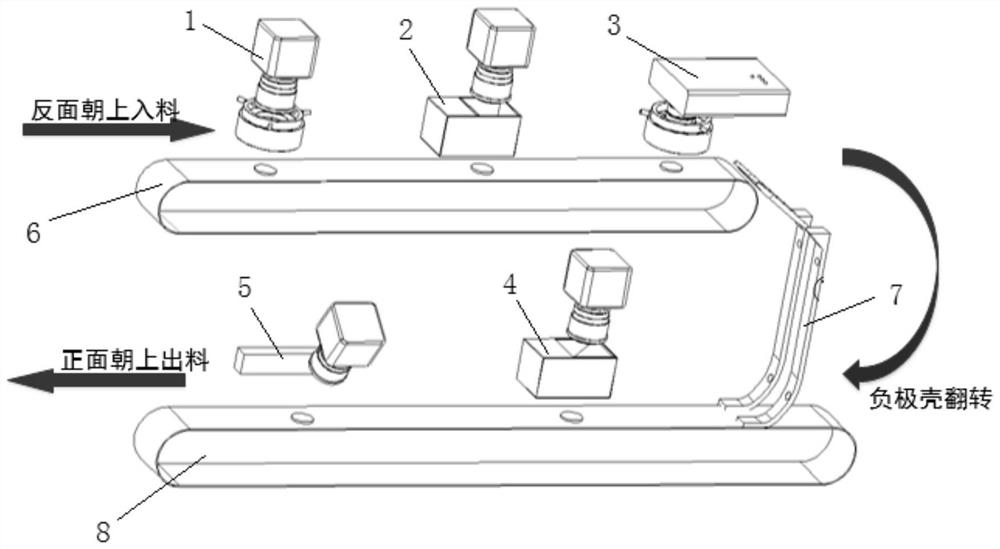

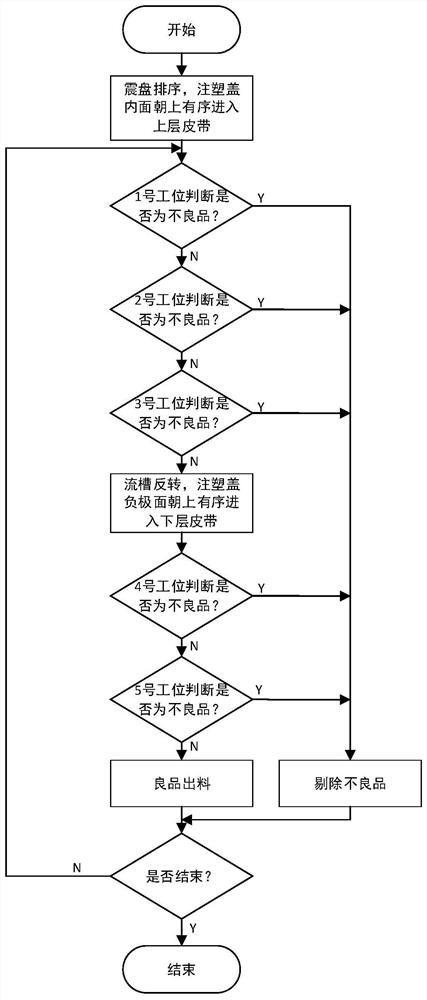

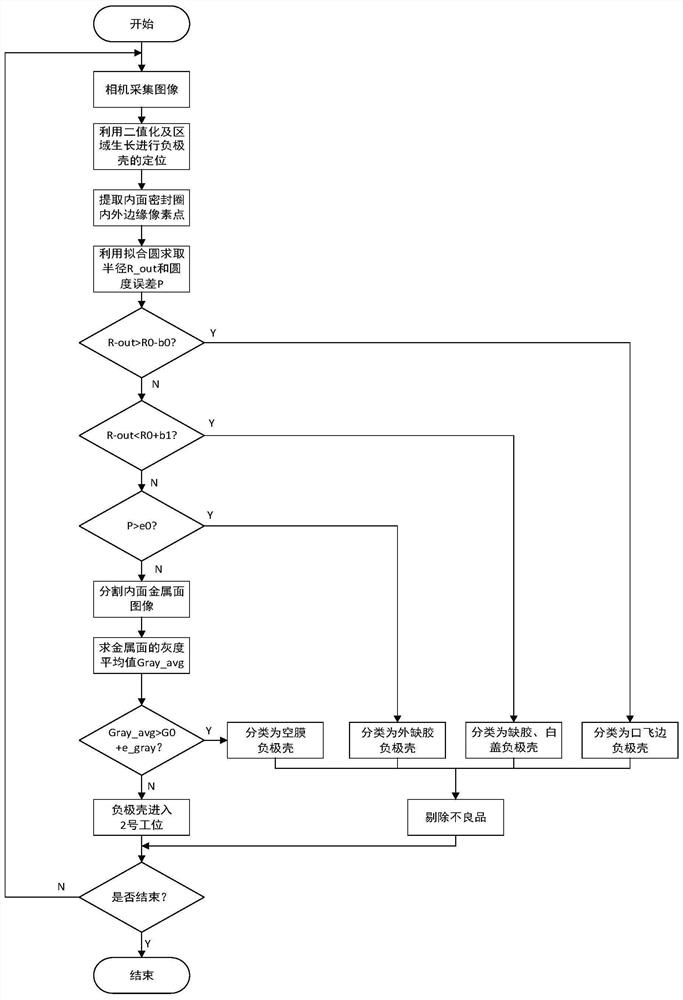

Button cell negative electrode shell defect detection method based on machine vision

ActiveCN111766245ARealize full quantile detectionImprove detection accuracyOptically investigating flaws/contaminationMachine visionButton battery

The invention relates to a button cell defect detection technology, in particular to a button cell negative electrode shell defect detection method based on machine vision, which comprises the following steps: a negative electrode shell is discharged, sequentially passes through a station I, a station II and a station III for defect detection in a manner that the reverse side faces upwards, then enters a turnover runner, and sequentially passes through a station IV and a station V in a manner that the front side faces upwards for defect detection; the station I is used for detecting colloid defects of a reverse sealing ring of the button cell negative electrode shell; the station II is used for detecting defects of a metal surface and a sealing ring on the reverse side of the button cell negative electrode shell; the third station is used for detecting defects of inner glue shortage and outer glue shortage of the reverse side of the button cell negative electrode shell; the station IVis used for detecting defects of a front sealing ring colloid and a metal surface of the button cell negative electrode shell; and the station V is used for performing external dotting and crushing defect detection on the front surface of the button cell negative electrode shell. According to the invention, different visual light source configurations are respectively adopted at a plurality of visual detection stations to carry out omnibearing detection on inner and outer edges, surfaces and the like of the front and back surfaces of the button cell negative electrode cover.

Owner:广州市讯思视控科技有限公司

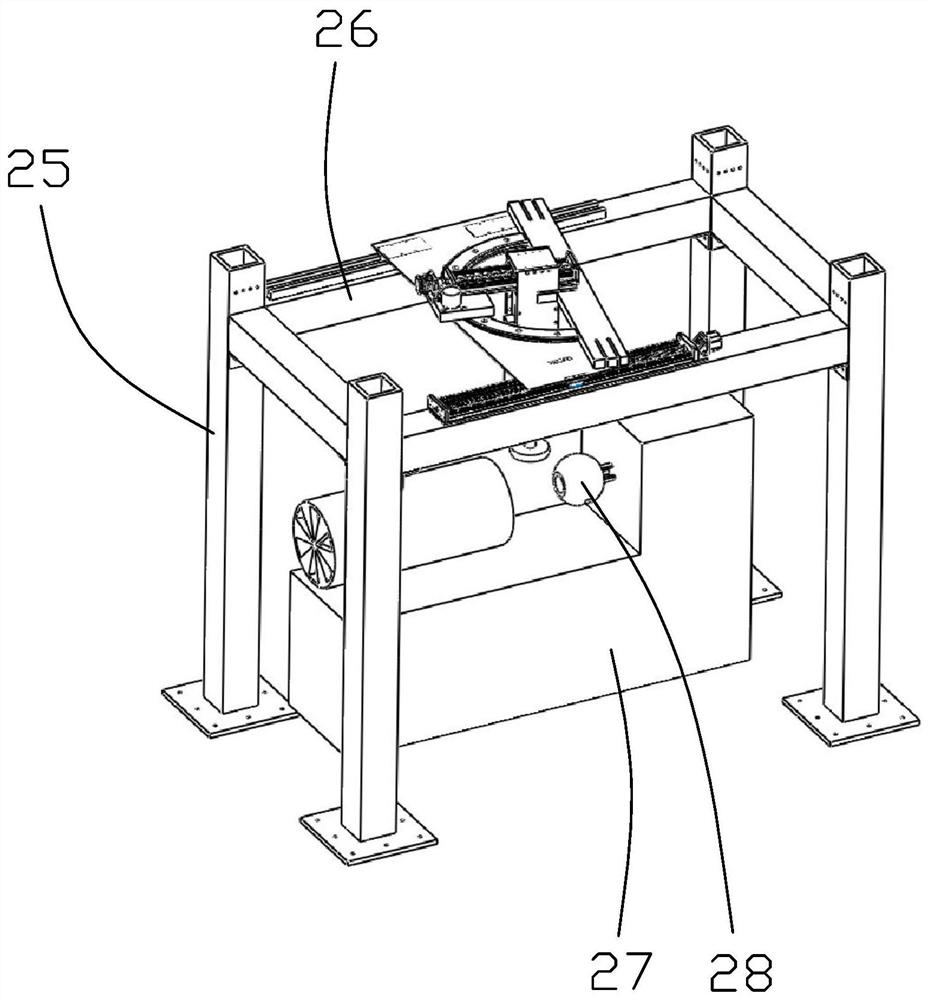

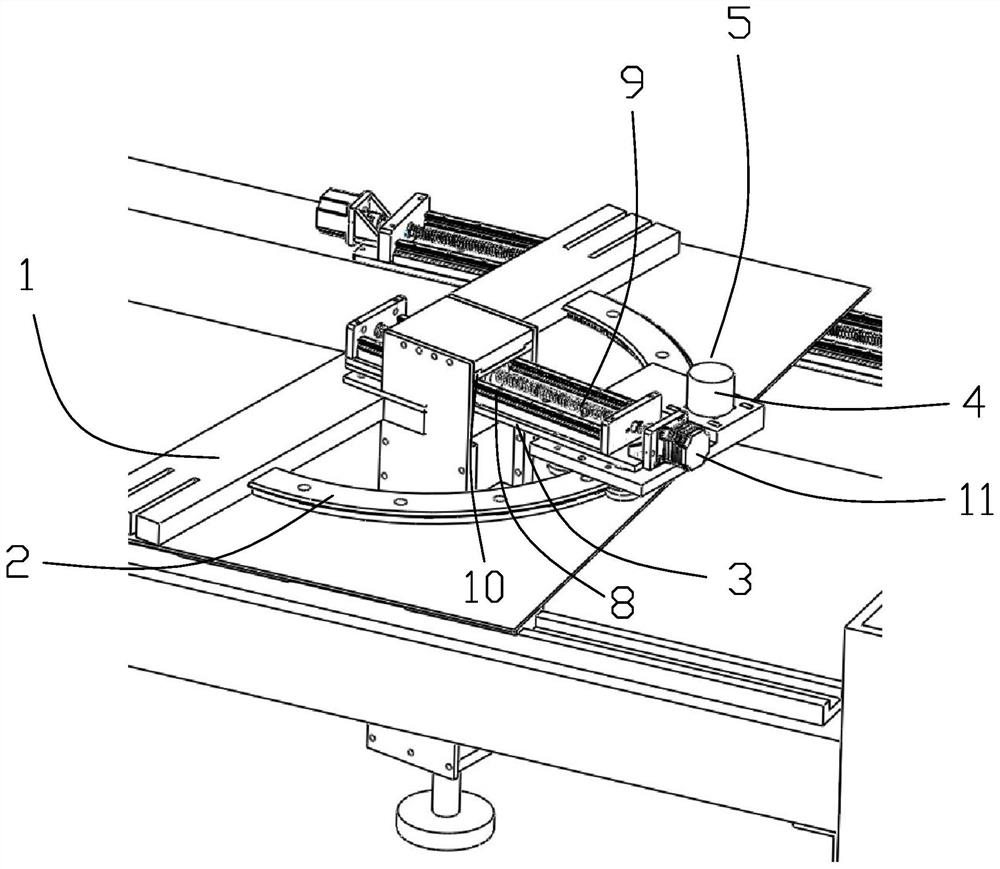

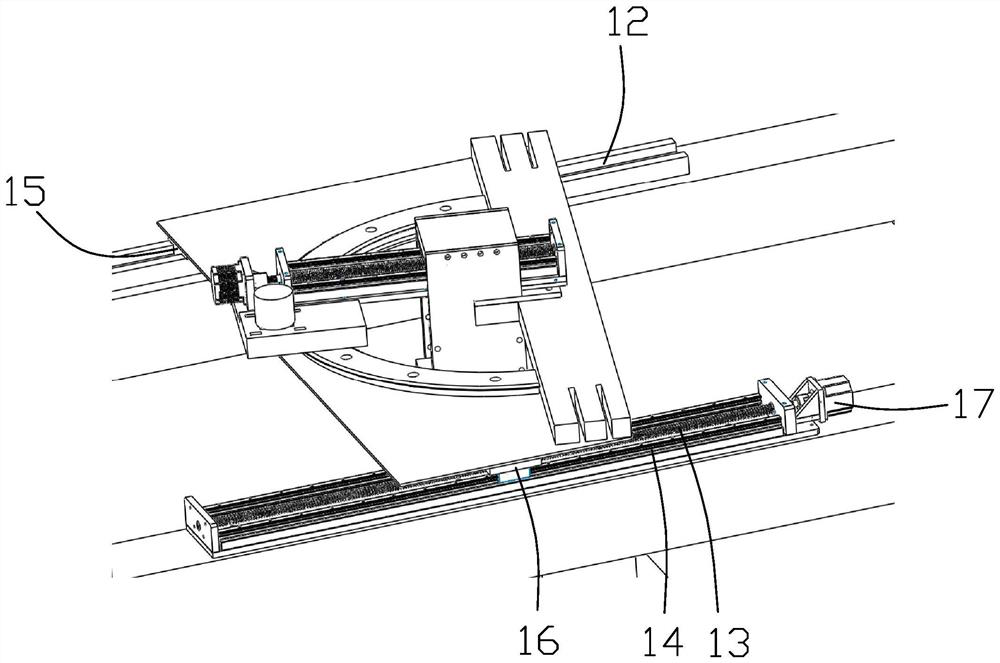

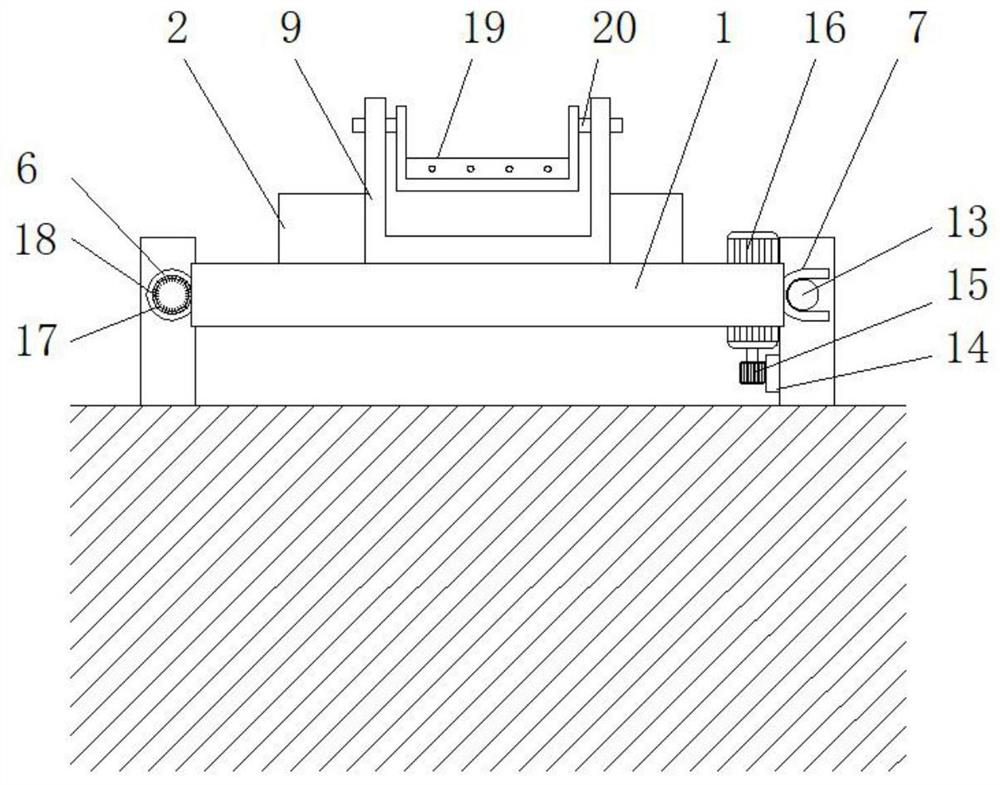

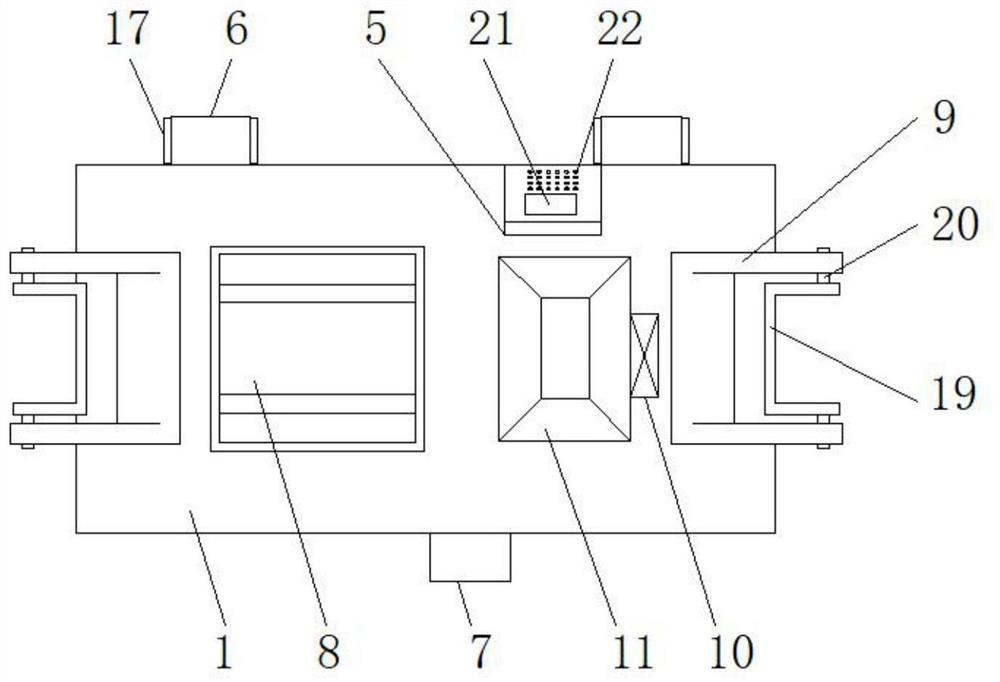

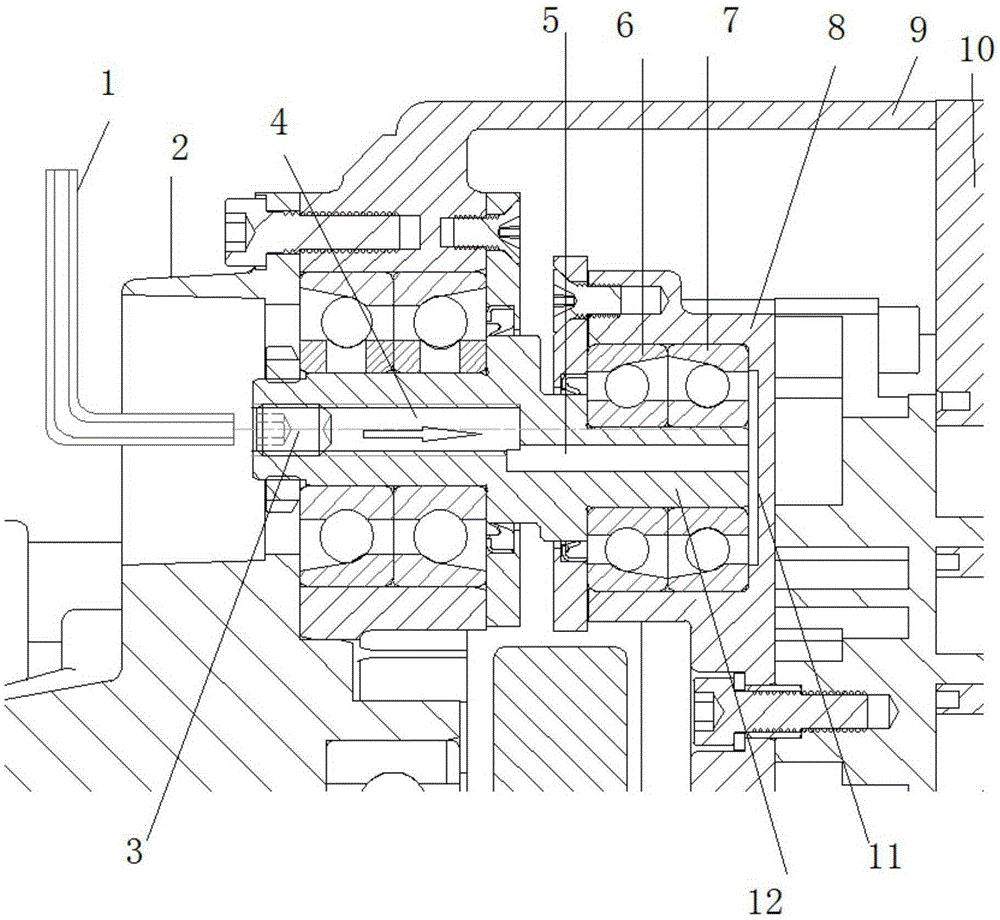

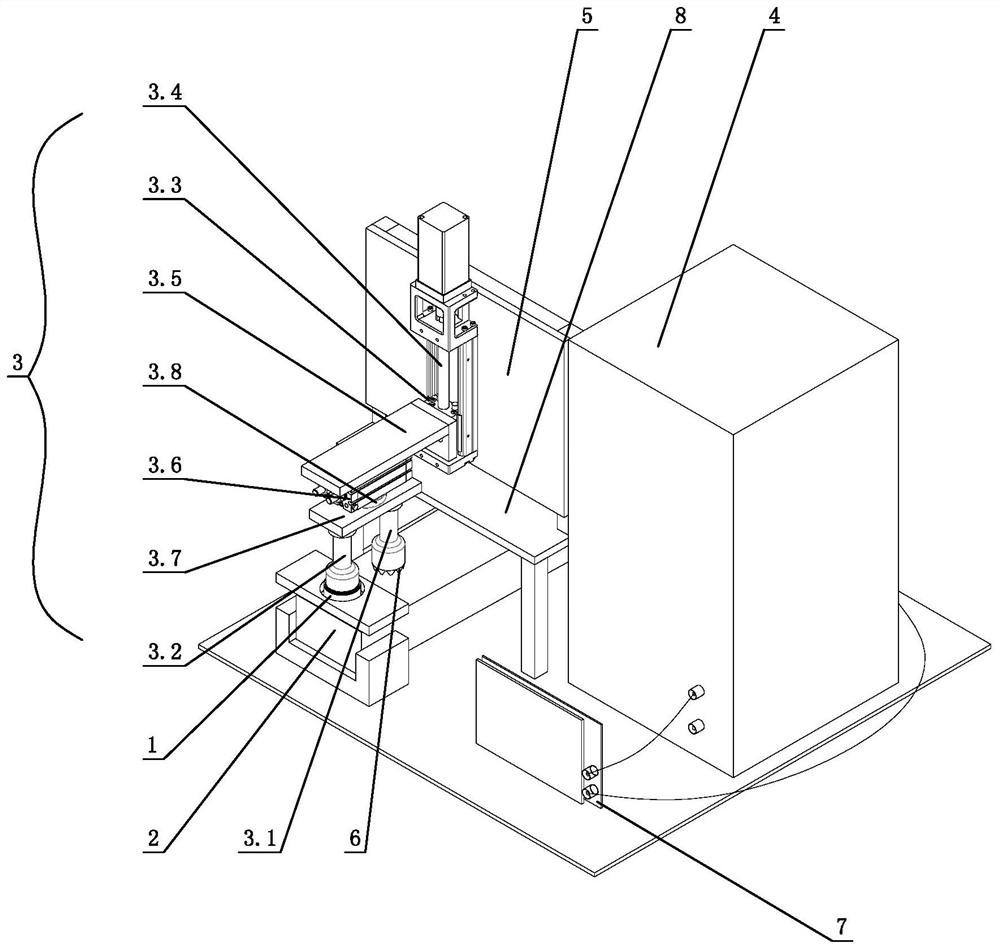

PE ball core automatic polishing system based on torque control and control method

ActiveCN112296853ALow operating experience requirementLow skill level requiredGrinding carriagesPolishing machinesPhysicsPolishing

The invention discloses a PE ball core automatic polishing system based on torque control and a control method. The invention solves the problem that PE ball core polishing equipment in the prior artis complex in structure, high in operating demand and narrow in applicability. The system comprises a supporting frame, wherein a ball core rotating mechanism that clamps a PE ball core is arranged inthe supporting frame, and a two-degree-of-freedom moving mechanism is arranged on the upper part of the supporting frame; the two-degree-of-freedom moving mechanism comprises a first moving assemblyand a second moving assembly, and the first moving assembly is slidably arranged on the supporting frame through a ball core positioning mechanism; a polishing mechanism is arranged on the second moving assembly and comprises a polishing cloth wheel, and the polishing cloth wheel performs a circular motion along the surface of the PE ball core. Polishing is performed according to a sequence of ball core clamping, ball core positioning, parameter setting, ball core polishing and stopping resetting. The system polishes the PE ball core automatically, is easy to operate, is low in demand on operating experience and technical level of an operator and wide in application range, and ensures high polishing precision.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Multi-position wire flattening forming jig

Owner:光路新能源材料(上海)有限公司

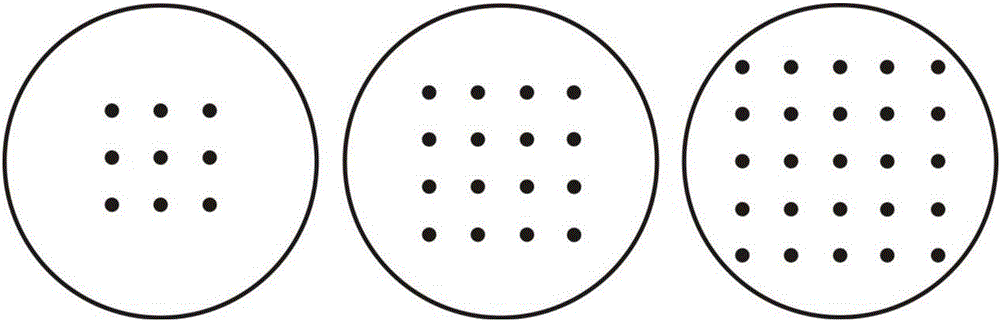

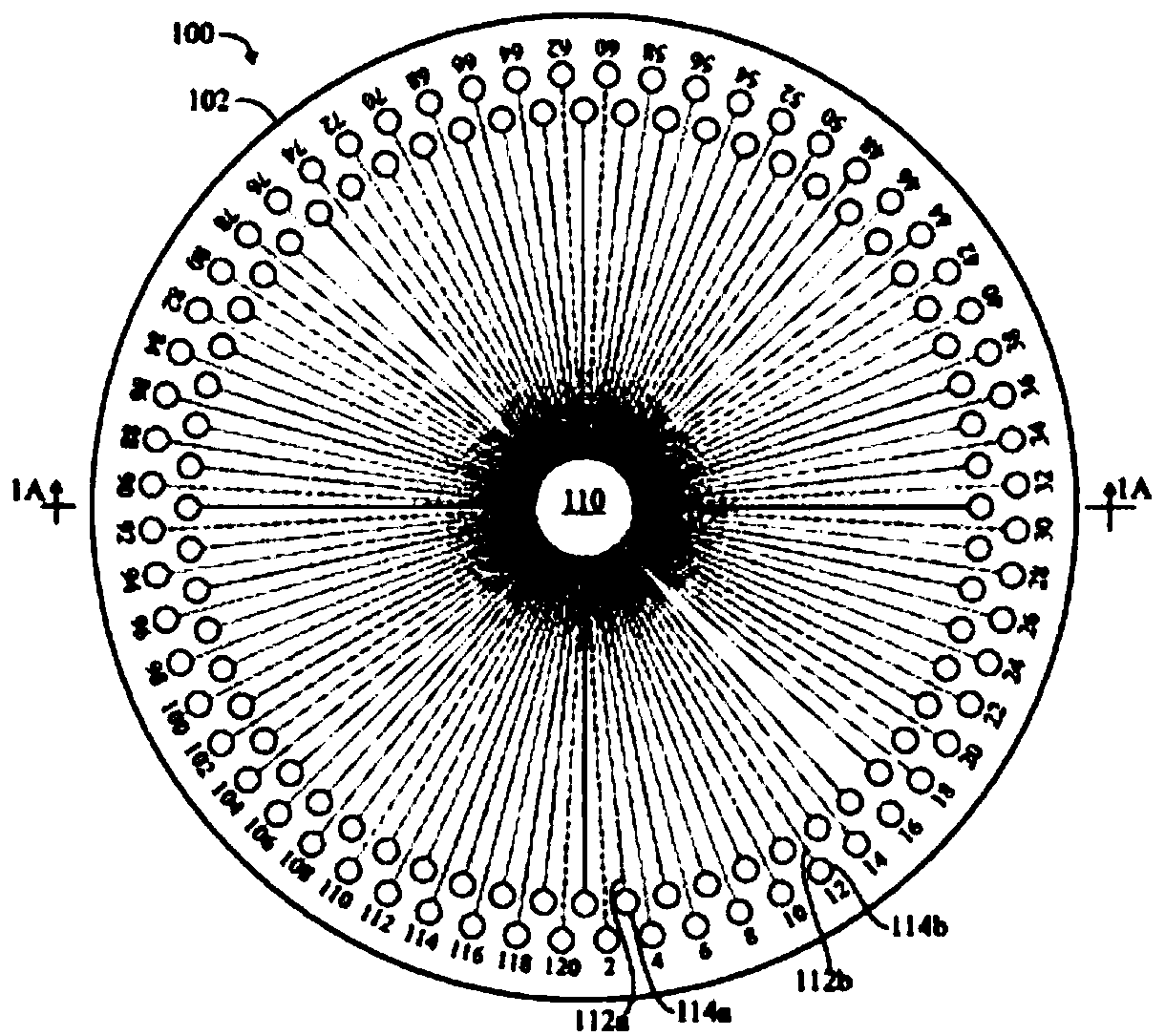

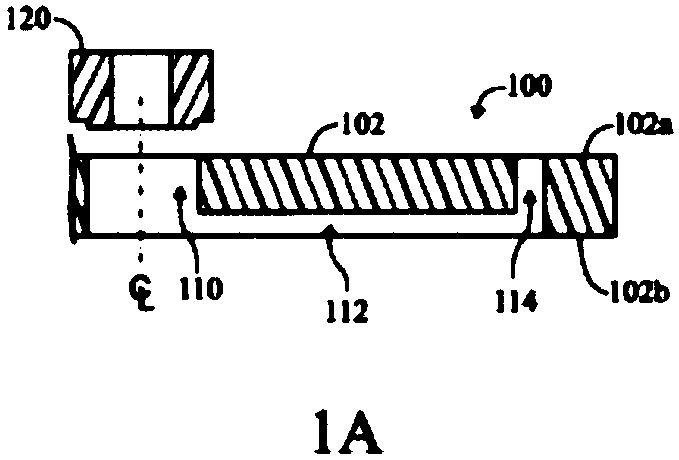

Microfluidic aliquoting for single-cell isolation

InactiveCN108779425AReduce lossesLow operating experience requirementBioreactor/fermenter combinationsBiological substance pretreatmentsHigh cellPetri dish

According to the invention, generally, a microfluidic aliquoting (MA) chip, adapted to fit in a Petri dish, has a center well (inlet) connected by a plurality of microchannels to a plurality of side wells (outlets). A relatively large (such as 120 muL) cell suspension having several cells may be injected into the inlet of the MA chip, and single cells may be substantially simultaneously and uniformly distributed, via positive pressure-driving flow, to the several (such as 120) side wells having single cells in less than 1 minute. The MA Chip has a high efficiency in cell recovery. Due to rapidisolation and easy identification of single cells, high cell viability, high enrichment factor, and convenient transfer of submicroliter single-cell suspension, MA Chips are well compatible with CTCisolation from blood, single-cell cloning, PCR, and sequencing.

Method for quickly obtaining apatite fission track annealing rate and spontaneous track density

ActiveCN106769999AQuick testEfficient separationChemical property predictionPreparing sample for investigationTime domainTrack density

The invention discloses a method for quickly obtaining an apatite fission track annealing rate and spontaneous track density. The method comprises the following steps: 1) establishing a fission track volume model, and acquiring total volume of fission tracks in a sample; 2) establishing an apatite particle volume model, and acquiring total volume of apatite particles in the sample; 3) proposing volume fraction of the fission tracks so as to propose a concept of a fission track volume index; 4) according to the fission track volume model and volume index, establishing a relation between the fission track volume index and the annealing rate and spontaneous track density; and 5) acquiring the absorption coefficient of the sample by use of terahertz time-domain spectroscopy, and representing the volume index of the fission tracks by use of the absorption coefficient. Thus, the fission track annealing rate and spontaneous track density of the sample are obtained through terahertz time-domain spectroscopy.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Handheld cutting machine applied to elevator non-metal board

PendingCN111390982AConvenient horizontal controlPrevent slippingMetal working apparatusHand heldEngineering

The embodiment of the invention discloses a handheld cutting machine applied to an elevator non-metal board. The handheld cutting machine applied to the elevator non-metal board comprises a shell, a rotary cutter head, a motor and a cutting line. The shell comprises an upper shell and a lower shell, and the lower shell is covered with the upper shell; the motor is fixed to the upper shell; the rotary cutter head comprises a rotary disc and a cutting knife, and the rotary disc is fixed to a rotary shaft of the motor; a containing groove is formed in the edge of the rotary disc, the cutting lineis wound round the containing groove, a second installation hole is formed in the edge of the containing groove, and the cutting knife is fixed into the second installation hole; and a cutting through hole is formed in the cutting knife, and the free end of the cutting line penetrates into the cutting through hole. The handheld cutting machine applied to the elevator non-metal board is simple instructure and convenient to operate, and the requirement for operation skills of a user is low.

Owner:上海华美电梯装饰有限公司

Automatic crawling device for magnetic powder detection by cross magnet yoke method

PendingCN112683998APromote sportsAutomatic even sprayingCleaning using toolsMaterial magnetic variablesNumerical controlGear wheel

The invention discloses an automatic crawling device for magnetic powder detection by cross magnet yoke method. The device comprises a fixing frame, a flaw detector, a spraying mechanism, a driving mechanism and a control box, the flaw detector and the control box are fixedly connected to the upper surface of the fixing frame, the spraying mechanism is fixedly connected to the left end and the right end of the fixing frame respectively, and the driving mechanism is arranged at the bottom of the fixing frame, a guide sliding sleeve is fixedly connected to the left side of the fixing frame, the spraying mechanism comprises a pump body, a box body and an atomizing nozzle, and the driving mechanism comprises guide rods, guide racks, driving gears and servo motors which are distributed on the two sides of the fixing frame. The driving mechanism and the spraying mechanism are fixedly connected to the surface of the fixing frame, the servo motors and the pump body are controlled in cooperation with a numerical control box, the fixing frame can conveniently and automatically move along the guide rods, magnetic suspension can be automatically and evenly sprayed, the number of participants in the detection process is reduced, the requirement on the operation experience of detection personnel in the detection process is reduced, and the detection precision is greatly improved.

Owner:淮安市计量测试中心

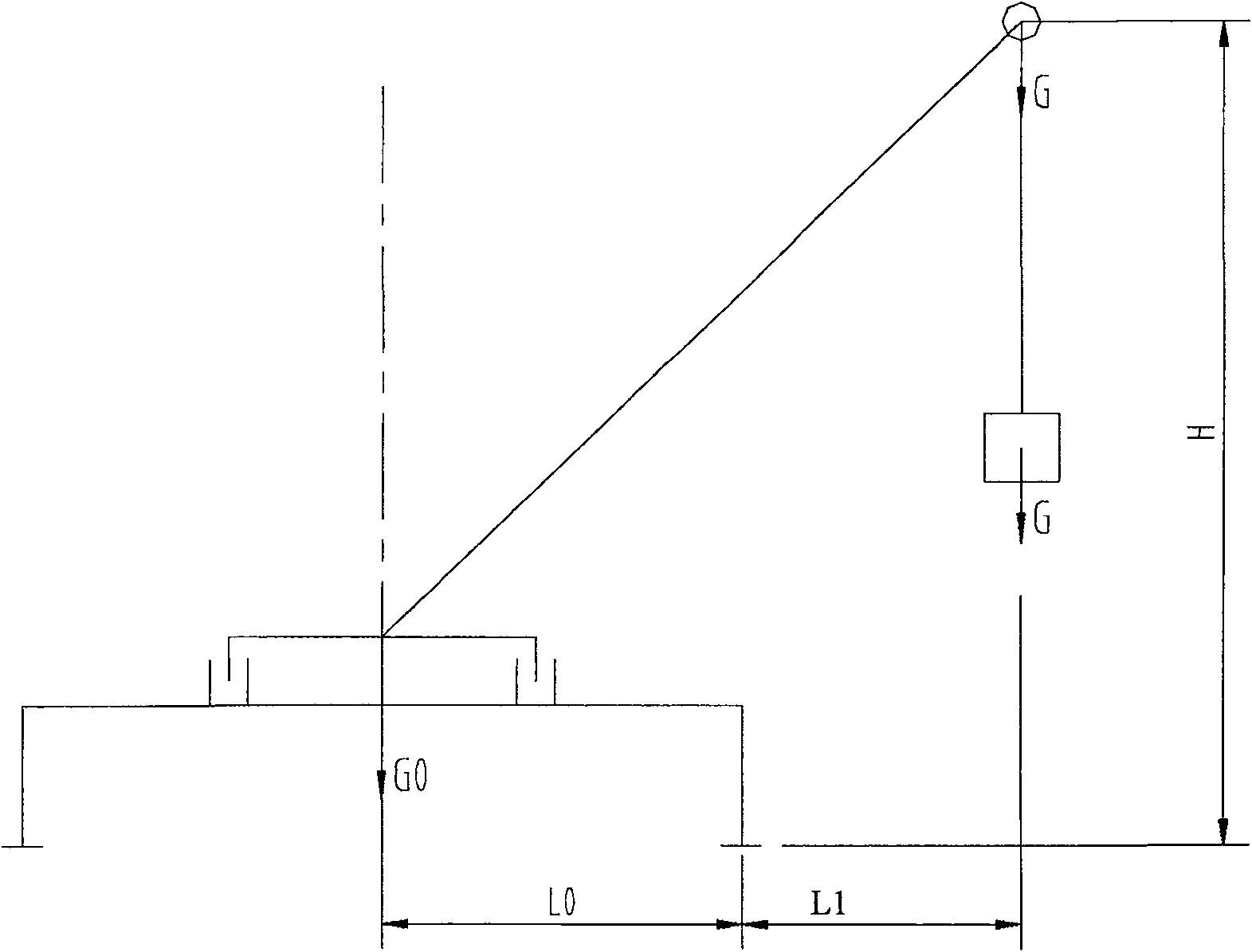

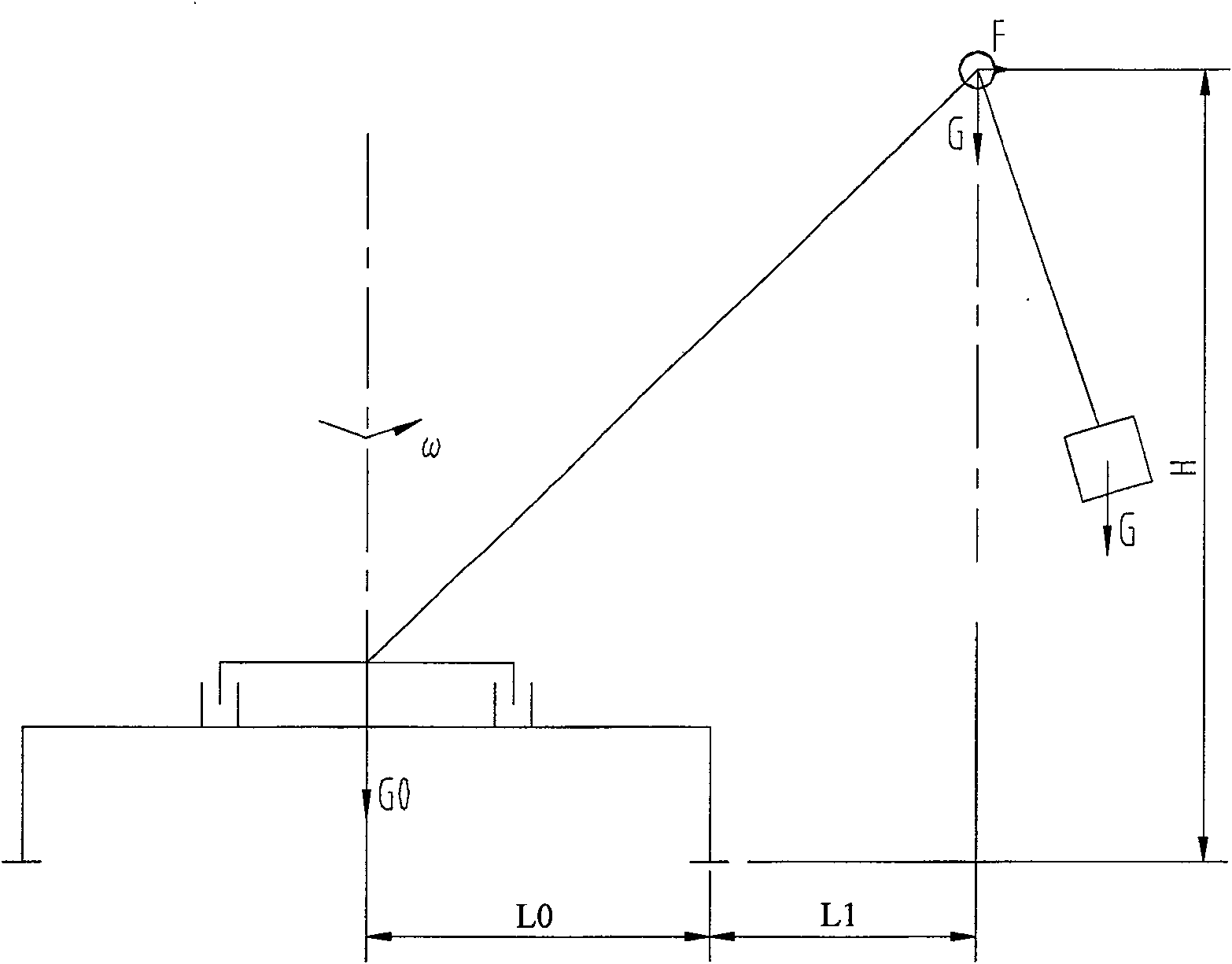

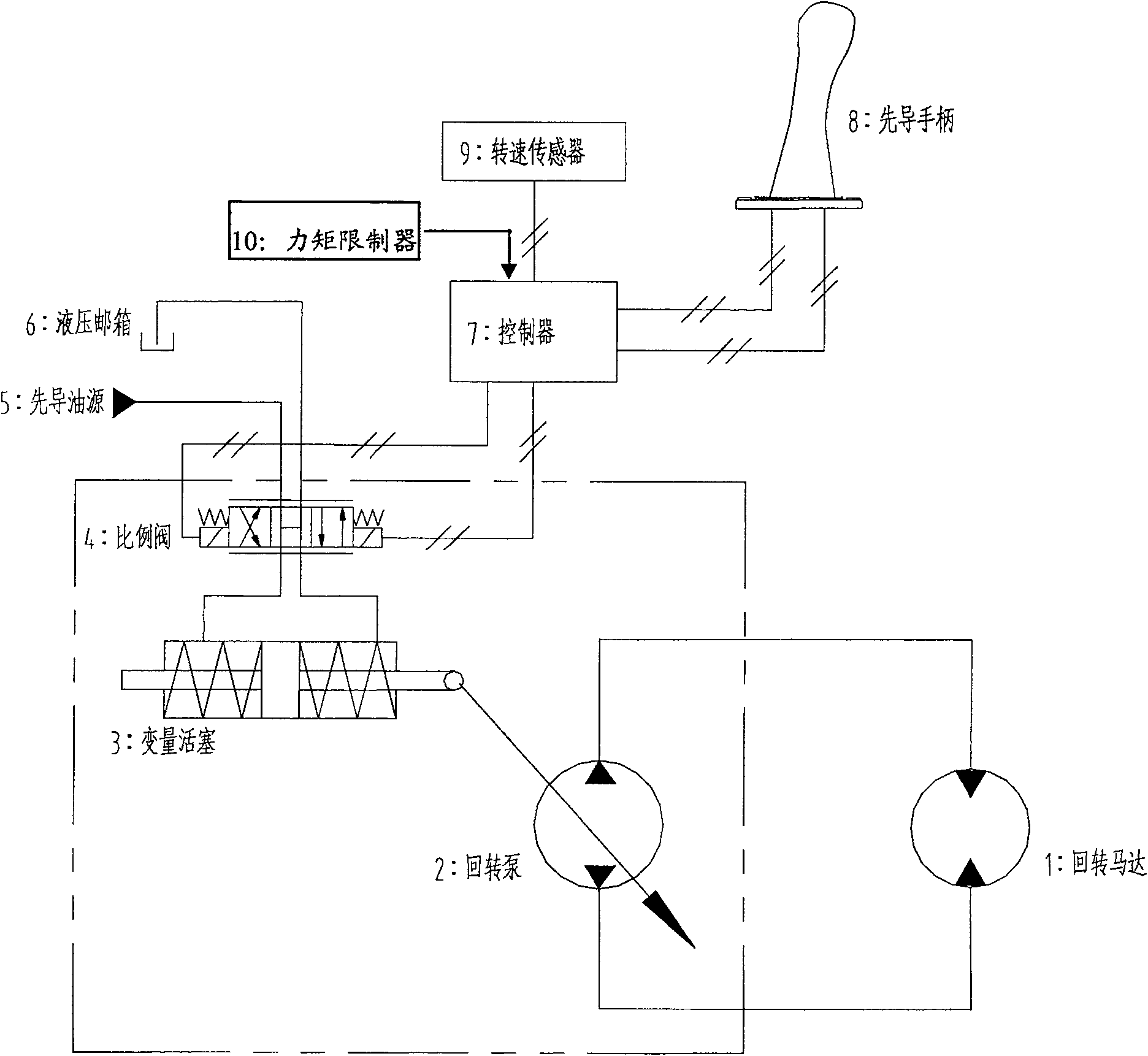

Method for maximum rotation speed restriction of rotary engineering machinery and system thereof

InactiveCN100572257CReduced strength requirementsLow operating experience requirementCranesRolling momentWeight lifting

Owner:SANY HEAVY IND CO LTD (CN)

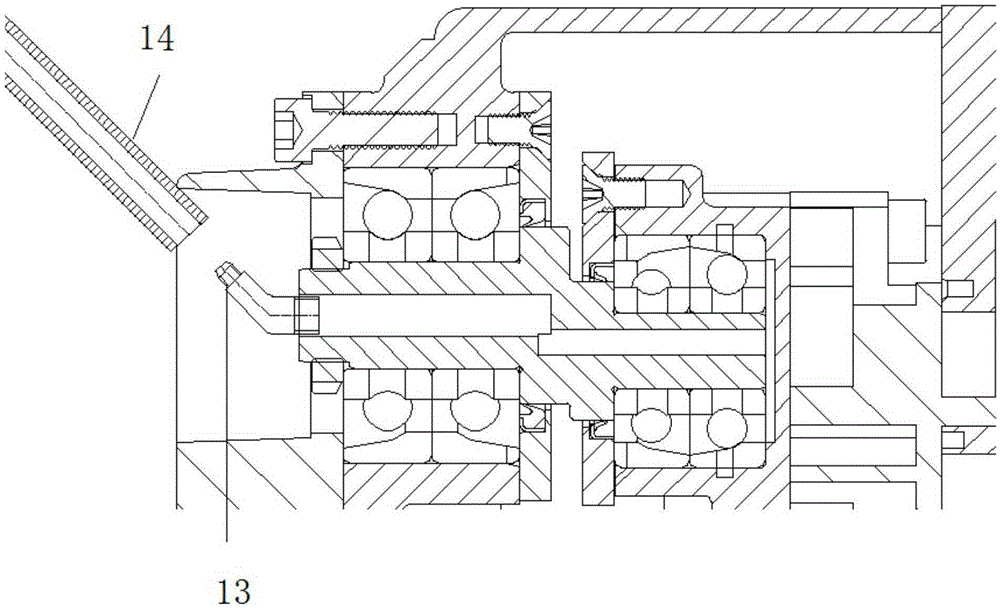

Improved rotary ultrasonic rock sampling device and method

InactiveCN106198093AThe device is compactImproved grinding removal abilityWithdrawing sample devicesPreparing sample for investigationGeophysicsUltrasonic assisted

The invention relates to an improved rotary ultrasonic rock sampling device and a method. The improved rotary ultrasonic rock sampling device and the method are improved on the basis of an ultrasonic assisted rock sampling device and a method. The improved rotary ultrasonic rock sampling device is characterized in that a sampling tool is improved, a rotary system with a control panel is arranged additionally, and a step motor rotates to drive a synchronous belt and synchronous pulleys A and B to rotate, so that synchronous rotation of a motor connection rod and an ultrasonic connection amplitude transformer A is realized; the improved sampling tool is improved by electroplating of diamond particles on the inner and outer walls and the tail end surface of a hollow tube at the lower end of the sampling tool. The sampling method includes: vertical rotary ultrasonic vibration is realized through the sampling tool under drive of the rotary system and an ultrasonic vibration system, grinding feed movement is realized in the vertical direction by adoption of an electric sliding table or a pneumatic component for driving the sampling tool or a rock blank material, and thus a grinding sampling process from the rock blank material to a rock sample is completed. By the improved rotary ultrasonic rock sampling device and the method, processing quality and efficiency in grinding sampling of the rock sample are effectively improved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

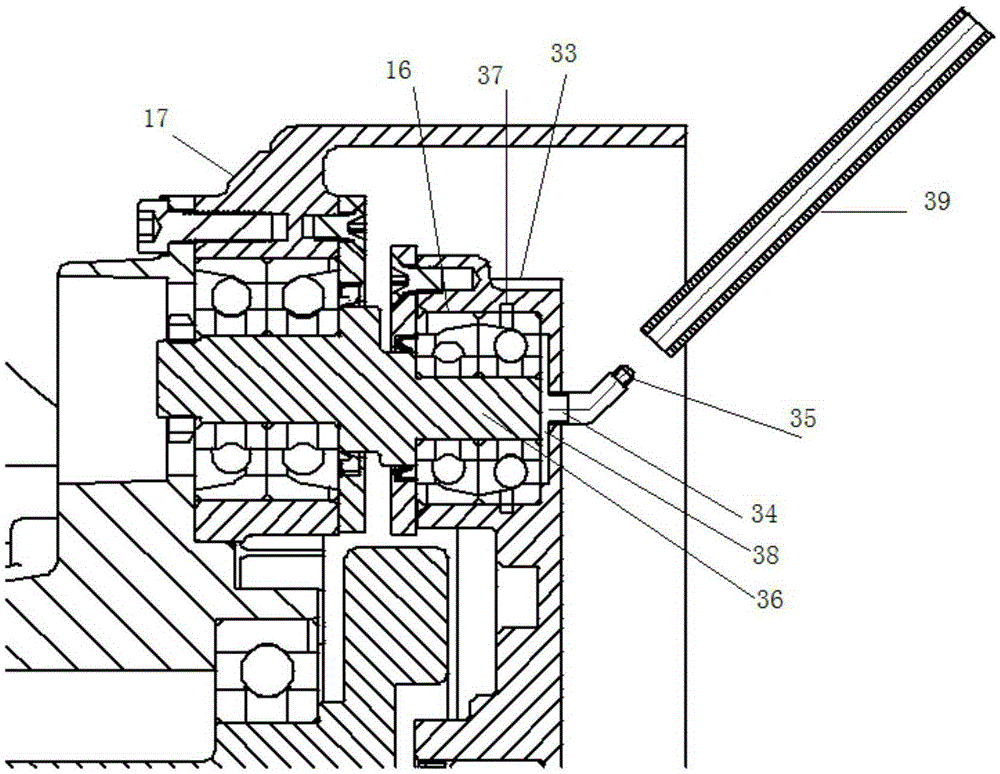

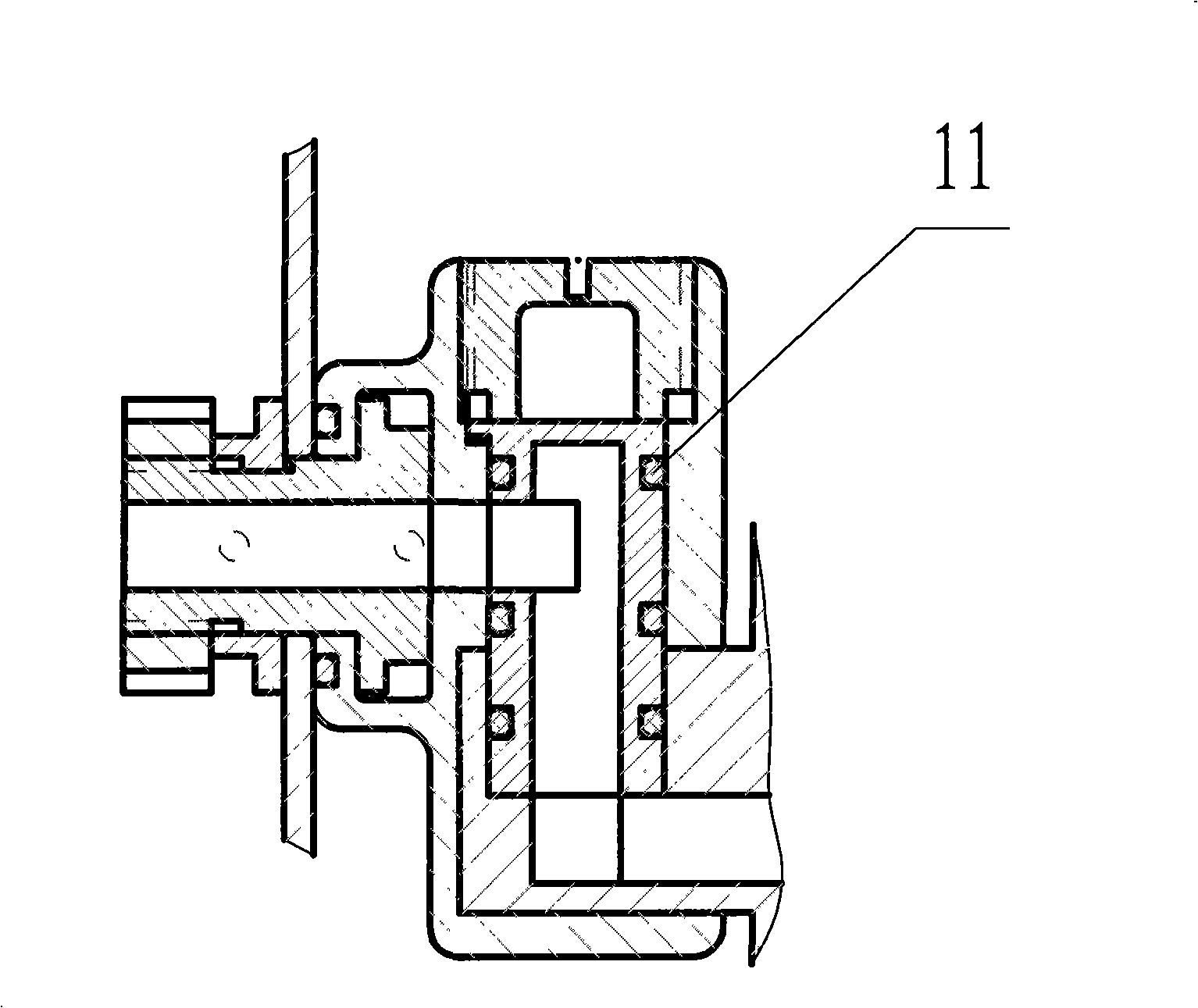

Bearing lubrication mechanism of oil-free scroll compressor

InactiveCN106762662AReduce workloadLow operating experience requirementRotary/oscillating piston pump componentsLiquid fuel engine componentsOil freeMechanical engineering

The invention discloses a bearing lubrication mechanism of an oil-free scroll compressor. The bearing lubrication mechanism comprises a housing, a first bearing, a second bearing, an outer bearing pedestal, a fixed scroll, a threaded hole, an unthreaded hole, a crankshaft and a bearing pedestal; the outer bearing pedestal, the housing and the fixed scroll form a sealed cavity; the first bearing and the second bearing are located in the sealed cavity; the crankshaft is made into a hollow shaft; the hollow shaft consists of the threaded hole and the unthreaded hole sequentially; the bearing pedestal and the crankshaft form a cavity; and the threaded hole, the unthreaded hole and the cavity form a channel communicating to lubrication parts of the first bearing and the second bearing. The bearing lubrication mechanism further comprises a lubrication oil filling mechanism which is connected with the threaded hole. Since no disassembling action requires in a maintenance operation process, the workload of maintenance staff is relieved, the operation experience requirement on the maintenance staff is reduced, the quality of rotating components is reduced, and the overall efficiency of the oil-free scroll compressor is improved to a certain extent.

Owner:SHANGHAI HANBELL PRECISE MASCH CO LTD

Separation method for separating peripheral blood immune cells

InactiveCN105505868ALow operating experience requirementReduce uncertaintyCell dissociation methodsBlood/immune system cellsSaline waterPeripheral blood mononuclear cell

The invention discloses a separation method for separating peripheral blood immune cells, and belongs to the field of biotechnology. The method comprises the following steps: diluting peripheral blood treated by an anticoagulant by using normal saline or a serum-free culture medium to obtain cell suspension; adding a separating medium containing dextran, phospholipid, trehalose and amino acid into a centrifuge tube, wherein the volume of the separating medium is not greater than 1 / 2 of that of the centrifugal tube; and spreading the cell suspension on the separating medium, carrying out centrifugation under the condition that the temperature is 8-25 DEG C, the weight is 200-800g, and the time is 10-30 minutes, and sucking buffy coat cells. According to the separation method disclosed by the invention, when the prepared separating medium is used, an operator can directly spread the cell suspension on the separating medium, the damages to the liquid surface are not needed to be considered too much during spreading, and the requirement on the operation experience of the operator is low; and all the raw materials in a formula provided by the invention are in line with an intravenous injection level raw medicinal material standard, the raw materials have small uncertainty and high safety, and the immune cells obtained by separation have relatively good tumoricidal activity.

Owner:北京弘润天源基因生物技术有限公司

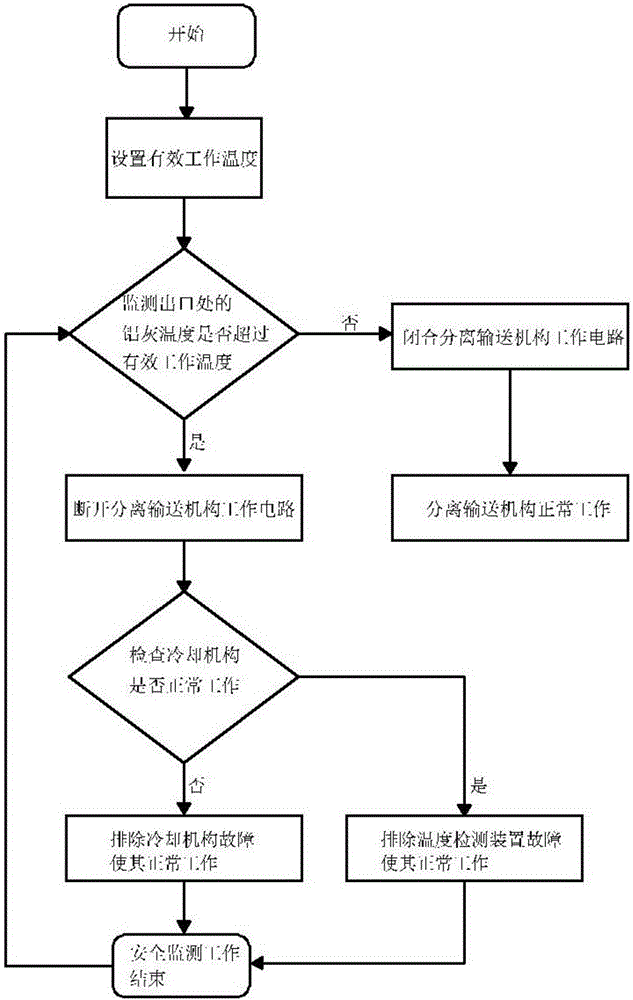

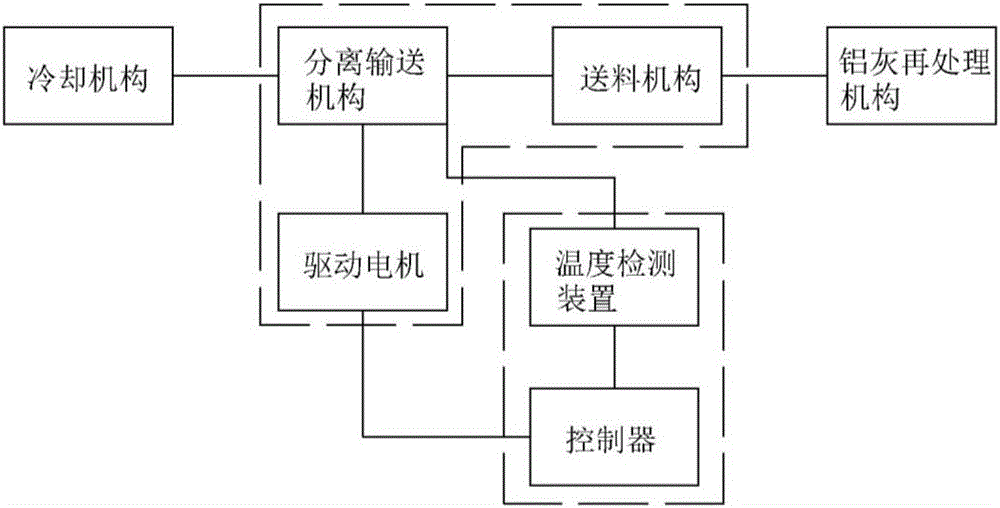

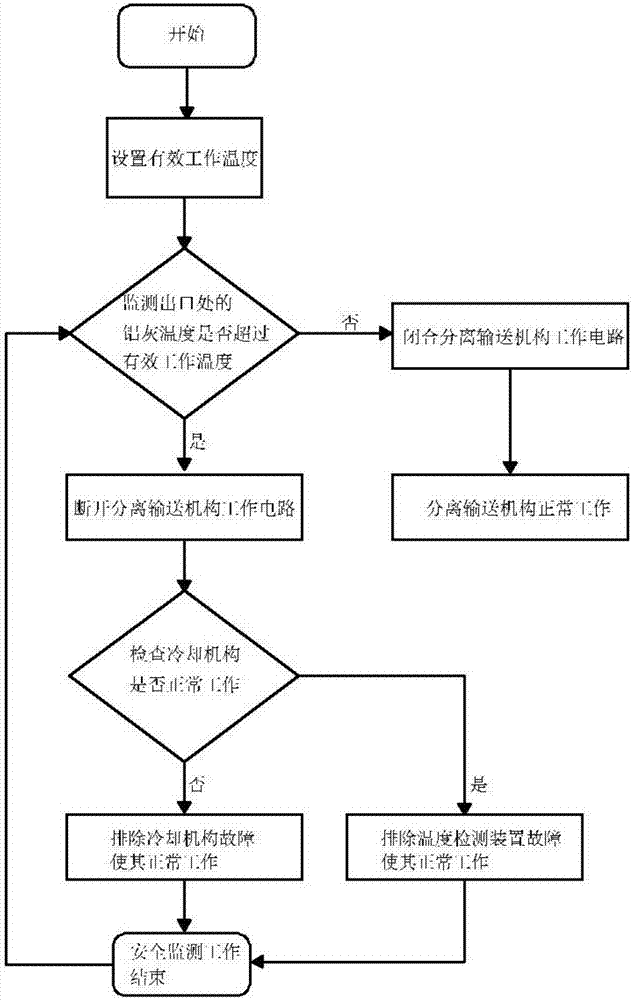

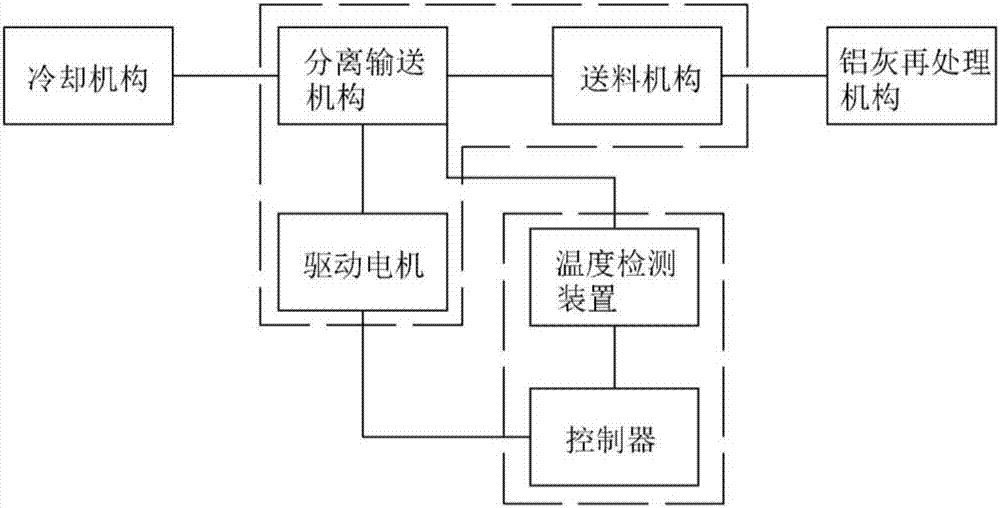

Safety monitoring system and method of aluminum ash conveying mechanism

InactiveCN105947597AImprove feeding efficiencyEnsure personal safetyControl devices for conveyorsDrive motorEngineering

The invention discloses a safety monitoring system and method of an aluminum ash conveying mechanism. The system comprises an aluminum ash cooling mechanism, a conveying mechanism and an aluminum retreating mechanism which are disposed successively; wherein the conveying mechanism includes a separating and conveying mechanism and a feeding mechanism. The system also comprises a safety monitoring mechanism used for monitoring the temperature of the aluminum ash at the outlet of the separating and conveying mechanism and controlling the a driving motor to start or stop based on the temperature signals; the feeding mechanism is a conveying belt; and the separating and conveying mechanism is driven by the driving motor. The system and method disclosed by the invention achieves the advantages of compact structure, low cost, simple operation and high degree of automation, can monitor the temperature of the aluminum ash at the outlet of the separating and conveying mechanism in real time, prolongs the service life of equipment and improves using safety.

Owner:SHANGHAI JIAO TONG UNIV +1

Electronic video multifunctional laryngoscope

InactiveCN101554318BShorten the vertical lengthEasy insertionBronchoscopesLaryngoscopesPhysical medicine and rehabilitationDisplay device

Owner:石学银 +1

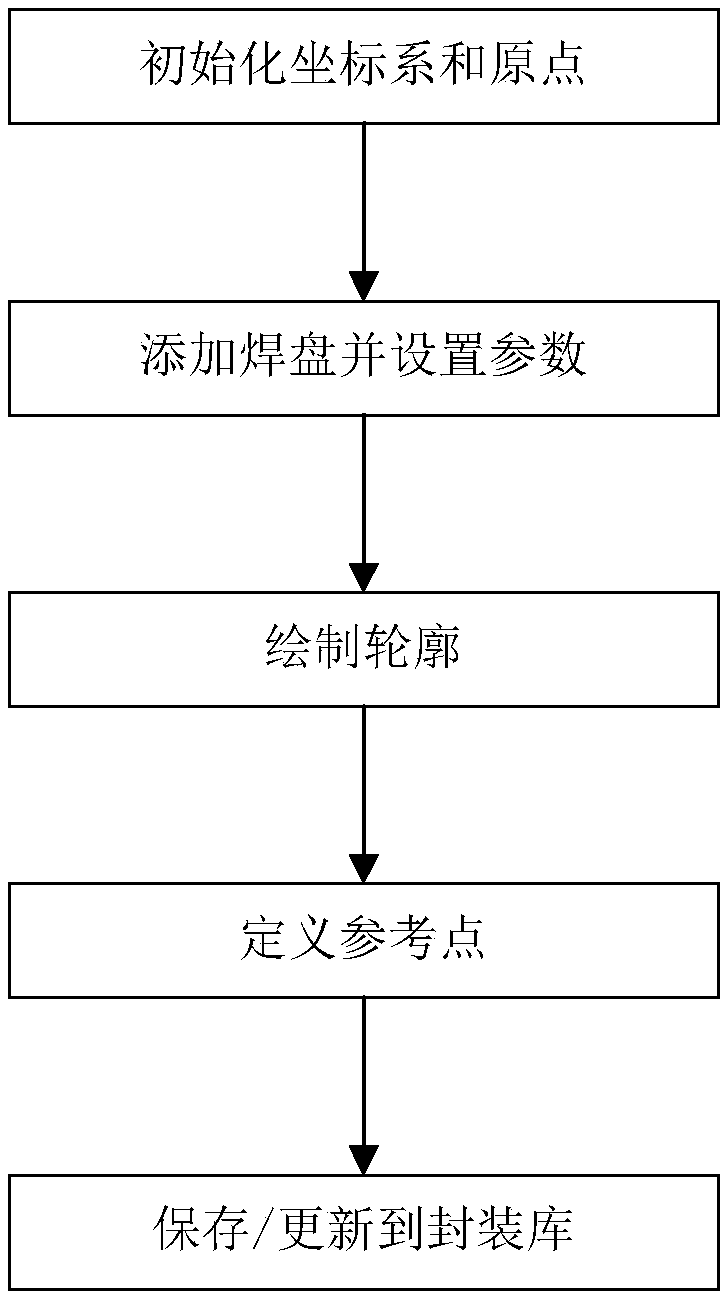

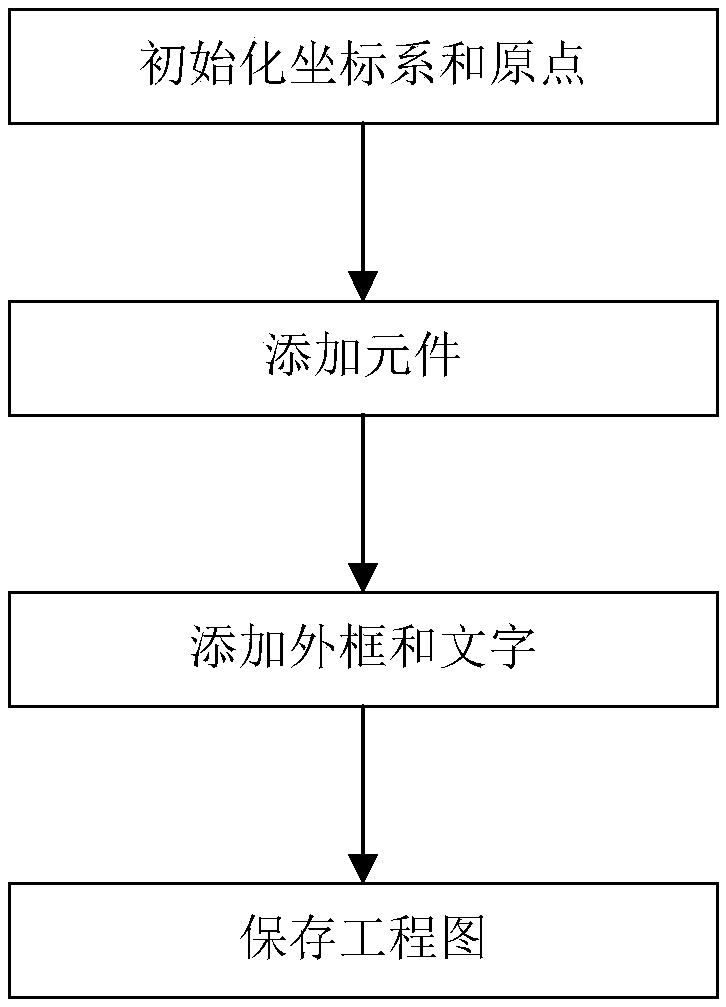

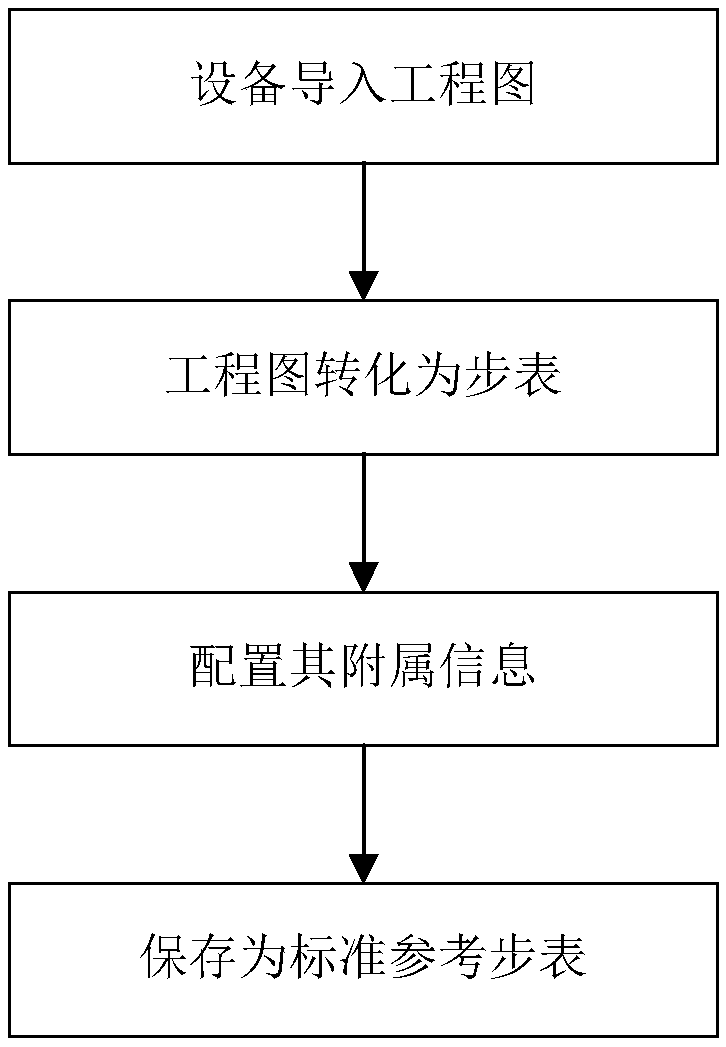

A modeling optimization method and system based on pcb board placement and insertion process

ActiveCN108256170BReduce occupancyReduce dependenceCAD circuit designSpecial data processing applicationsWiring diagramEngineering

The invention discloses a modeling optimization method based on a PCB board sticking and inserting process. The method comprises the following steps that a system builds an element packaging diagram according to size information of a welding element; the system builds a corresponding engineering drawing according to a CAD diagram or a wiring diagram of a PCB board; the system imports the engineering drawing into equipment and converts the engineering drawing into a standard reference step table; the system automatically verifies and updates the standard reference step table according to real-time production deviance. The invention further discloses a modeling optimization system based on the PCB board sticking and inserting process, the system comprises an element packaging diagram establishment module, an engineering drawing establishment module, a standard reference step table establishment module and a verification module. According to the modeling optimization method and system based on the PCB board sticking and inserting process, modeling, validation and updating steps of the standard reference step table can greatly reduce occupation and dependency on resources such as equipment, people and the like, the system is convenient and quick, the production efficiency is improved, the production cost is reduced, and the method and the system can be widely applied to the field of sticking and inserting control of components and parts.

Owner:深圳市万相源科技有限公司

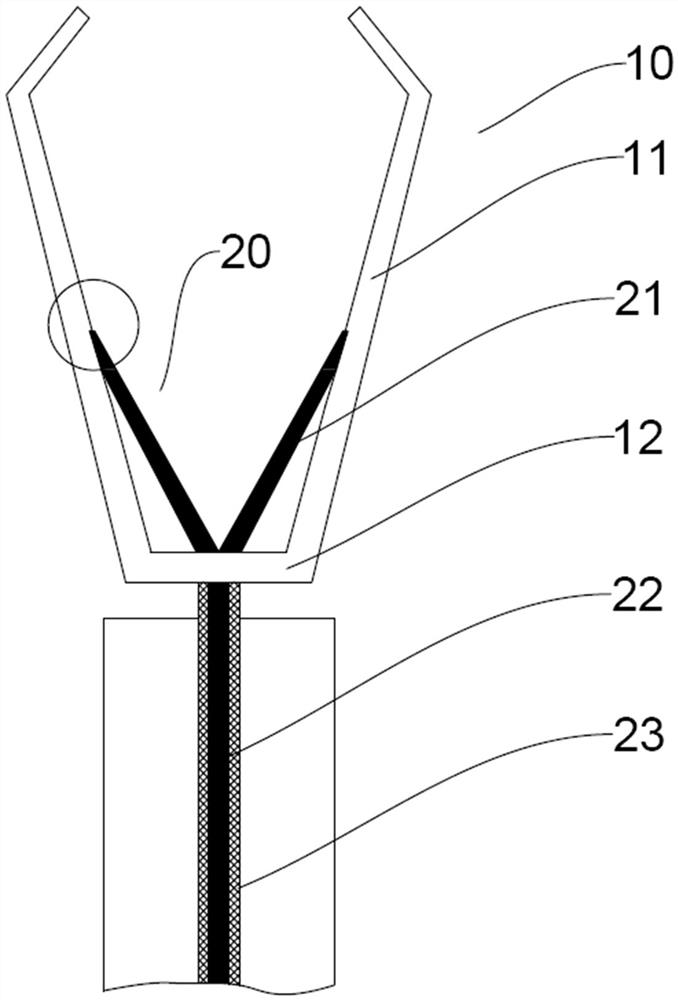

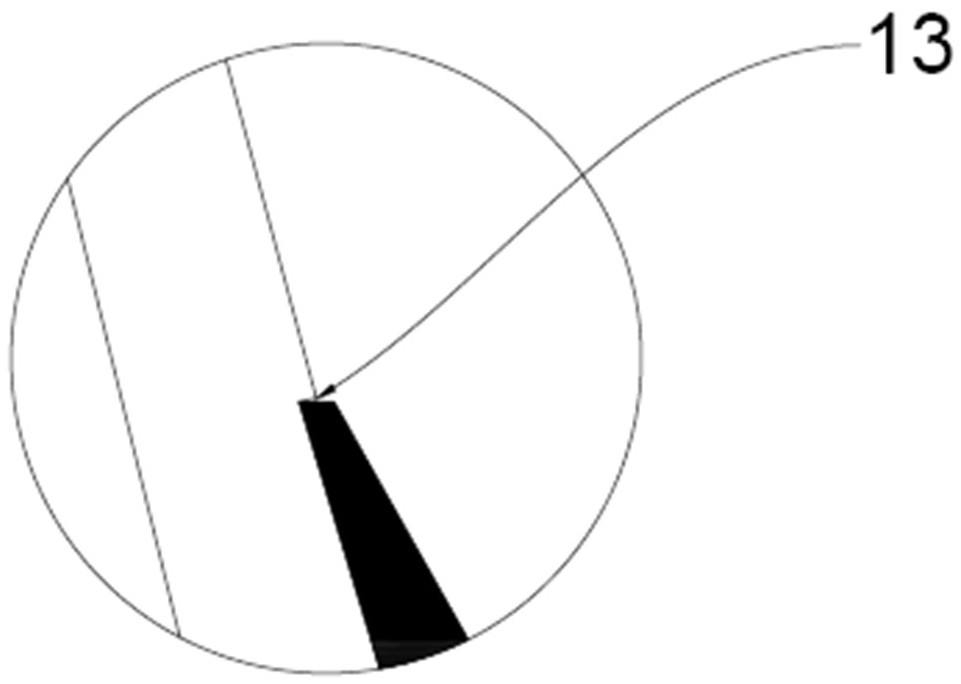

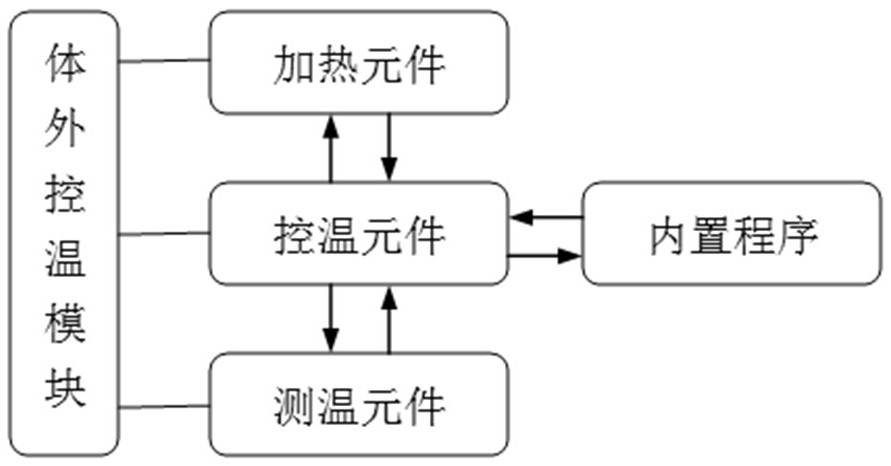

Digestive tract drug delivery system

PendingCN114082090AAvoid human interventionLow operating experience requirementMedical devicesPharmaceutical drugSurgery

The invention provides a digestive tract drug delivery system, which comprises a drug carrying clamp body and a clamp body release piece, wherein the drug carrying clamp body is used for carrying drugs, the drug carrying clamp body and the drugs are clamped on the designated part of the inner wall of a digestive tract together, the clamp body release piece is used for carrying the drug carrying clamp body and releasing the drug carrying clamp body after the drug carrying clamp body reaches the designated part, the clamp body release piece comprises a shape memory supporting head and a temperature conduction wire, the supporting legs of the shape memory supporting head are assembled on the clamping sheet portion of the drug carrying clamp body in an open state, the clamping sheet portion is opened by applying force to elastic clamping sheets on the two sides of the clamping sheet portion, and when the shape memory supporting head reaches a deformation temperature, the supporting legs are deformed into a contraction state from the open state, the clamping sheet portion loses supporting and is in a clamping state, and the system further comprises an in-vitro temperature control module used for transmitting energy needed for reaching the deformation temperature to the shape memory supporting head through the temperature conduction wire. According to the invention, a temperature control shape memory function material is introduced to achieve elastic release of a drug medicine carrying clamp body after reaching a diseased part, so that in-situ slow clamping of the diseased part is achieved, manpower intervention is avoided, and the success rate is increased.

Owner:SHANDONG PROVINCIAL HOSPITAL AFFILIATED TO SHANDONG FIRST MEDICAL UNIVERSITY

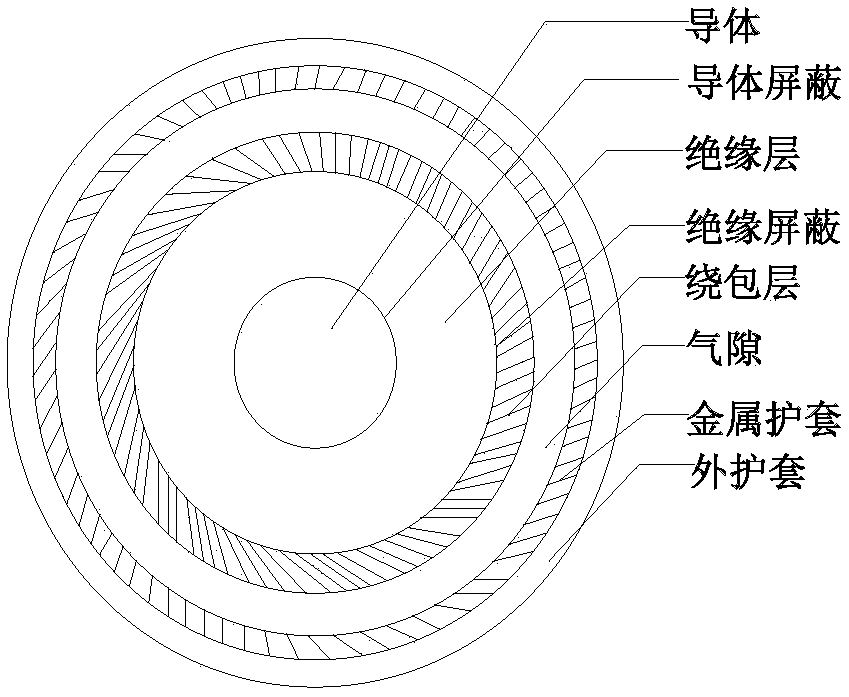

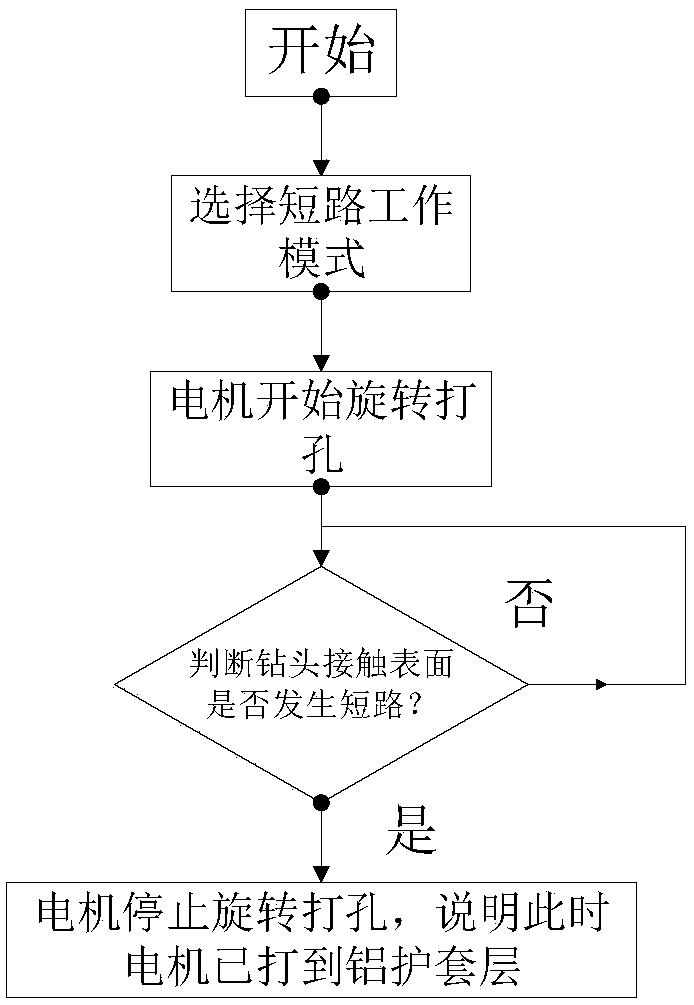

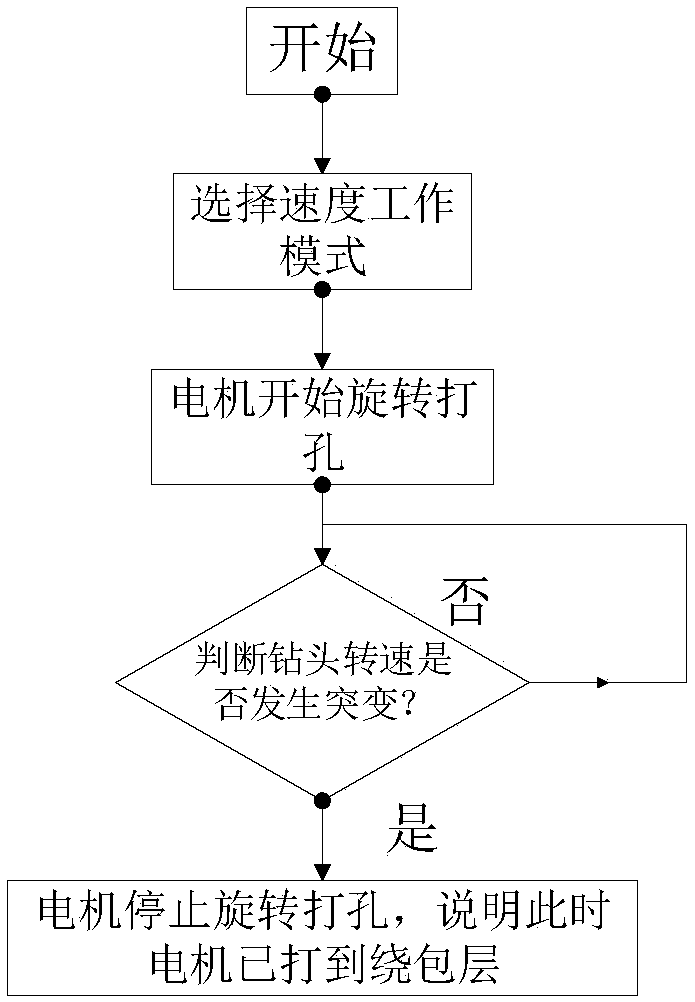

Automatic cable punching method capable of accurately positioning

ActiveCN108405913ALow technical requirementsLow operating experience requirementBoring/drilling machinesPunchingAutomatic control

The invention discloses an automatic cable punching method capable of accurately positioning. The automatic cable punching method comprises the following steps of (S1) adjusting an operating mode of amotor to a short circuit operating mode on the basis of the radial profile of a cable first, and punching the cable until a drill stops operating; (S2) adjusting to an inching operating mode, and performing inching punching on the cable; (S3) adjusting to a speed operating mode, and punching the cable until the drill stops operating; (S4) adjusting to a distance operating mode, and punching the cable by selecting a set value on the basis of the type and parameters of the cable until the drill stops operating, wherein the condition shows that the cable is punched to an insulating layer at themoment; (S5) adjusting to the short circuit operating mode again, punching the cable until the drill stops operating, then adjusting to the inching operating mode, and performing inching punching treatment on the cable until all layers of the cable are punched. According to the automatic cable punching method, on the basis of an automatic control theory, the automatic cable punching with accuratepositioning is realized, and the automatic cable punching method has a high application value in engineering practice.

Owner:SOUTH CHINA UNIV OF TECH

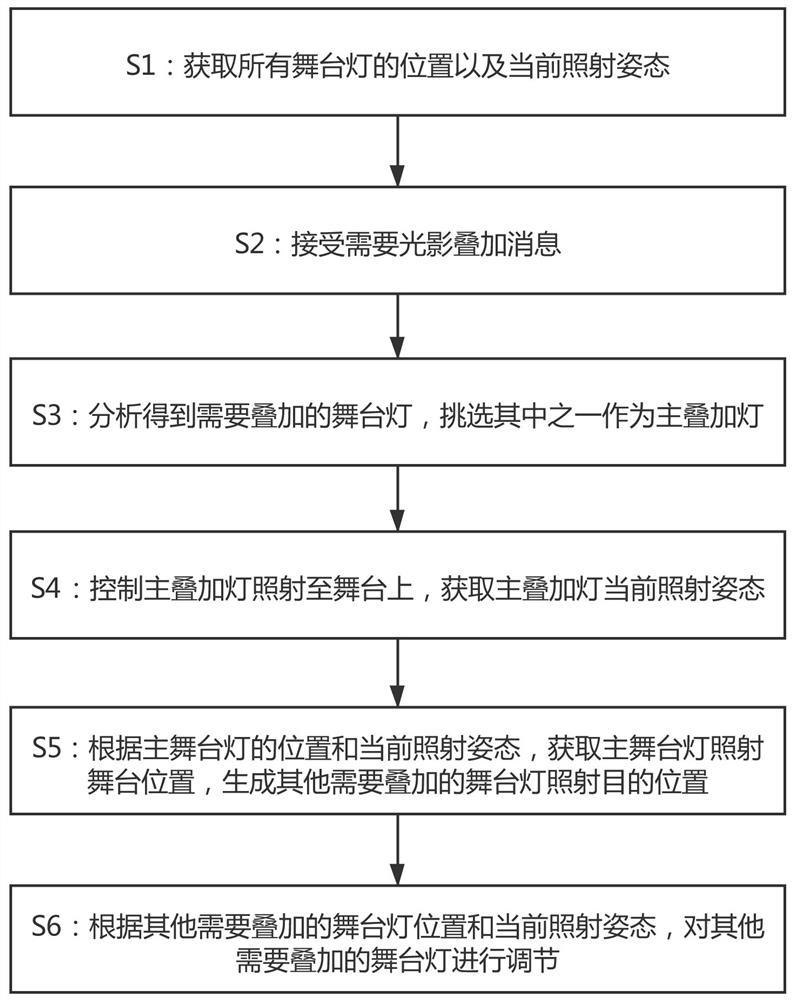

A kind of stage lighting and shadow superposition control method

ActiveCN110944438BLow operating experience requirementEasy to implementElectrical apparatusEnergy saving control techniquesStage lightingSuperimposition

The present invention provides a stage light and shadow superimposition control method, which relates to the technical field of stage equipment, and includes the following steps: S1: Obtaining the positions and current illumination postures of all stage lights; S2: Accepting the need for light and shadow superimposition messages; S3: Analyzing and obtaining Stage lights, select one of them as the main overlay light; S4: Control the main overlay light to shine on the stage, and obtain the current irradiation posture of the main overlay light; S5: According to the position of the main stage light and the current irradiation posture, obtain the main stage light to illuminate the stage position to generate the irradiation target position of other stage lights that need to be superimposed; S6: adjust other stage lights that need to be superimposed according to the position of other stage lights that need to be superimposed and the current irradiation posture. The present invention provides a superimposition control method for stage lights and shadows with simple implementation, good light and shadow superimposition effect, fast superimposition speed, superimposition without manual adjustment, intelligent control, high precision, and low requirement for operating experience of staff.

Owner:杭州友邦文化科技有限公司

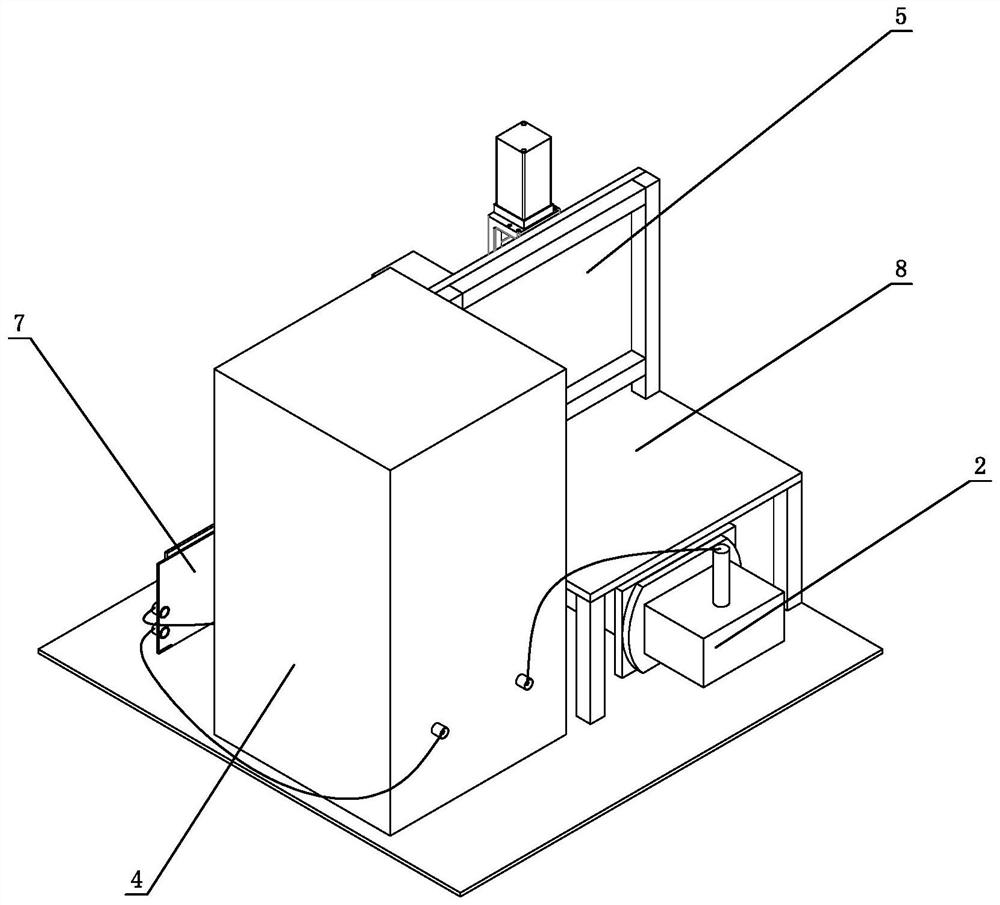

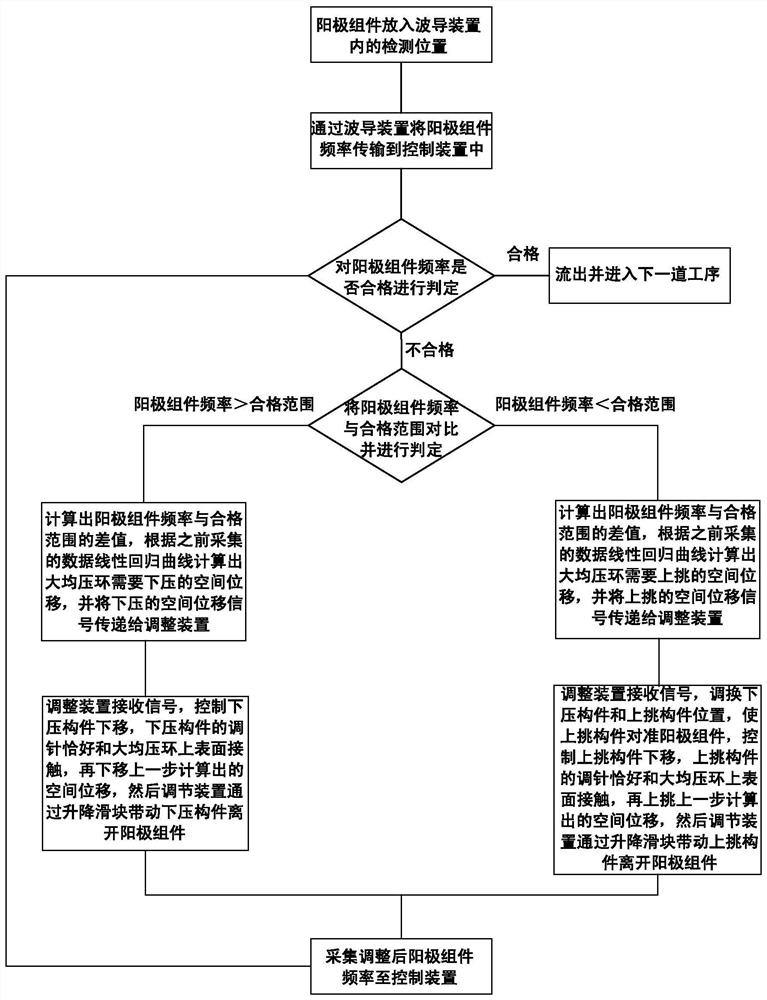

A kind of adjustment method of anode component frequency adjustment equipment

ActiveCN111613501BLow operating experience requirementClear division of laborMagnetronsElectrode assembly manufactureElectrical connectionComputational physics

An adjustment method for an anode component frequency adjustment device, the adjustment device includes a waveguide device for detecting and transmitting the frequency value of the anode component, and an adjustment device for adjusting the spatial displacement of a large pressure equalizing ring in the anode component, one side of the waveguide device is provided for collecting The control device for collecting, storing, analyzing and comparing the frequency value of the anode assembly each time, and collecting, storing, analyzing and comparing the spatial displacement data of the large pressure equalizing ring in the anode assembly for each adjustment, the waveguide device, the adjustment device and the control device respectively form a communication system Electrically connected, the adjusting device is provided with an adjusting component and a lifting slider that are matched and connected, the frequency value of the anode component is transmitted to the control device through the waveguide device, and the control device collects, stores and analyzes the comparison data, and then controls the adjusting component of the adjusting device, Adjust the assembly to pick up or press down the large pressure equalizing ring in the anode assembly to realize automatic adjustment of the frequency of the anode assembly. The invention effectively improves the adjustment efficiency of the frequency of the anode assembly.

Owner:GUANGDONG GALANZ GRP CO LTD +1

A safety monitoring system and method for an aluminum ash conveying mechanism

InactiveCN105947597BImprove feeding efficiencyEnsure personal safetyControl devices for conveyorsEngineeringDrive motor

The invention discloses a safety monitoring system and method of an aluminum ash conveying mechanism. The system comprises an aluminum ash cooling mechanism, a conveying mechanism and an aluminum retreating mechanism which are disposed successively; wherein the conveying mechanism includes a separating and conveying mechanism and a feeding mechanism. The system also comprises a safety monitoring mechanism used for monitoring the temperature of the aluminum ash at the outlet of the separating and conveying mechanism and controlling the a driving motor to start or stop based on the temperature signals; the feeding mechanism is a conveying belt; and the separating and conveying mechanism is driven by the driving motor. The system and method disclosed by the invention achieves the advantages of compact structure, low cost, simple operation and high degree of automation, can monitor the temperature of the aluminum ash at the outlet of the separating and conveying mechanism in real time, prolongs the service life of equipment and improves using safety.

Owner:SHANGHAI JIAOTONG UNIV +1

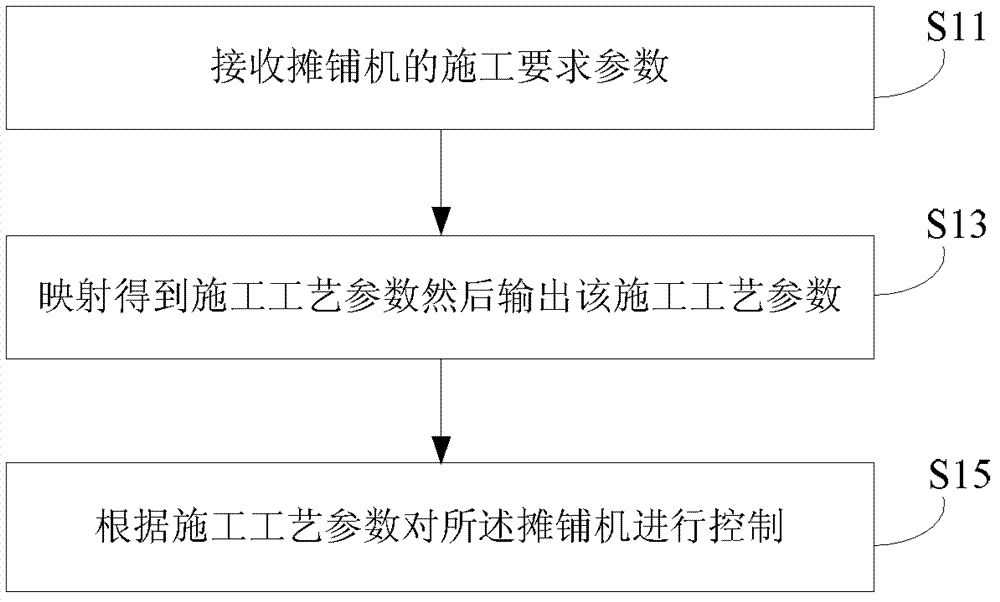

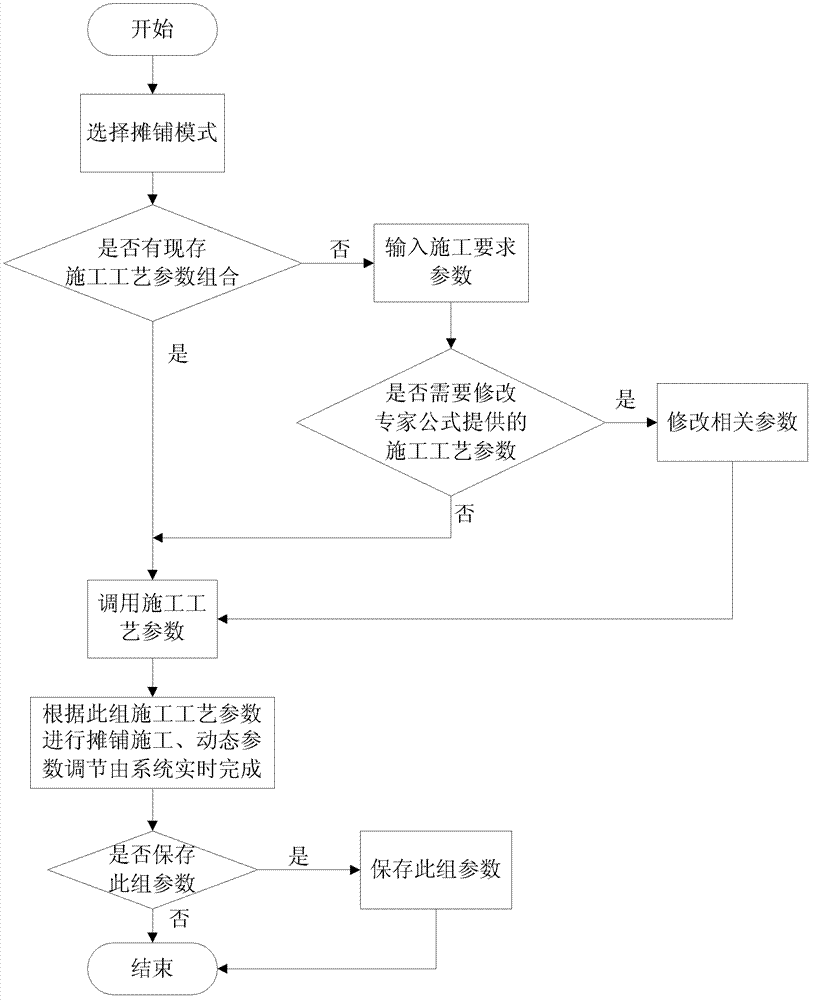

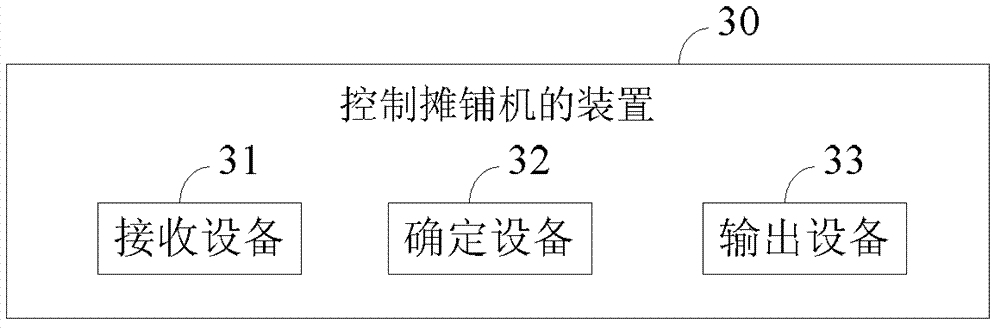

Spreading machine and method, device and system for controlling spreading machine

InactiveCN102330404BImprove the quality of workLow operating experience requirementRoads maintainenceWork qualityComputer science

A paver and a method, device (30) and system (40) for controlling same are provided to solve the problem in the prior art that the working quality of the paver is not good. The method comprises: receiving a construction requirement parameter of a paver (S11); according to the construction requirement parameter and a preset mapping relationship between the construction requirement parameter and a construction process parameter, obtaining through mapping the construction process parameter according to the mapping relationship by using the construction requirement parameter and outputting the construction process parameter (S13); and controlling the paver according to the construction process parameter (S15). A preferred control effect of the paver is achieved through the technical solution.

Owner:ZOOMLION HEAVY IND CO LTD

Electric video laryngoscope

InactiveCN101554320AShorten the vertical lengthAvoid getting stuck in the patient's chestRespiratorsBronchoscopesVideo laryngoscopeDisplay device

The invention provides an electronic video laryngoscope. The laryngoscope comprises a bracket component, an arc oropharynx air duct and spatula assembly, an image shooting component, a cell box and a display, wherein the arc oropharynx air duct and spatula assembly is positioned on the front end of the bracket component; the image shooting component is positioned at the lower part of the arc oropharynx air duct and spatula assembly; the image shooting component comprises a camera and an illuminating lamp; the display can be rotatably arranged on the rear end of the bracket component; the camera is connected with the display through a data wire; the cell box is connected with the illuminating lamp, the camera and the display through electric wires. The electric video laryngoscope also comprises a cell kit which can also be used as an operation handle; the cell box is arranged in the cell kit; and the cell kit is arranged on the side of the bracket component. The electric video laryngoscope can effectively shorten the handle length, can be operated conveniently, and has lower requirement on operation experience of a doctor.

Owner:石学银 +1

Electric video laryngoscope

InactiveCN101554320BShorten the vertical lengthEasy insertionRespiratorsBronchoscopesVideo laryngoscopeDisplay device

The invention provides an electronic video laryngoscope. The laryngoscope comprises a bracket component, an arc oropharynx air duct and spatula assembly, an image shooting component, a cell box and a display, wherein the arc oropharynx air duct and spatula assembly is positioned on the front end of the bracket component; the image shooting component is positioned at the lower part of the arc oropharynx air duct and spatula assembly; the image shooting component comprises a camera and an illuminating lamp; the display can be rotatably arranged on the rear end of the bracket component; the camera is connected with the display through a data wire; the cell box is connected with the illuminating lamp, the camera and the display through electric wires. The electric video laryngoscope also comprises a cell kit which can also be used as an operation handle; the cell box is arranged in the cell kit; and the cell kit is arranged on the side of the bracket component. The electric video laryngoscope can effectively shorten the handle length, can be operated conveniently, and has lower requirement on operation experience of a doctor.

Owner:石学银 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com