Automatic crawling device for magnetic powder detection by cross magnet yoke method

A magnetic particle detection and automatic crawling technology, which is applied in the fields of material magnetic variables, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of lower detection accuracy, higher operating experience requirements for technicians, and many participants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

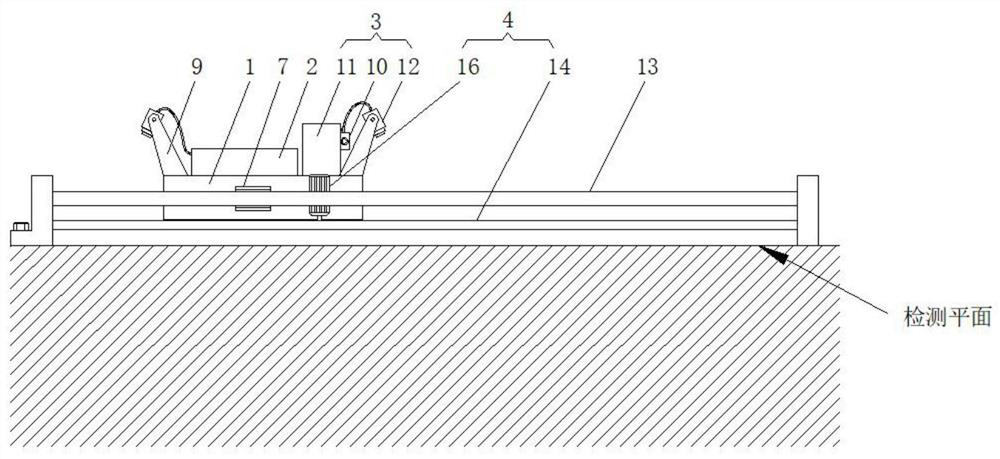

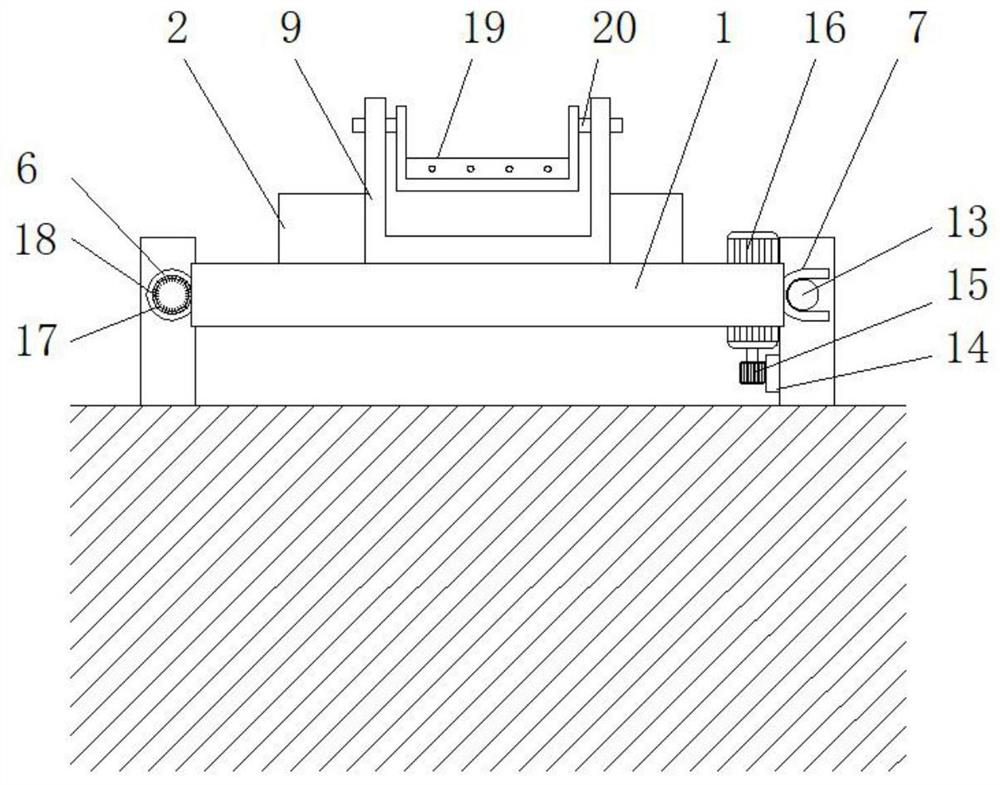

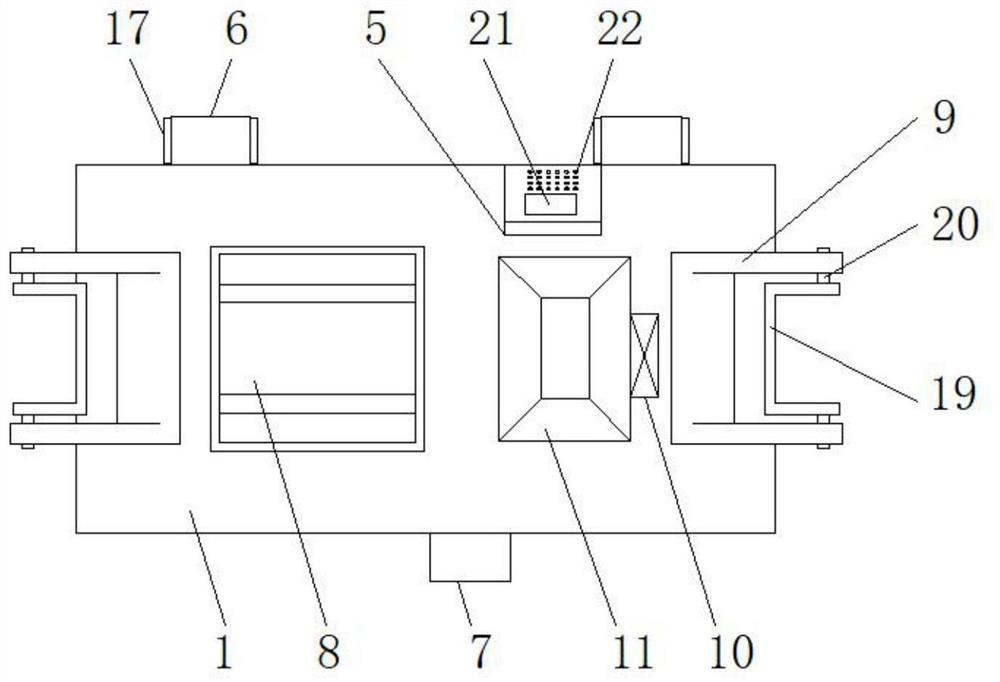

[0033] When the present invention is in use, the guide sliding sleeve 6 on the left side of the fixed frame 1 is sleeved on the surface of the left guide rod 13, and the left guide rod 13 is fixedly installed on the surface of the detection plane, and then the right guide rod One section of 13 is rotationally connected with the detection plane, and the right guide rod 13 is rotated so that the guide rod 13 is engaged with the guide buckle 7 on the right side of the fixed frame 1, and then the other end of the right guide rod 13 is fixedly connected with the detection plane using bolts , the guide rack 14 is fixedly installed under the right guide bar 13, the servo motor 16 is installed on the edge of the fixed frame 1 and the drive gear 15 at the end is adjusted to mesh with the guide rack 14, and finally the fixed frame 1 Install the flaw detector 2, the injection mechanism 3 and the control box 5 in sequence on the surface of the surface.

Embodiment 2

[0035]When the present invention is working, the magnetic suspension liquid is injected into the box body 11, and by setting relevant parameters on the surface of the control box 5, the control box 5 automatically controls the rotation of the servo motor 16, drives the fixed frame 1 to reciprocate along the surface of the guide rod 13, and The pump body 10 is controlled to evenly spray the magnetic suspension, so that the convenience and detection accuracy of the flaw detector 2 are improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com