Bearing lubrication mechanism of oil-free scroll compressor

A scroll compressor, bearing lubrication technology, applied in machine/engine, rotary piston/oscillating piston pump components, mechanical equipment, etc., can solve the problems of increased maintenance time, complicated disassembly and assembly process, etc. The effect of reducing operating experience requirements, improving overall efficiency, and reducing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

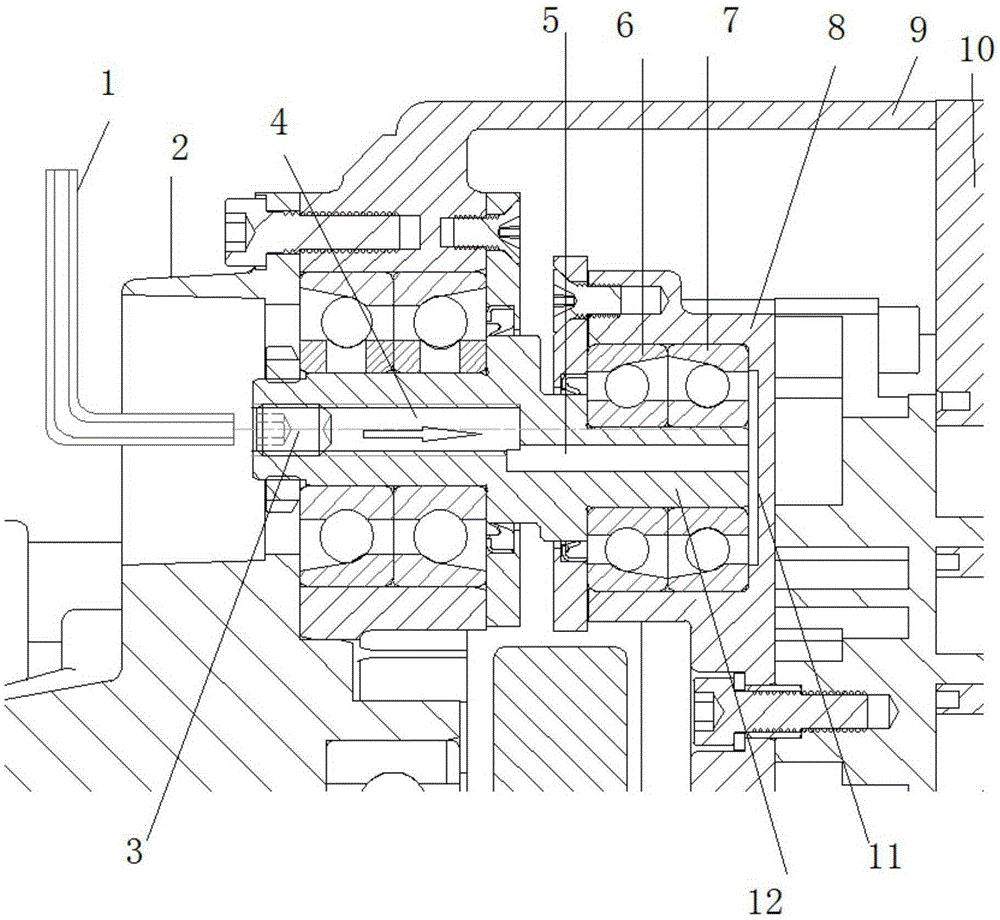

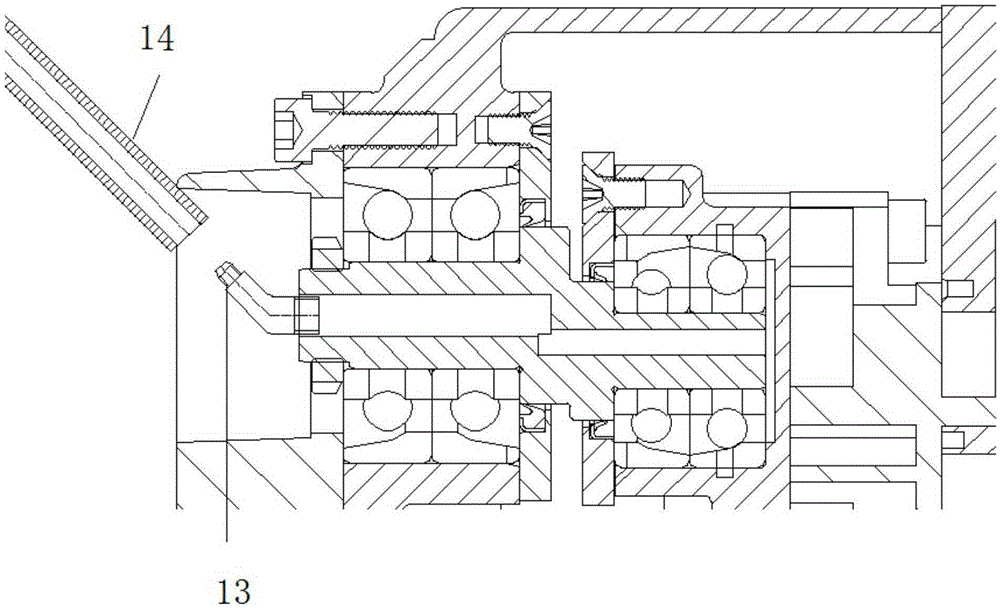

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

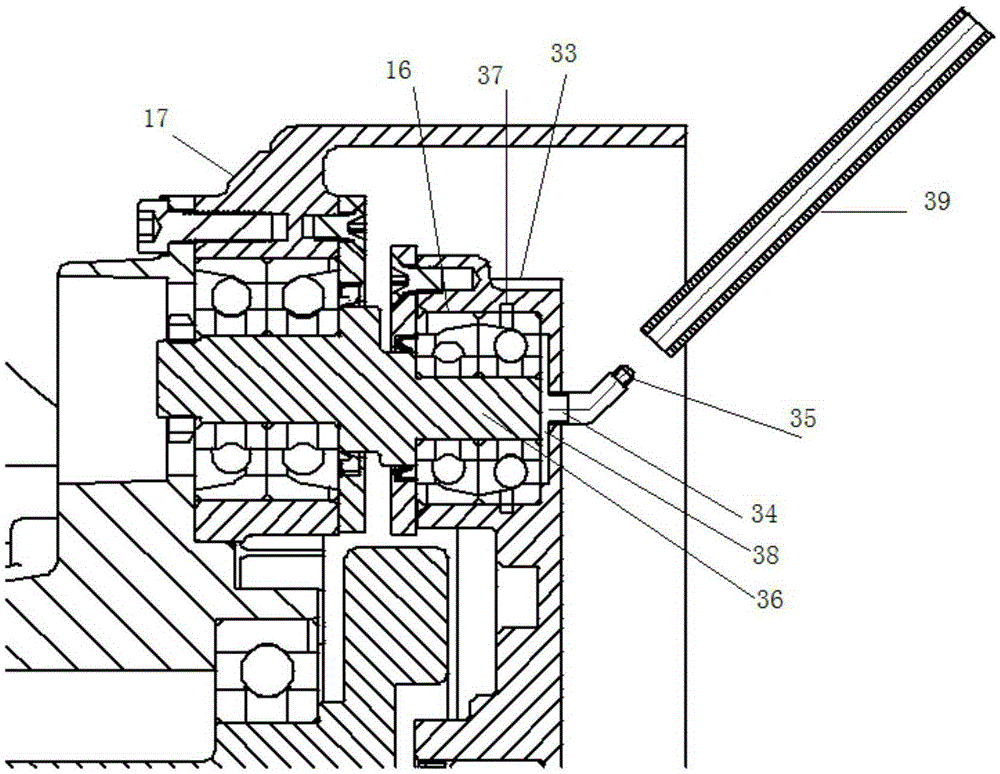

[0013] Depend on figure 2 , image 3 It can be seen that the present invention includes: housing 9, first bearing 6 and second bearing 7; also includes: outer bearing seat 2, fixed scroll 10, threaded hole 4, light hole 5, crankshaft 12, bearing seat 8; The outer bearing seat 2, the casing 9 and the fixed scroll 10 form a closed cavity; the first bearing 6 and the second bearing 7 are in the closed cavity; the crankshaft 12 is made into Hollow shaft, this hollow shaft is made up of threaded hole 4 and light hole 5 in turn; Described bearing block 8 and crankshaft 12 form cavity 11; Described threaded hole 4, light hole 5 and cavity 11 form and communicate with the first The channel of the lubricating part of the bearing 6 and the second bearing 7; also includes: a lubricating oil filling mechanism; the lubricating oil filling mechanism is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com