Method for maximum rotation speed restriction of rotary engineering machinery and system thereof

A technology of construction machinery and slewing speed, which is applied to cranes and other directions, and can solve problems such as incorrect estimation of crane reserved space, lack of experience, and on-site environmental restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

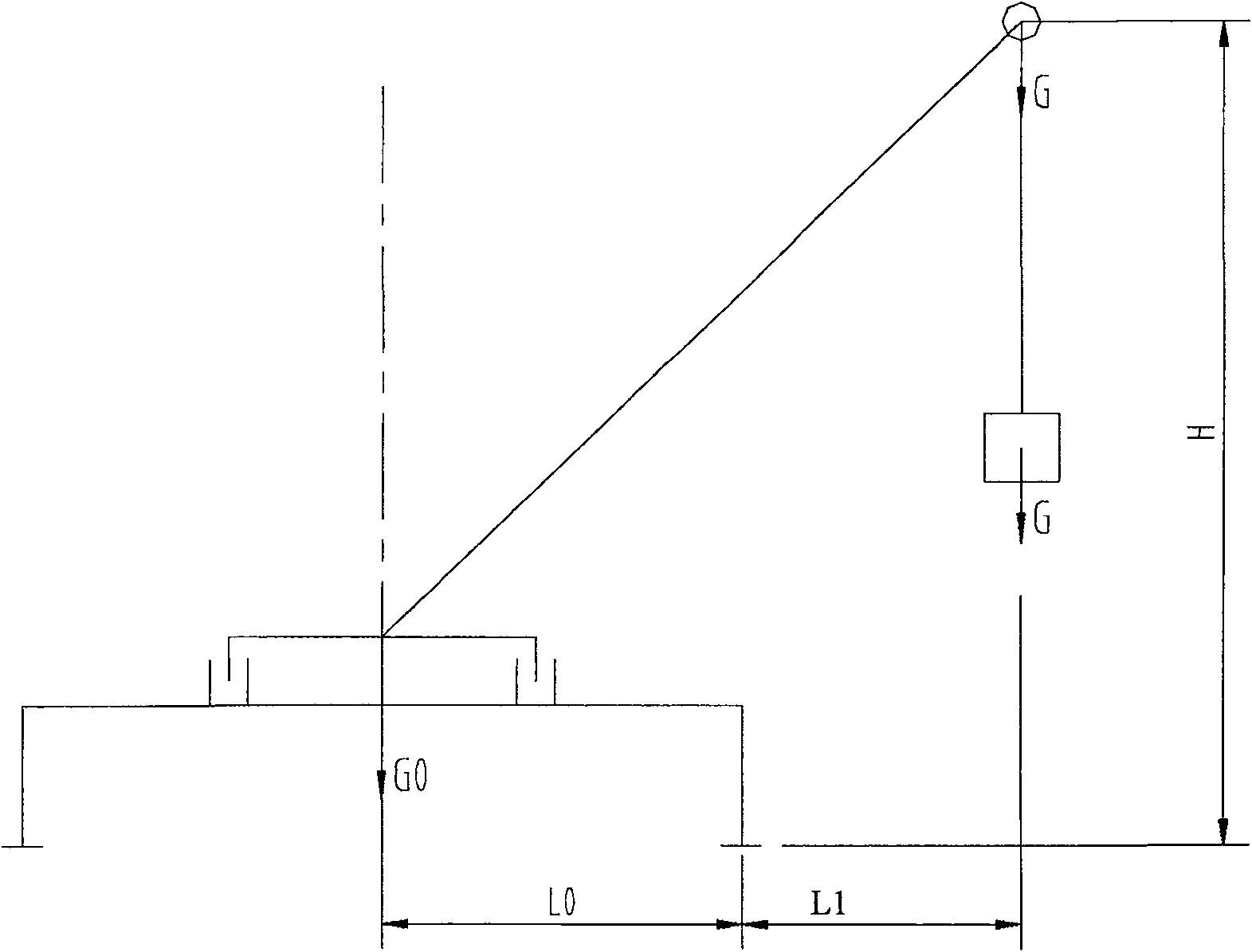

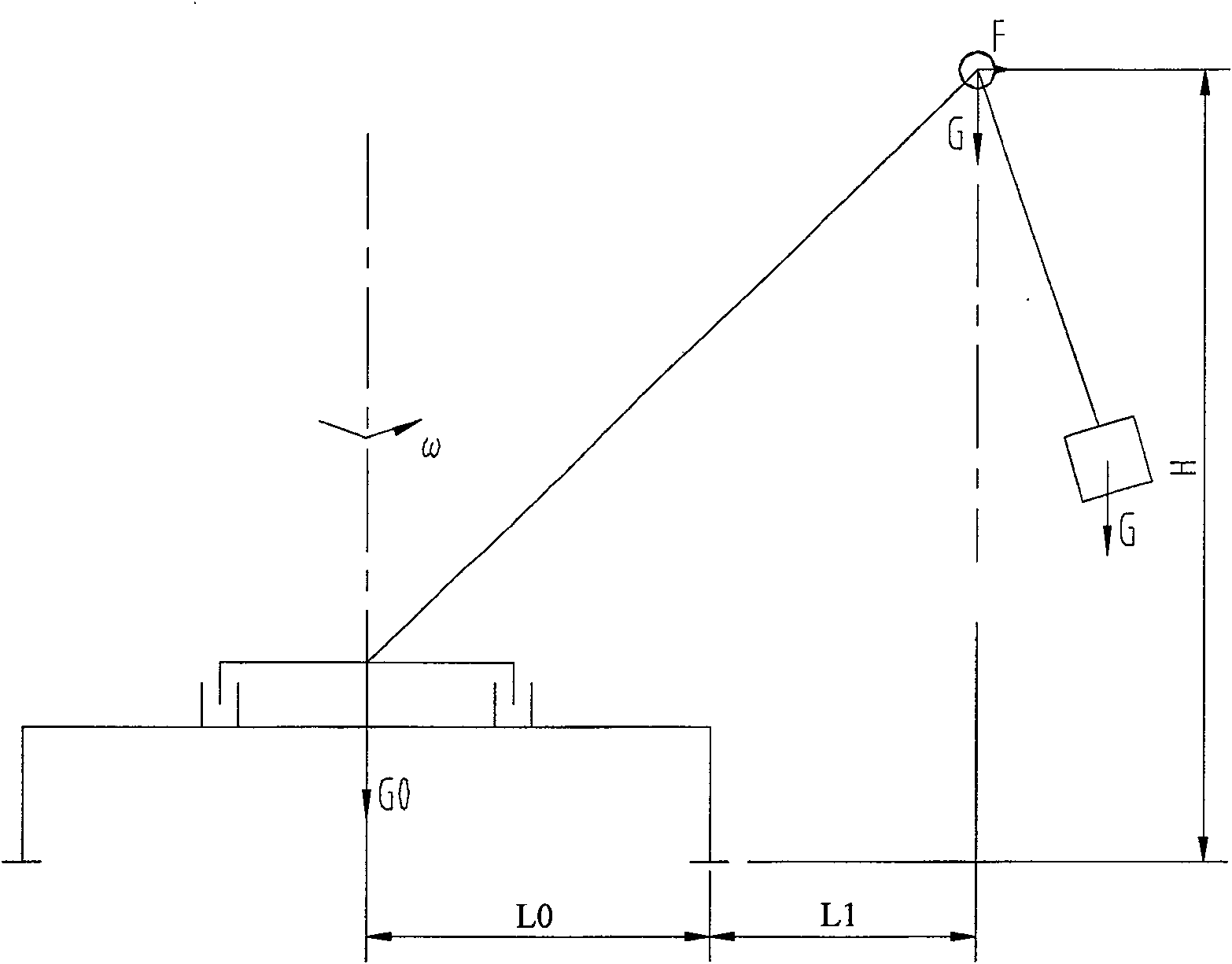

[0050] The first embodiment of the present invention takes a crane as an example to provide a method for limiting the maximum slewing speed of a slewable engineering machinery from overturning. The basic principle of this method is to obtain the dynamic overturning moment space T based on calculation dmax , and determine the maximum rotation speed according to this value, and then control the rotation speed within this range.

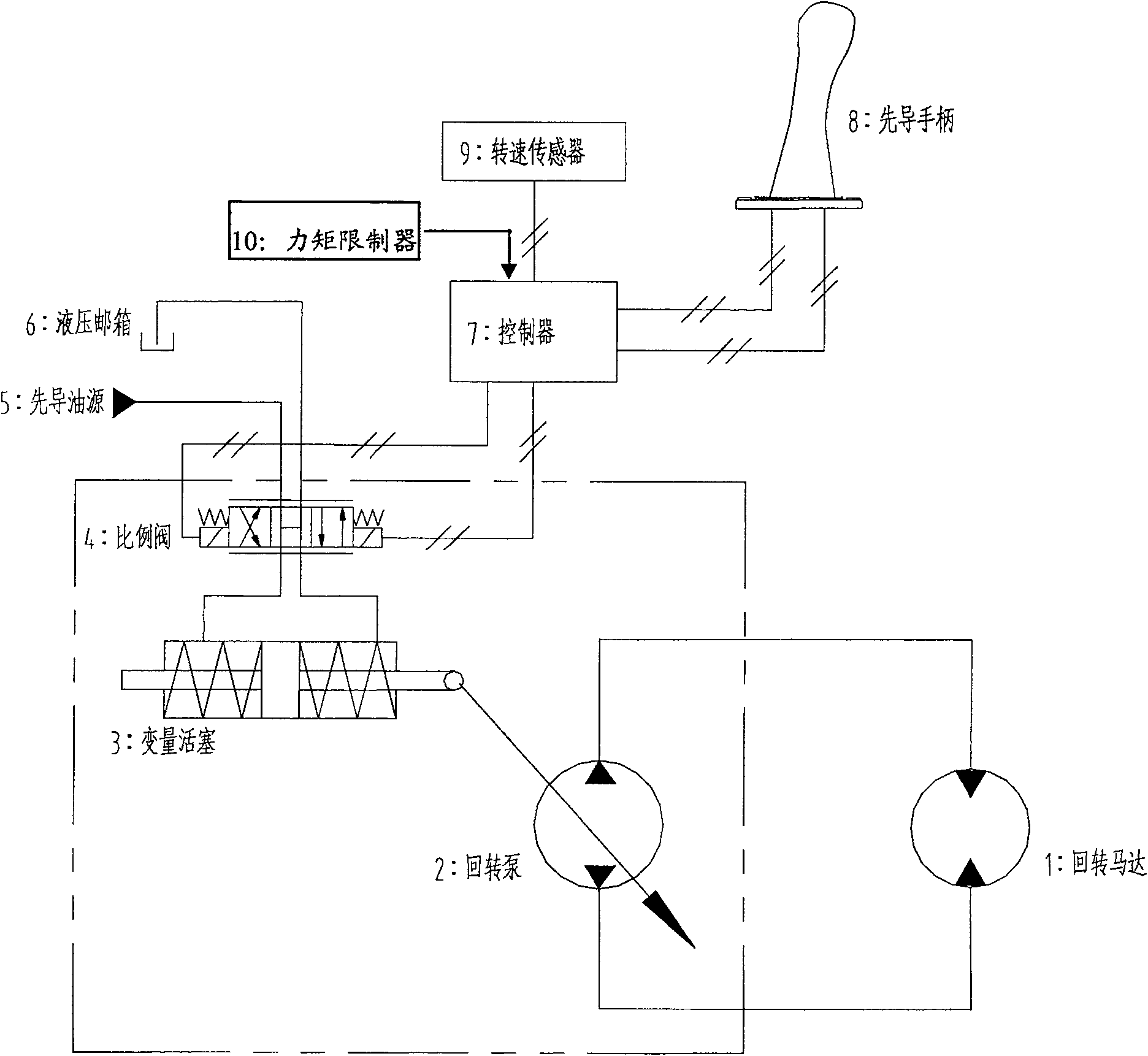

[0051] Please see image 3 The picture shows a closed hydraulic control system of a crane. The system includes a rotary pump 1 and a hydraulic rotary motor 2 interconnected to form the main circuit of a closed hydraulic system, an electronically controlled proportional valve 3 and a variable piston 4 that control the displacement of the rotary pump 1, and a supply for the proportional valve 3 and variable piston 4. The pilot oil source 5 and the hydraulic oil tank 6 of the oil source; the control system also includes a pilot handle 8 for the operator t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com