Safety monitoring system and method of aluminum ash conveying mechanism

A conveying mechanism and safety monitoring technology, which is applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of low efficiency of aluminum ash treatment, damage of aluminum ash treatment mechanism, high equipment cost, etc., and reduce high temperature burns Accidents, compact structure, high degree of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

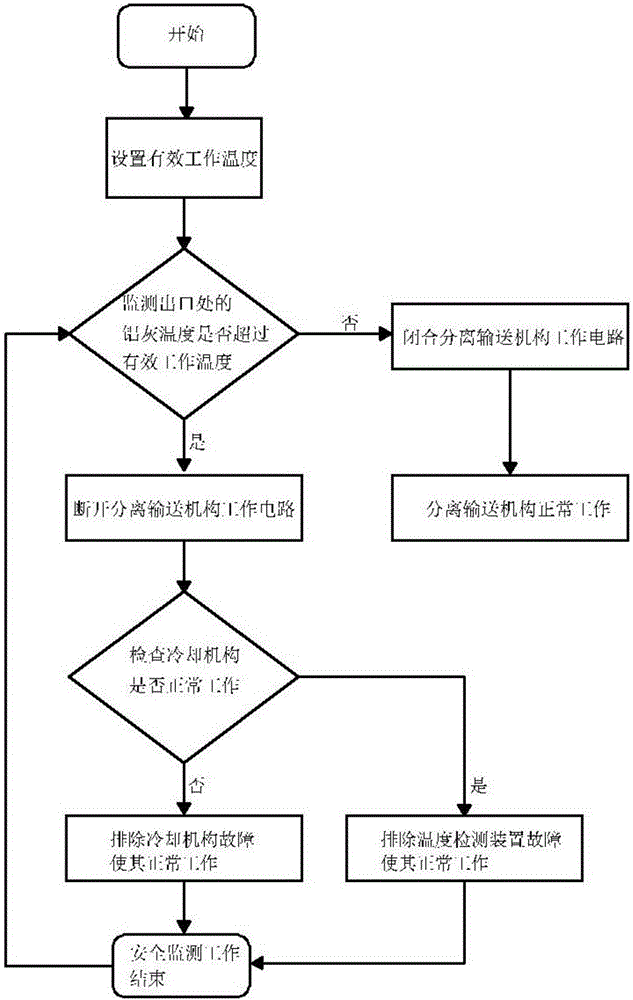

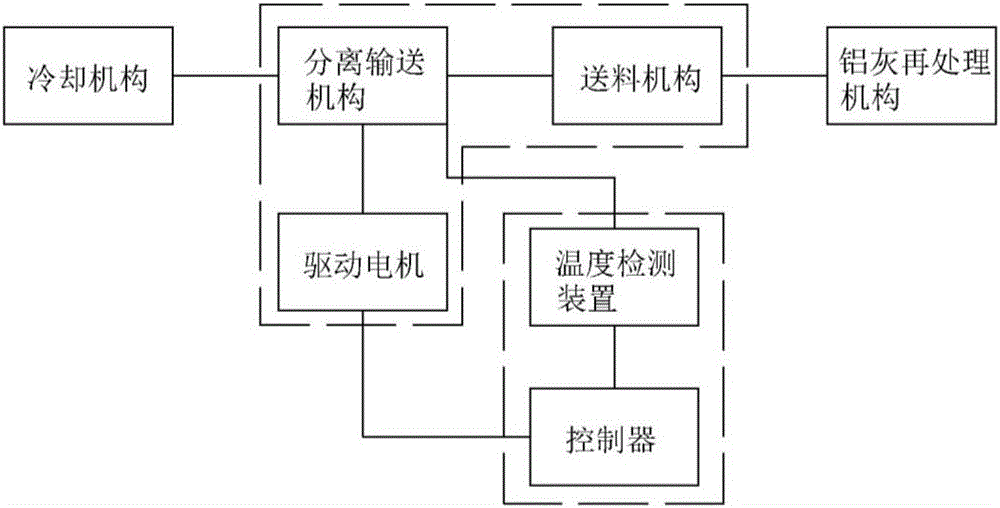

[0019] The safety monitoring mechanism includes a temperature detection device, and also includes a controller for processing the signal detected by the temperature detection device and controlling the start and stop of the drive motor. The temperature detection device is arranged at the outlet of the separation conveying mechanism. The temperature detection device is a temperature alarm or an infrared temperature sensor. Of course, as long as the aluminum dust temperature at the outlet of the separation conveying mechanism is detected and fed back to the controller, other devices or components are also applicable to this.

[0020] The starting circuits of the cooling mechanism and the separation conveying mechanism are unified, that is, the cooling mechanism must work with the circuit of the separation conveying mechanism at the same time, so as to avoid high temperature damage caused by misoperation or forgetting to start the cooling mechanism during the operation by the opera...

Embodiment 2

[0023] The safety monitoring mechanism includes a fuse set in the drive circuit of the drive motor, and the fuse is buried at the exit of the separation conveying mechanism. When the temperature is too high, the fuse will be automatically blown, thereby disconnecting the working circuit of the conveying mechanism and making the separation conveying mechanism stop working. This method is not only convenient to implement, strong practicability, but also relatively inexpensive, and the replacement of the fuse is also quite convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com