Patents

Literature

59results about How to "Improve installation and debugging efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

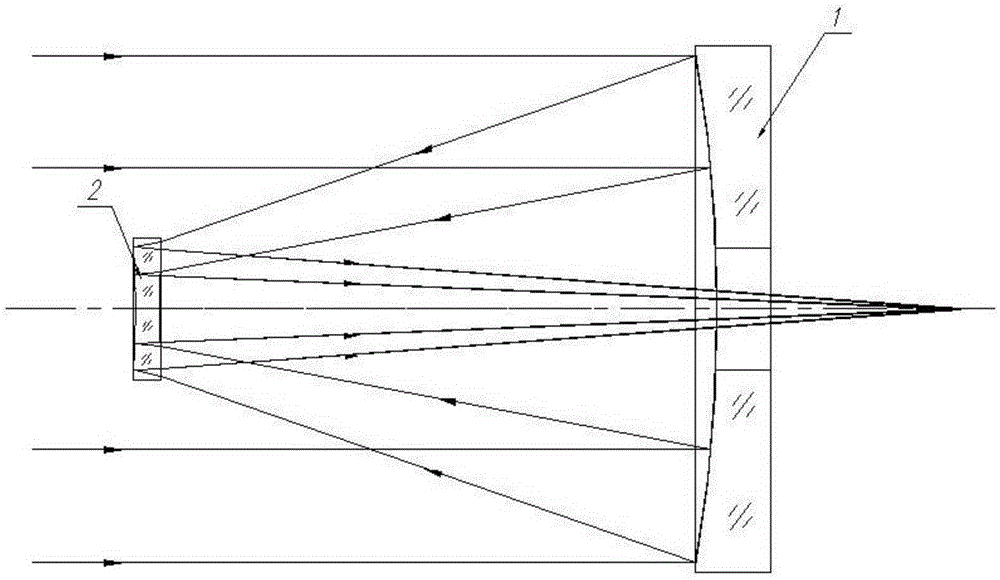

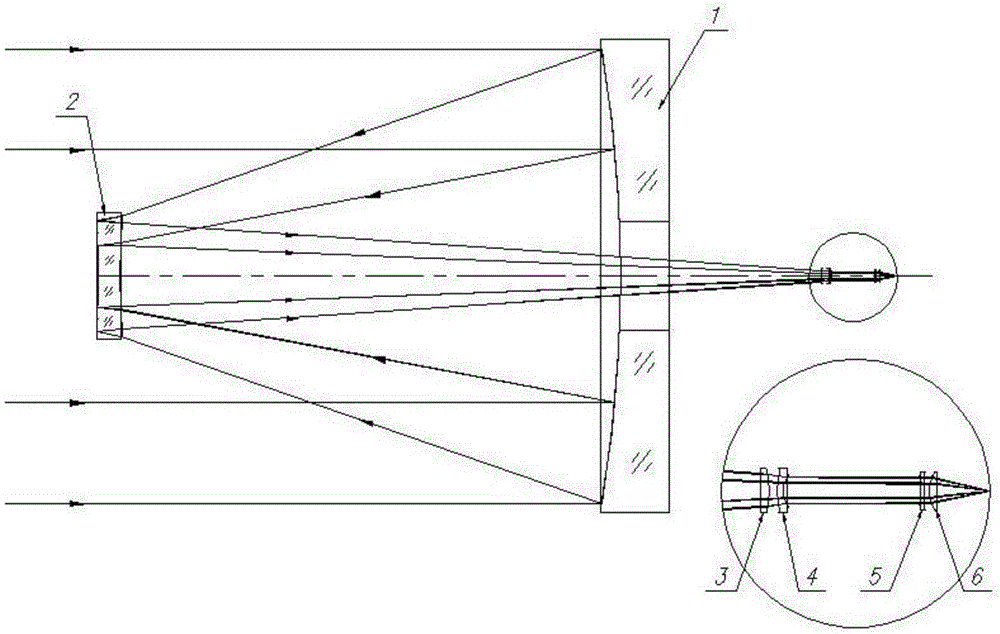

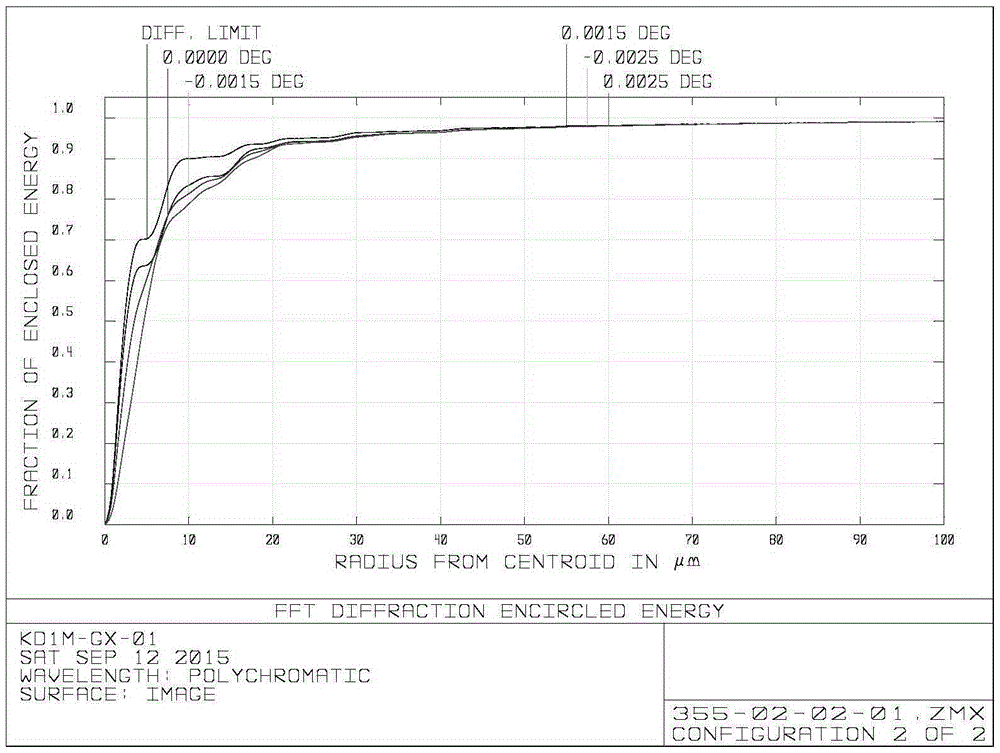

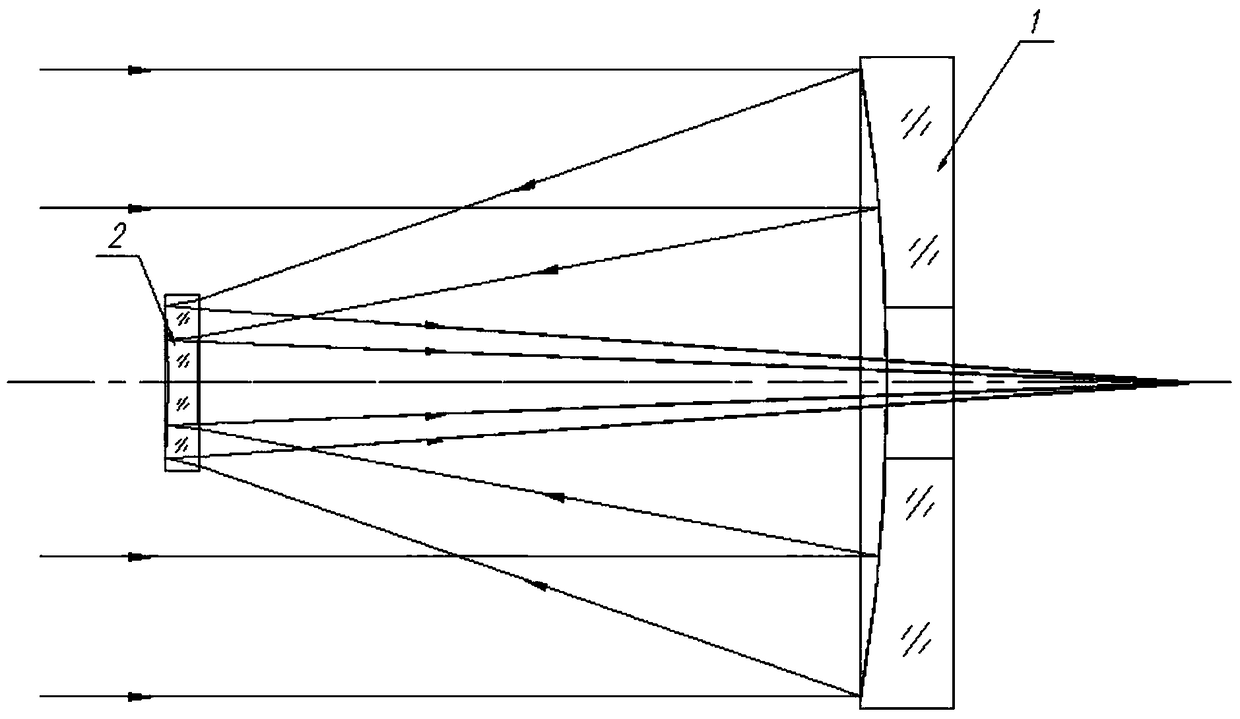

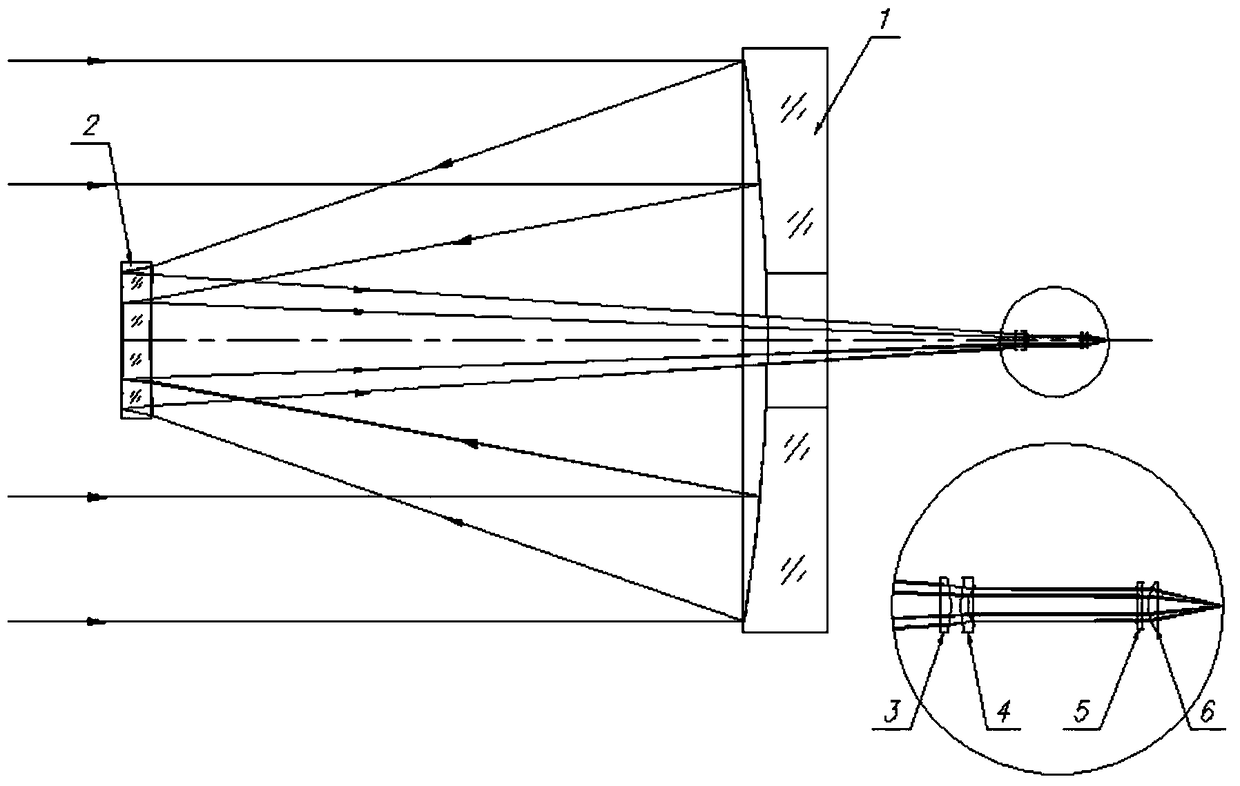

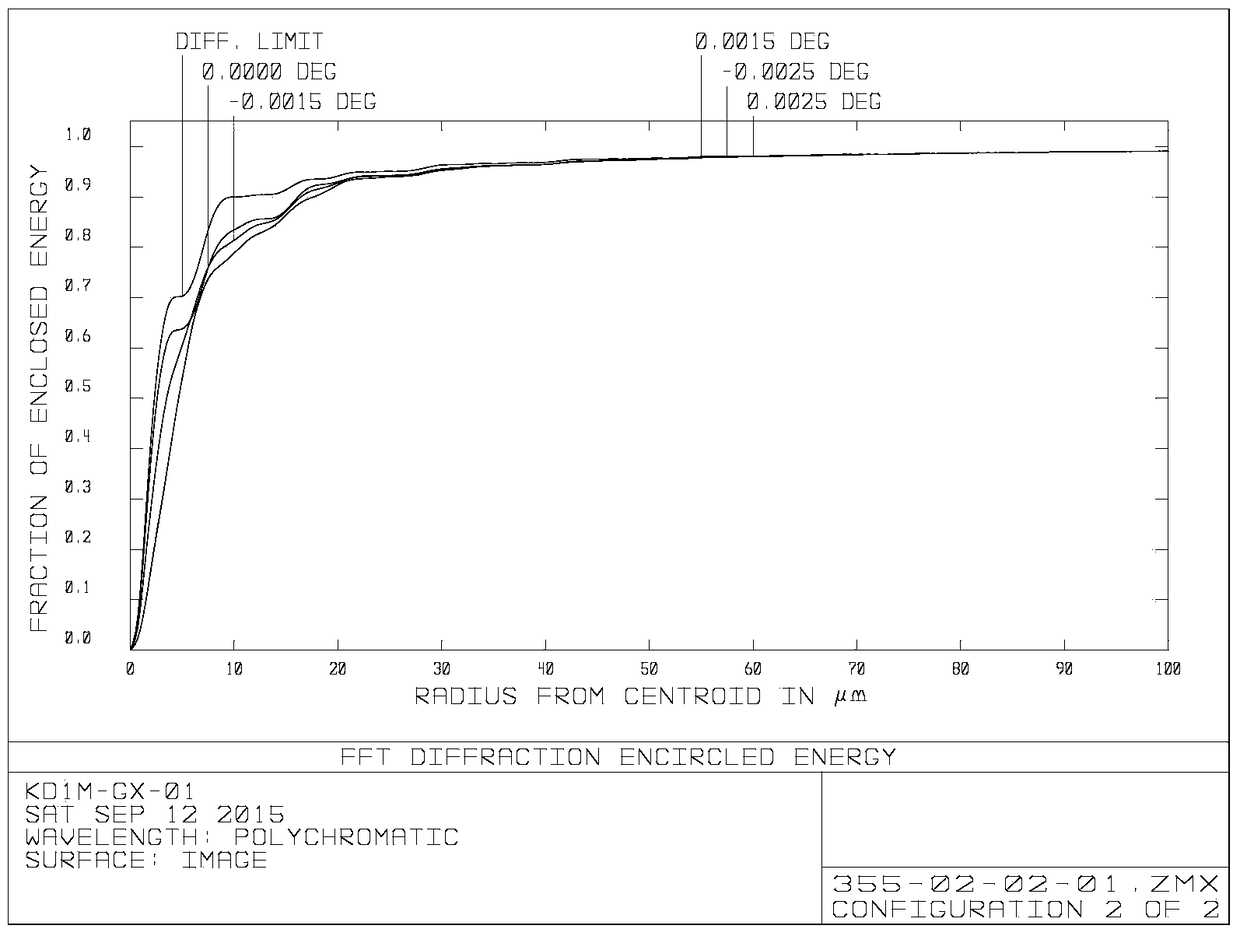

Large-caliber fully-spherical laser radar optical system

The invention provides a large-caliber fully-spherical laser radar optical system. All the optical surfaces of the optical system are spherical. A double-focus switching mode is designed. A Margin system adopts a multiple-structure design. Through changing the switching of laser between the output wavelength and the detection wavelength, the front-end Margin system can be used alone and can be self-collimated and detected to form a first focus. The Margin system and a front correction lens group form a beam compression optical system, and the front correction lens group and a rear correction lens group focus a collimating beam at a second focus position. Compared with a traditional transmission type and aspheric system structure, the difficulty in optical lens machining, installing and debugging is reduced greatly, the efficiency of installing and debugging and the imaging quality of the system are improved, the utilization efficiency of received laser echo signals is increased, and the requirement for compact structure and low cost is satisfied. The large-caliber fully-spherical laser radar optical system of the invention is reasonable in structure, easy to produce and assemble, good in extension performance, low in cost, and suitable for mass production.

Owner:合肥瑞利光学仪器有限公司

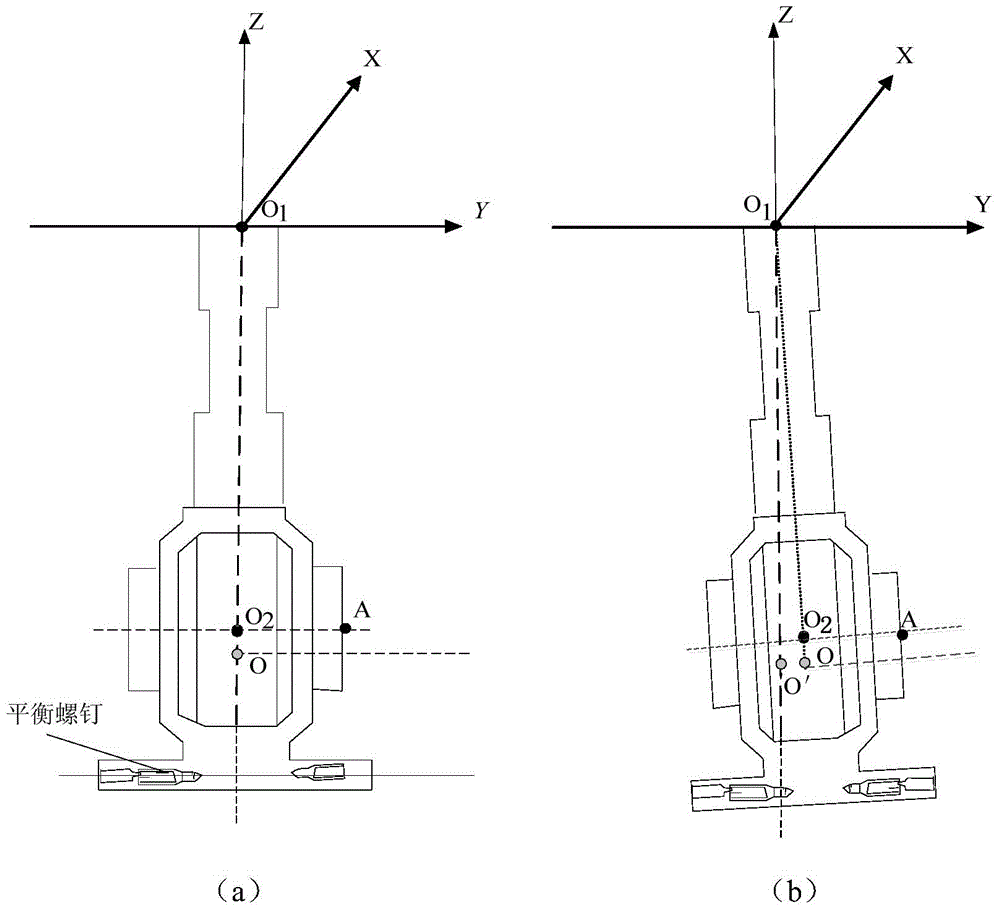

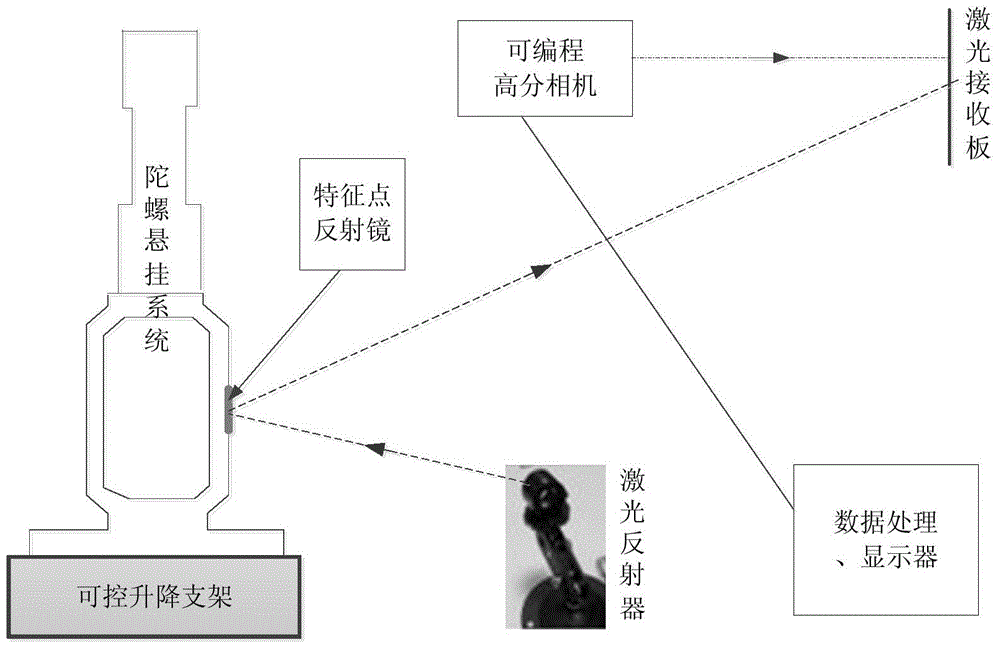

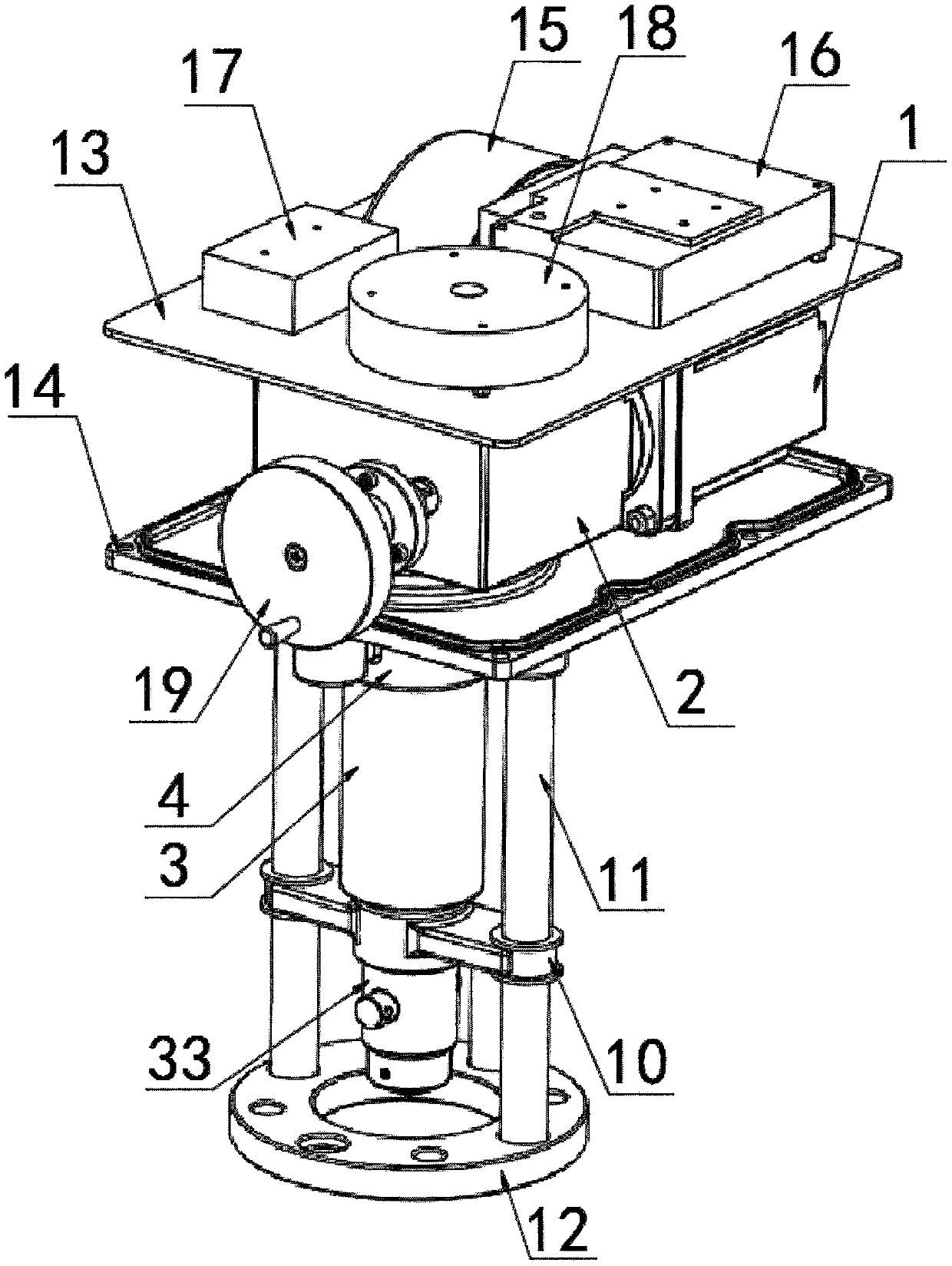

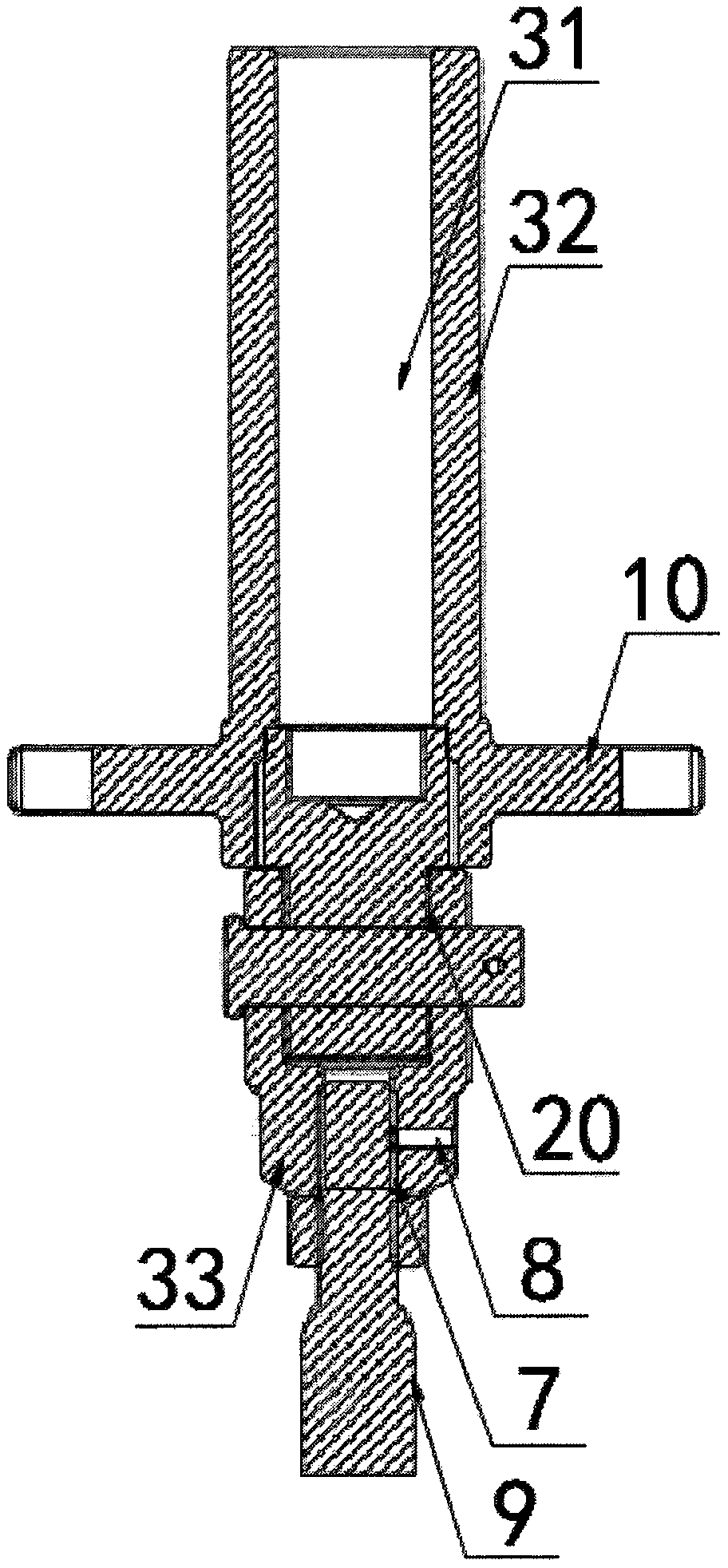

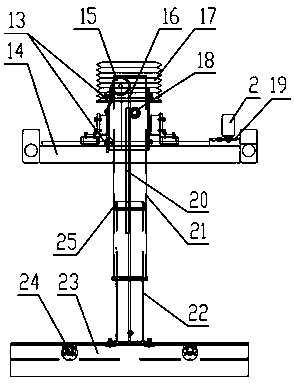

Static balance testing device and method of high-precision gyroscope suspension system

ActiveCN104655154AImprove performanceLow operating experience requirementStatic/dynamic balance measurementLaser transmitterGlass cover

The invention discloses a static balance testing device and method of a high-precision gyroscope suspension system. The device comprises a controllable lifting gyroscope suspension system support, a laser emitter, a receiving plate, a high-resolution programmable industrial camera, a positioning support of the high-resolution programmable industrial camera, a high-precision level meter, a transparent glass cover for protecting the suspension system, and a computer. Method comprises the following steps of accurately capturing the motion track of a feature point; calculating the static balance residual amount of a gyroscope suspending system by determining the motion track of the feature point, namely the gravity center deviation; and converting parameters which cannot be observed directly into observable parameters so as to provide a scientific basis for the determination of the static balance residual amount of the gyroscope suspending system. The determination of the static balance residual amount of the gyroscope suspending system can be used for providing the scientific basis for the research and production debugging of a high-precision gyroscope with the precision superior to + / -5s; the installation and debugging efficiency are improved; the requirement of the high-precision gyroscope on operation experience of installation and debugging personnel is lowered.

Owner:CENT SOUTH UNIV

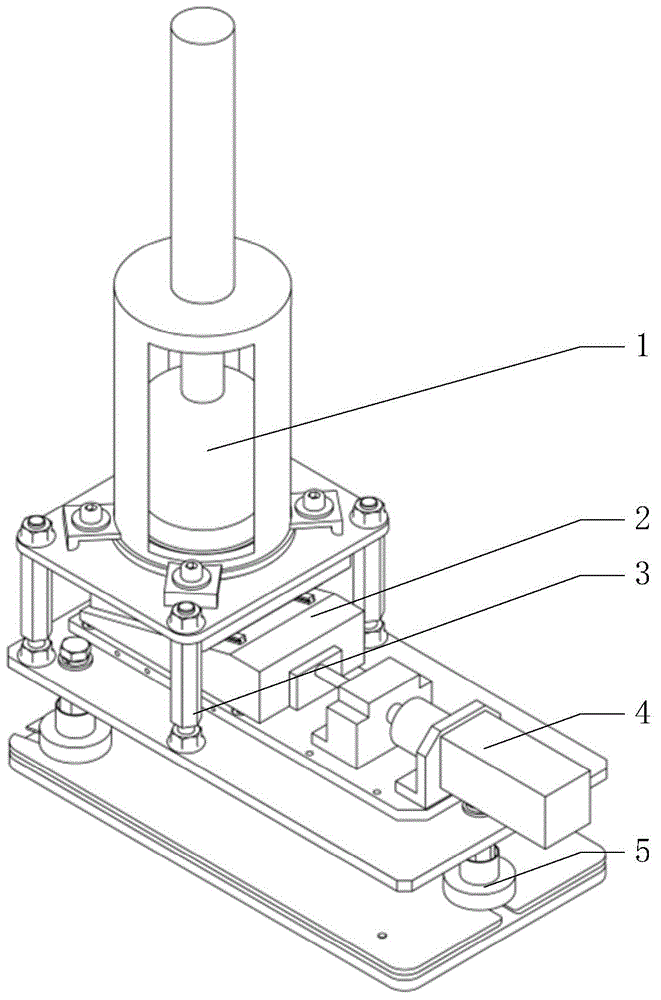

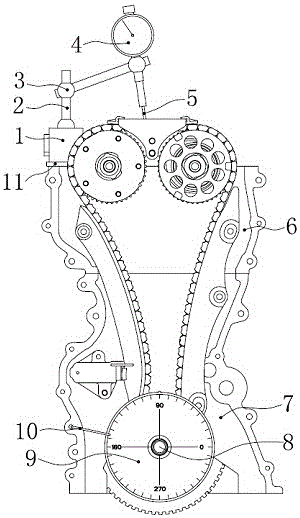

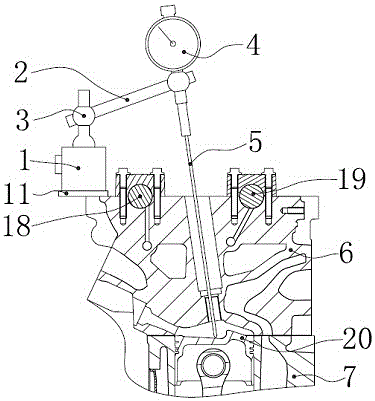

Valve lift measuring device and method

ActiveCN105953692AReduce manufacturing costImprove installation and debugging efficiencyMechanical measuring arrangementsOil canMagnetic tension force

The invention relates to a valve lift measuring device. The device comprises a magnetic gauge stand, a support fixedly connected to the upper surface of the magnetic stand, and a dial gauge and a probe connected to a support bar via a universal joint; the magnetic gauge stand is placed on a support block which is fixedly connected to the top surface to a cylinder cap via a bolt; and the device is characterized by also comprising a dial in coaxial connection with the front end of a crankshaft via a bolt and a pointer connected to a crankcase via a bolt, the pointer corresponds to the edge of the dial, and the indication direction of the pointer penetrates the center of the dial. The invention also provides a valve lift measuring method. According to the invention, pressure without machine oil can be established in the measuring process, a hydraulic column is in a non-work state, a gap of a gas distribution mechanism cannot be eliminated, the valve lift can be measured under the condition that the position of a rocking arm of a rolling bearing is uncertain, the mutual relation between the valve lift and the rotation angle of the crankshaft can be also measured, installation and debugging are rapid, the measuring precision is high, and rapid verification is provided for engine development.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

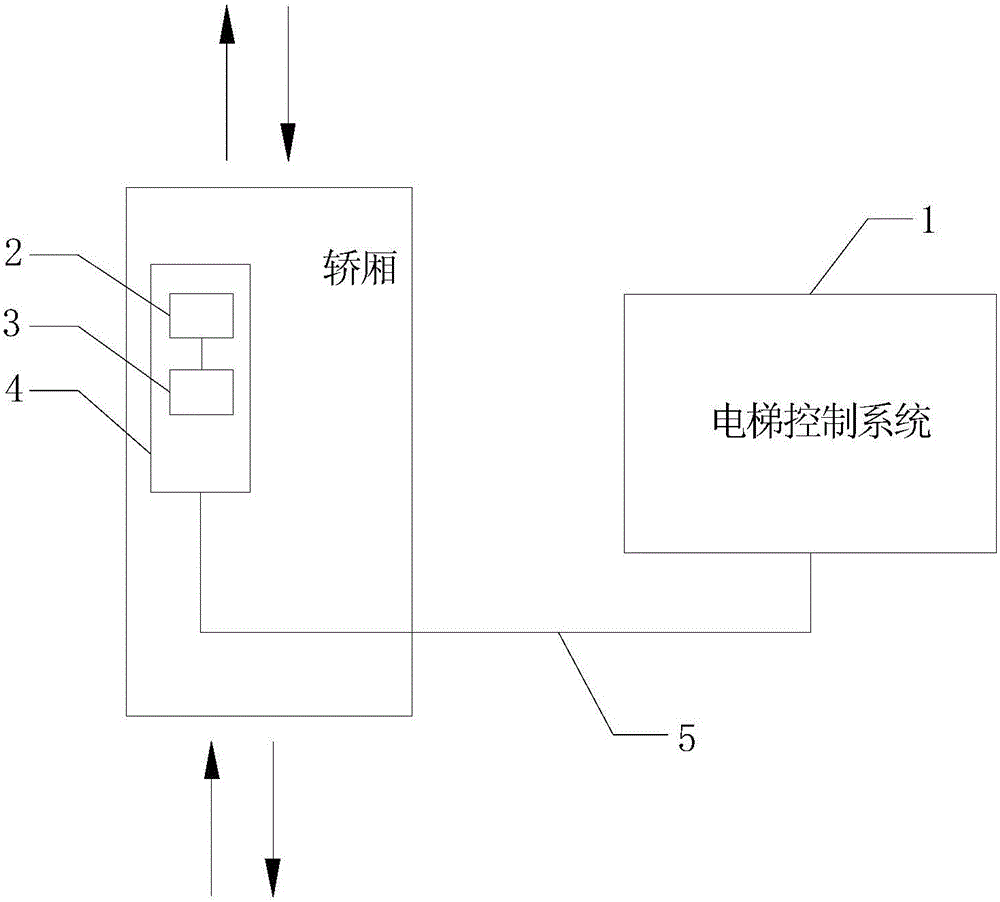

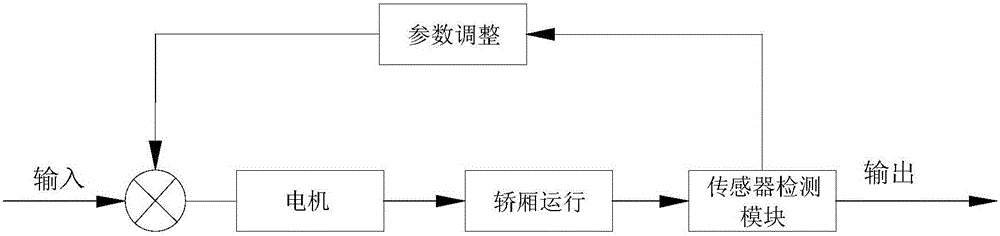

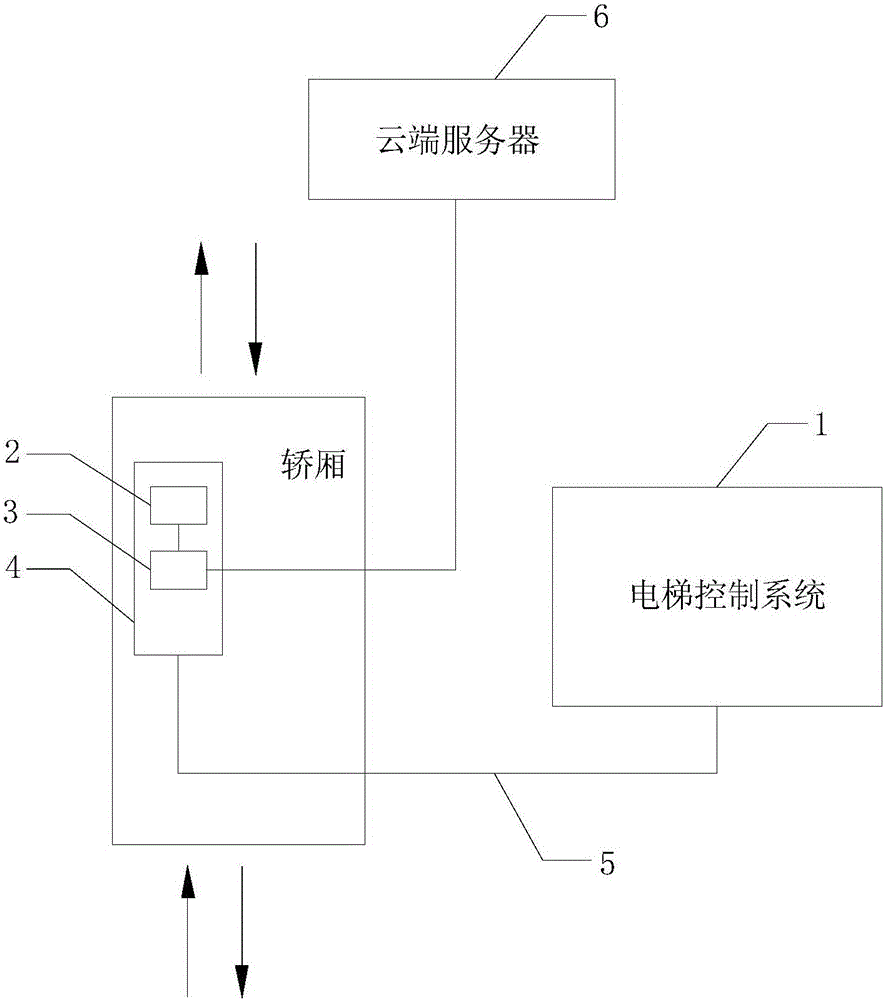

Sensor-based intelligent automatic regulating system and method

InactiveCN105923475ARealize the running status detection functionRealize intelligent upgradeElevatorsAnalysis dataGyroscope

The invention discloses a sensor-based intelligent automatic regulating system and method. The system comprises an elevator control system and a sensor detection module, wherein the sensor detection module comprises a six-axis gyroscope and a data processor which are arranged on an elevator car; the six-axis gyroscope, the data processor and the elevator control system are sequentially connected with one another; the six-axis gyroscope is used for detecting the running condition of the elevator car in real time, acquiring three-dimensional motion angular velocity data and acceleration data of the elevator car, and feeding back the acquired data to the data processor; the data processor is used for receiving the three-dimensional motion angular velocity data and the acceleration data fed back by the six-axis gyroscope, analyzing the received three-dimensional motion angular velocity data and acceleration data, and feeding back the analysis data to the elevator control system; and the elevator control system is used for analyzing the current elevator running condition according to the analysis data fed back by the data processor, and regulating the elevator running according to the analysis result of the current elevator running condition. The system provided by the invention is relatively low in cost, simple and convenient in later development, and easy to maintain.

Owner:GUANGZHOU GUANGRI ELEVATOR IND

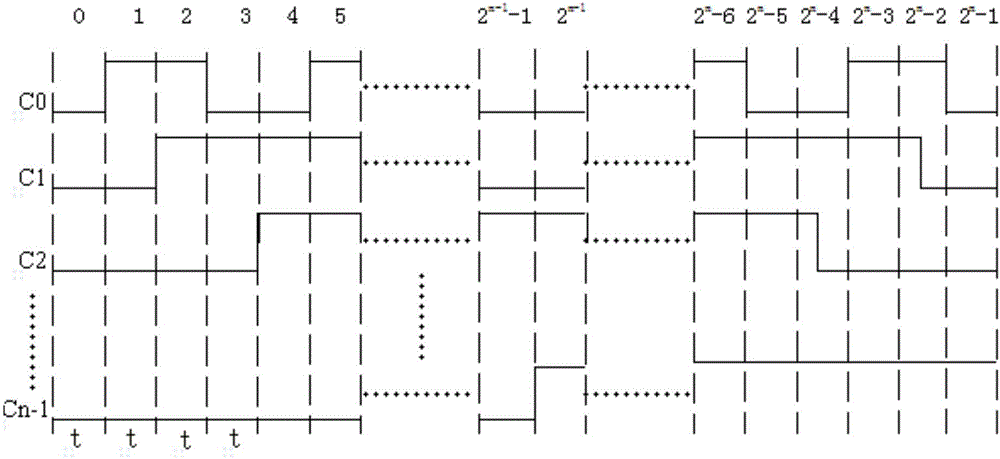

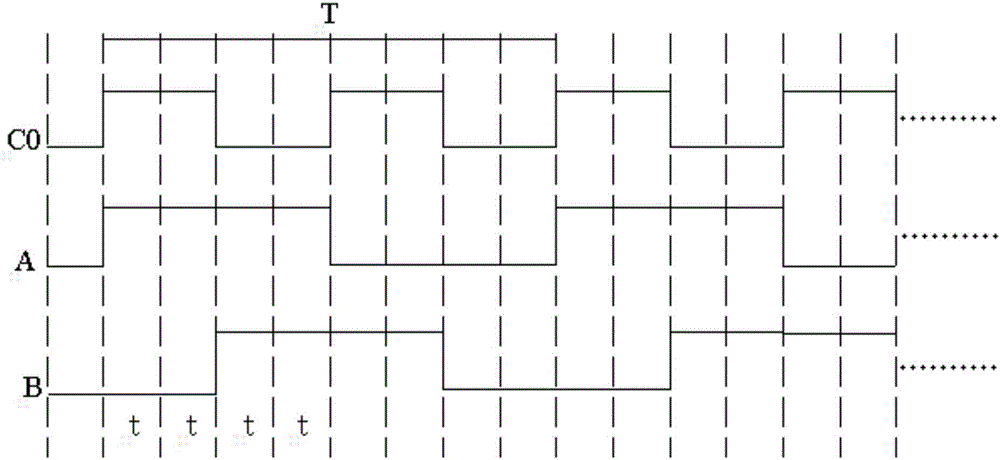

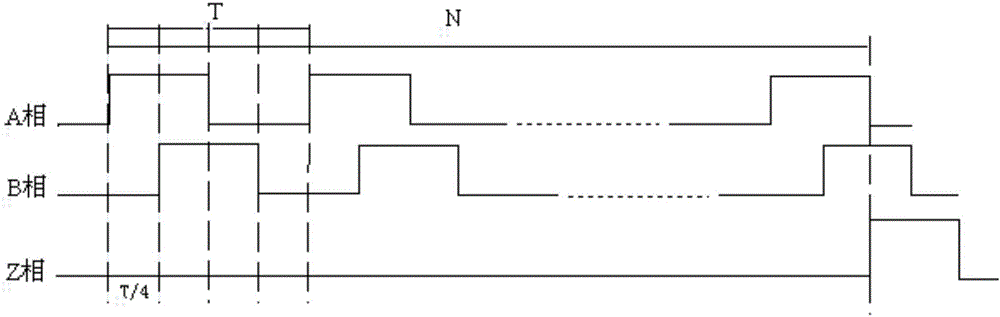

Method for converting absolute encoder signal into incremental encoder signal

ActiveCN106773897AReduce complexityImprove flexibility and installation and commissioning efficiencyProgramme controlComputer controlSignal linesGray code

The invention discloses a method for converting an absolute encoder signal into an incremental encoder signal and relates to the field of encoder signal conversion. Disadvantages that complexity of system signal processing is increased and flexibility and installation debugging efficiency of a control system are reduced since an encoder should be installed repeatedly during conversion of an absolute encoder signal into an incremental encoder signal in the prior art are overcome. According to the invention, a lowest order signal line and a highest order signal line of an absolute encoder output Gray code are connected to an IO port of a single chip microcomputer; the single chip microcomputer receives Gray code data in the lowest order and the highest order sent by the absolute encoder, and simulates to output a corresponding signal of the incremental encoder according to the level change condition of the received absolute encoder signal; and after the single chip microcomputer receives the Gray code data of the eight groups of absolute encoders, the corresponding single chip microcomputer finishes to control outputting of a complete encoding pulse signal.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

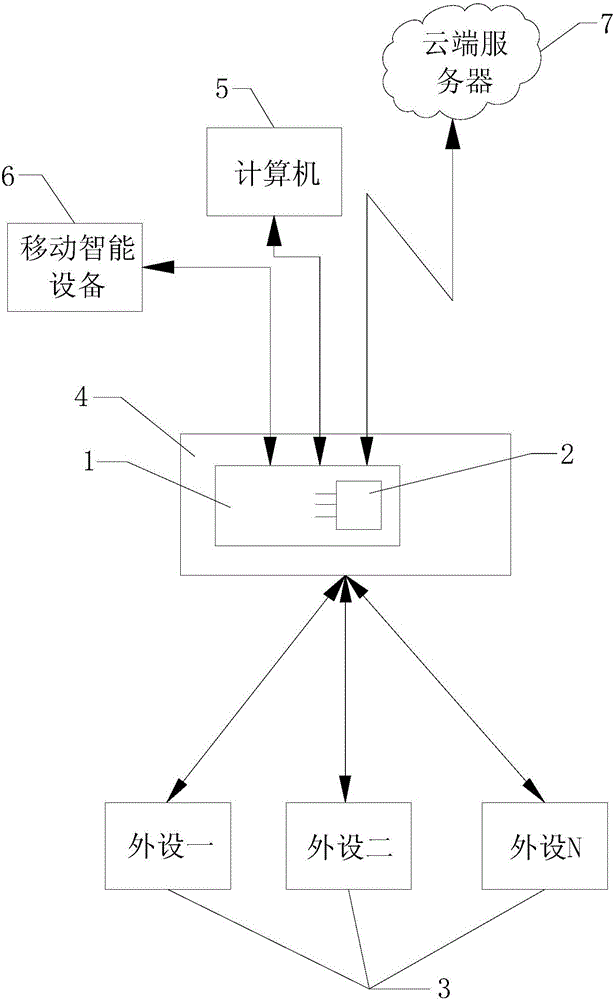

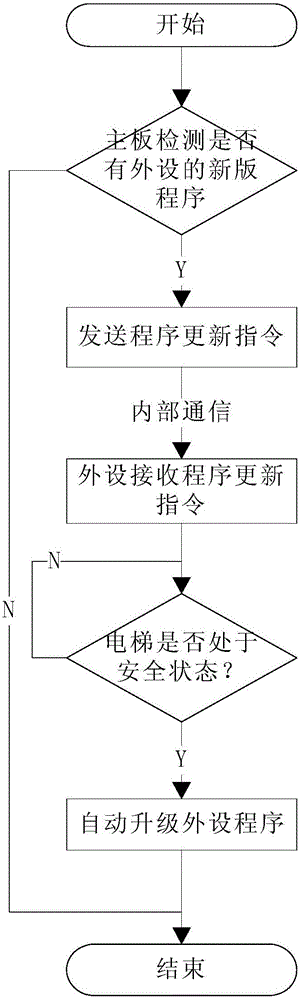

Automatic upgrading system and method for elevator peripheral programs

The invention discloses an automatic upgrading system and method for elevator peripheral programs. The system comprises a mainboard, a storage module and at least one peripheral; when a new program of a peripheral is detected by the mainboard, the mainboard receives the new program sent by a user through peripheral equipment, stores the new program in the storage module, sends a program upgrading instruction to the peripheral according to an address of the peripheral, and sends the new program in the storage module to the peripheral, and the peripheral overlays the current program by the new program so as to complete the automatic upgrading of the program; or the peripheral sends a program version inquiry instruction to the main board, when the new program is detected, the mainboard feeds the new program in the storage module to the peripheral according to the address of the peripheral, and the peripheral overlays the current program by the new program so as to complete the automatic upgrading of the program. According to the automatic upgrading system and method for elevator peripheral programs, the mounting and debugging efficiencies are greatly improved, the manual debugging cost is reduced, and the product performance and user experience are enhanced.

Owner:GUANGZHOU GUANGRI ELEVATOR IND

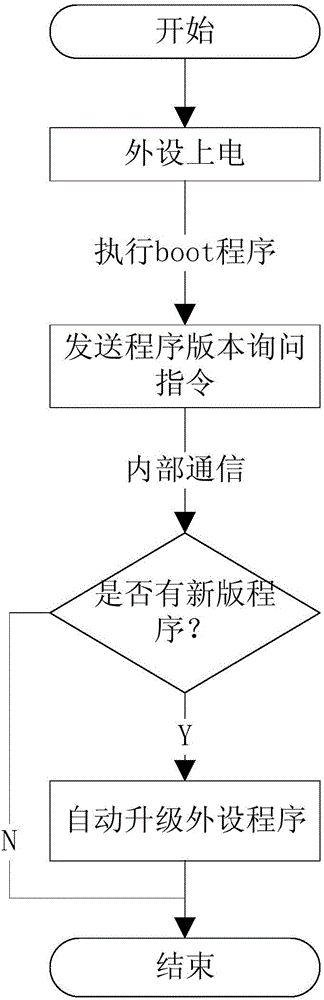

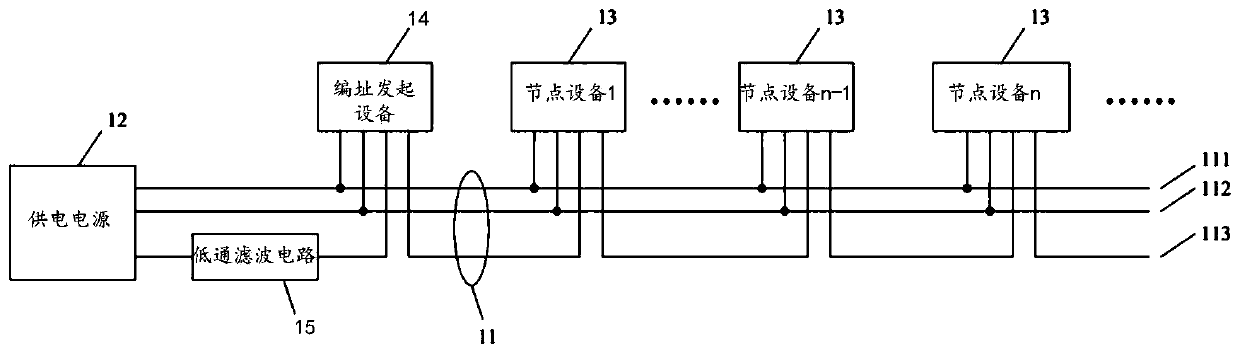

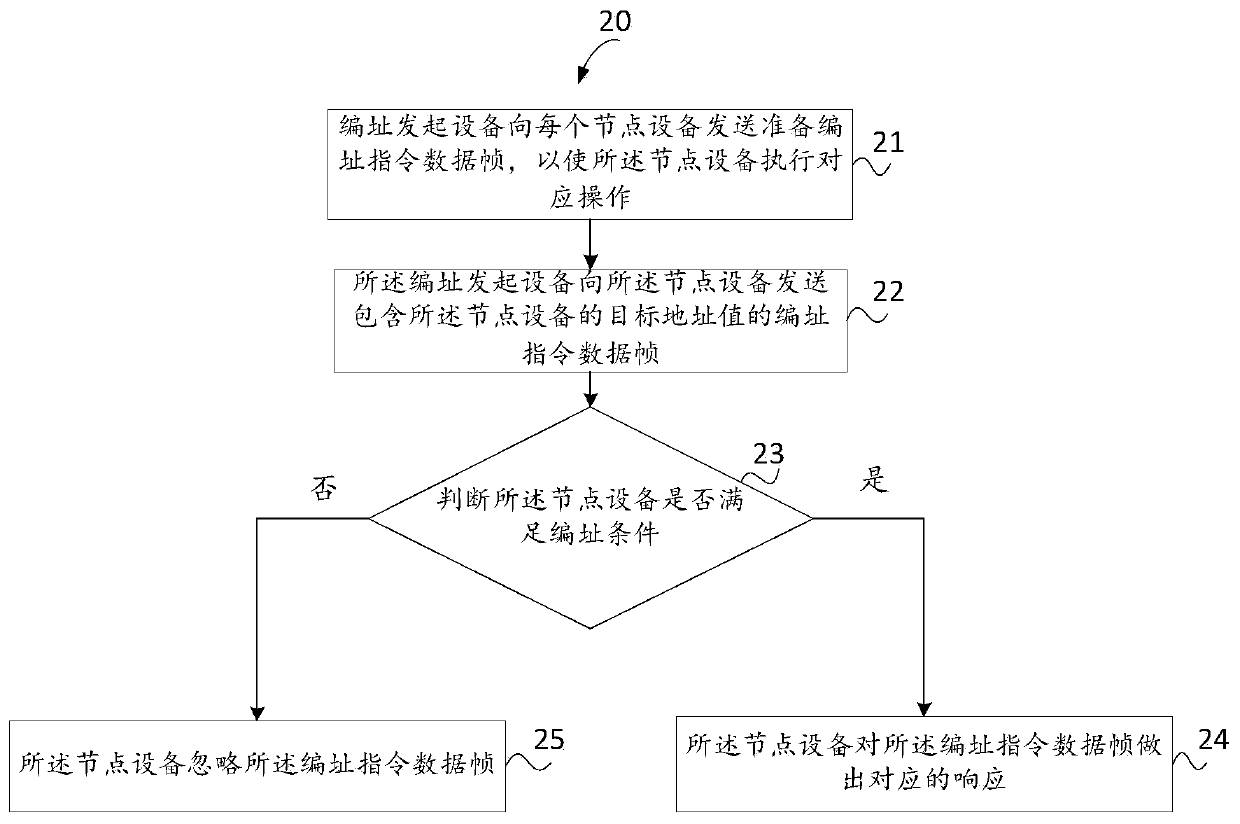

Bus type communication control system and online addressing method

PendingCN110839091ALow costImprove installation and debugging efficiencyTransmissionEmbedded systemElectric energy

The invention relates to the field of communication control, and discloses a bus type communication control system and an online addressing method, and the system comprises a three-core bus, a power supply, addressing initiating equipment and a plurality of node equipment. The power supply, the addressing initiating equipment and the plurality of node equipment carries out transmission of electricquantity and serial instruction frames. The power supply is used for providing working electric energy to equipment connected to the three-core bus. The addressing initiating device is used for generating a serial instruction data frame and sending the serial instruction data frame to the three-core bus; and the node equipment is used for carrying out corresponding actions according to the serial instruction data frames received from the three-core bus. According to the embodiment of the invention, the power supply, the addressing initiating equipment and all pieces of the node equipment areconnected to the three-core bus, and all the pieces of node equipment are subjected to online addressing, so that the cost is reduced, and the installation and debugging efficiency of the system is improved.

Owner:派诺西智能科技(苏州)有限公司

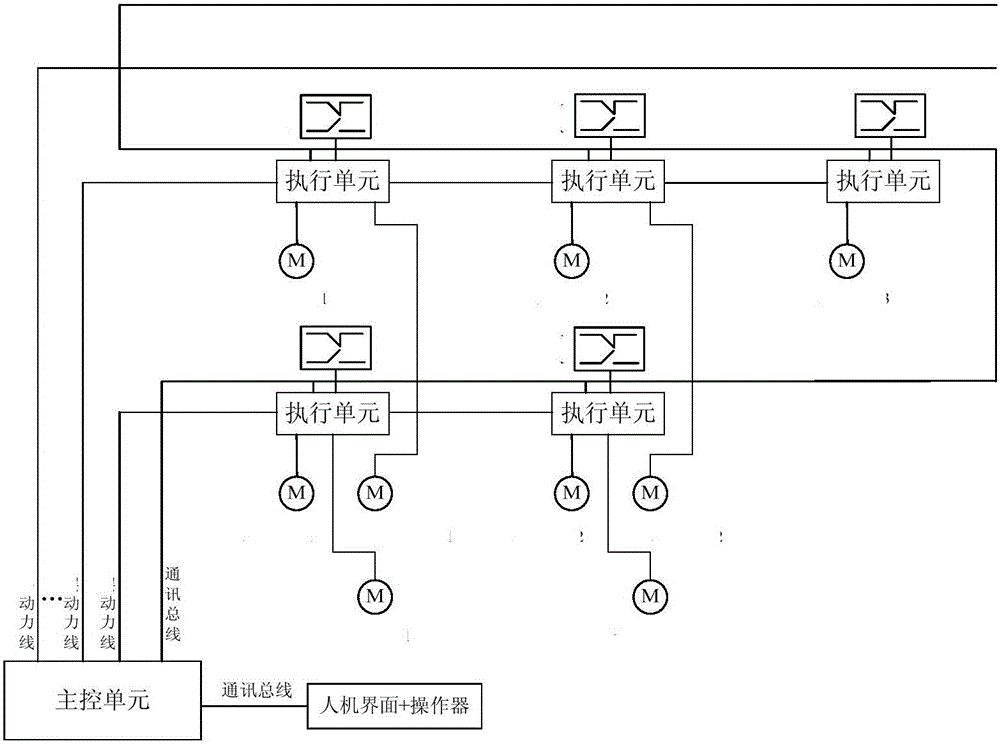

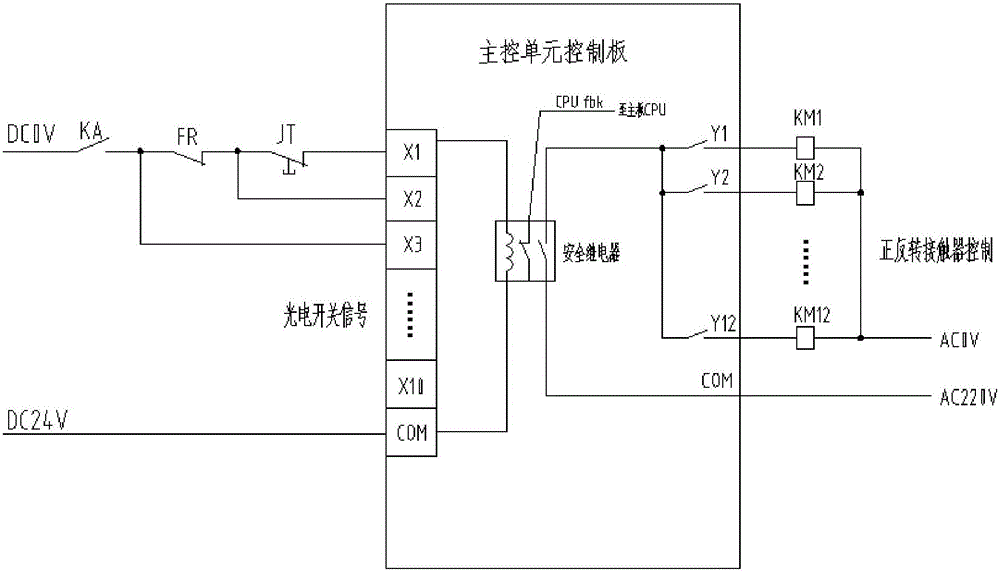

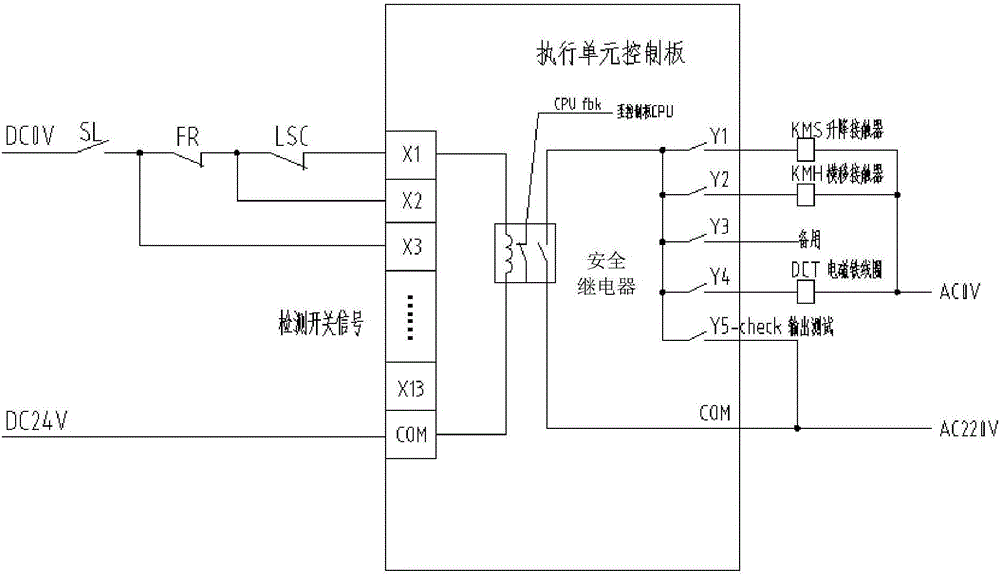

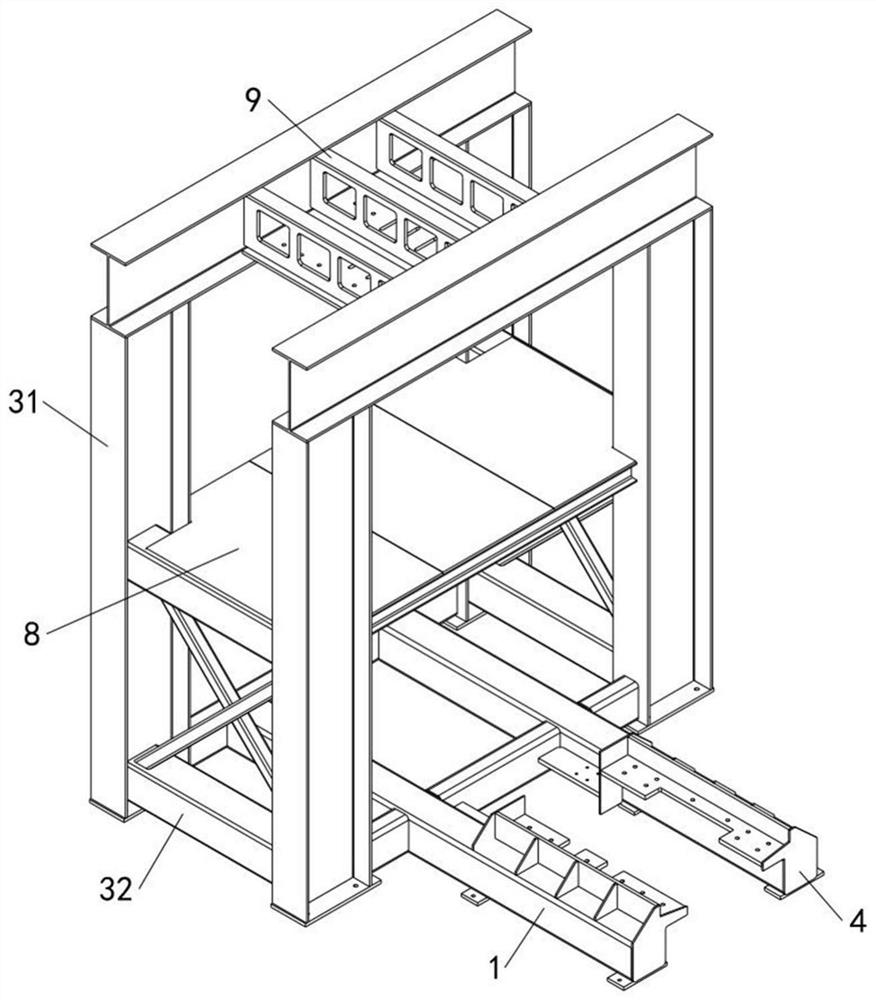

Stereoscopic parking garage control system based on CAN buses

ActiveCN105133900AImprove installation and debugging efficiencyReduce failureParkingsControl systemComputer module

The invention discloses a stereoscopic parking garage control system based on CAN buses. The stereoscopic parking garage control system comprises a main control unit and execution units used for controlling vehicle carrying plates to move, wherein the execution units are connected with the main control unit based on the CAN buses and arranged according to the layer number of parking places where the execution units are located in groups; transverse movement driving mechanisms of the vehicle carrying plates are connected into and controlled by the corresponding execution units of the adjacent upper layer, and lifting driving mechanisms of the vehicle carrying plates are connected into and controlled by the corresponding execution units of the layer where the vehicle carrying plates are located. The total number of system modules of the control system is further reduced, particularly a great number of signal line connecting cables and power line cables are saved for a large stereoscopic parking garage, the number of the main control and execution modules and the length of connecting cables are standardized more easily, the cost and installing difficulty of the system are reduced, and the installing and debugging efficiency of the garage is improved.

Owner:HANGZHOU OPTIMAX TECH

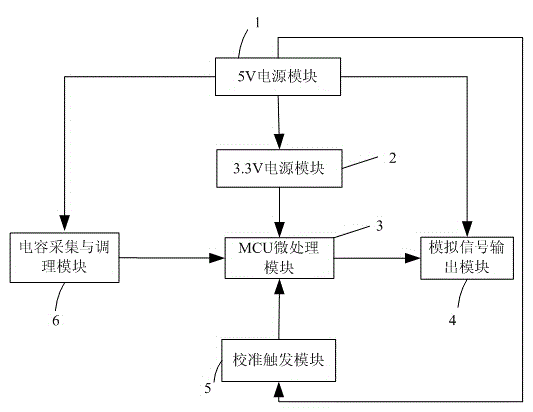

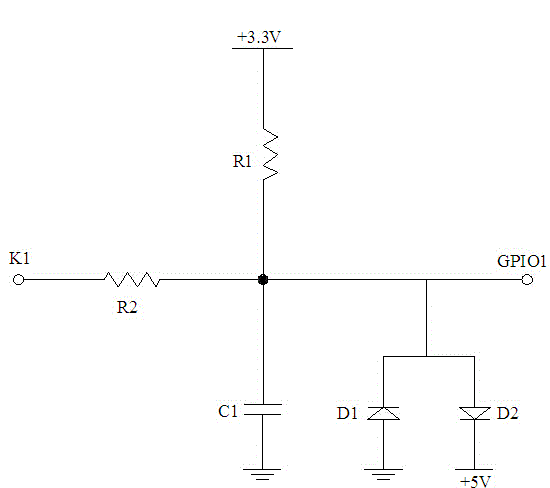

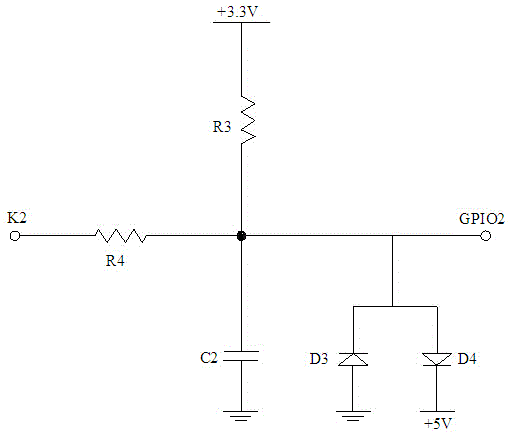

Capacitor liquid level sensor allowing site calibration

ActiveCN104697604APrevent returnImprove installation and debugging efficiencyTesting/calibration apparatusLevel indicators by physical variable measurementCapacitanceEngineering

A capacitor liquid level sensor allowing site calibration comprises a power module of 5V, a power module of 3.3V, an MCU micro-processing module, an analog signal output module, a calibration trigger module and a capacitor acquisition regulation module. The power module of 3.3V, the analog signal output module, the calibration touch module and the capacitor acquisition regulation module are connected with the MCU micro-processing module. The power module of 5V is connected with the power module of 3.3V, the analog signal output module, the calibration touch module and the capacitor acquisition regulation module. The capacitor liquid level sensor allows calibration on site, avoids the returning to the manufacturer for calibration, provides convenience to users, improves the installing and commissioning efficiency, and reduces the calibration cost.

Owner:FIRSTRATE SENSOR

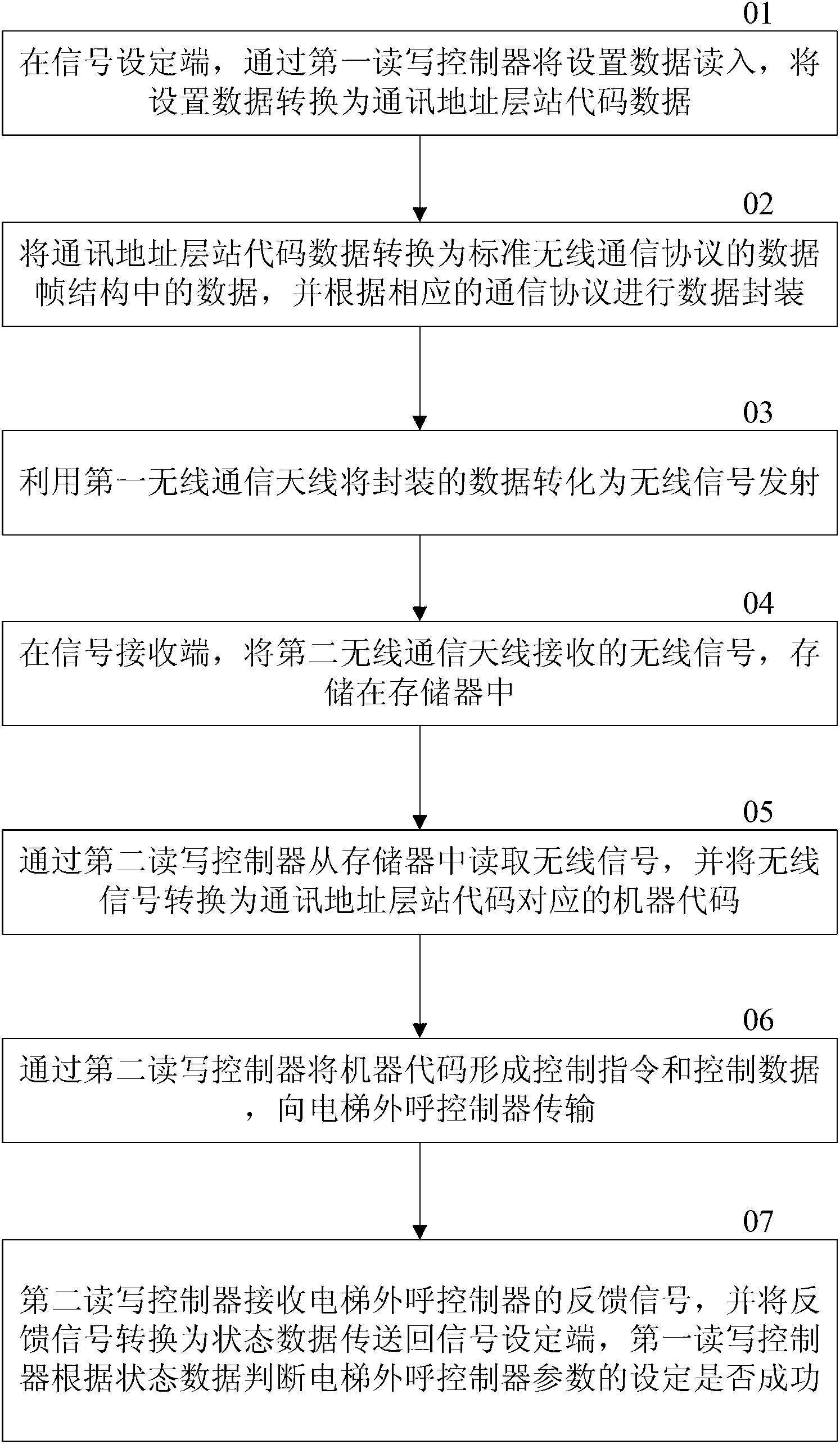

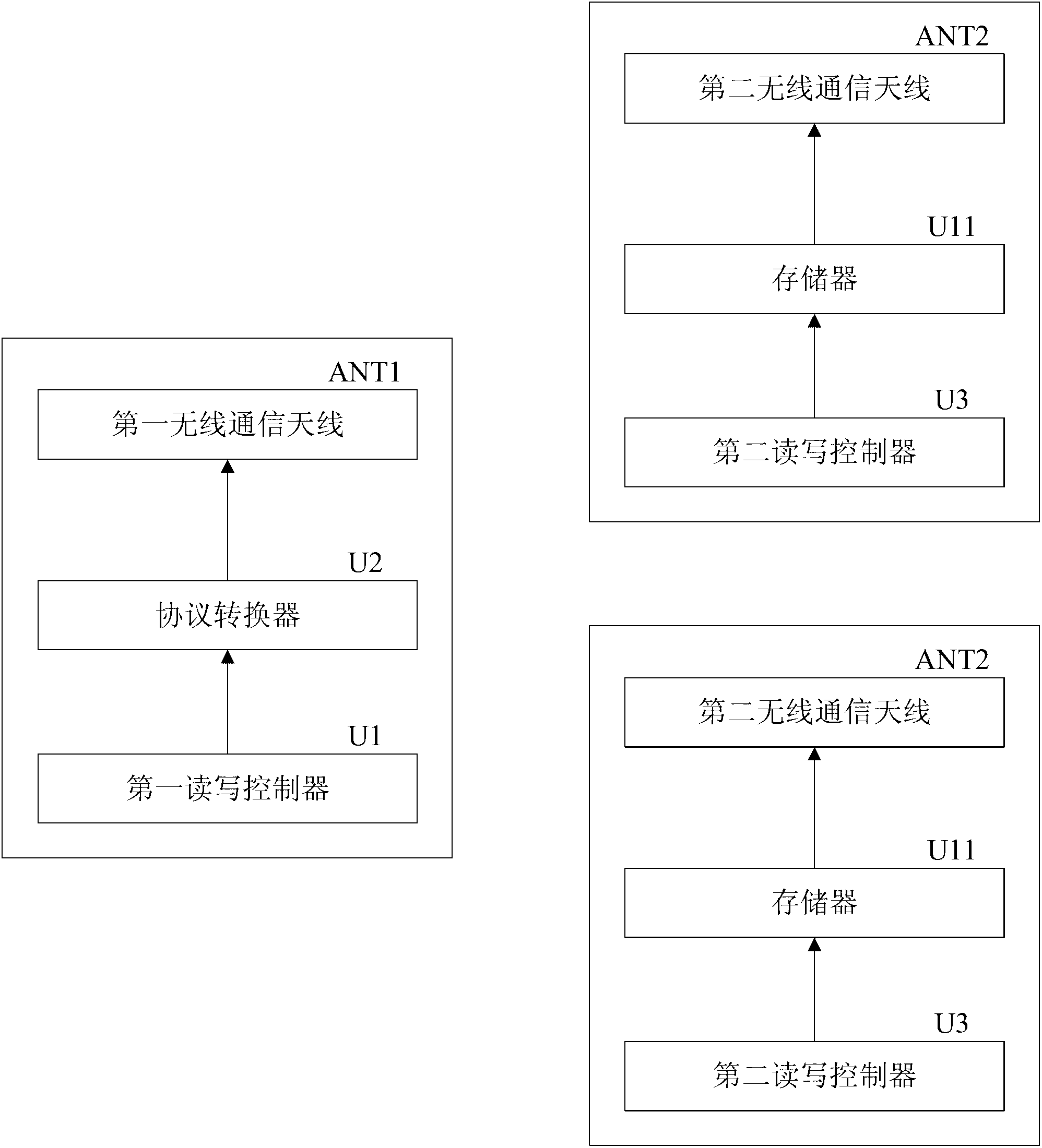

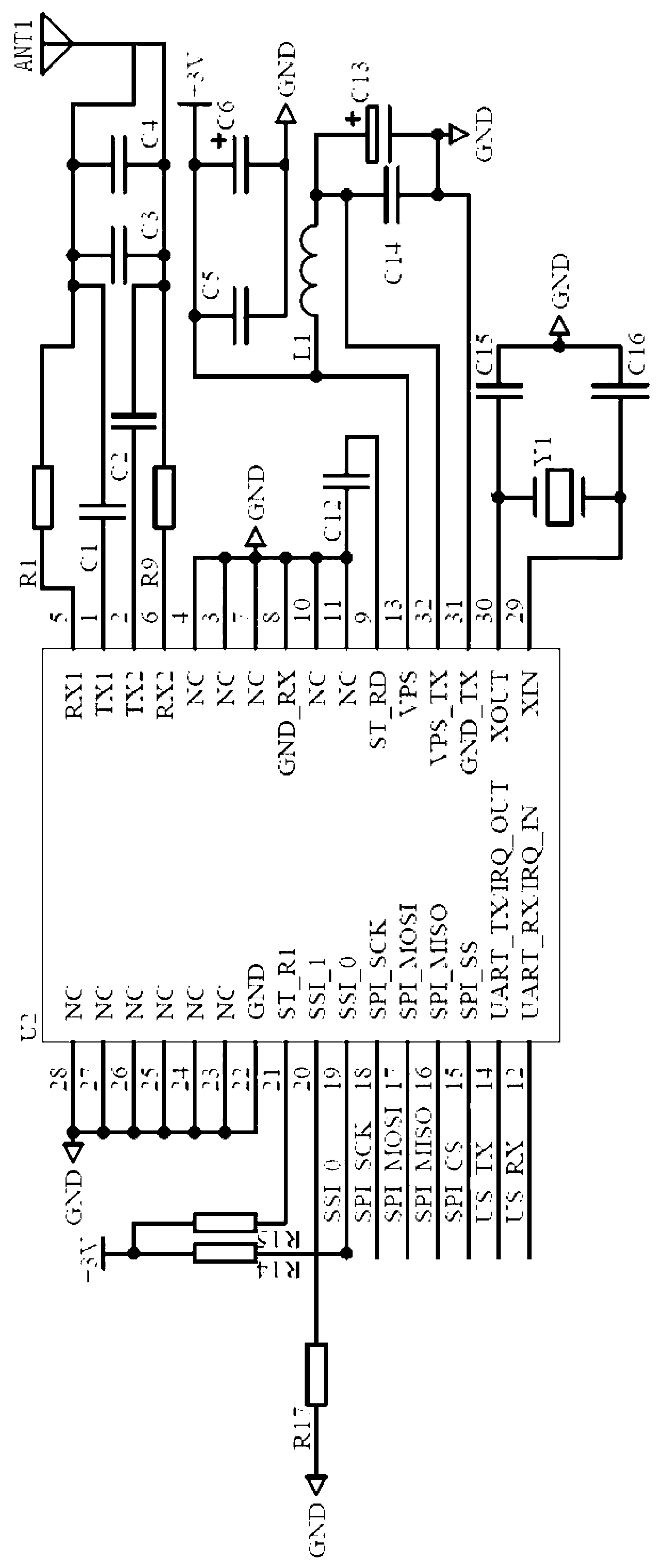

Wireless setting method and wireless setting device of parameters of elevator hall-call controller

ActiveCN102708663AImprove efficiencyReduce limitationsNear-field transmissionNon-electrical signal transmission systemsWireless communication protocolCommand and control

The invention discloses a wireless setting method of parameters of an elevator hall-call controller and relates to a circuit parameter setting method. The wireless setting method comprises the steps of: reading in setting data at a signal setting end by a first read-write controller and converting the setting data into communication address landing code data; converting the communication address landing code data into data in a data frame structure of a standard wireless communication protocol and carrying out data packaging; transmitting the packaged data by a first wireless communication antenna; storing a wireless signal received by a second wireless communication antenna in a storage at a signal receiving end; reading the wireless signal by a second read-write controller and converting the wireless signal into a machine code corresponding to a communication address landing code; and forming a control command and control data and transmitting the control command and the control data to the elevator hall-call controller. According to the wireless setting method and wireless setting device provided by the invention, installing and commissioning test of an elevator can be simplified; the installing and commissioning potential hazards are reduced; and the accuracy of setting the data is improved. The invention also discloses a device for implementing the method.

Owner:BEIJING SWORD ELECTRIC IND

Digital intelligent direct-travel electric actuator

InactiveCN109915642AReduce installation and debugging cumbersomeReduce maintenance frequencyOperating means/releasing devices for valvesMotor driveReduction drive

The invention discloses a digital intelligent direct-travel electric actuator, and particularly relates to the field of electric actuators. The digital intelligent direct-travel electric actuator comprises a stepping motor, a speed reducer and a screw rod transmission mechanism, wherein the speed reducer is arranged on the front side of the stepping motor and is in transmission connection with thestepping motor, the screw rod transmission mechanism is arranged at the bottom of the speed reducer and is in transmission connection with the speed reducer through a longitudinal rotating shaft, andthe stepping motor is connected with a transverse rotating shaft. The stepping motor is controlled by a control module to drive the screw rod transmission mechanism to work, the intelligent control actuator enters the initialization stage, the stepping motor drives the transverse rotating shaft to rotate forwards and backwards, the stepping motor is blocked through mechanical limiting of the connected valve, a memory zero point position and a 100% point position are memorized by a CPU, the CPU is used for equally dividing according to a preset precision grade, the debugging is completed, theinstallation and debugging are simple, the zero position is not required to be adjusted frequently, the self-diagnosis can be carried out, and the maintenance frequency is reduced.

Owner:深圳市新可优科技有限公司

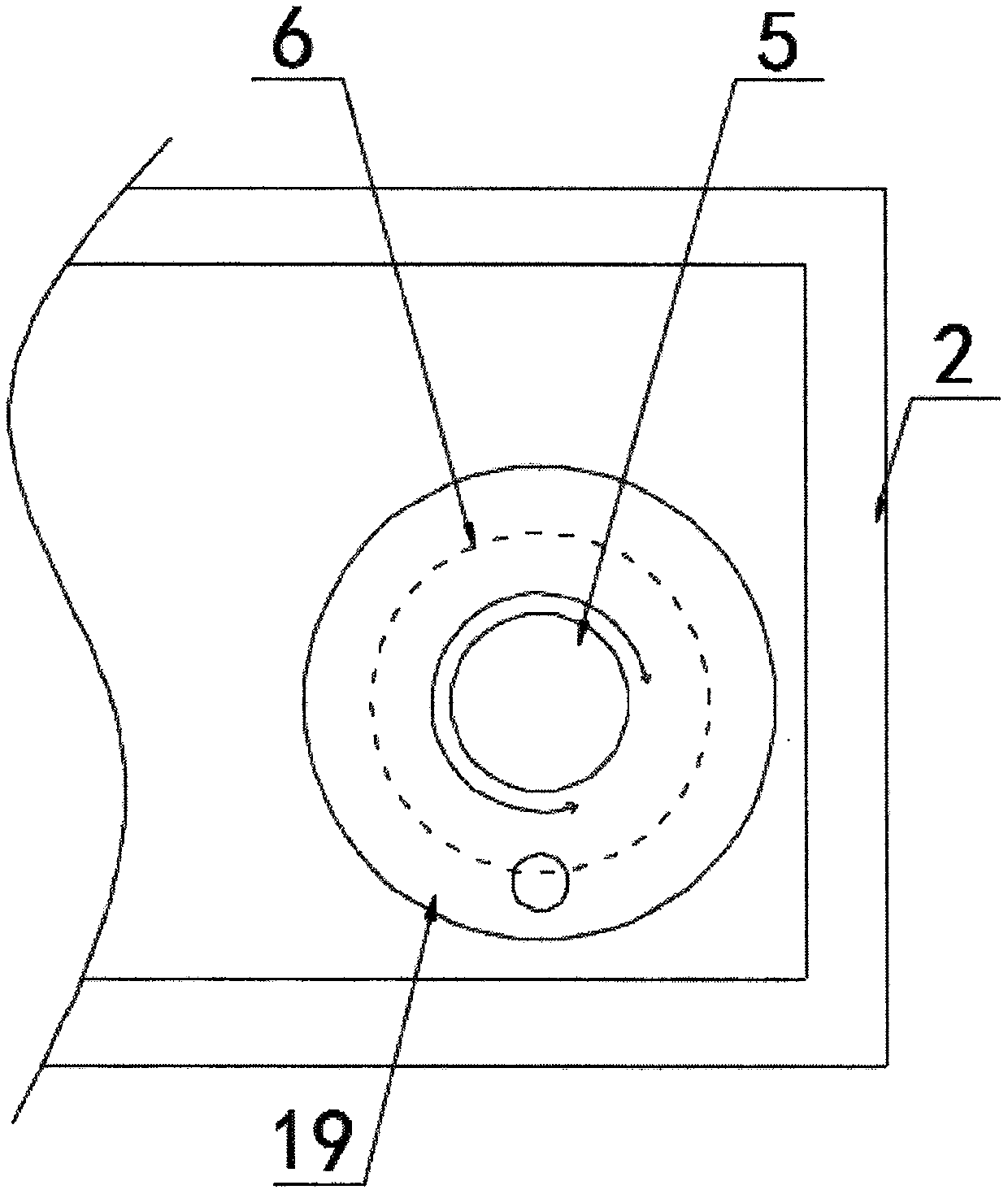

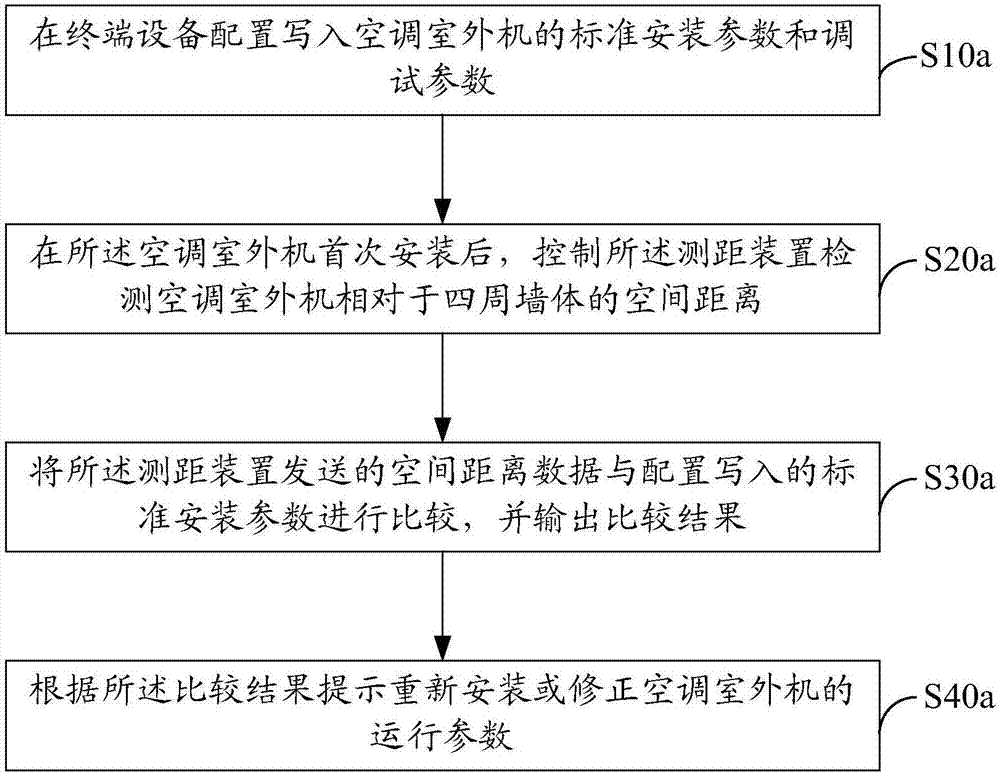

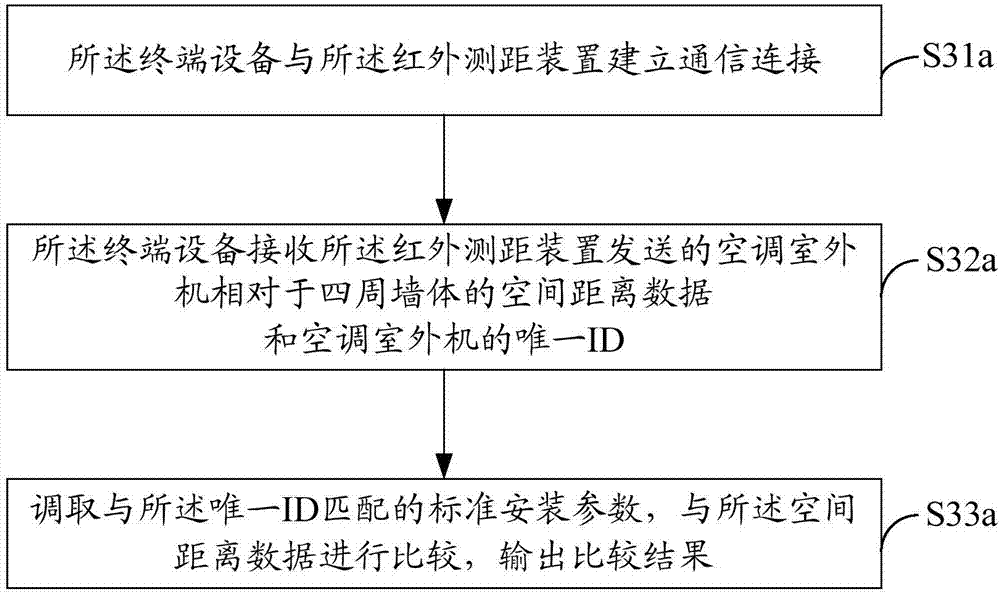

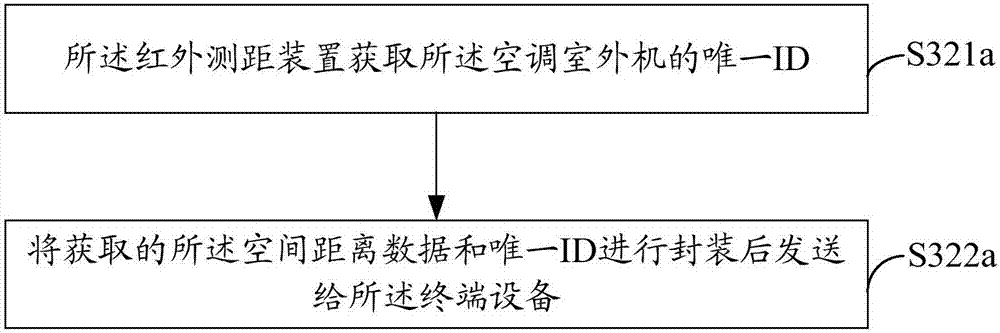

Debugging method of outdoor unit of air conditioner and outdoor unit of air conditioner

ActiveCN107062434AImprove installation and debugging efficiencyGuaranteed effective heat transfer efficiencyMechanical apparatusSpace heating and ventilation safety systemsTerminal equipmentEngineering

The invention provides a debugging method of an outdoor unit of an air conditioner and the outdoor unit of the air conditioner. A ranging device is arranged on the outer unit of the air conditioner, a corresponding space distance between the outer unit of the air conditioner and the surrounding wall bodies is detected after the outer unit of the air conditioner is mounted firstly, then whether the space distance meets the standard or not is judged by terminal equipment or a main control unit of the outdoor unit of the air conditioner according to configured and written standard mounting parameters, and finally, according to the comparison result, a re-mounting prompt and automatic correction of operation parameters of the outer unit of the air conditioner can be carried out, so that the effective heat exchange efficiency of the air conditioner is guaranteed, and heating or refrigeration effects of the air conditioner is guaranteed; moreover, only when re-mounting is prompted, electronic unlocking is needed, so that the mounting and debugging efficiency of the outer unit of the air conditioner are improved, and the workload of engineering supervision is reduced.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

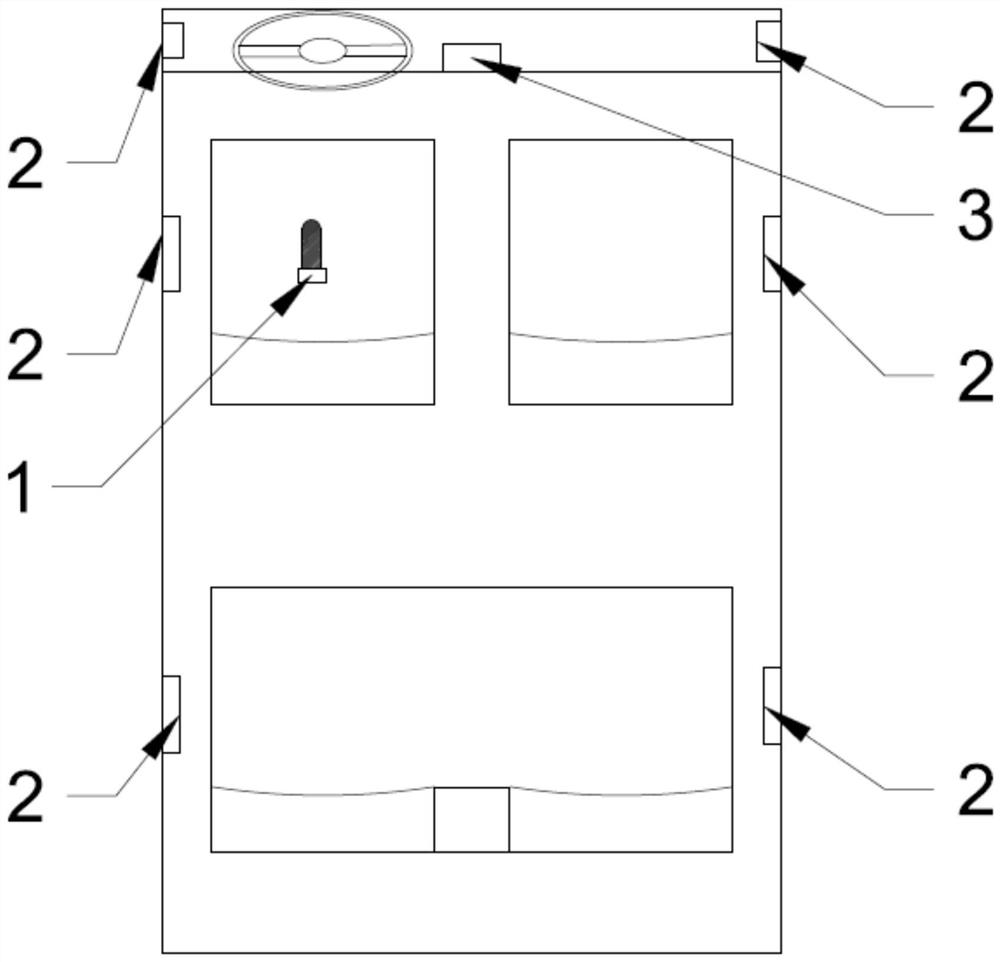

Intelligent door and window debugging system

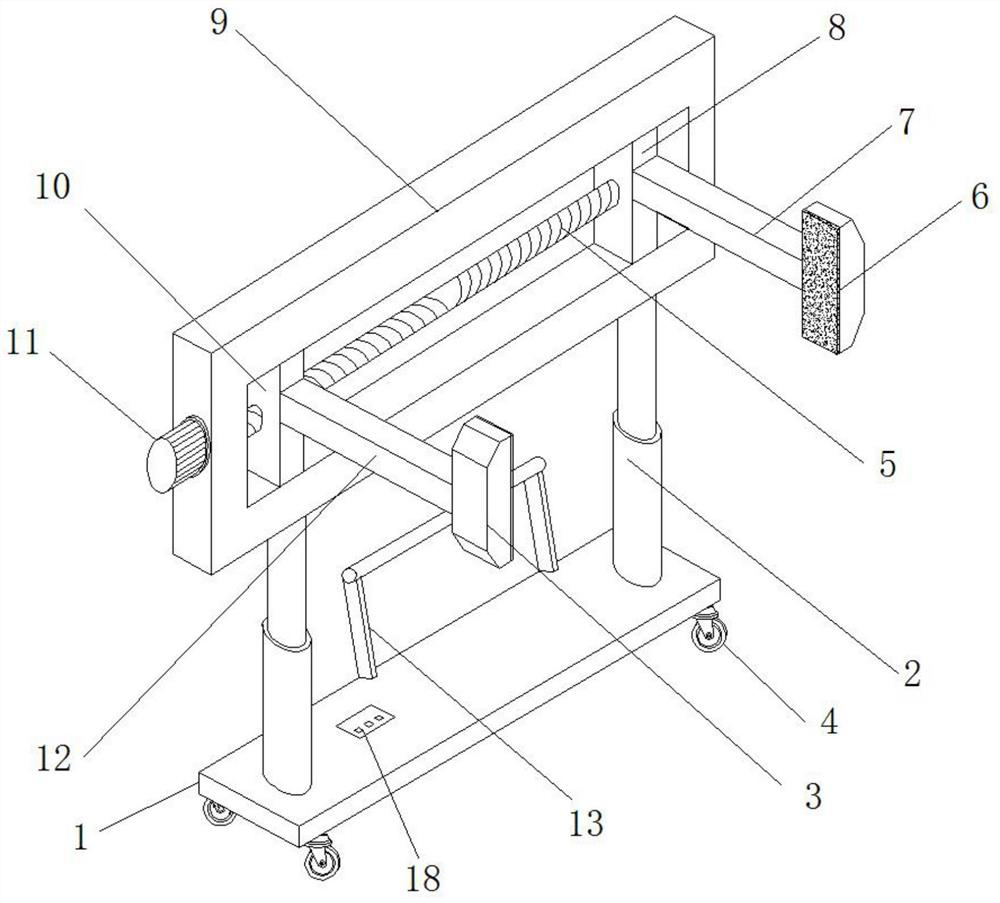

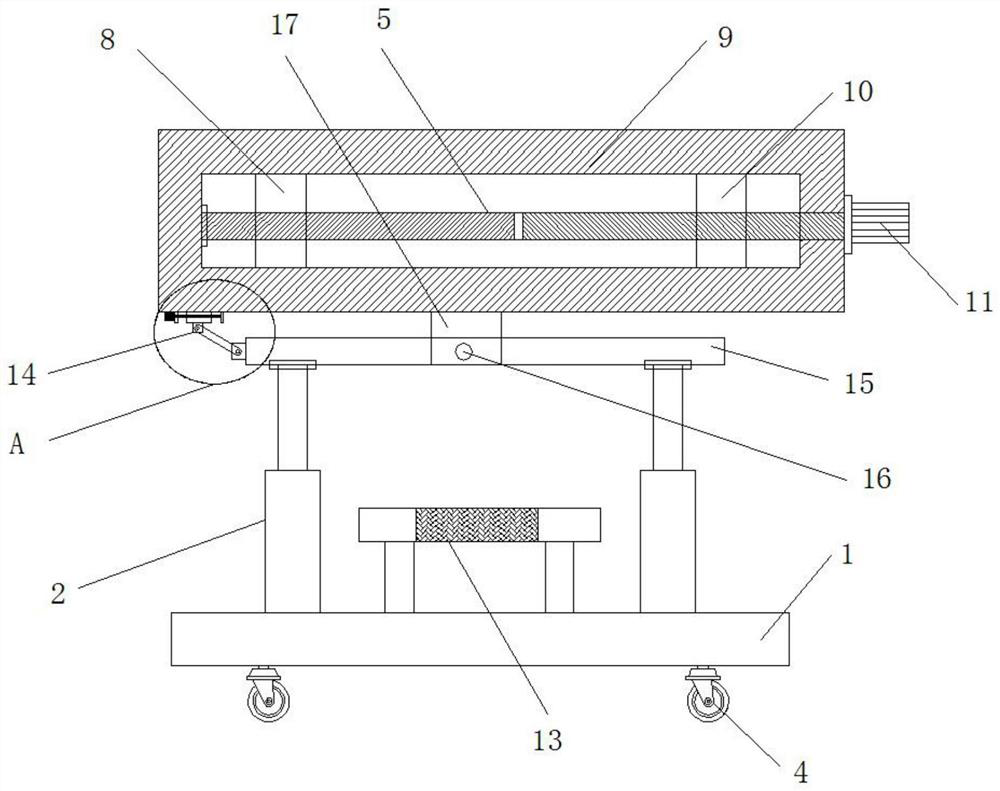

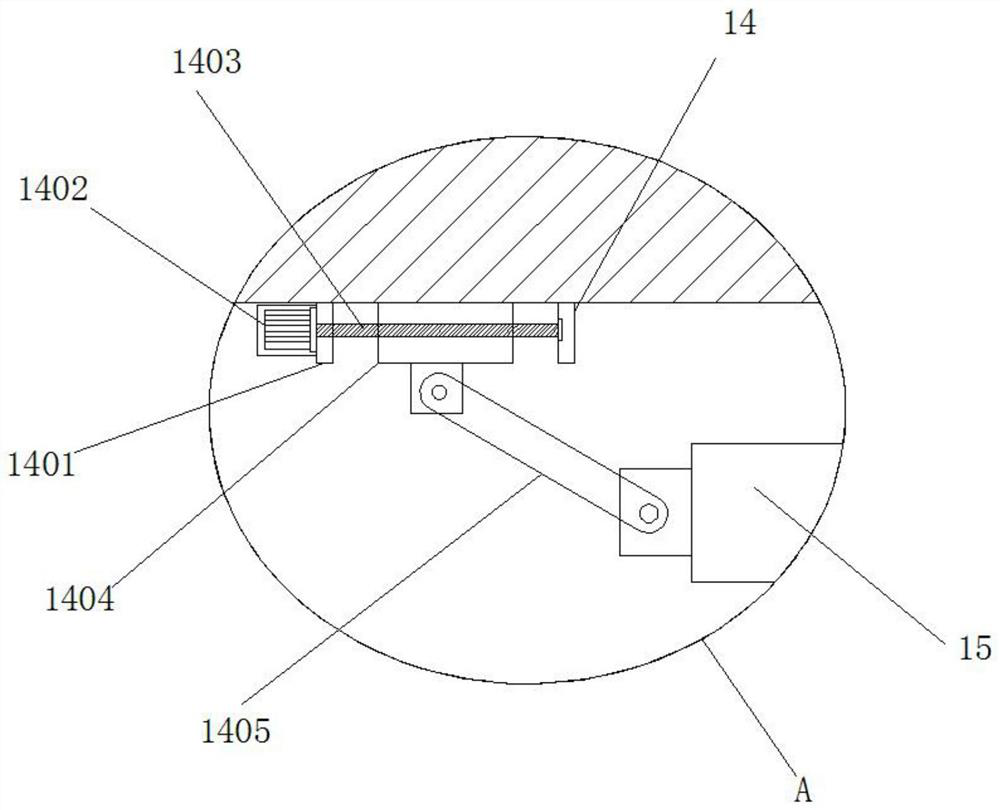

The invention discloses an intelligent door and window debugging system. The intelligent door and window debugging system comprises a bottom plate and universal wheels installed at the bottom end of the bottom plate. Two hydraulic telescopic rods are symmetrically welded to the two sides of the top end of the bottom plate, a supporting plate is welded to the top ends of the two hydraulic telescopic rods, a rectangular fixing frame is installed at the top end of the supporting plate, a bidirectional threaded rod is installed in the middle of the rectangular fixing frame through a bearing, and the two ends of the bidirectional threaded rod are sleeved with a first moving block and a second moving block in a threaded connection mode. The bidirectional threaded rod is driven to rotate through a first servo motor, so that a first clamping block and a second clamping block get close to each other to clamp an intelligent door and window, the door and window leave the ground by controlling the hydraulic telescopic rods to extend, and the door and window are moved into a hole reserved in a wall through supporting cooperation of the universal wheels and debugged to a proper mounting position; and the door and window can be installed by one person without being supported by other people, time and labor are saved, and the installation and debugging efficiency is improved.

Owner:深圳市泰然荣昌装饰工程有限公司

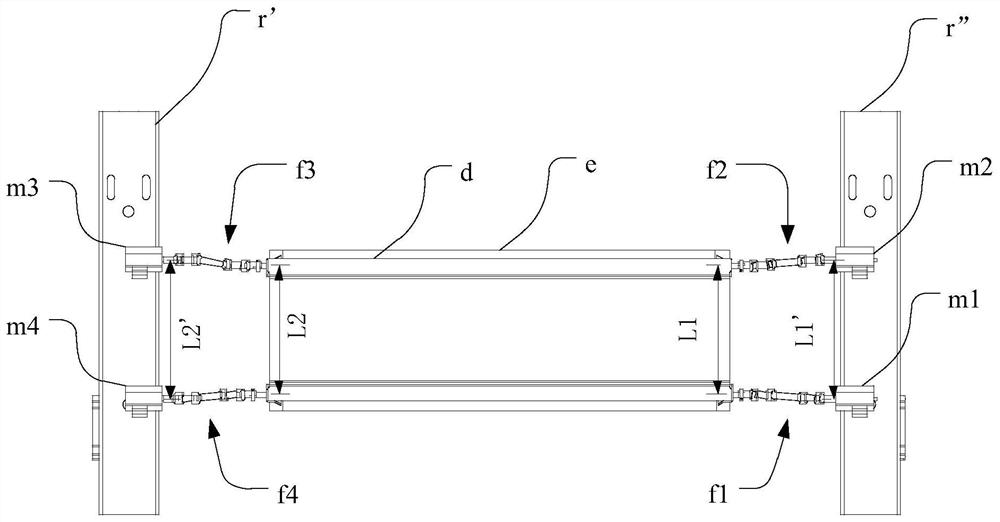

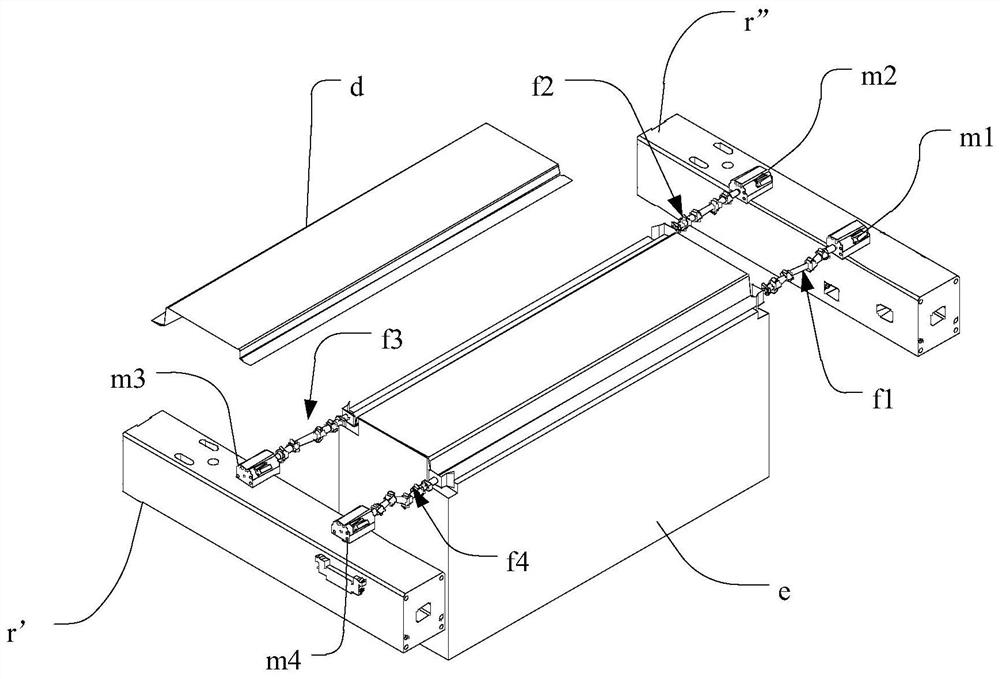

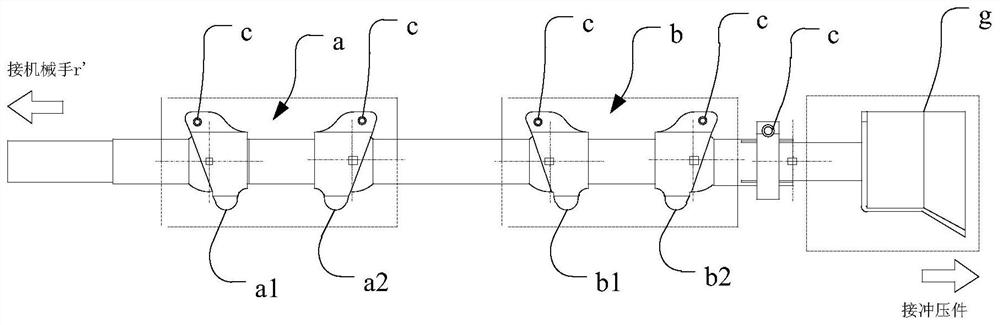

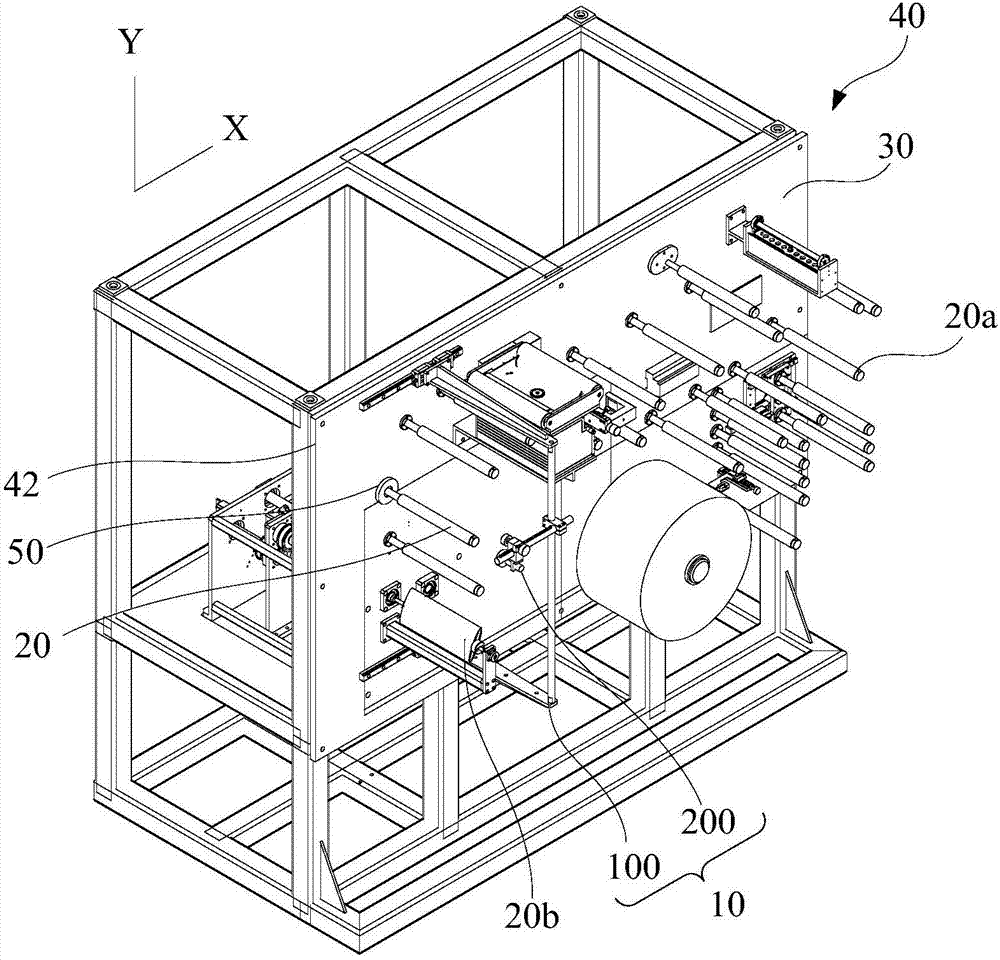

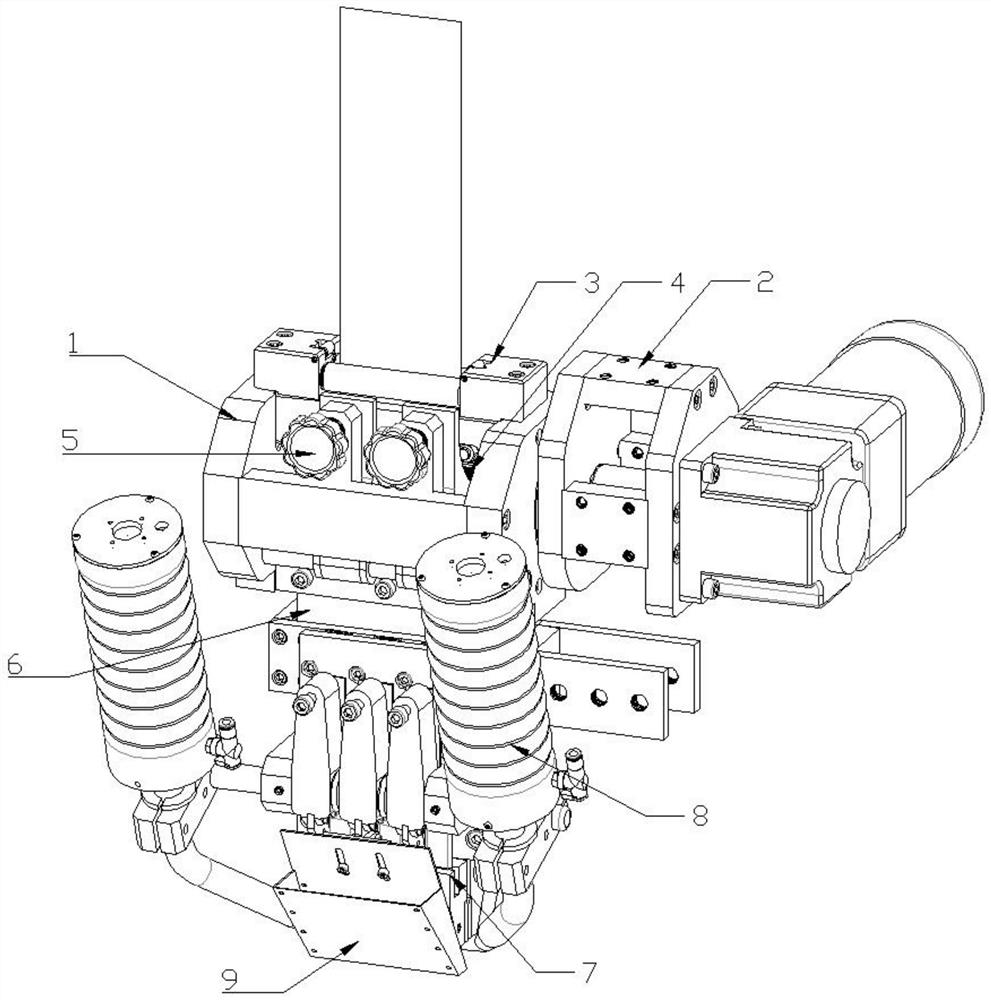

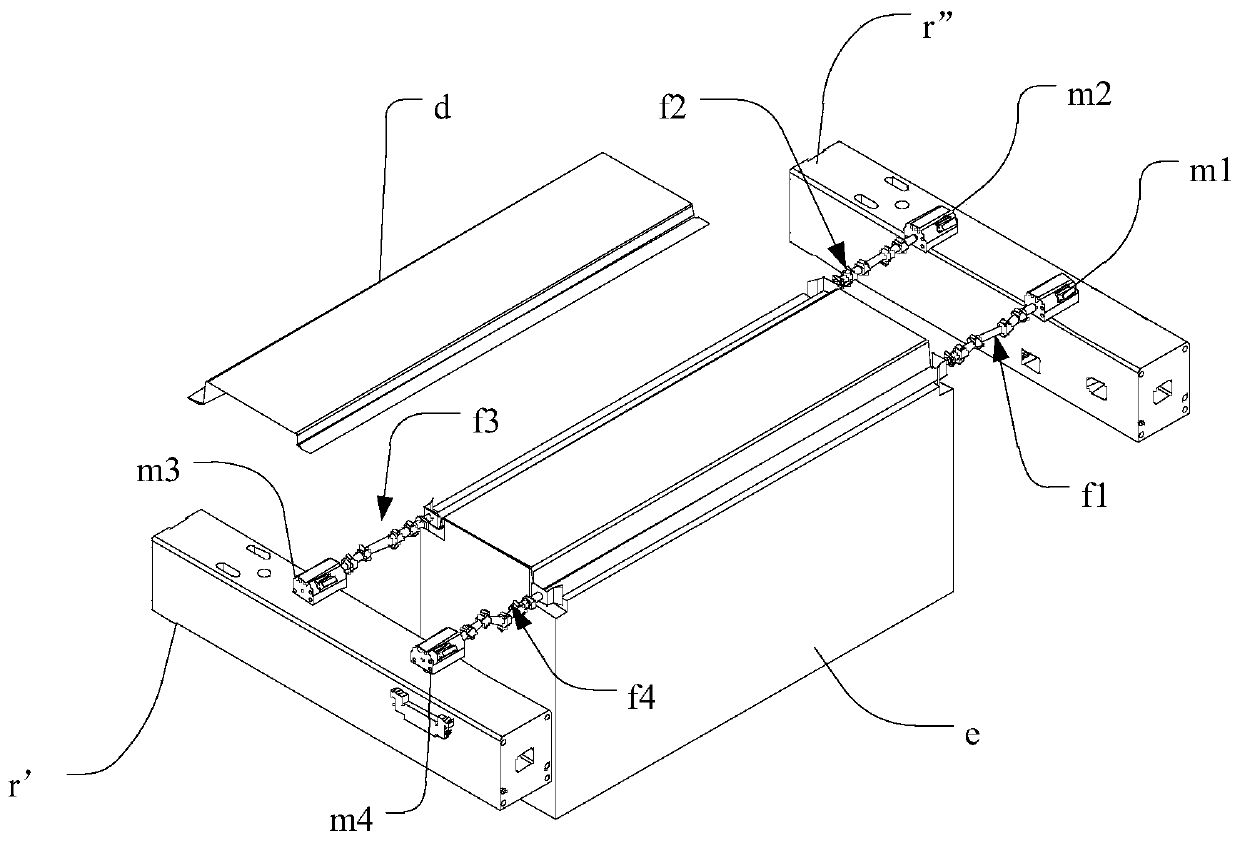

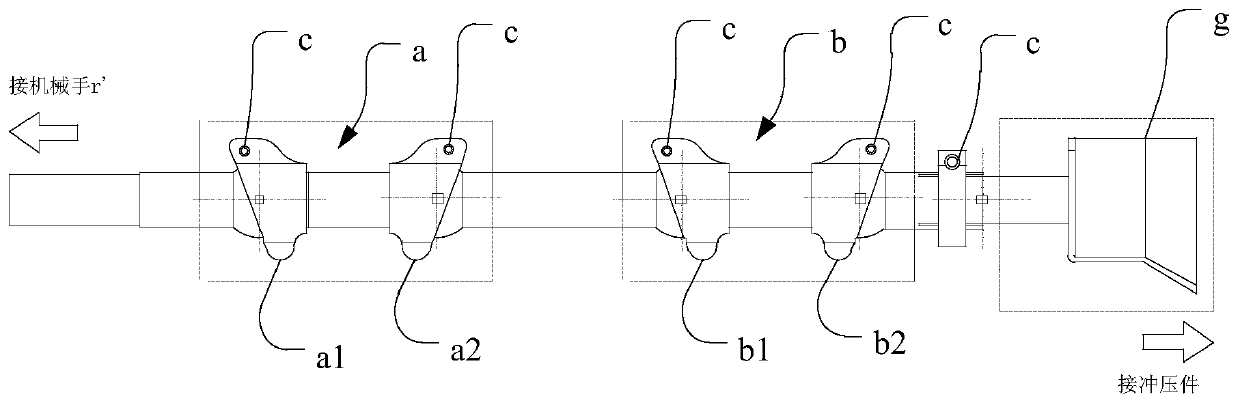

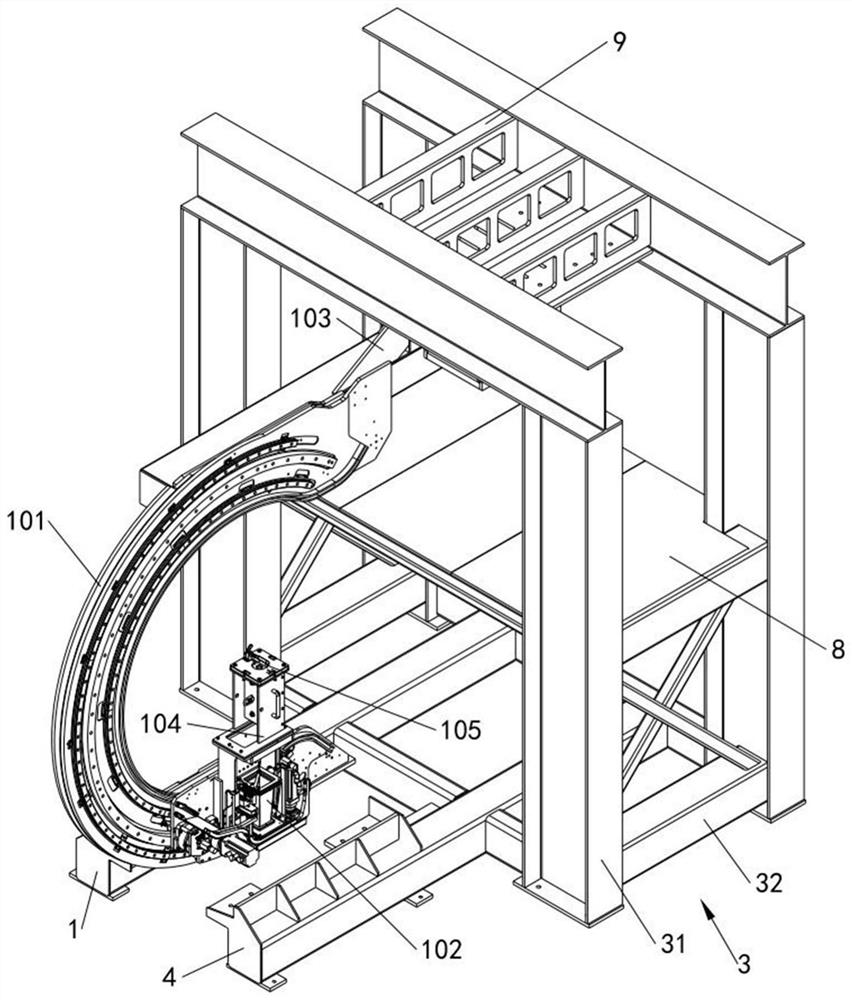

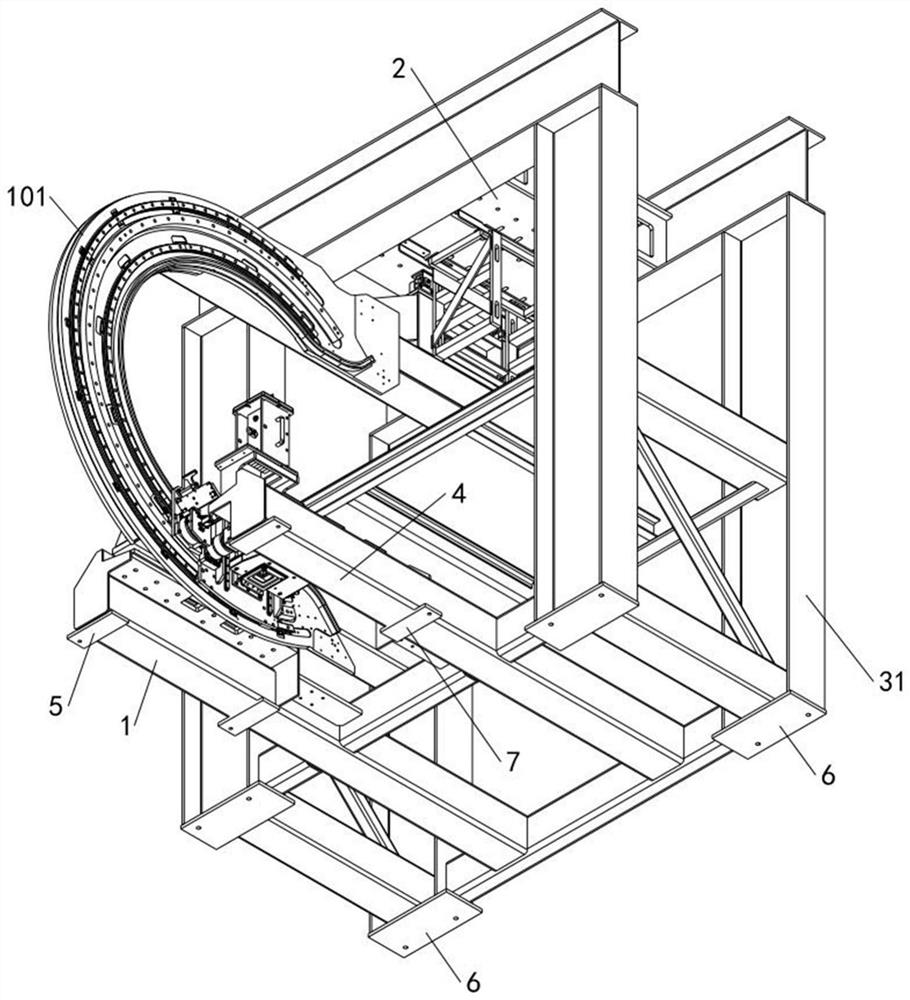

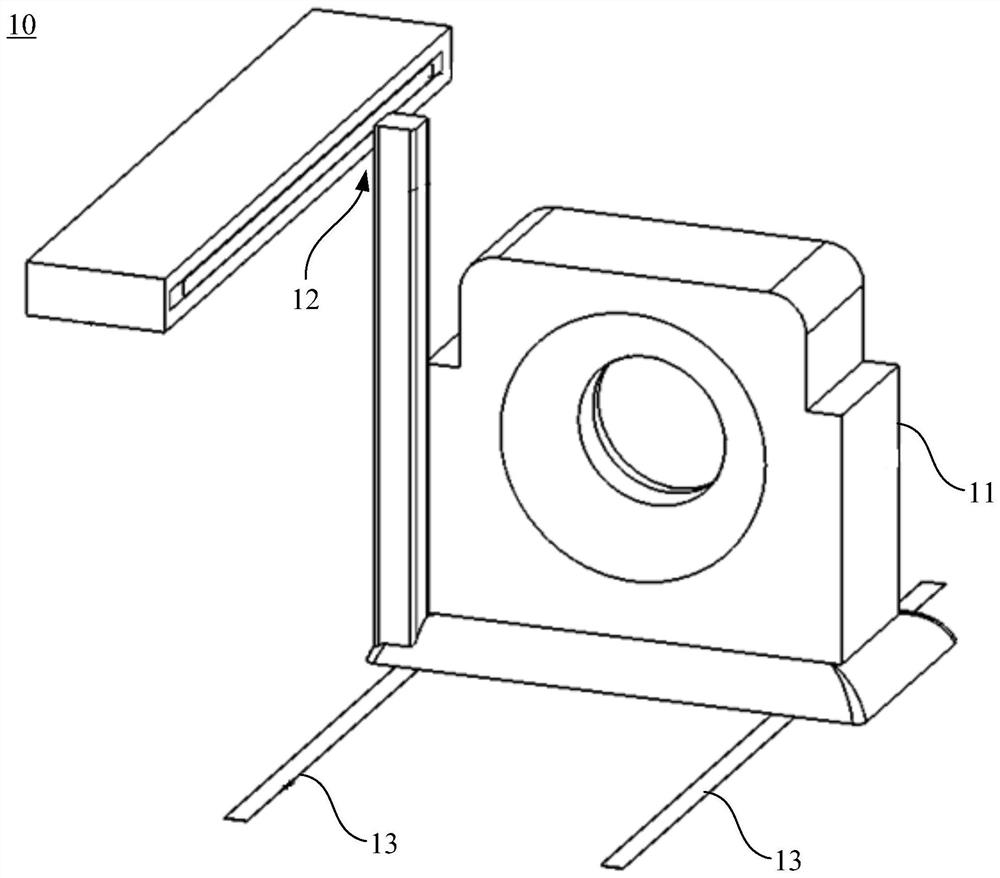

Stamping multi-station conveying system

ActiveCN110238301BIncreased rotational freedomIncreased installation flexibilityMetal-working feeding devicesPositioning devicesRobot handBall joint

The invention relates to a stamping multi-station conveying system, which comprises: a plurality of end pickers, the first ends of the end pickers are used for teaching to stamping parts, each of the end pickers The device includes the first group of ball joint seats and the second group of ball joint seats respectively, the first group of ball joint seats and the second group of ball joint seats respectively include the first ball joint seat and the second ball joint seat, each group of ball joint seats The first spherical joint seat is plugged into the second spherical joint seat in the group, and the first spherical joint seat is rotatable relative to the second spherical joint seat in the group; the number of manipulators is two, and each The manipulators respectively include a manipulator and a mount, the mount is slidably disposed on the corresponding manipulator, and the mount is connected to the second end of a corresponding one of the end pickers. The stamping multi-station conveying system can significantly improve the analysis and planning efficiency of the end effector, and the early analysis and planning results can be directly used for later on-site assembly, thus greatly improving the efficiency of installation and commissioning.

Owner:CH AUTO TECH CORP CO LTD

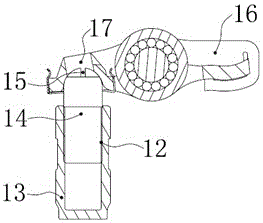

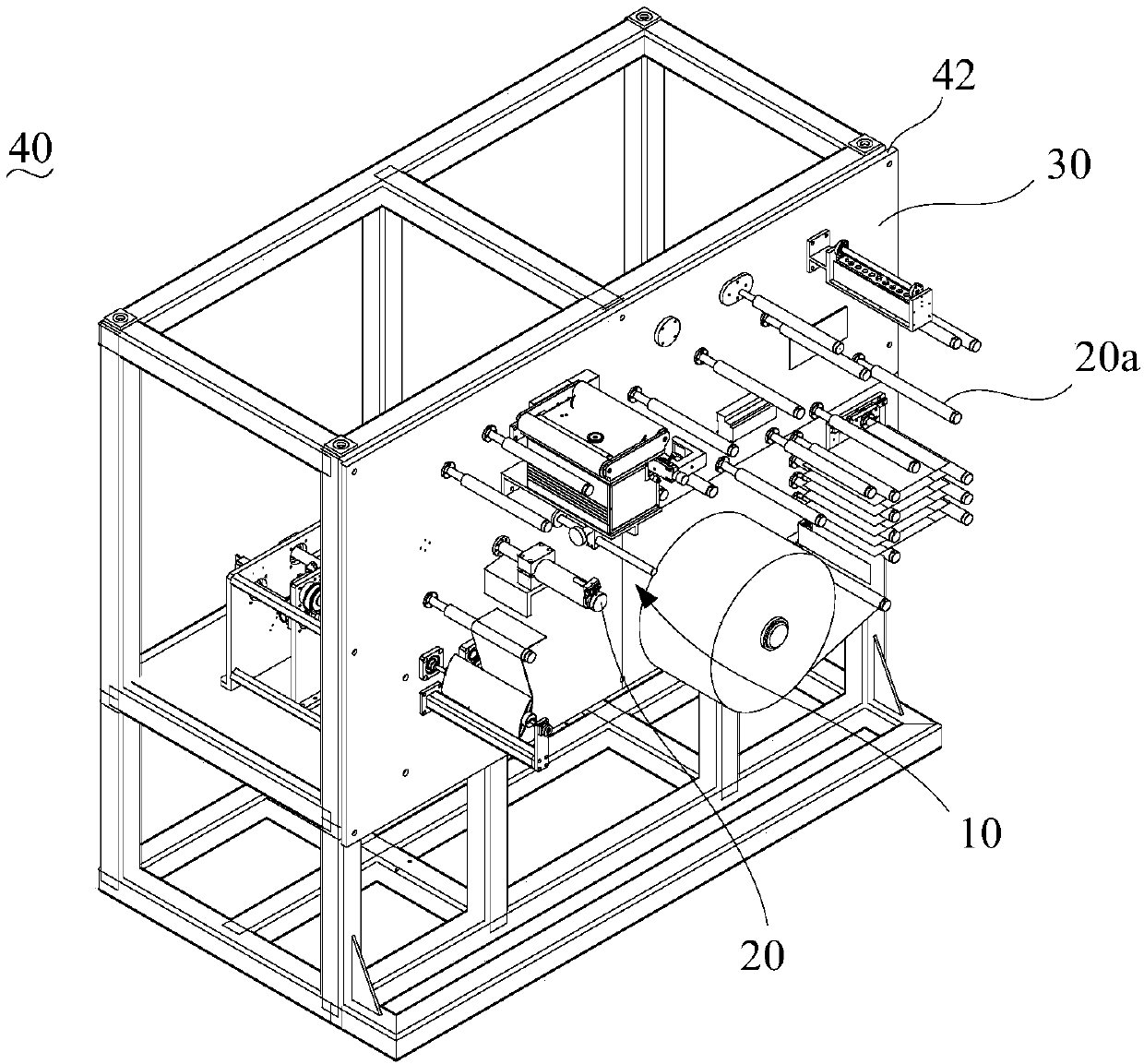

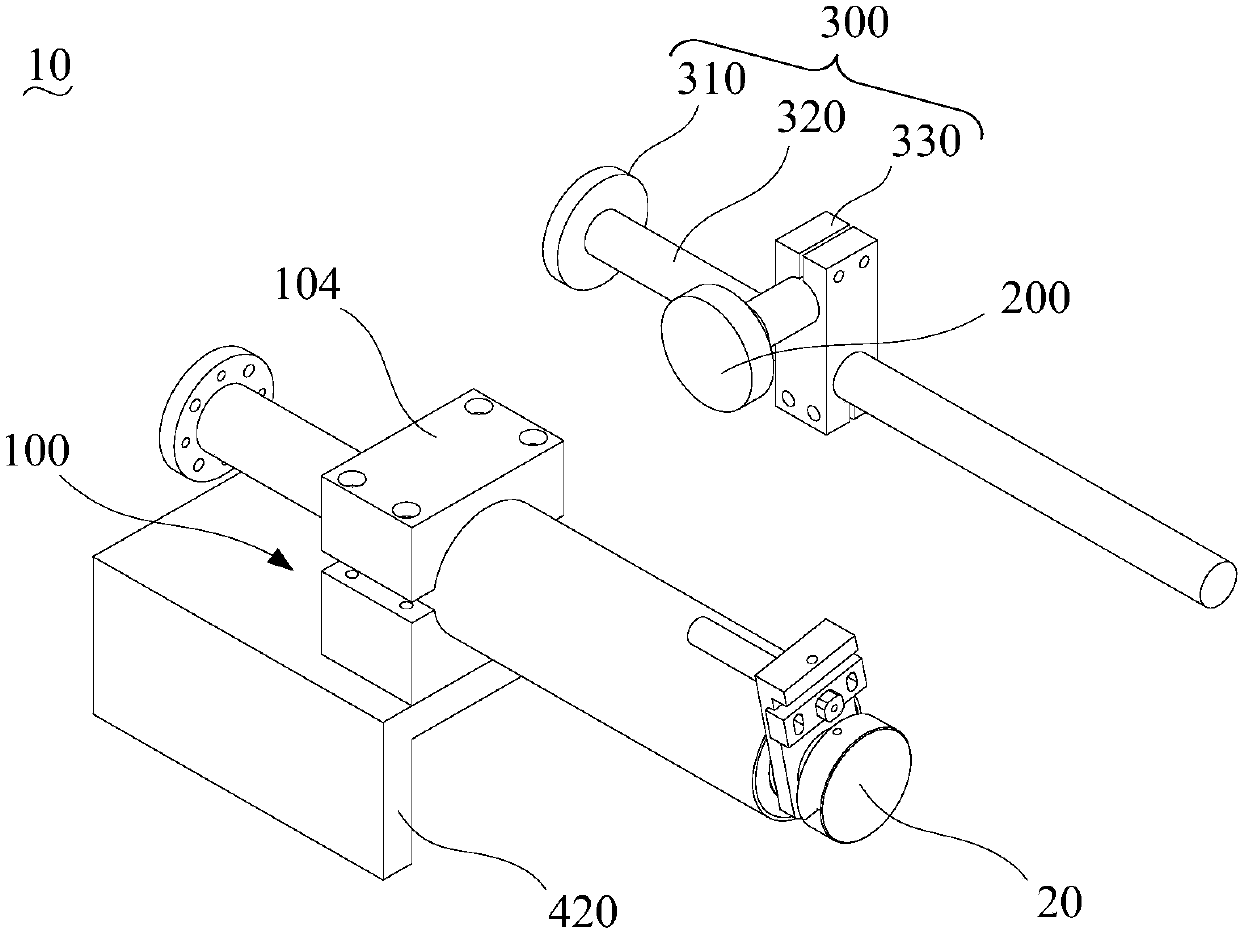

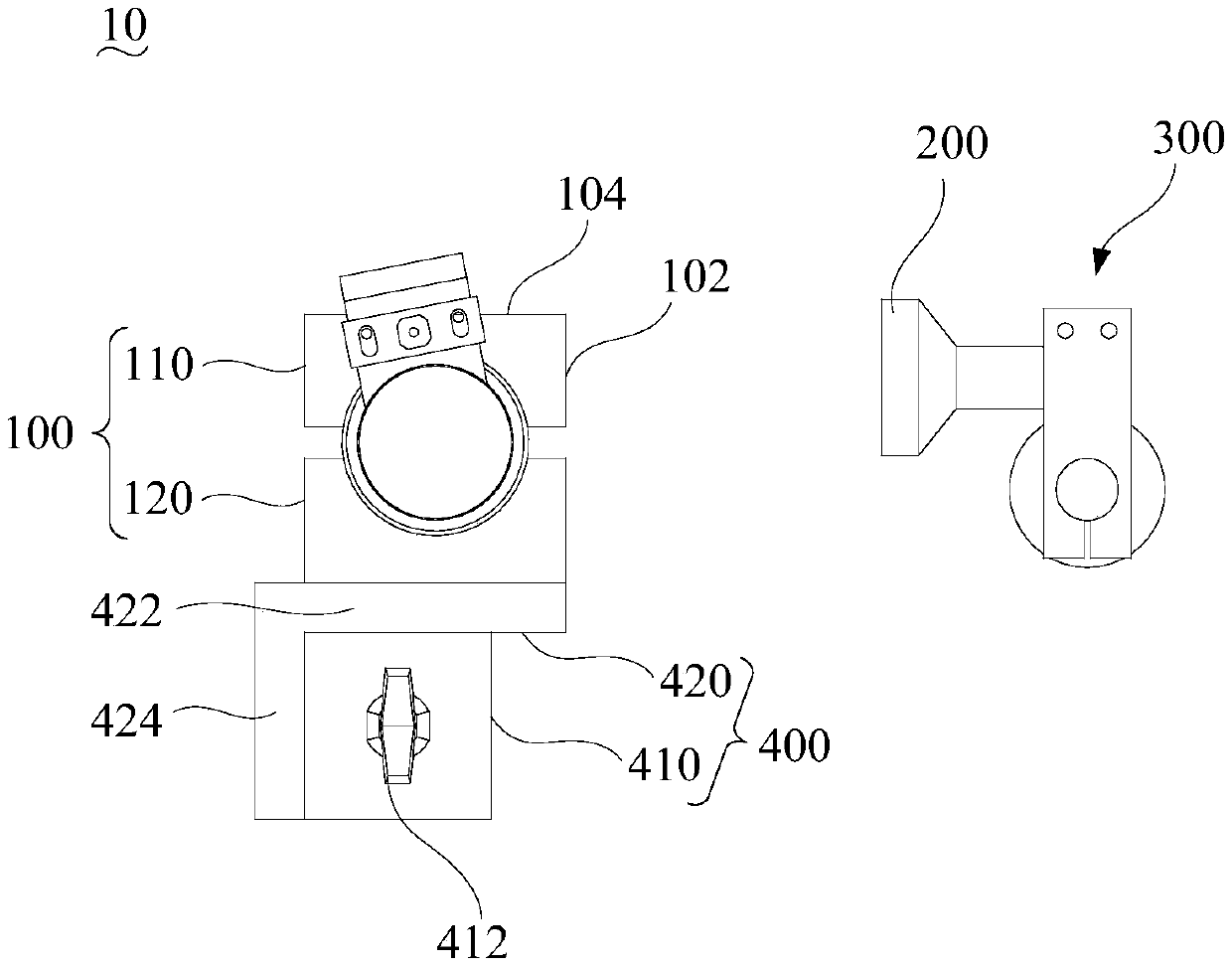

Verticality detection device and winding machine

ActiveCN107655424AGuaranteed alignmentShorten detection timeUsing optical meansWinding machineOptical axis

The invention relates to a verticality detection device and a winding machine. The device comprises an auxiliary module and a light source, and the auxiliary block is disposed on a workpiece in a sleeving manner and comprises a reflection plane and a measurement plane, which are adjacent to each other, are perpendicular to each other and are perpendicular to the axis of the workpiece. The opticalaxis of the light source is parallel to an intersection line of the measurement plane and a reference plane, and the light source is opposite to the reflection plane. After the light source is turnedon, the light source emits incident light to the reflection plane on the auxiliary block, and the incident light will be reflected by the reflection plane to form reflected light. If an inclined anglebetween the reflected light and the incident light is close to zero, it indicates that the verticality of the workpiece relative to the reference plane accords with the requirements; if there is an apparent inclined angle between the reflected light and the incident light, it indicates that the workpiece can be adjusted according to the propagation direction of the reflected light. The device candetect the verticality of the workpiece relative to the reference plane visually, can greatly shorten the detection time, and improve the detection efficiency.

Owner:深圳市大族锂电智能装备有限公司

Verticality detecting device and winder

ActiveCN107270834AGuaranteed alignmentShorten detection timeUsing optical meansPhysicsReference surface

The invention relates to a verticality detecting device and a winder. The verticality detecting device comprises a bracket and an emitter which is connected with the bracket. The bracket is connected with a reference surface. The emitter can emit parallel light which is perpendicular with the reference surface. A projection of a workpiece on the reference surface is in a light spot which is formed by the parallel light on the reference surface. In operation of the emitter, the parallel light irradiates the workpiece and the workpiece forms a projection on the reference surface. The shape of the projection is compared with an ideal shape or a scale, wherein the ideal shape is the projection shape on the reference surface on the condition that the workpiece is perpendicular with the reference surface. If the shapes are approximately same, verticality of the workpiece relative to the reference surface satisfies a requirement; and if the shapes are different, the mounting position of the workpiece can be corrected according to the offset direction of the projection. The method for detecting verticality of the workpiece relative to the reference surface by means of the verticality detecting device can realize higher visuality and can reduce detecting time. The verticality detecting device can greatly reduce mounting time and debugging time of a roller when equipped on the winder.

Owner:深圳市大族锂电智能装备有限公司

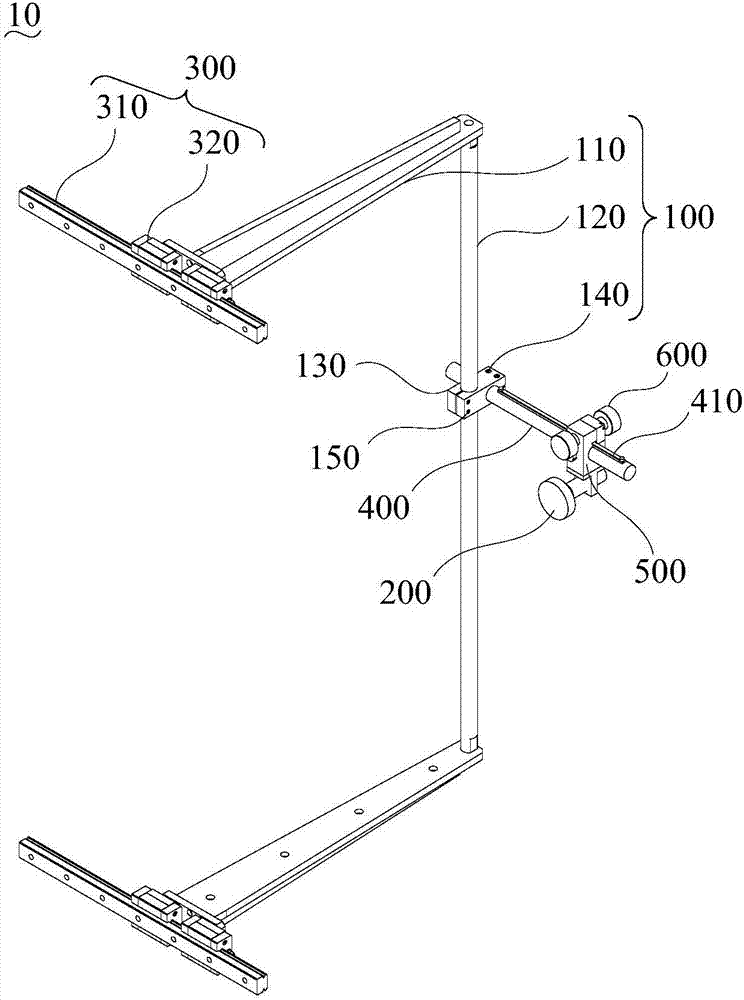

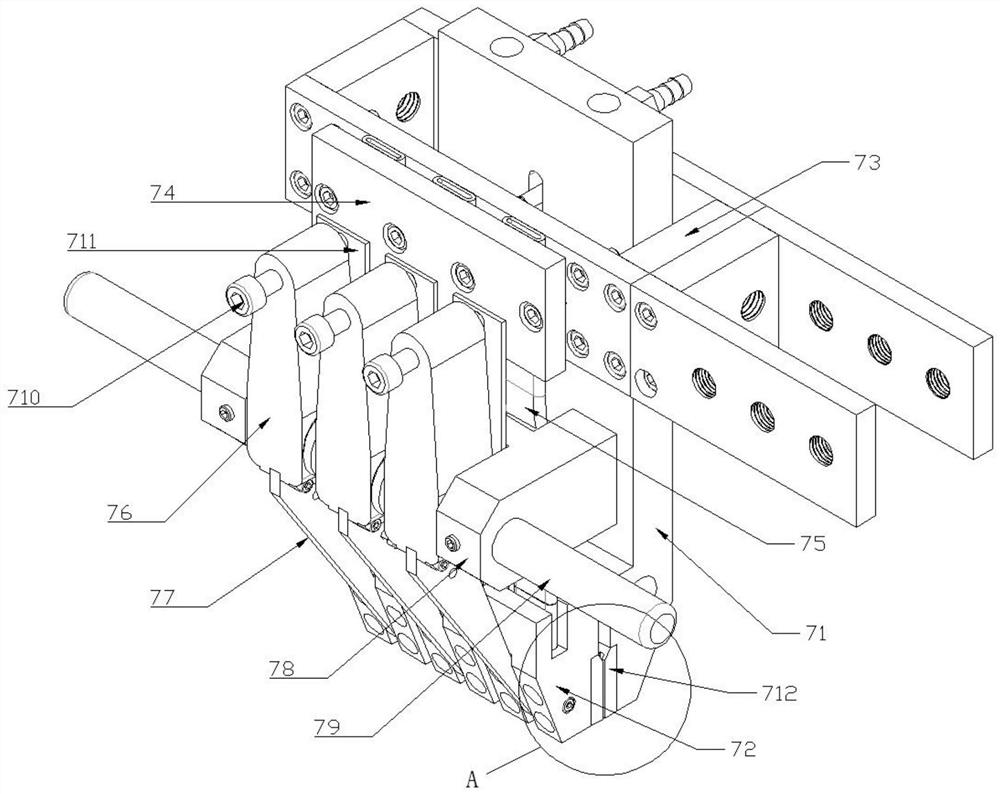

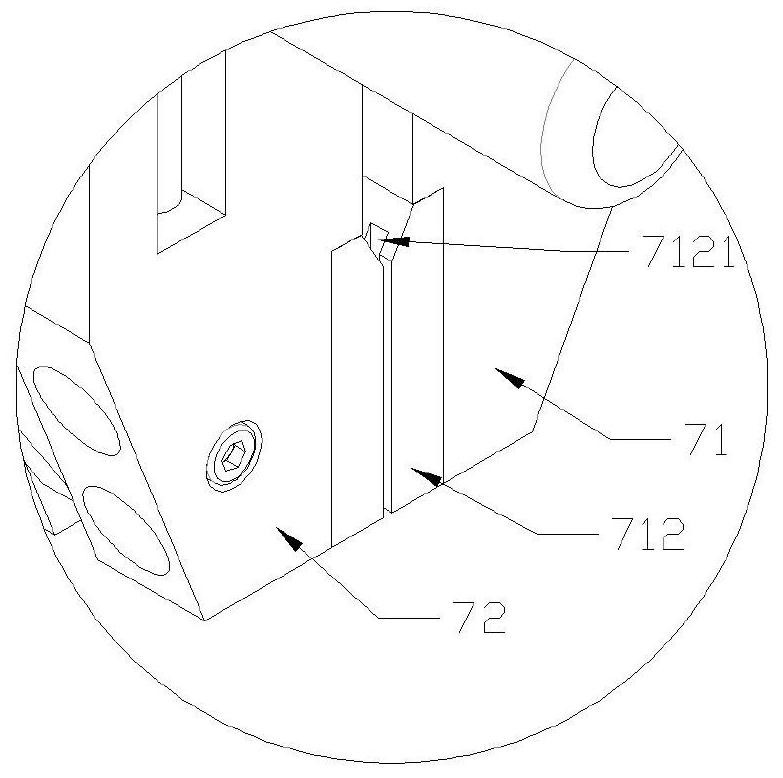

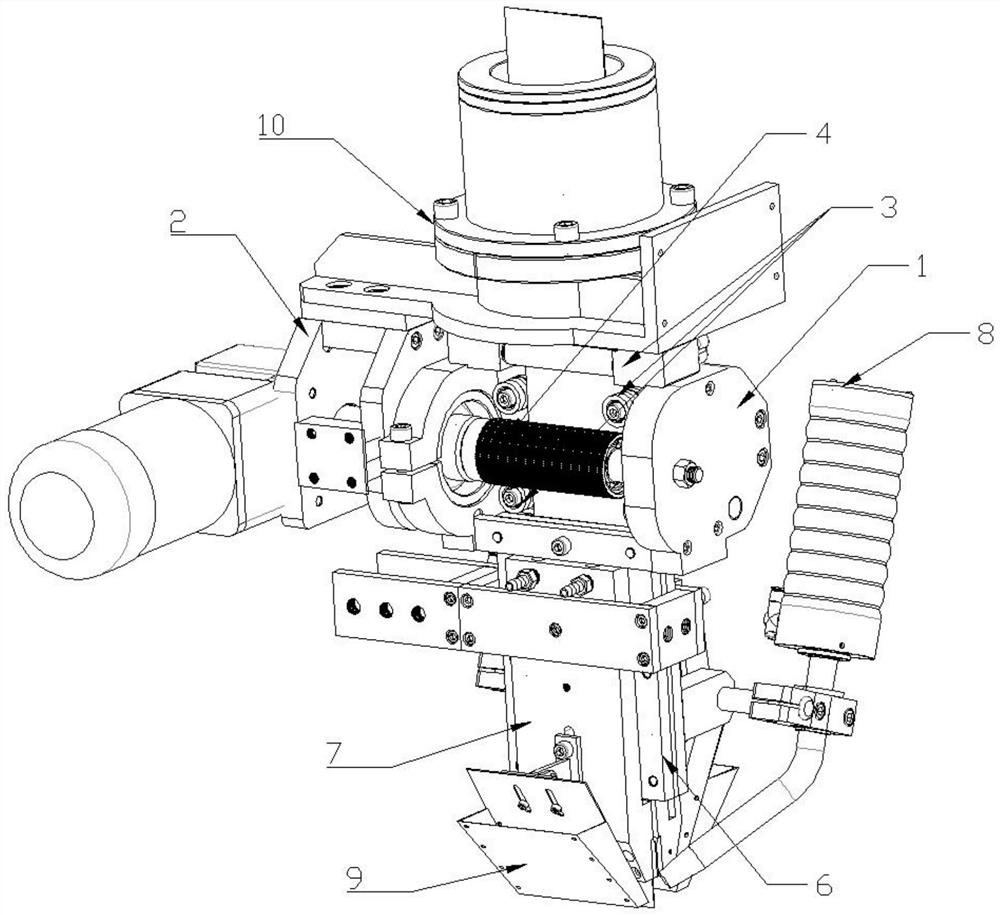

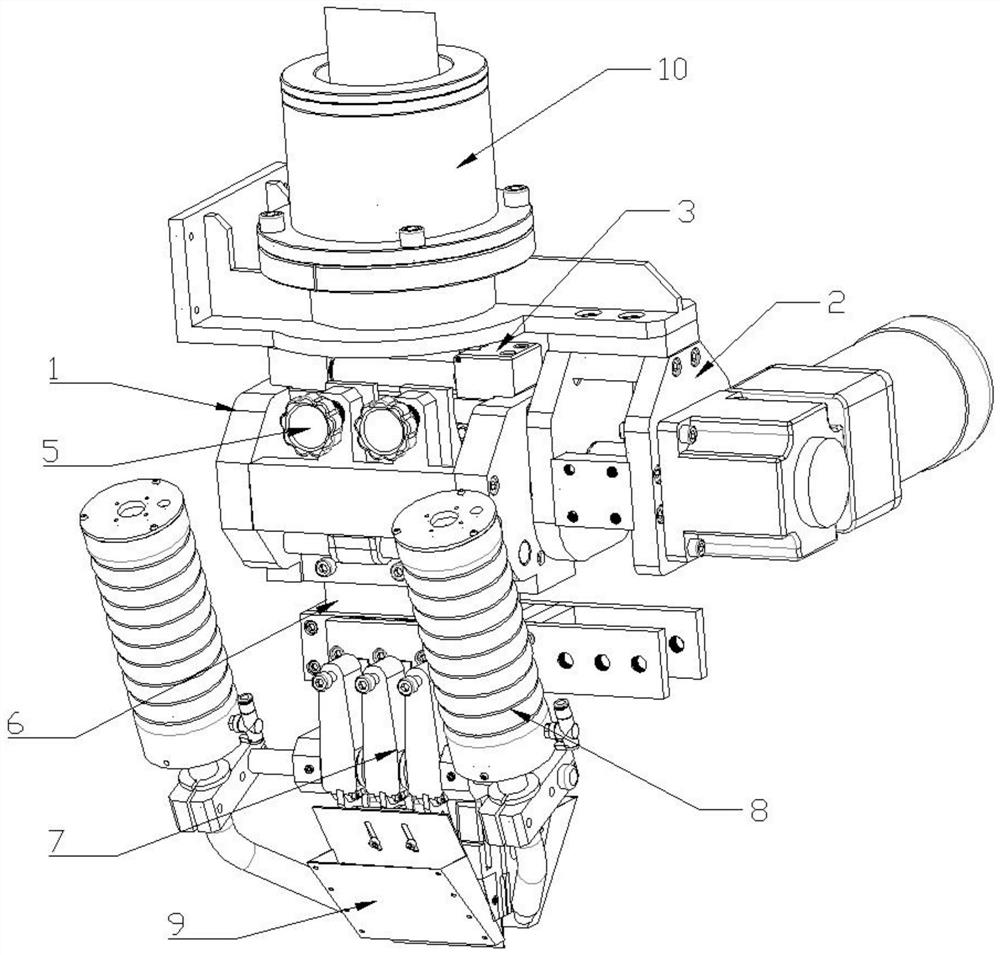

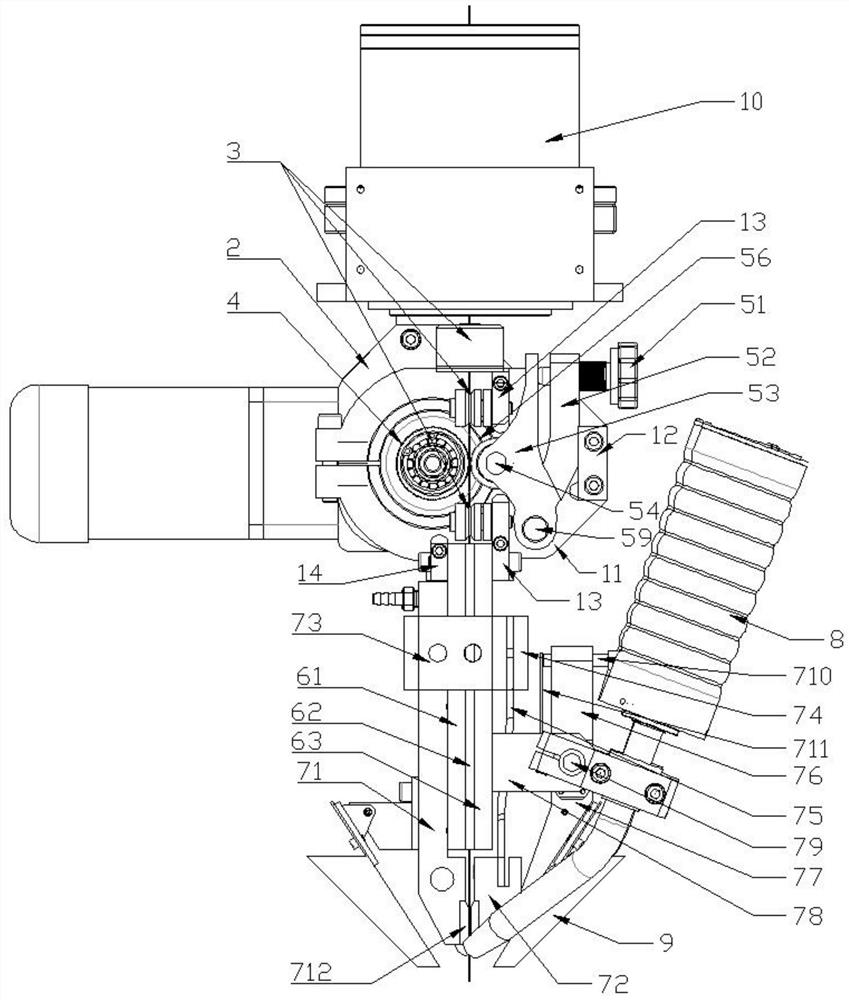

Contact tube assembly and strip

PendingCN111774703AImprove fitGuarantee welding qualityElectrode accessoriesEngineeringMechanical engineering

The invention provides a contact tube assembly and a strip submerged arc surfacing machine head, relates to the field of strip surfacing equipment, and solves the problem of unstable welding quality in the prior art. The contact tube mounted on the strip submerged arc surfacing machine head comprises an integral electrode, a single-petal electrode, an electrode connecting plate, an electrode pressing plate and an electrode pressing mechanism, wherein the electrode connecting plate is connected with the integral electrode and the electrode pressing plate, the electrode pressing plate is connected with the single-petal electrode through a conductive cable, and the integral electrode and the single-petal electrode are oppositely arranged and used for clamping a welding strip; the electrode pressing mechanism comprises a lever mechanism and a first elastic piece, the lever mechanism is fixedly connected with the electrode connecting plate, one end of the lever mechanism is connected with the first elastic piece, the other end of the lever mechanism is connected with the single-petal electrode, and the electrode pressing mechanism is used for pushing the single-petal electrode to the integral electrode to clamp the welding strip. The contact tube assembly provided by the invention enables the welding strip to be in good contact with the electrode, and the welding quality is improved.

Owner:张敏

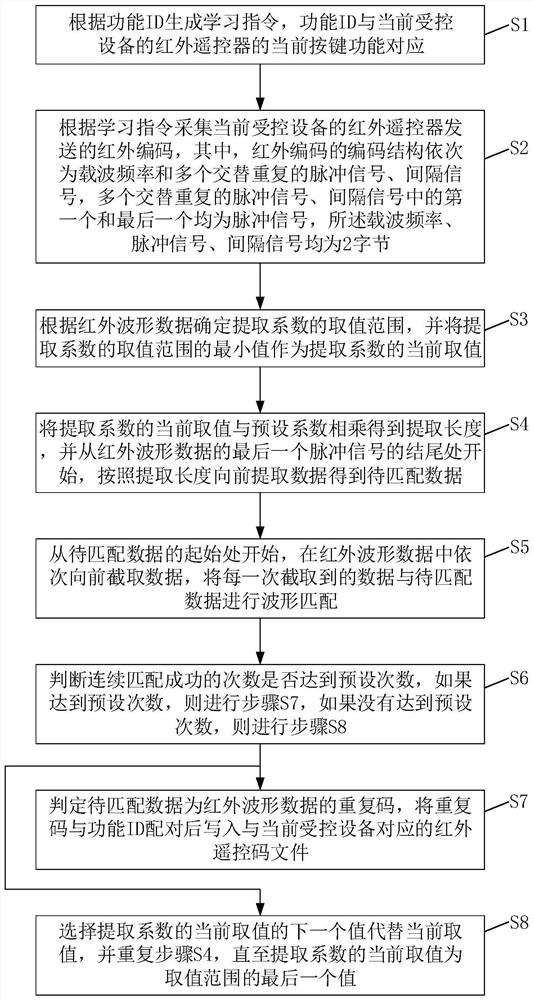

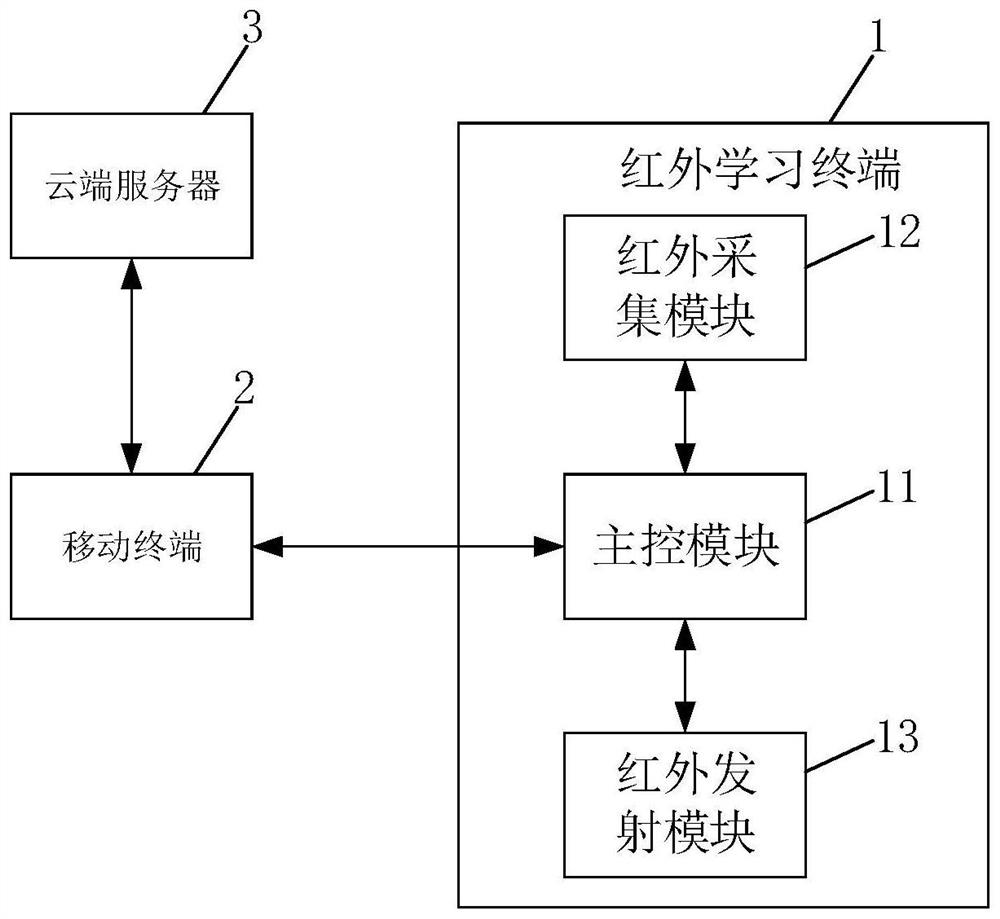

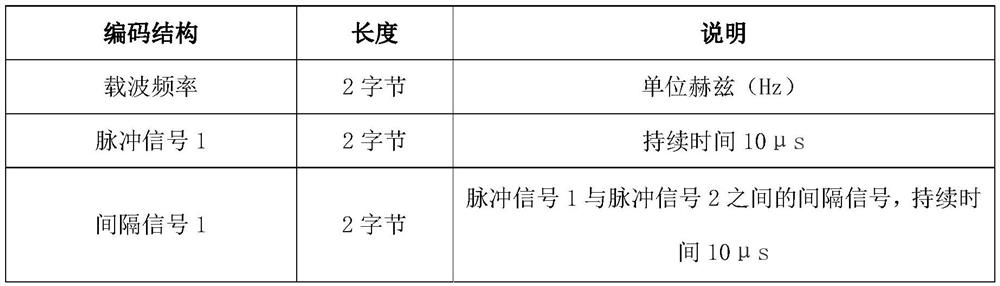

Infrared repeat code learning method and infrared remote control system applied to Internet of Things

ActiveCN111968361AImprove user experienceImprove installation and debugging efficiencyNon-electrical signal transmission systemsInternet of ThingsEngineering

The invention discloses an infrared repeat code learning method and an infrared remote control system applied to the Internet of Things. The method comprises the following steps: determining an extraction length according to the total byte length of an infrared code sent by an infrared remote controller; forward extracting to-be-matched data from the end of the last pulse signal of the infrared code according to the extraction length; forwards matching the to-be-matched data for multiple times; when the continuous matching success frequency reaches a preset frequency, judging that the to-be-matched data is a repeated code. Therefore, learning of the infrared repeat code is realized. The purpose of simulating the key long-press function is achieved, learning and simulation of the key long-press function of any equipment remote controller are achieved, the user experience is greatly improved, the learned infrared codes can be stored in the cloud, it is avoided that equipment needs to belearned again every time, and the installation and debugging efficiency of an Internet of Things project is greatly improved.

Owner:成都埃克思智创科技有限公司

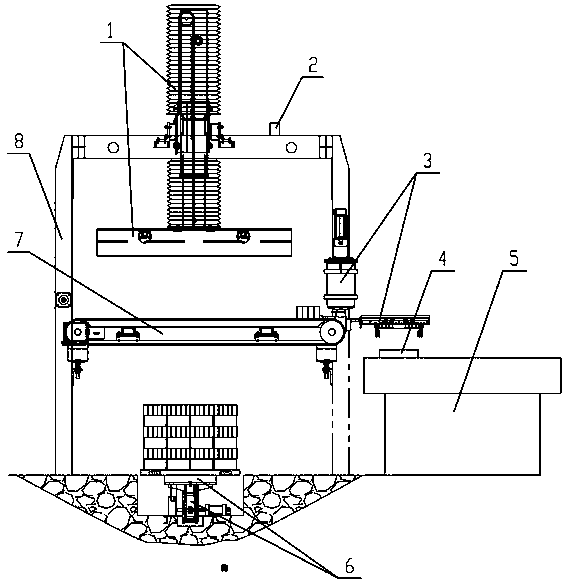

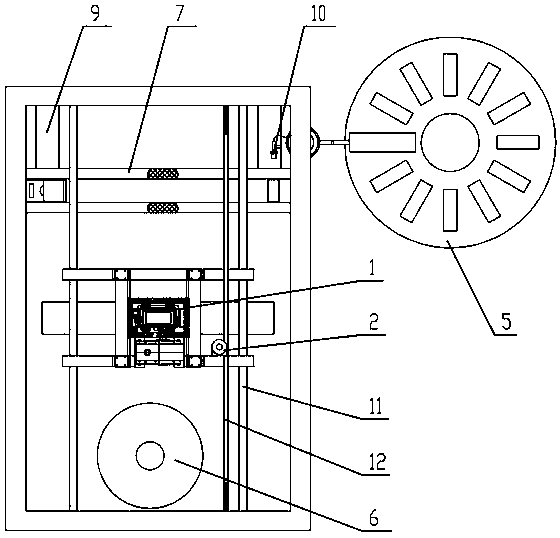

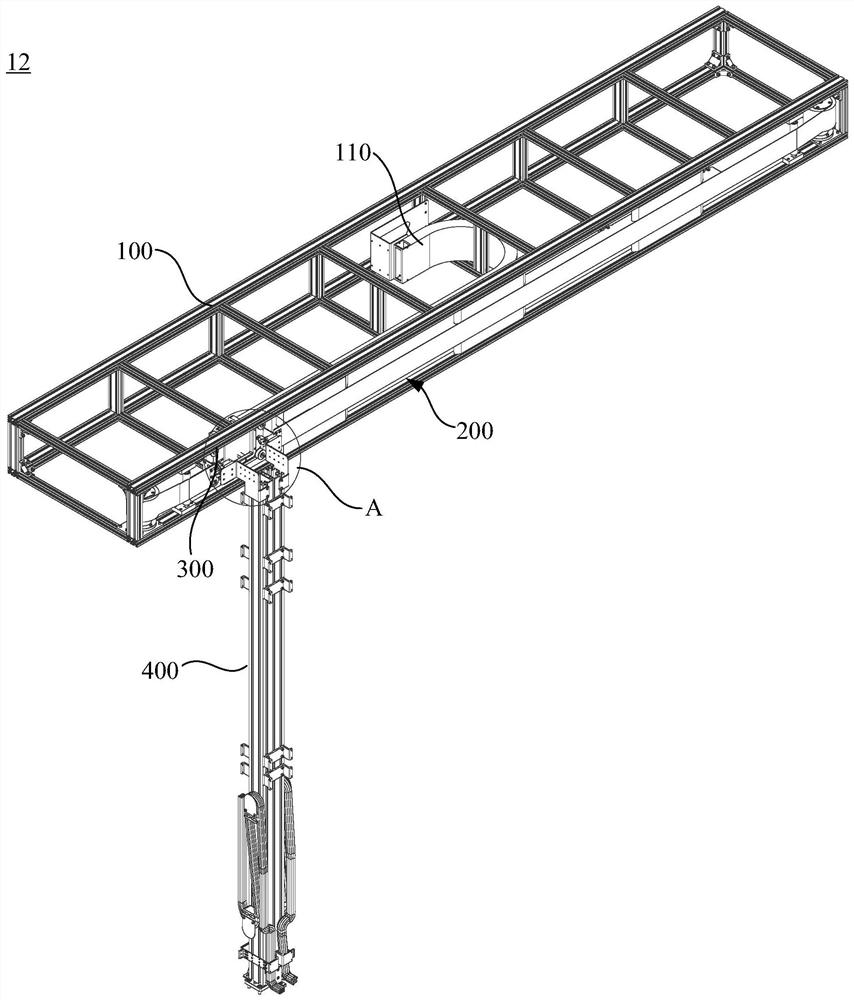

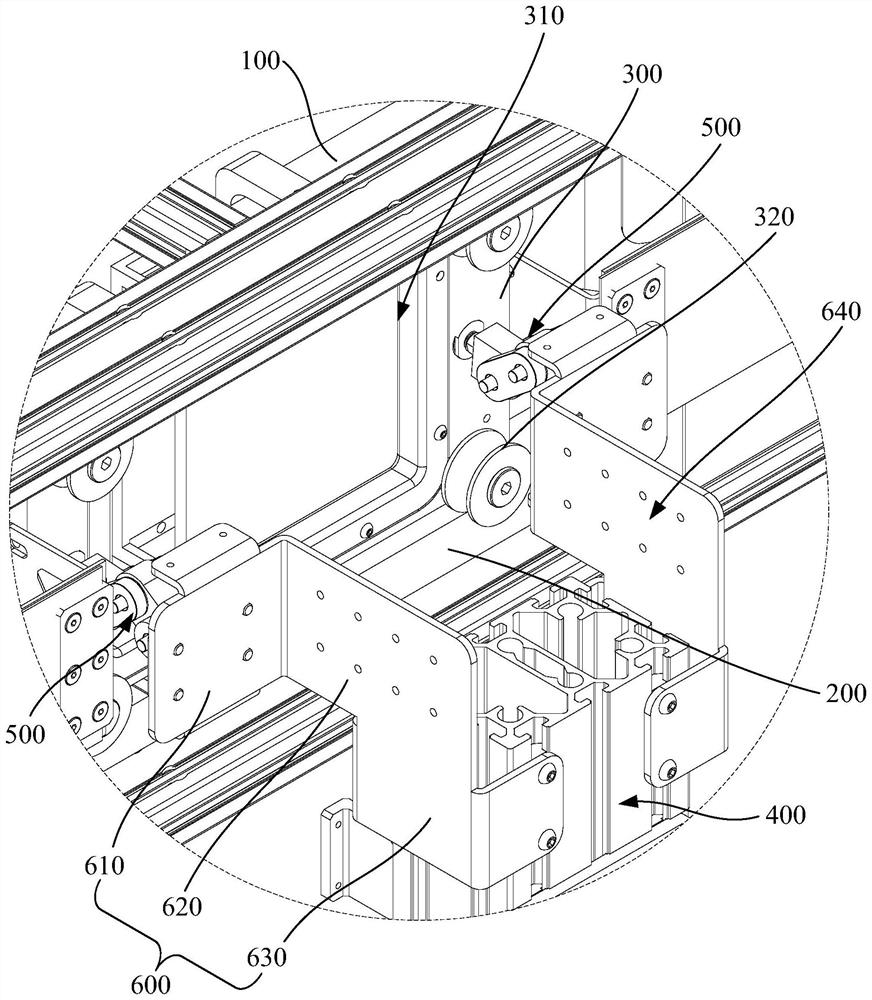

Green brick stacking robot

ActiveCN109761059ALower installation heightSave installation spaceStacking articlesDe-stacking articlesBrickEngineering

The invention relates to a green brick stacking robot which comprises a gantry frame, a big manipulator and a small manipulator vertically and downwards arranged on the gantry frame, and a belt conveyor arranged in the gantry frame. A green brick crossing perpendicular stacking device is arranged on the ground in front of the inner part of the gantry frame; an outer stand column capable of movingup and down is arranged in the middle of a base support; a lifting drive rack is vertically and fixedly arranged on the outer side wall of the outer stand column; a lifting drive motor is arranged onthe base support; a steel wire pulley is further arranged on an upper end port of the outer stand column; an inner stand column is arranged in the outer stand column in a sleeving way; and a flexiblesteel wire rope is solidified and drawn from the outer wall of the bottom part of the inner stand column. The green brick stacking robot provided by the invention is simple and practical in structuredesign, is stable, reliable and efficient in green brick stacking compared with an existing green brick stacking mechanism, and has a good practical use and promotion value.

Owner:湖北成吉智能机械科技有限公司

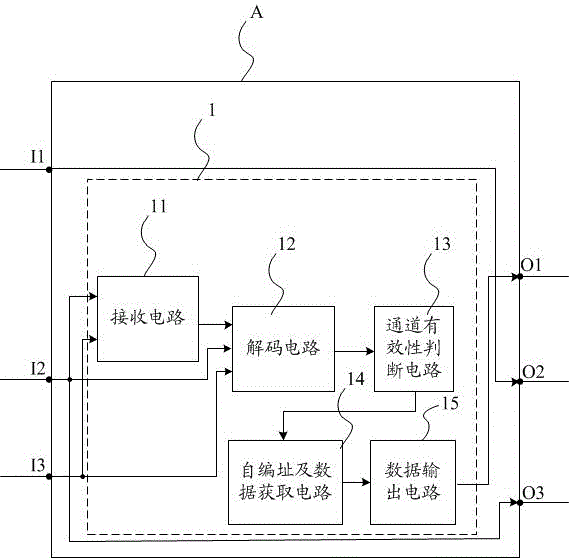

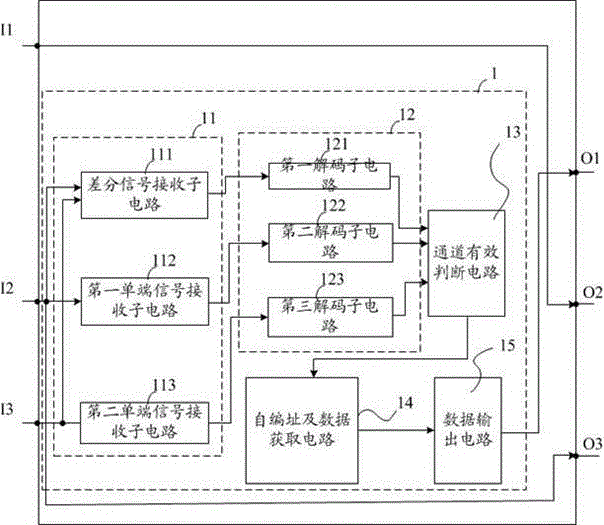

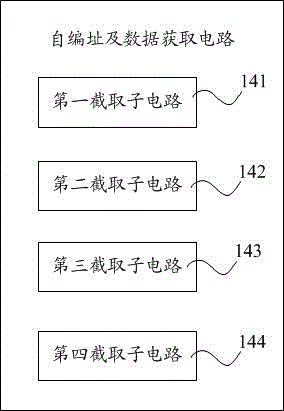

LED driving module, LED driving module processing method and LED driving cascade system

InactiveCN106163019AImprove installation and debugging efficiencyReduce commissioning costsElectrical apparatusElectroluminescent light sourcesData segmentData acquisition

The invention provides an LED driving module, an LED driving module processing method and an LED driving cascade system. A first input end of the LED driving module is connected with a second output end, and a second input end is connected with a third output end; a receiving circuit of an LED driving chip differentially receives for the second input end of the LED driving module and a third input end of the LED driving module and outputs first single-ended signals, receives for the second input end in a single-ended way and outputs second single-ended signals, and receives for the third input end in the single-ended way and outputs third single-ended signals. A channel validity judgment circuit makes validity judgment on decoded data to judge the validity of a channel. A self-addressing and data acquisition circuit performs self-addressing according to the validity of the channel, and intercepts a corresponding data segment in valid data according to self-addressing. The output end of a data output circuit is in output connection with a first output end of the LED driving module so that the valid data segment remained after intercepting is output through the first output end.

Owner:DONGGUAN CITY MINLEON ELECTRONICS CO LTD

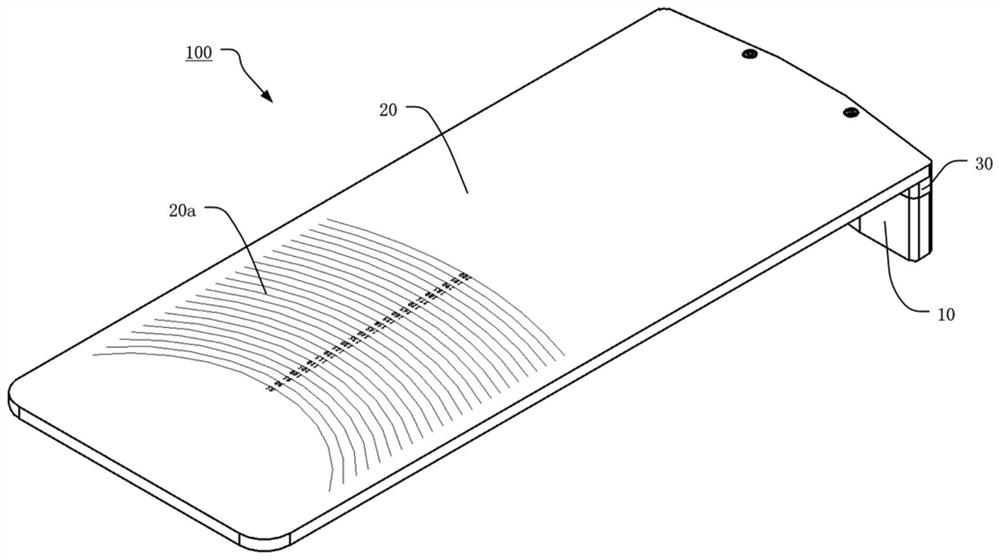

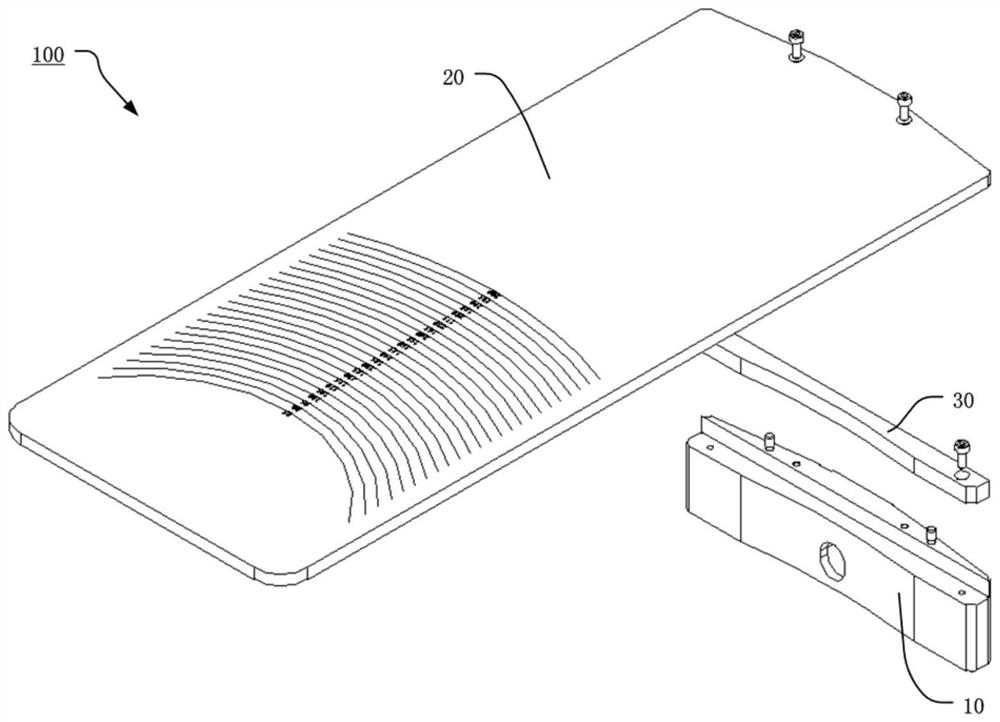

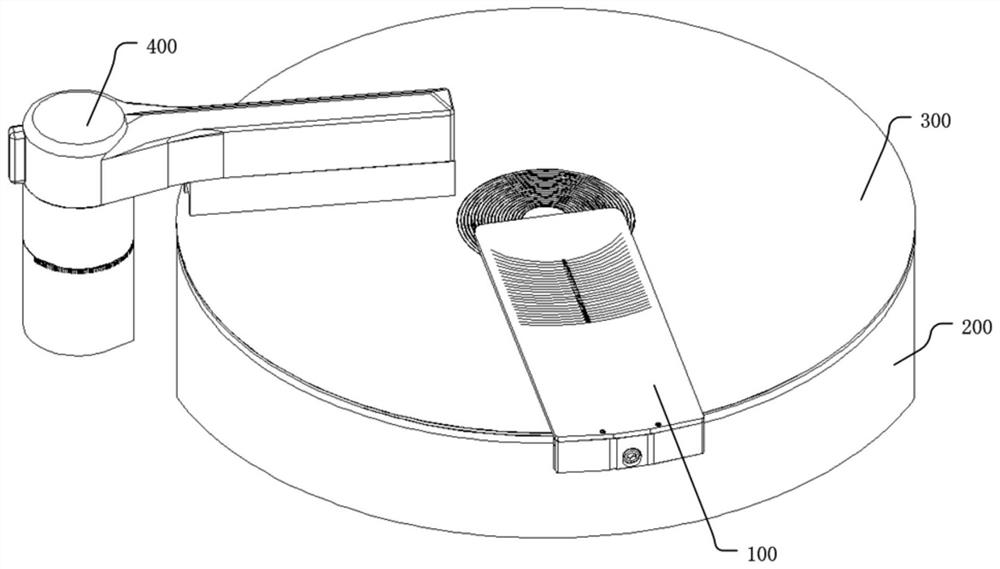

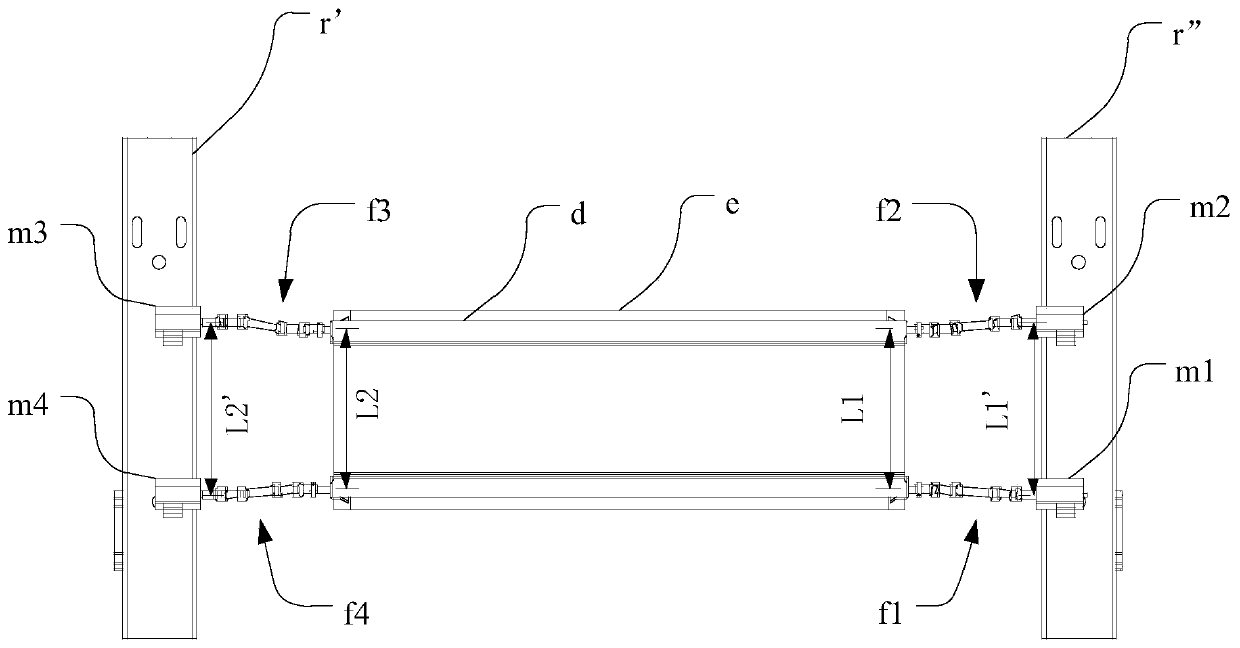

Polishing solution supply performance checking device and chemical mechanical polishing system

InactiveCN112658970AAccurately check the drop pointGuaranteed supplyLapping machinesGrinding feed controlPolishingEngineering

The invention discloses a polishing solution supply performance checking device and a chemical mechanical polishing system. The polishing solution supply performance checking device comprises a fixed seat, a horizontal plate and a locating piece, wherein the fixed seat is detachably arranged on the peripheral wall of a polishing disk; the horizontal plate is connected to the top of the fixed seat and faces the center of the polishing disk; the locating piece is arranged at the side part of the fixed seat and positioned at the lower portion of the horizontal plate; the inner side wall of the locating piece is of a circular arc structure; and the size of the circuit arc structure is matched with the outer diameter of a polishing pad. The horizontal plate is arranged between the polishing pad and a polishing solution supply arm, polishing solution drips to the top face of the horizontal plate from the end portion of the polishing solution supply arm, and scale marks are arranged on the top face of the horizontal plate so as to measure the dripping position of the polishing solution.

Owner:HWATSING TECH

Stamping multi-station transport system

ActiveCN110238301AIncreased rotational freedomIncreased installation flexibilityMetal-working feeding devicesPositioning devicesTransport systemEngineering

The invention relates to a stamping multi-station transport system. The stamping multi-station transport system comprises multiple end pickers and manipulators, wherein one end of each end picker is used for guiding to a stamping part, each end picker comprises a first group of spherical hinged supports and a second group of spherical hinged supports, each group in the first group of the spherical hinged supports and the second group of the spherical hinged supports comprises a first spherical hinged support and a second spherical hinged support, the first spherical hinged support in each group is inserted into the second hinged support in the same group, the first spherical hinged support in each group can rotate relatively to the second hinged support in the same group, the number of the manipulators is two, each manipulator comprises an mechanical arm and an installation seat, the installation seats can be respectively arranged on the corresponding mechanical arms in slidable mode, and each installation seat is connected with a second end of each corresponding end picker. The stamping multi-station transport system can significantly improve analysis and planning efficiency of the end pickers, and early analysis and planning results can be directly used in late field assembly, and therefore installation and debugging efficiency is greatly improved.

Owner:CH AUTO TECH CORP CO LTD

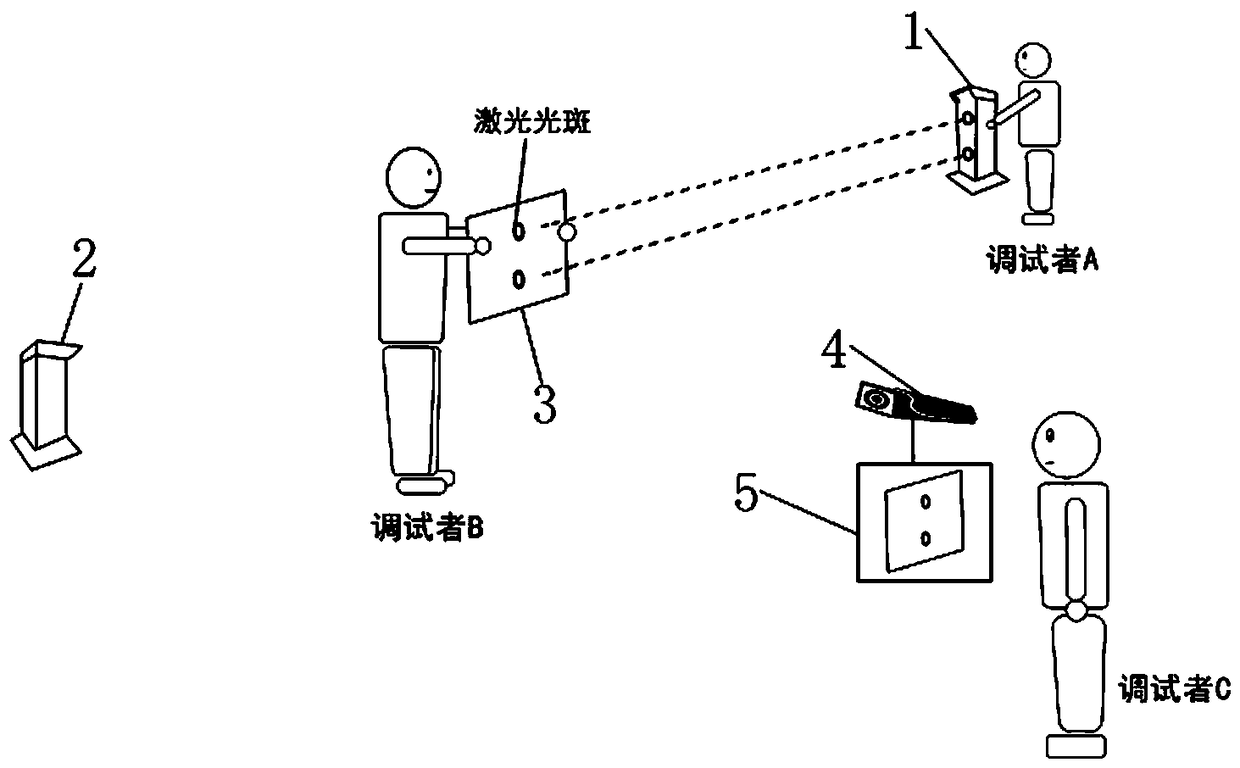

Visual debugging method of invisible laser intrusion detector

PendingCN108898810AImprove installation and debugging efficiencyImprove accuracyAlarmsDisplay deviceOptoelectronics

The invention discloses a visual debugging method of an invisible laser intrusion detector. The visual debugging method is characterized that required main equipment and tools comprise a laser correlation emitter and a laser correlation receiver which form a laser intrusion detector, a paper board of which the area is slightly larger than that of the front surface of the laser correlation emitter,a black-white infrared camera, a display mated with the camera and field debugging staff A, B and C. By utilizing the visual debugging method of the invisible laser intrusion detector, disclosed by the invention, a user can be helped directly and clearly observe accurate positions of invisible laser beams emitted by a laser emitter of the laser intrusion detector during an installation and debugging or maintaining process of the laser intrusion detector, the user can be helped easily solve the problem that accurate alignment cannot be realized by the laser emitter and a laser receiver of thelaser intrusion detector, the efficiency and the accuracy of installation and debugging of the laser intrusion detector can be increased, and misinformation caused as accurate focusing cannot be realized by the laser intrusion detection in the past can be completely eradicated.

Owner:广州市艾礼富电子科技有限公司

Strip electrode submerged arc build up welding equipment

PendingCN111774704ARealize the twistRealization of surfacingWelding accessoriesEngineeringMechanical engineering

The invention provides strip electrode submerged arc build up welding equipment, and relates to the field of strip electrode build up welding equipment. Problems in the prior art can be solved, the equipment comprises a machine head mounting base and a strip electrode submerged arc build up welding machine head, the machine head mounting base is provided with an upper connecting base and a lower connecting base which are coaxially mounted and can oppositely rotate around the axis, the lower connecting base is fixedly connected with a hanging base assembly with the strip electrode submerged arcbuild up welding machine head, the equipment is divided into an upper part and a lower part which can oppositely rotate, 90-degree torsion of a welding strip can be achieved, and build up welding intwo directions is achieved.

Owner:张敏

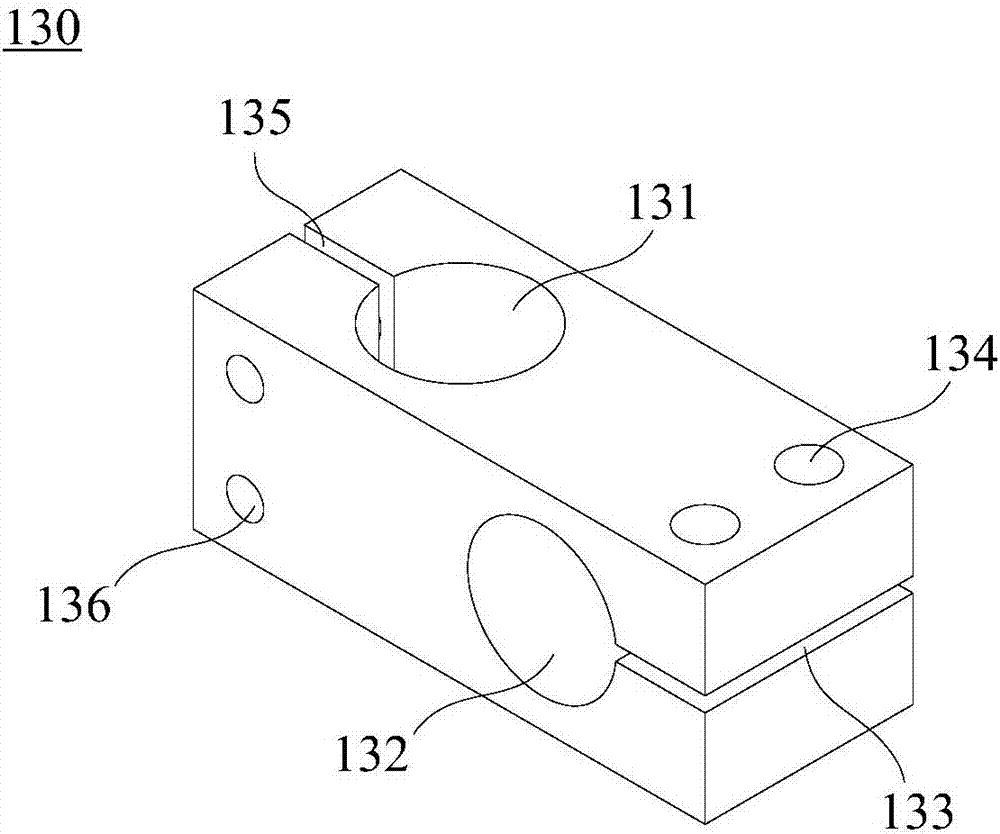

C-shaped inner rack rotation center debugging method and C-shaped inner rack mounting structure

ActiveCN113624132AReduce maintenance costsEasy to moveUsing optical meansMedical equipmentStructural engineering

The invention relates to the field of medical equipment, and discloses a C-shaped inner rack rotation center debugging method and a C-shaped inner rack mounting structure. According to the C-shaped inner rack rotation center debugging method, the position of a C-shaped inner rack relative to the C-shaped inner rack mounting structure and the position of a treatment head relative to the C-shaped rack are adjusted through cooperation of a theodolite and a ruler; the run-out error of the rotating center of the C-shaped inner rack is within the preset run-out error range, and the maintenance cost is greatly reduced. According to the C-shaped inner rack mounting structure provided by the invention, a first mounting hole and / or a second mounting hole are / is kidney-shaped holes, so that the C-shaped inner rack can move relative to the C-shaped inner rack mounting structure, and the C-shaped inner rack can rotate relative to the C-shaped inner rack mounting structure, so that the position of the C-shaped inner rack relative to the C-shaped inner rack mounting structure can be adjusted in cooperation with the theodolite and the ruler, and the purpose of improving the mounting precision and the mounting and debugging efficiency of the C-shaped inner rack is achieved.

Owner:MEVION MEDICAL EQUIP CO LTD

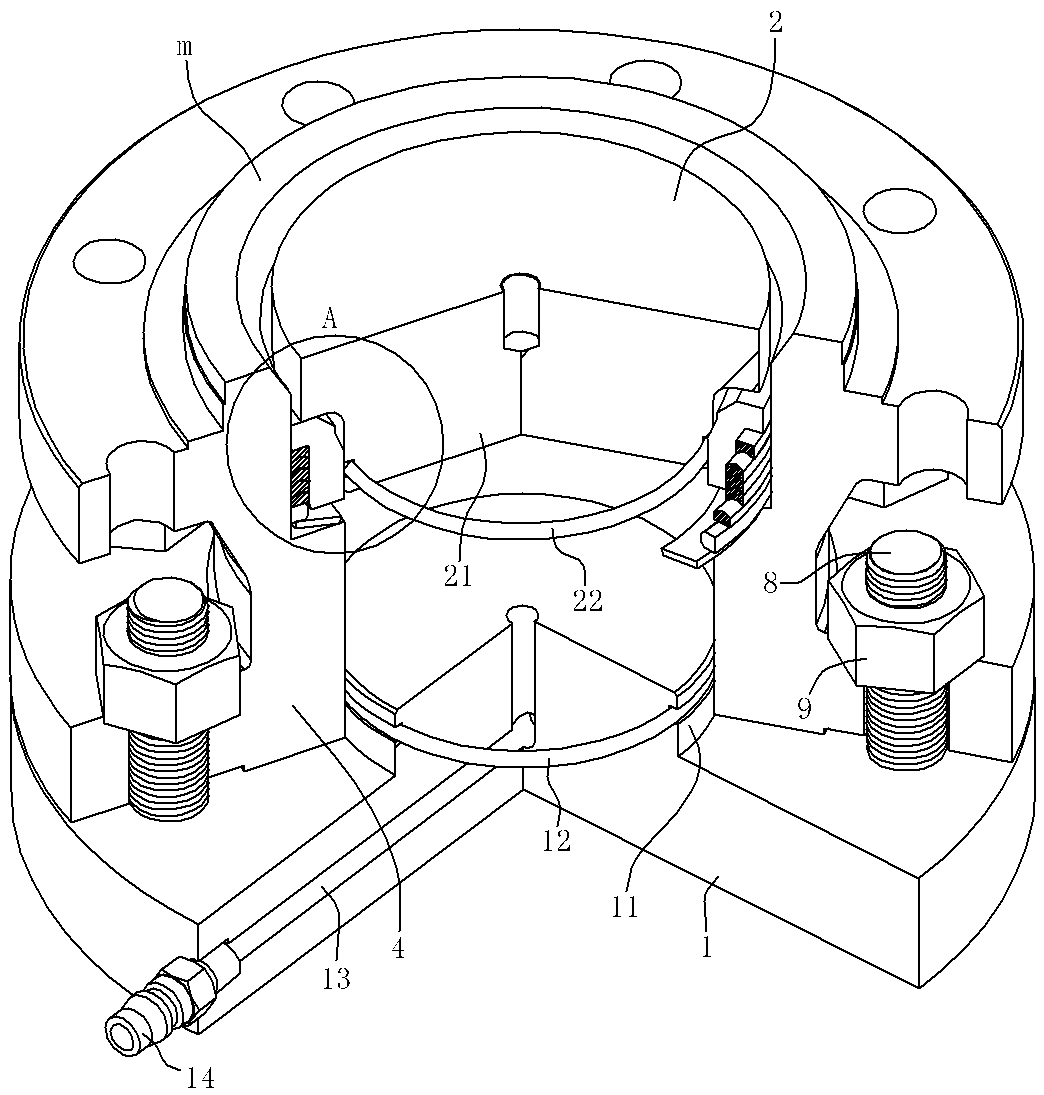

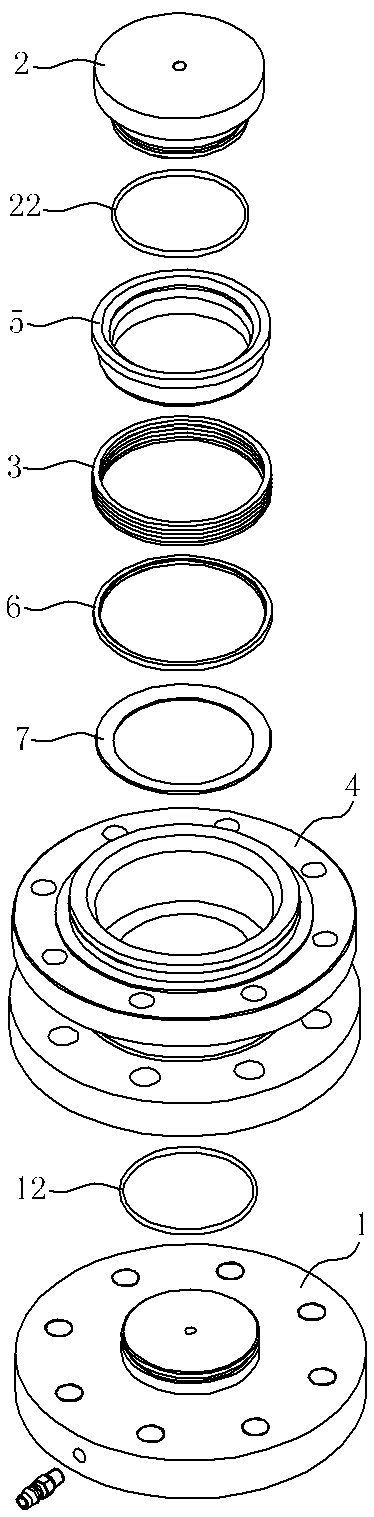

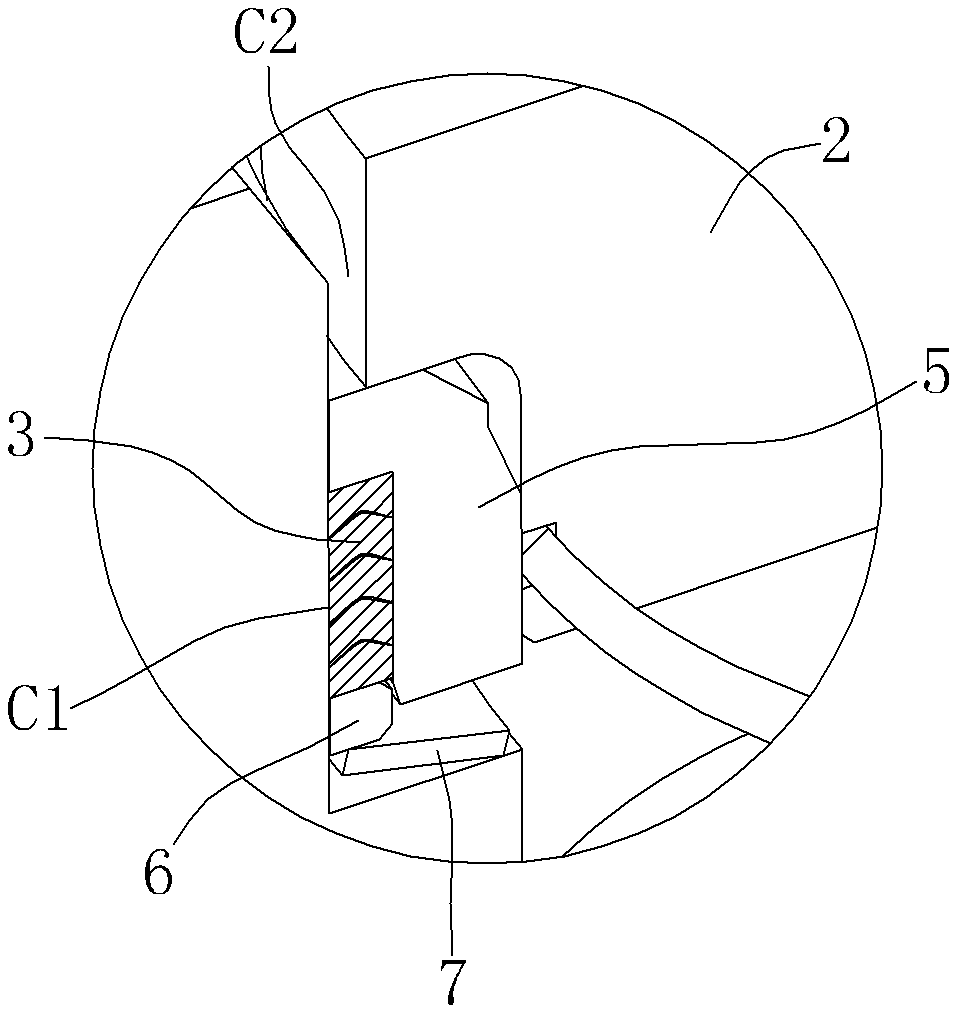

Installation test tool for graphite seal ring of metal hard seal ball valve

PendingCN109459189AMinimize the impact of sealing testsCheck air tightnessDetection of fluid at leakage pointValve arrangementsGraphiteAir tightness

The invention discloses an installation test tool for a graphite seal ring of a metal hard seal ball valve. The installation test tool comprises a base and a press plate, and is applied to a valve body, a valve base and a seal ring base of the metal hard seal ball valve; the base is detachably connected with the lower end of the valve body and seals a lower port of the valve body; the press platepresses the upper end of the valve base and seals a pore channel of the valve base, and the outer peripheral surface of the press plate, the upper end face of the valve base and the upper end inner wall of the valve body define an airtight observation ring groove for containing liquid. The installation test tool can solve various problems in the process of installation and adjustment of the graphite seal ring, simplify the adjustment steps, test the seal performance of the seal ring and influence parameters, and greatly improve the efficiency of installation and adjustment of the metal hard seal ball valve.

Owner:WUXI SCORE AUTOMATIC CONTROL EQUIP CO LTD

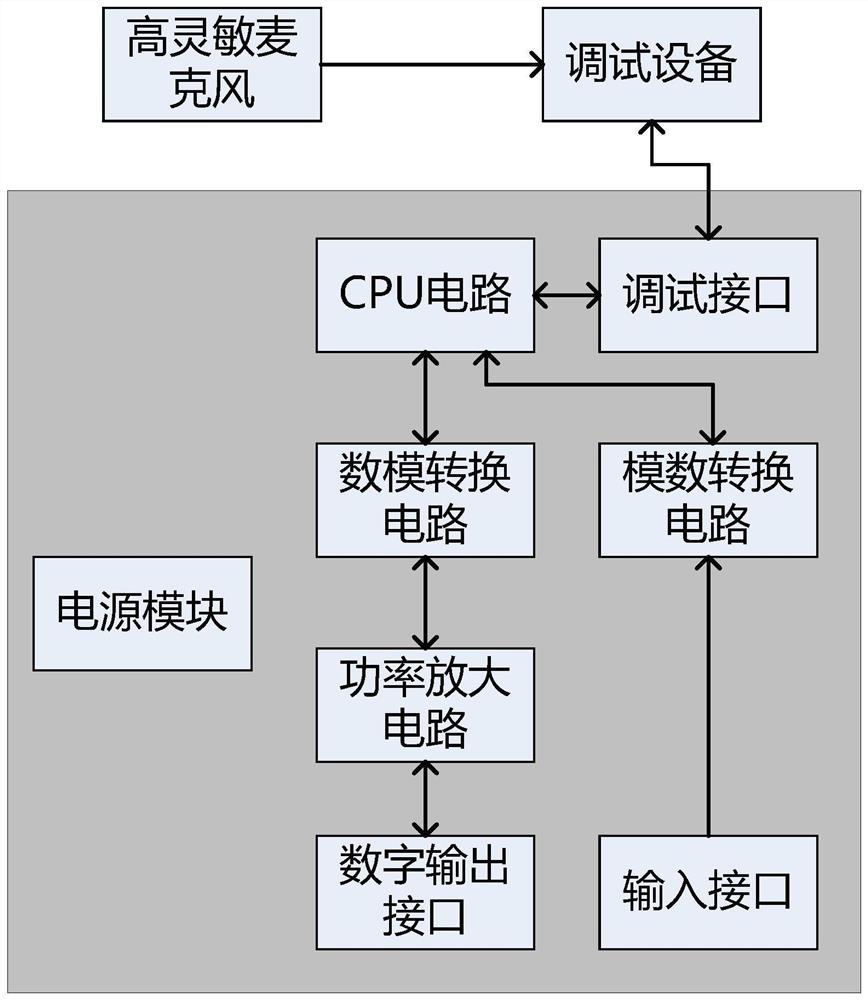

A kind of car intelligent tuning equipment and method

InactiveCN109246544BReduce demandRealize intelligent tuningFrequency response correctionEngineeringEmbedded system

Owner:广东梦之音车载科技有限公司

A Large Aperture Spherical LiDAR Optical System

The invention provides a large-caliber fully-spherical laser radar optical system. All the optical surfaces of the optical system are spherical. A double-focus switching mode is designed. A Margin system adopts a multiple-structure design. Through changing the switching of laser between the output wavelength and the detection wavelength, the front-end Margin system can be used alone and can be self-collimated and detected to form a first focus. The Margin system and a front correction lens group form a beam compression optical system, and the front correction lens group and a rear correction lens group focus a collimating beam at a second focus position. Compared with a traditional transmission type and aspheric system structure, the difficulty in optical lens machining, installing and debugging is reduced greatly, the efficiency of installing and debugging and the imaging quality of the system are improved, the utilization efficiency of received laser echo signals is increased, and the requirement for compact structure and low cost is satisfied. The large-caliber fully-spherical laser radar optical system of the invention is reasonable in structure, easy to produce and assemble, good in extension performance, low in cost, and suitable for mass production.

Owner:合肥瑞利光学仪器有限公司

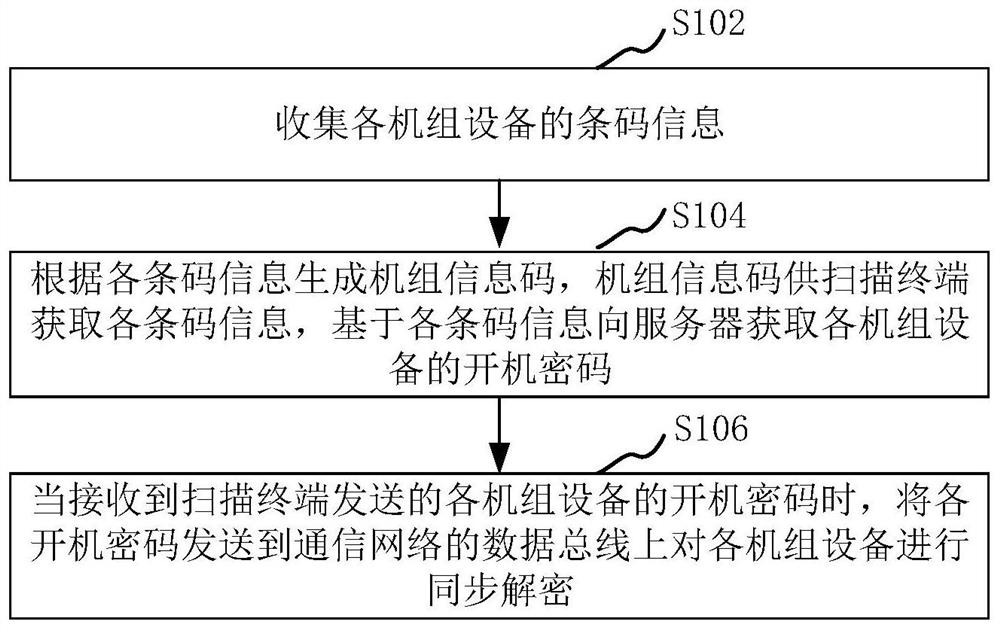

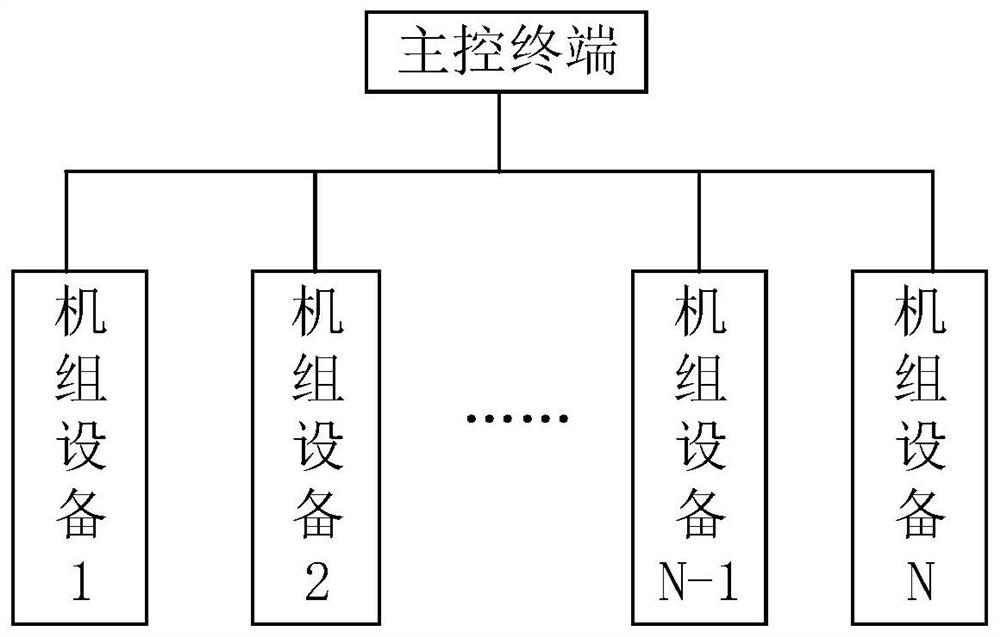

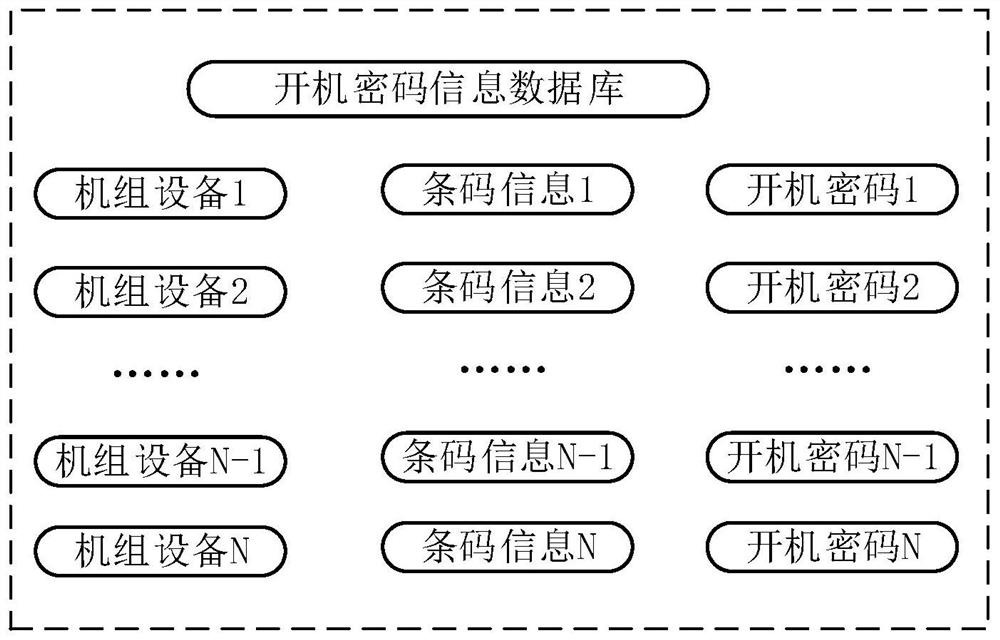

Multi-unit decryption method, system and device and computer equipment

ActiveCN112862040ARealize one-key decryptionReduce stepsCo-operative working arrangementsTransmissionPasswordSecret code

The invention relates to a multi-unit decryption method, system and device and computer equipment. The method comprises the following steps: collecting bar code information of each unit device; generating unit information codes according to the bar code information, enabling a scanning terminal to obtain the bar code information through the unit information codes, and obtaining power-on passwords of the unit devices from a server based on the bar code information; and when the power-on passwords of the unit devices sent by the scanning terminal are received, sending the power-on passwords to a data bus of a communication network to synchronously decrypt the unit devices. By adopting the method, the installation and debugging efficiency can be improved.

Owner:GREE ELECTRIC APPLIANCES INC

Flexible connecting mechanism, wiring device and movable medical imaging equipment

ActiveCN113594981AImprove the installation error marginReduce installation difficultyElectrical apparatusComputerised tomographsMedical imagingEngineering

The invention discloses a flexible connecting mechanism, a wiring device and movable medical imaging equipment. The flexible connection mechanism is applied to the wiring device. The flexible connecting mechanism comprises a first connecting piece, a second connecting piece and a flexible connecting assembly. The first connecting piece comprises a first connecting part fixedly connected with the sliding piece, and the second connecting piece comprises a second connecting part fixedly connected with the wiring column; and the flexible connecting assembly is connected with the first connecting piece and the second connecting piece so that the position between the first connecting piece and the second connecting piece can be adjusted. According to the flexible connecting mechanism, the wiring device and the movable medical imaging equipment, the installation and debugging difficulty of the movable medical imaging equipment can be reduced.

Owner:BEIJING NEUSOFT MEDICAL EQUIP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com