Green brick stacking robot

A robot and adobe technology, applied in the field of automatic adobe stacking equipment, can solve problems such as low repeat positioning accuracy, unreasonable flipping and lifting strokes, complicated and difficult installation, etc., achieve good practical use and promotion value, stable, reliable and efficient adobe stacking, Simple and practical structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

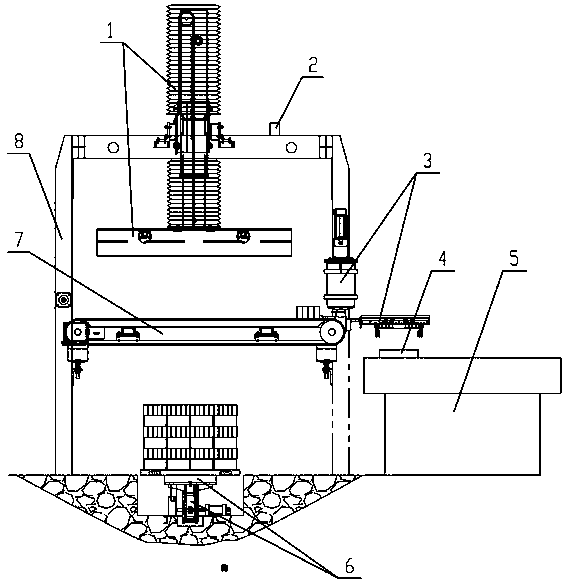

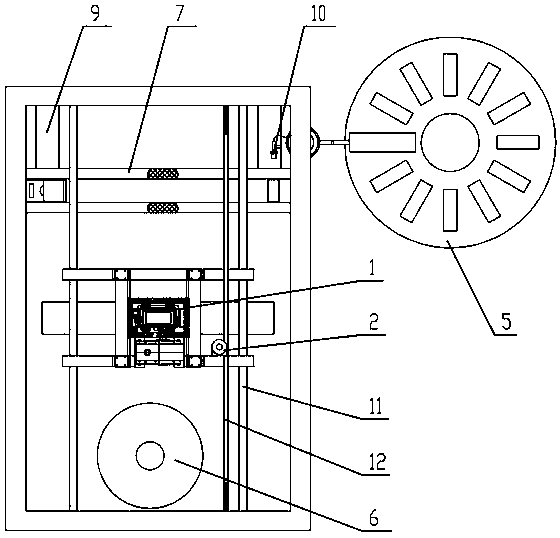

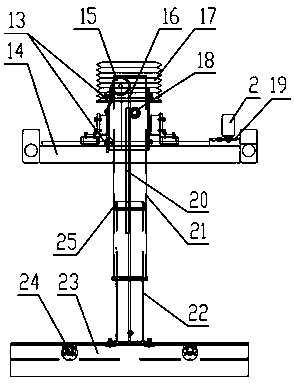

[0031] see Figure 1-Figure 10 , the present invention is an adobe stacking robot, the adobe stacking robot is set in cooperation with an automatic brick making machine 5, so that the adobe stacking robot can grab and stack adobes from the automatic brick making machine; the adobe stacking robot includes a gantry frame 8, The large manipulator 1 vertically set on the gantry frame, the small manipulator 3 set on the side of the gantry frame and the belt conveyor 7 fixed on the gantry frame, wherein the small manipulator is used to grab bricks from the automatic brick making machine Placed on a belt conveyor, a manipulator guide bar 11 and a manipulator translation chain 12 are arranged in parallel on the top of the gantry frame, and the large manipulator engages with the manipulator translation chain through a sprocket 19 installed thereon and uses a sprocket motor 2 to drive and translate; The small manipulator is hung upside down and fixed on the beam on the side of the gantr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com