Contact tube assembly and strip

A contact tip and electrode technology, used in arc welding equipment, electrode accessories, electrode characteristics, etc., can solve problems such as unbalanced heating status of the welding belt, slippage of the welding belt, and electrode heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

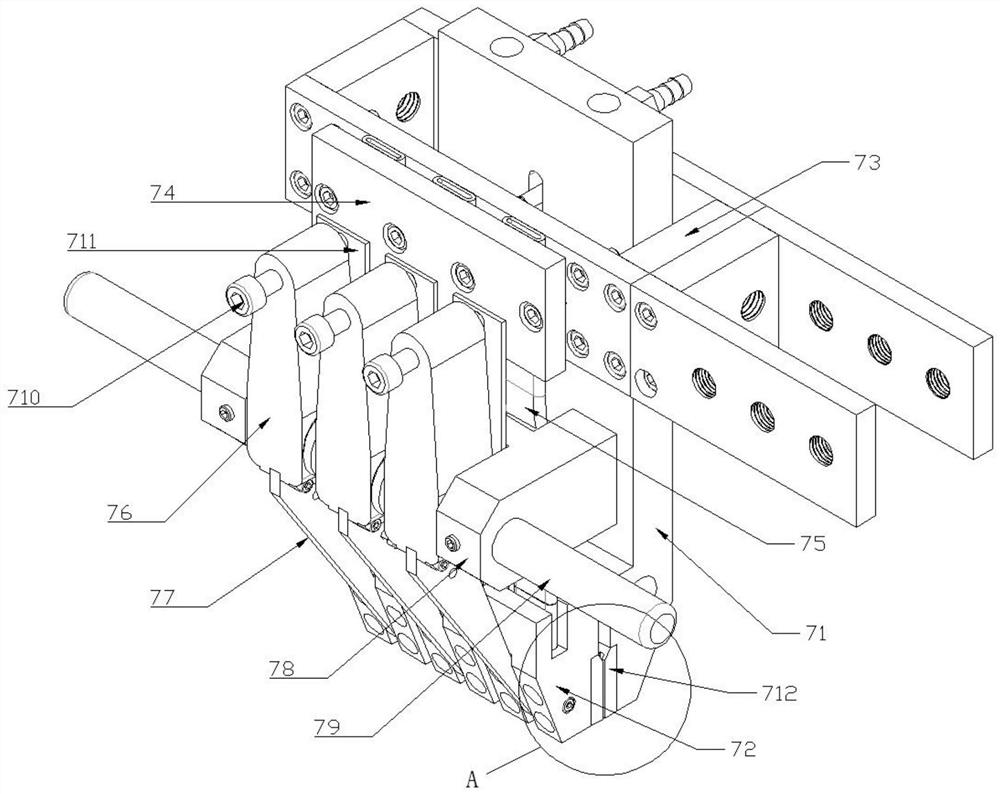

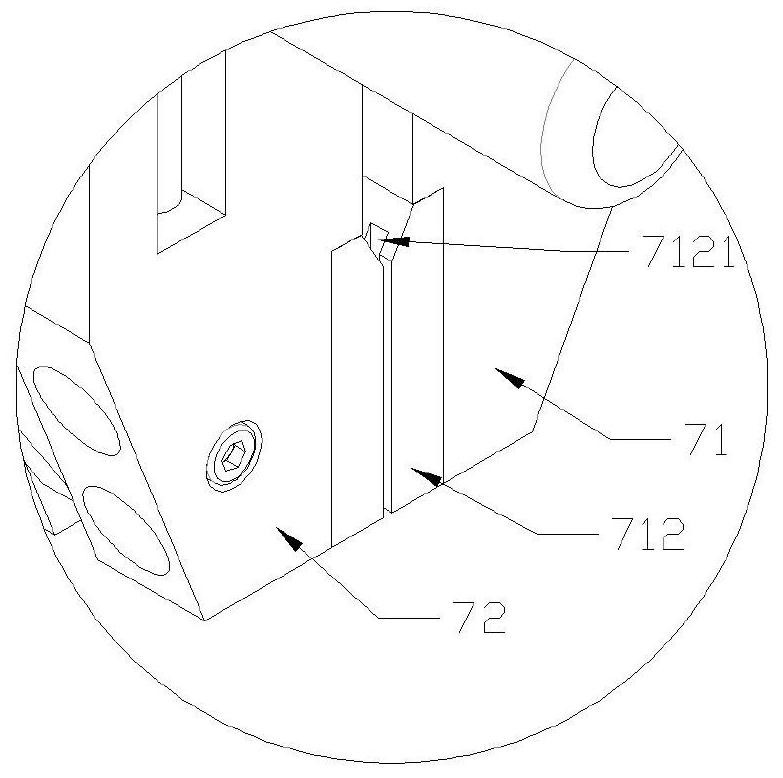

[0084] A conductive tip assembly, which can make the welding strip and the electrode in good contact and improve the welding quality, such as Figure 1-Figure 11 As shown, specifically set to the following structure:

[0085] The contact tip assembly includes an integral electrode 71 , a single-lobe electrode 72 , an electrode connecting plate 73 , an electrode pressing plate 74 and an electrode pressing mechanism. The electrode connection plate 73 is mainly composed of a rectangular frame body spliced by four plates and two extension plates, and the extension plates are used for connecting cables.

[0086] The width of the integral electrode 71 is larger than that of the welding strip, and its top end is inserted into the inner side of the electrode connecting plate 73 and attached to and fixedly connected to the inner wall of the electrode connecting plate 73 . The electrode pressing plate 74 is arranged on the opposite side of the integral electrode 71, and the electrode...

Embodiment 2

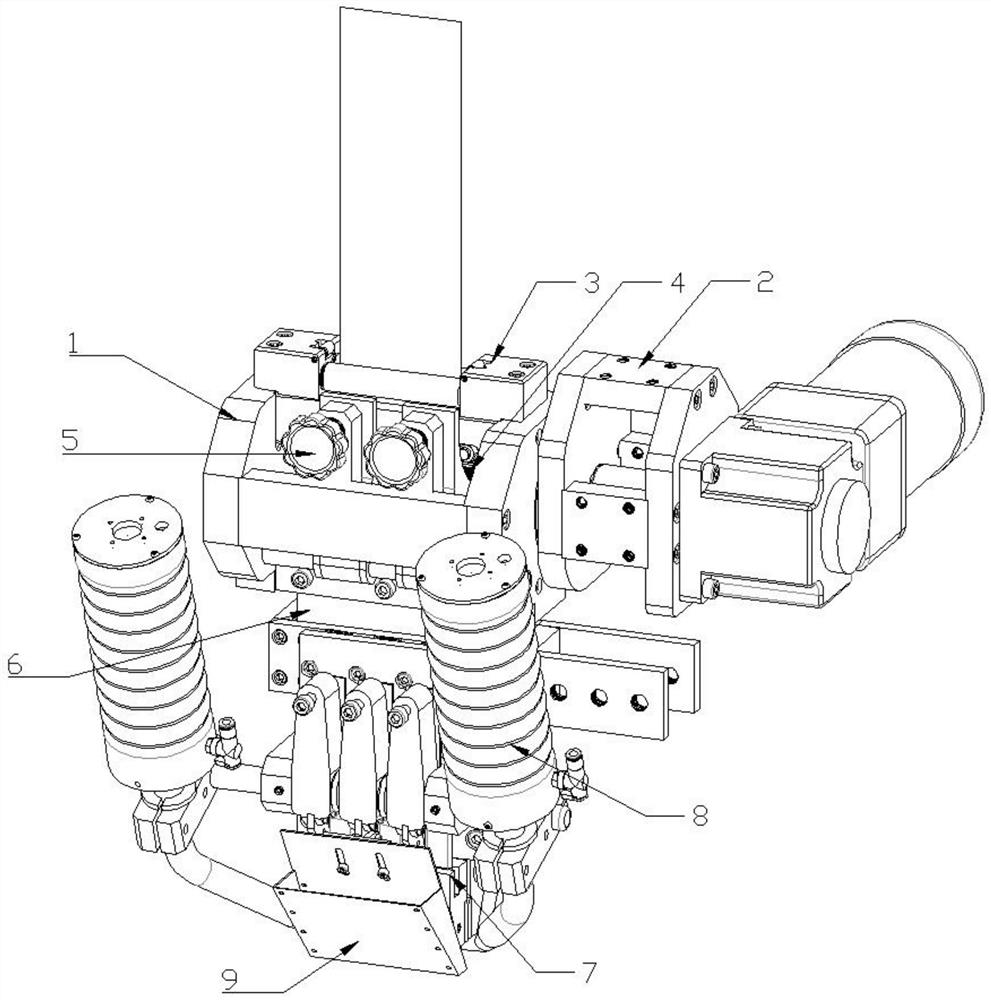

[0092] This embodiment further provides a strip submerged arc surfacing welding head on the basis of the above embodiments, and particularly adopts the following configuration structure:

[0093] Including pulley assembly 3, tape cassette assembly 6, machine base assembly 1, hanger assembly 2, motor drive assembly 4, right-angle middle solid deceleration motor, pressure wheel assembly 5, flux box 9 and the contact tip in Embodiment 1 components.

[0094] The hanging base assembly 2 is fixedly connected with the organic base assembly 1 and the right-angle center solid deceleration motor.

[0095] The base assembly 1 includes two vertical plates 11 arranged oppositely, an outer connecting plate 12 connecting the two vertical plates 11, two inner connecting plates 13 distributed up and down and a lower connecting plate 14,

[0096] The pulley assembly 3 is installed on the vertical plate 11 and the two inner connecting plates 13 of the base assembly 1 .

[0097] The tape box as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com