Sensor-based intelligent automatic regulating system and method

An automatic adjustment and sensor technology, applied in elevators, transportation and packaging, etc., can solve problems such as failure to meet equipment safety requirements, high debugging costs, failure to grasp elevator hardware wear or loss, etc., to improve user experience and equipment safety , Improve stability and reliability, and improve the efficiency of installation and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

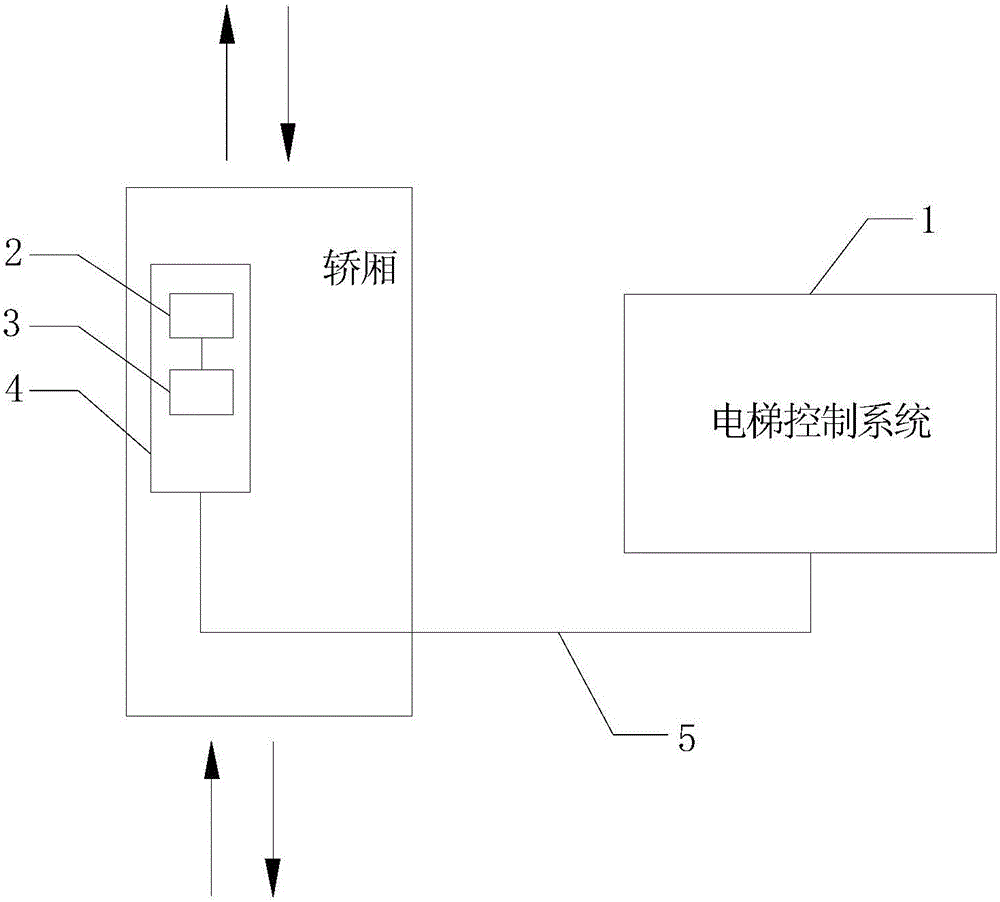

[0041] like figure 1As shown, the intelligent automatic adjustment system of this embodiment includes an elevator control system 1 and a sensor detection module, and the sensor detection module includes a six-axis gyroscope 2 and a data processor 3, and the six-axis gyroscope 2 and the data processor 3 Set on the car, preferably integrated on the car communication board 4, the six-axis gyroscope 2 is connected to the data processor 3 through an internal communication mode, an external wired communication mode or an external wireless communication mode, and the data processor 3 is connected through the car The car communication board 4 is connected with the elevator control system 1, wherein the car communication board 4 and the elevator control system 1 are connected by a traveling cable.

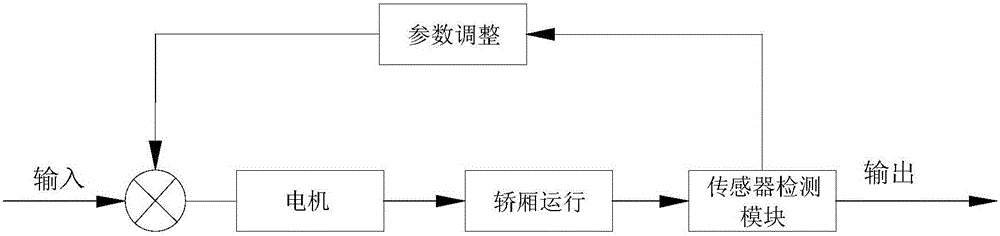

[0042] The six-axis gyroscope 2 preferably adopts the MPU6050 six-axis sensor, which runs up and down with the car for real-time detection of the running situation of the car, and obtains t...

Embodiment 2

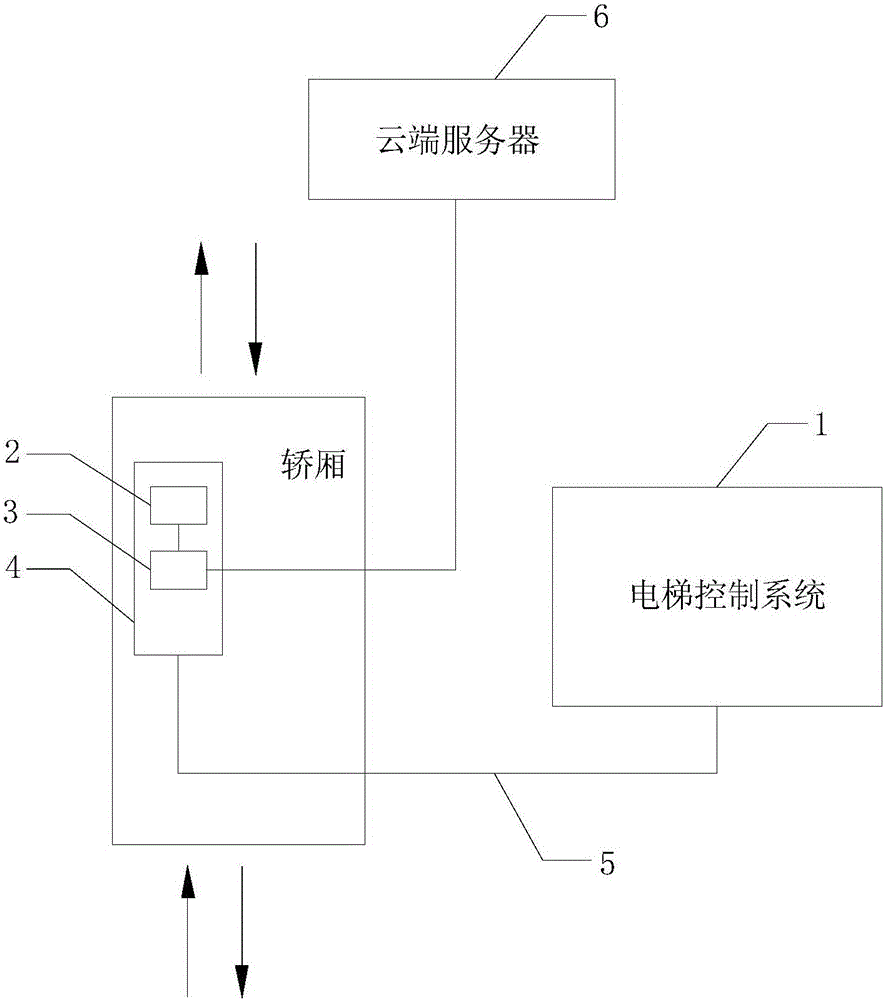

[0054] like image 3 As shown, the data processor 3 of this embodiment is also connected to the cloud server 6 through wireless communication, the data of the data processor 3 is sent to the cloud server 6, and the data is analyzed and stored in the cloud server 6, and the cloud server 6 calculates Analyze more accurate data and dig out more information. Users or debuggers can view the running curve through the cloud server 6, which can realize one-key initialization or one-key self-adjustment function, assist on-site personnel in debugging, and improve installation and debugging efficiency , reduce labor costs.

Embodiment 3

[0056] like Figure 4 As shown, the data processor 3 of this embodiment is also connected to the mobile device 7 through wired or wireless communication. If the mobile device 7 is the mobile device of the user or the debugger, the user or the debugger can use the mobile device to monitor the running curve. View, can realize one-key initialization or one-key self-adjustment function, assist on-site personnel to debug, improve installation and commissioning efficiency, and reduce labor costs; control parameter.

[0057] In this embodiment, the mobile device may be a smart phone, a PDA handheld terminal, a tablet computer, and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com