A method for controlling the output torque of an electric impact wrench

An electric impact wrench, output torque technology, applied in the direction of wrenches, power tools, manufacturing tools, etc., can solve the problem of not meeting the monitoring and traceability of operation data, not realizing intelligent and Internet of Things applications, and difficult to guarantee the accuracy of torque control. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The output torque control method of the electric impact wrench of the present invention, the torque control process is as follows:

[0056] 1) Based on the electric impact wrench powered by a brushless motor, according to the specification and type of the screw pair to be twisted and the characteristics of the workpiece, the impact torque calibration device is used to establish the "speed-torque" and "speed" at different speeds through multiple tests. -Impact times-torque" relationship data table, select commonly used thread specifications and types, and establish the relationship of "thread pair specification-current" and "thread pair type-current" by taking the average value through multiple measurements under the condition of tightening space data tables, and store these data tables in the microprocessor of the electric impact wrench controller;

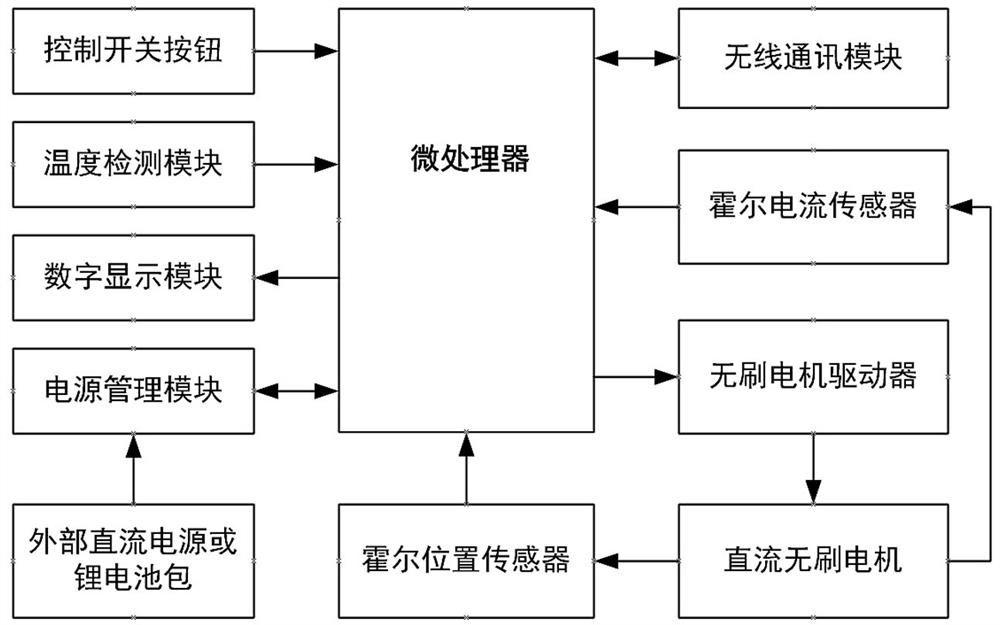

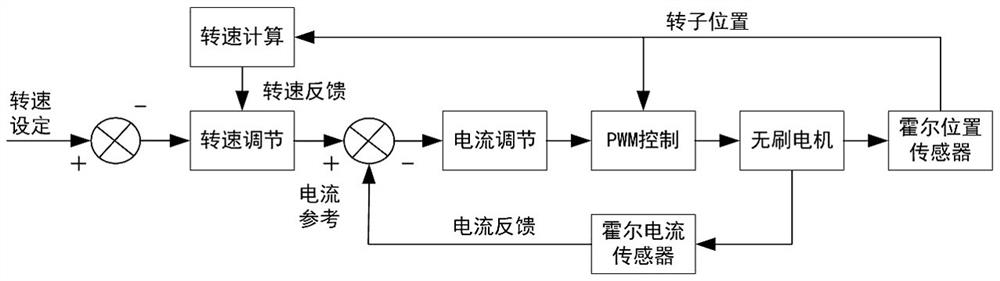

[0057] 2) The microprocessor, the brushless motor and its driver, the Hall position sensor, and the Hall current sensor c...

Embodiment 2

[0063] The difference between the output torque control method of the electric impact wrench in this embodiment and that in Embodiment 1 is that the user, according to the characteristics of the workpiece and the specification and type of the thread pair to be twisted, through such as Figure 7 or Figure 8 The graphical interface of the shown external device configures the torque control mode of the electric impact wrench, forms a configuration file and sends it to the controller, and the controller receives the configuration file and stores it in the microprocessor.

[0064] The torque control mode is a combination of a group of features and parameters associated with each feature, including combination mode and / or program mode, and the features include: output torque, motor speed, number of impacts, thread pair specification, thread pair type , the number of thread pairs, the number of tightening times, tightening, loosening, and the number of loosening turns.

[0065] The...

Embodiment 3

[0068] see Figure 7 , The difference between this embodiment and Embodiment 2 is that further, it specifically discloses a possible combination of features of the method for controlling the output torque of the electric impact wrench, including:

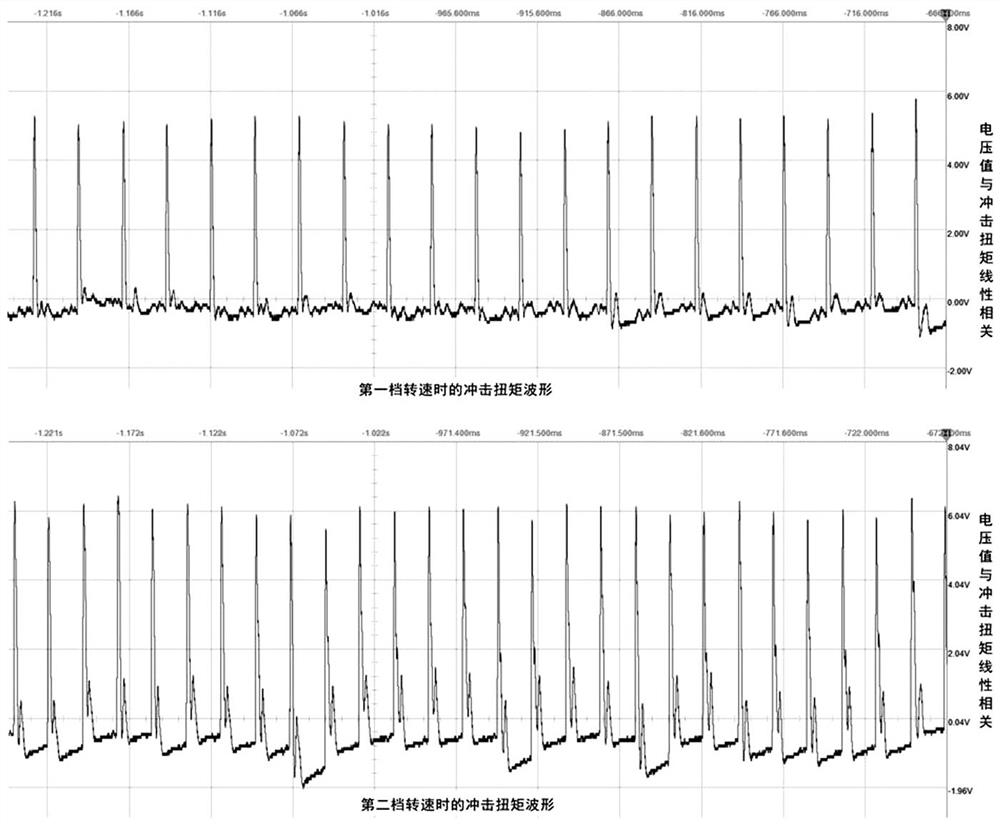

[0069] 1) Figure 9 It is a flow chart that combines the two characteristics of brushless motor speed and tightening into a torque control mode. First, input the speed value, and the controller calculates and displays the torque reference value at this speed according to the speed-torque relationship data table. Start the wrench to impact the thread pair at the set speed, and continue for a certain period of time until the thread pair receiving the impact stops rotating. The torque at this time is the maximum output positive torque of the wrench at this speed;

[0070] 2) Figure 10 It is a flow chart that combines the two features of loosening and loosening turns into a torque control mode, which is used to prevent bolts or nuts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com