Automatic cable punching method capable of accurately positioning

An accurate positioning and cable technology, which is applied in the direction of boring/drilling, drilling/drilling equipment, metal processing equipment, etc., to achieve the effect of improving accuracy and efficiency and reducing technical and operating experience requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

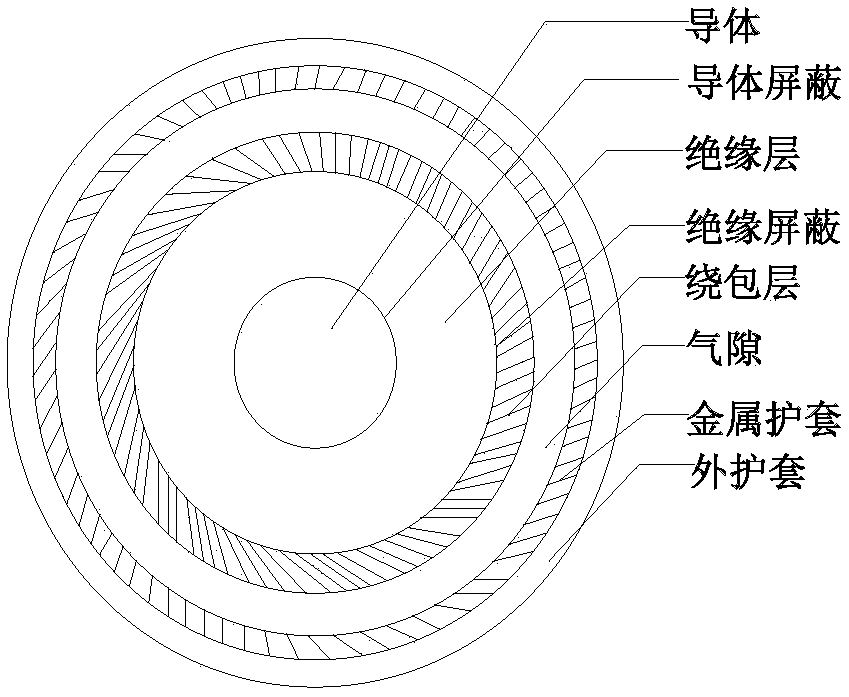

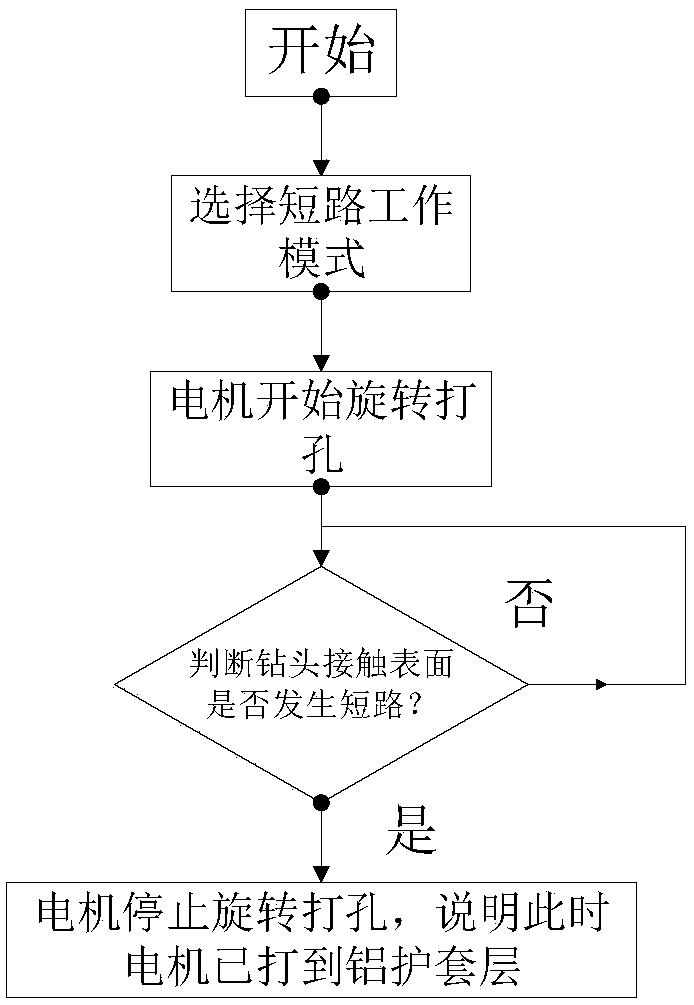

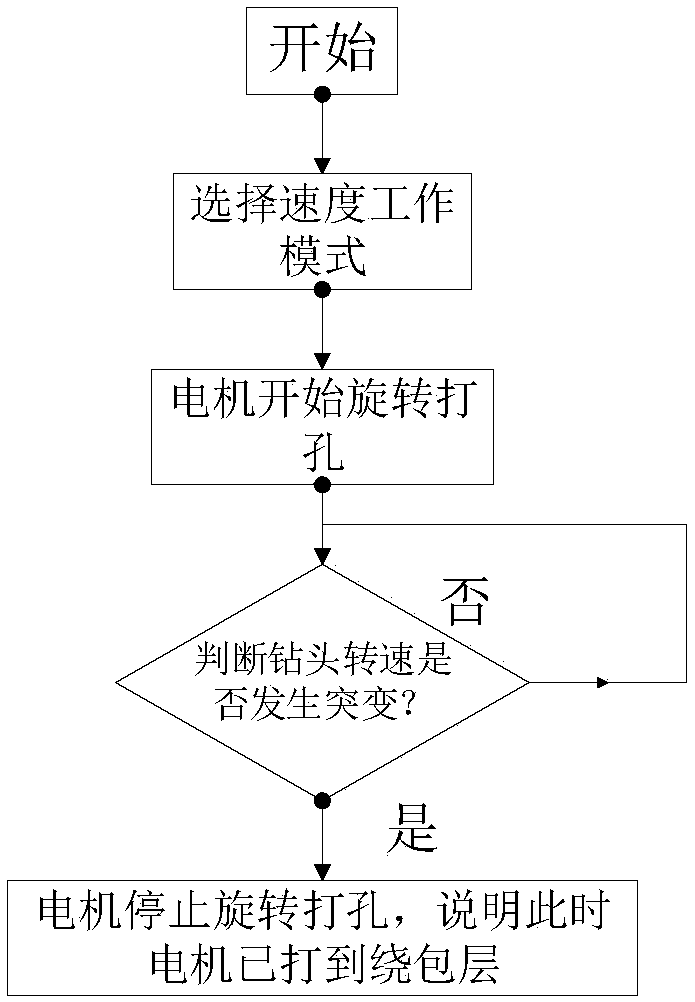

[0026] This embodiment discloses an automatic cable punching method capable of accurate positioning. The punching is performed based on the cable punching motor. The working modes of the punching motor include: 1) short-circuit working mode, which is determined by judging whether a short circuit occurs on the contact surface of the drill bit. Whether the drill bit should stop working; 2) Speed work mode, that is, determine whether the drill bit should stop working by judging whether the drill bit rotation speed changes suddenly; 3) Distance work mode, that is, set a target distance, when the drill bit advances to reach the target distance , the drill stops working; 4) Jog mode, that is, when the jog button is pressed, the drill stops working after rotating for 0.1s.

[0027] Attached below Figure 6 Specifically introduce the method for automatic punching of cables, including the following steps:

[0028] S1. Based on the radial section of the cable, firstly adjust the work...

Embodiment 2

[0040] The cable punching method for accurate positioning described in this embodiment is 64 / 110kV 1×630mm for single-core cables 2 The single-core cable is automatically punched, and the details are as follows:

[0041] S1. Based on the radial section of the 110kV single-core cable, first switch the working mode of the motor to the short-circuit working mode, and drill holes in the cable until the drill bit stops working, indicating that the drill bit has hit the aluminum sheath layer of the cable at this time.

[0042] S2. Adjust the working mode of the motor to the jogging working mode, and jog the cable for 0.1s to punch holes. This is a treatment for better arranging thermocouples on the surface of the metal layer.

[0043]S3. Adjust the working mode of the motor to the speed working mode, and drill the cable until the drill bit stops working, indicating that the drill bit has hit the wrapping layer at this time.

[0044] S4. Adjust the working mode of the motor to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com