Button cell negative electrode shell defect detection method based on machine vision

A defect detection, button battery technology, applied in the direction of optical testing defects/defects, instruments, measuring devices, etc., can solve the problems of difficult training, low detection accuracy, high missed detection rate, saving human resources, high detection accuracy, Detecting fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

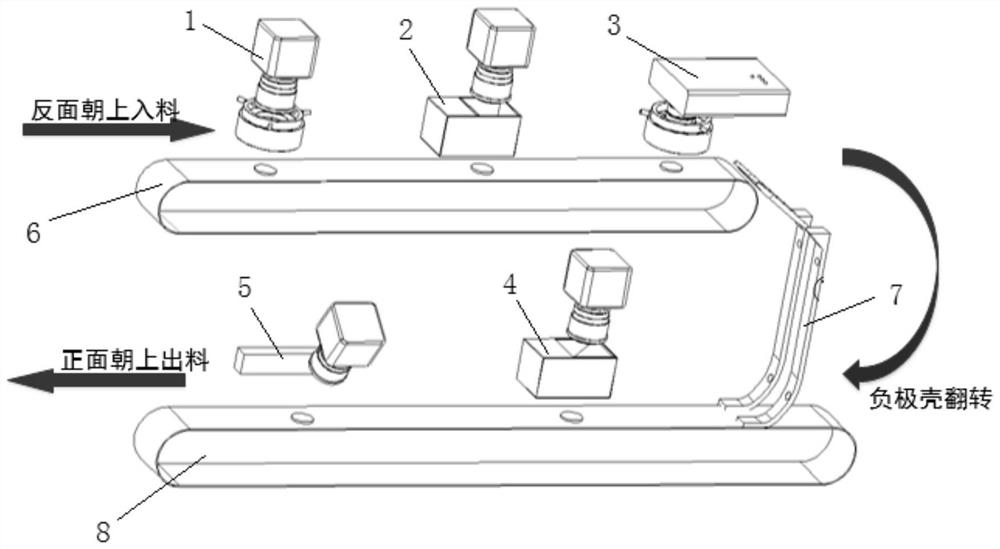

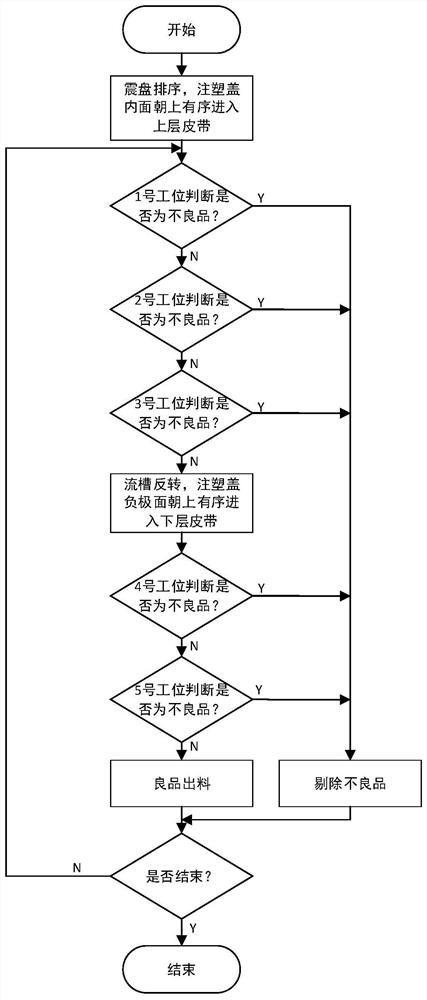

[0038] figure 1 It is a schematic diagram of a button battery negative shell defect detection system applying the detection method of the present invention. The negative shell enters the upper conveyor belt 6 in an orderly manner from the reverse side of the shock plate discharge, and passes through the first station 1, the second station 2, and the third station successively. The camera at the No. 3 station performs defect detection. After passing through the No. 3 station, it enters the overturning launder 7, and enters the lower conveyor belt 8 with the front face up, and then passes through the cameras at the No. 4 station 4 and No. 5 station 5 to detect defects. , if it is judged as a defective product, it will be rejected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com