A modeling optimization method and system based on pcb board placement and insertion process

A technology of PCB board and optimization method, which is applied in the field of modeling optimization method and system based on PCB board placement and insertion process, can solve the problems of long-time learning and training, affecting the use of equipment, and inability to operate offline, so as to overcome the problem of payment problems, improve productivity, and reduce operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0046] The present invention provides a kind of modeling optimization method based on PCB board sticking technology, and it comprises the following steps:

[0047] The system creates a component package drawing based on the size information of the soldered component;

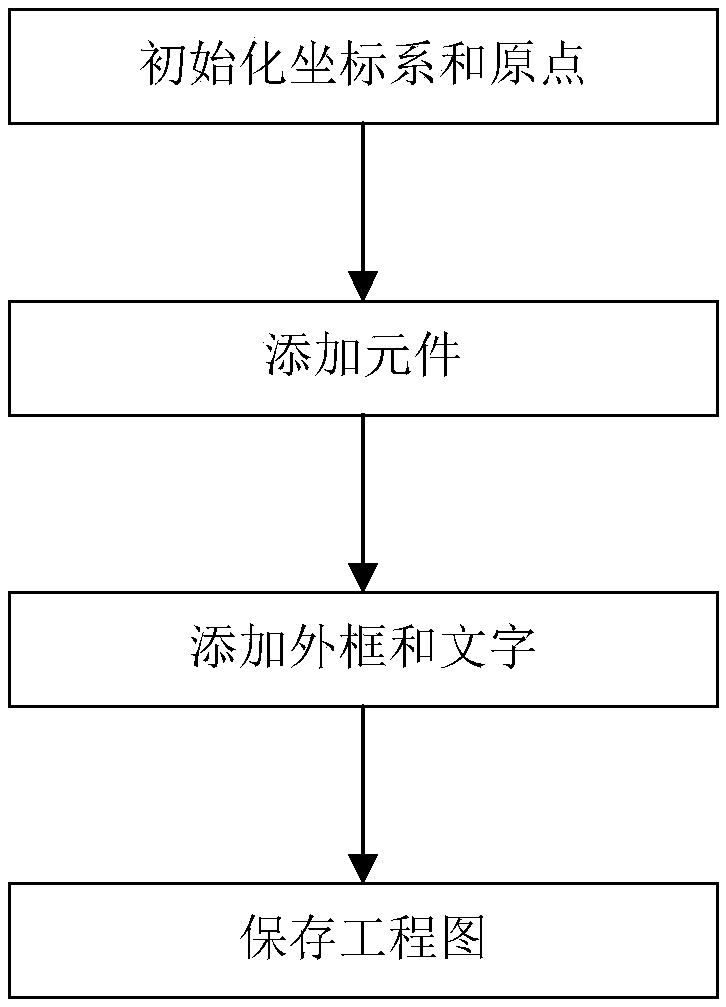

[0048] The system creates corresponding engineering drawings according to the CAD drawing or wiring diagram of the PCB board;

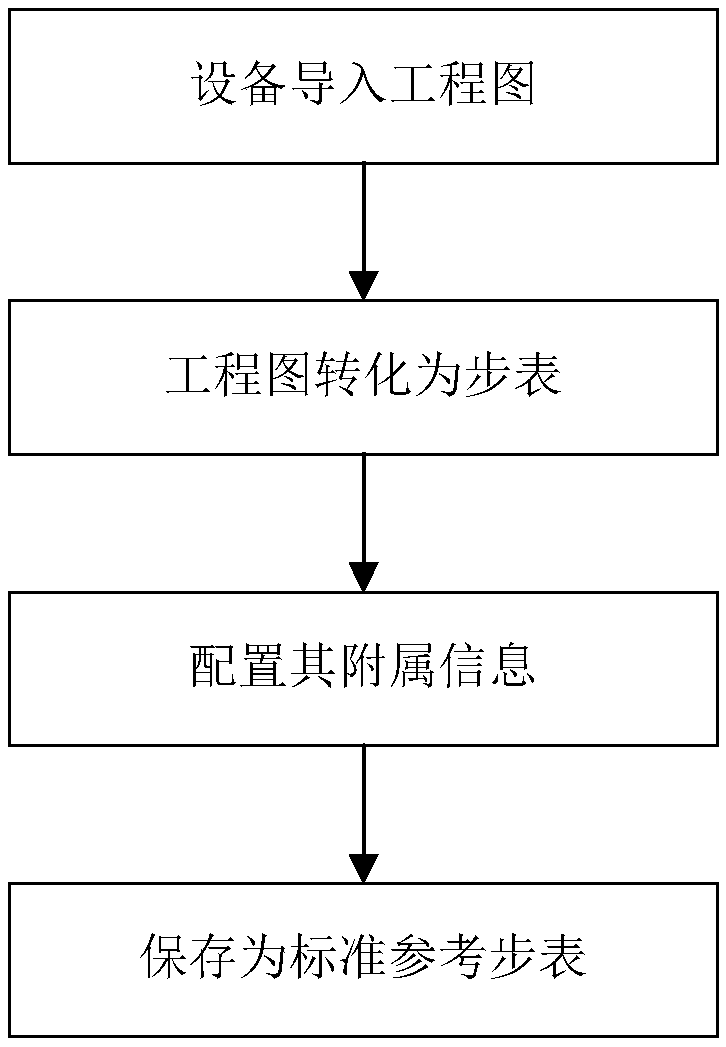

[0049] The system imports the engineering drawing into the equipment, and converts the engineering drawing into a standard reference step table;

[0050] The system automatically verifies and updates the standard reference step table according to the real-time production deviation.

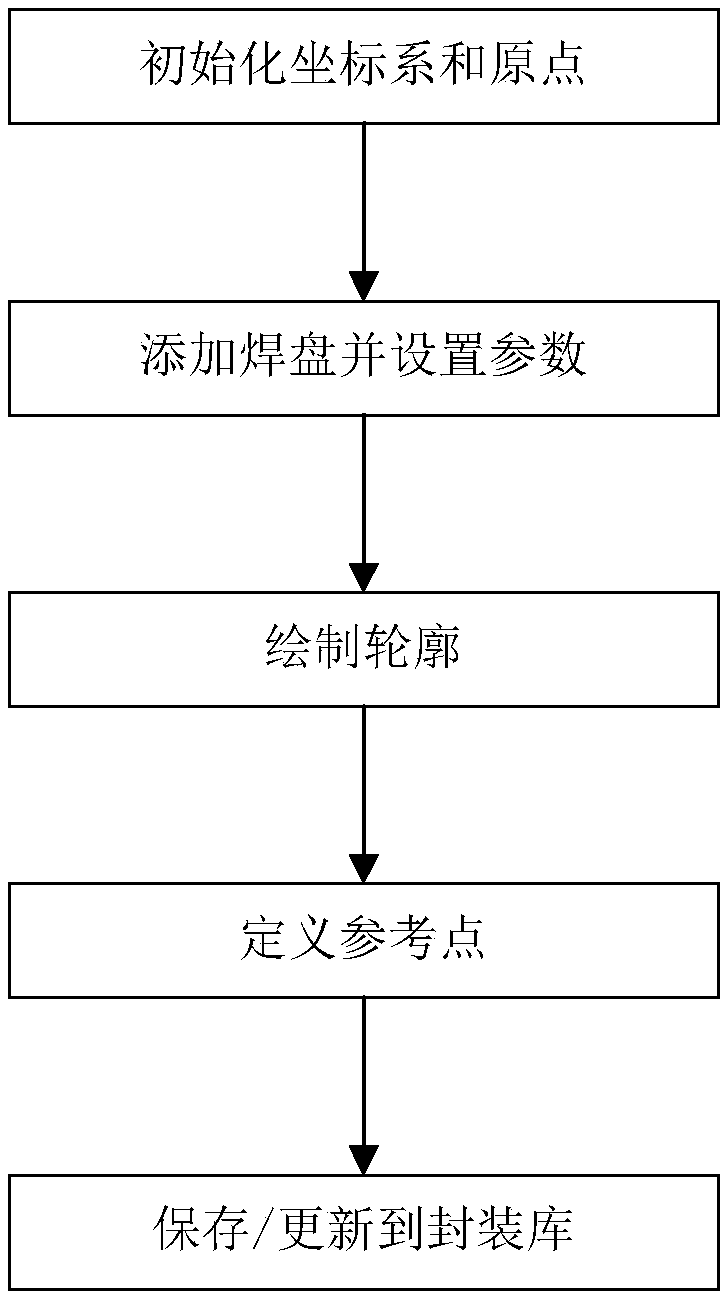

[0051] As an improvement of the technical solution, the step system establishes a component package diagram according to the size in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com